Solar silicon wafer processing method and device

A technology of solar silicon wafers and processing methods, applied to fine working devices, stone processing equipment, working accessories, etc., to achieve the effect of reducing labor intensity and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

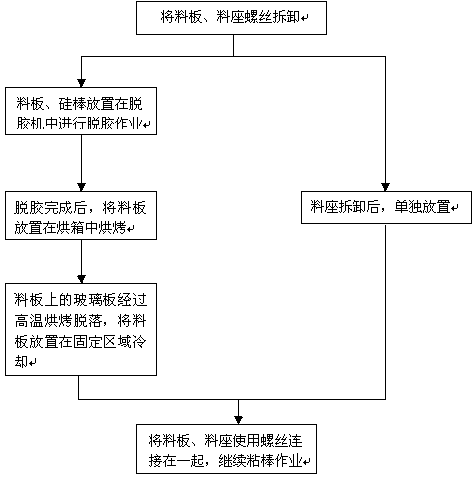

[0012] The present invention will be further described below with reference to accompanying drawing: figure 2 , image 3 and Figure 4 , a kind of solar silicon chip processing method concrete steps are as follows:

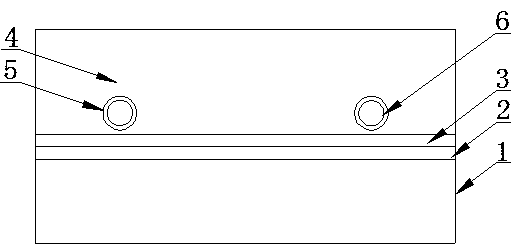

[0013] (1) First, drill two through holes 5 in the lower part of the side of the material seat 4, and then carry out the sticking operation (glue the solar silicon rod 1, the glass plate 2, and the material plate 3, and fix the material plate 3 and the material seat 4 with screws) .

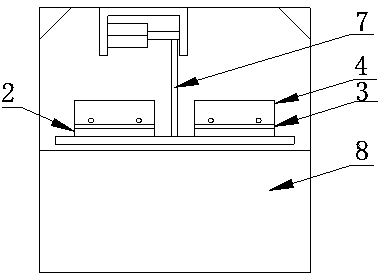

[0014] (2) After cutting the solar silicon rods with a wire cutting machine, insert two metal round rods 6 into the two through holes 5 on the side of the material holder 4 (such as figure 2 shown), the two ends of the two metal round rods 6 protrude from the two through holes 5 on the side of the material seat 4 respectively, and the operator uses the two metal round rods 6 to place the solar silicon rod 1, the glass plate 2, and the material plate 3 Together with the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com