Linear feeding and discharging mechanism of full-automatic bar chamfering machine

A feeding mechanism and fully automatic technology, applied in the direction of grinding feed movement, machine tools suitable for grinding workpiece edges, grinding workpiece supports, etc., can solve equipment efficiency loss, excessively long conveying line, workpiece collapse, etc. problems, to avoid waste of working hours, reduce personnel costs, and avoid dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

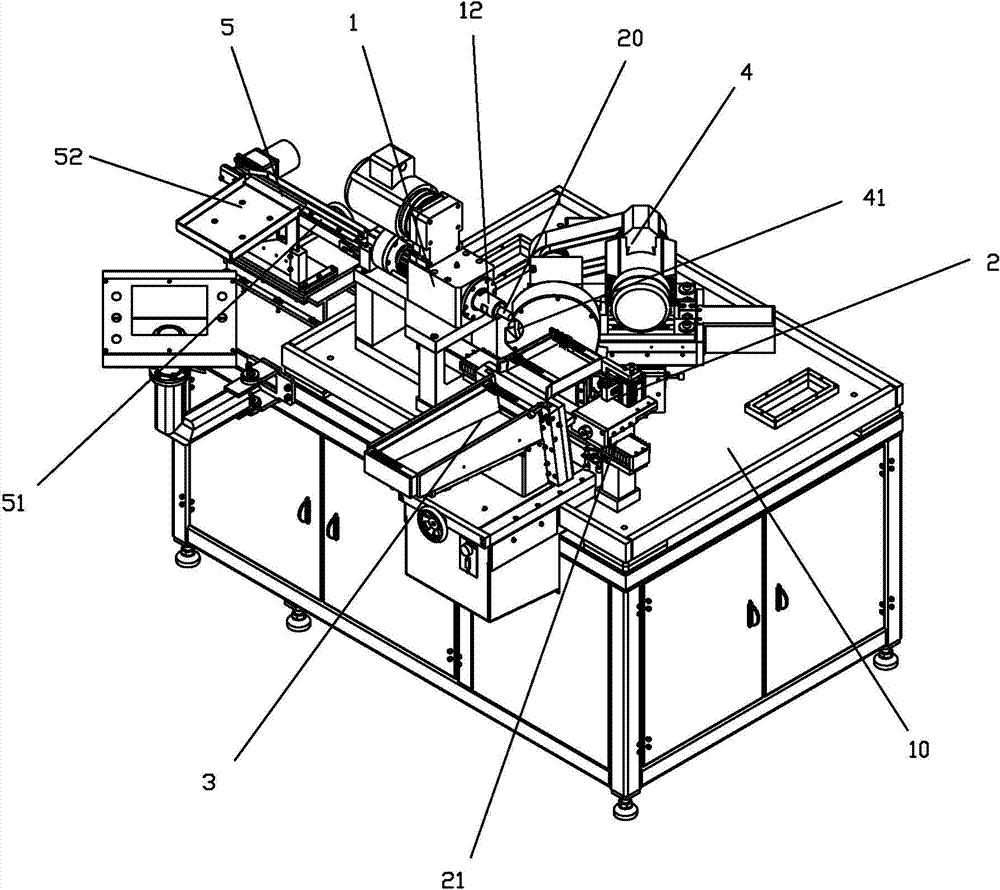

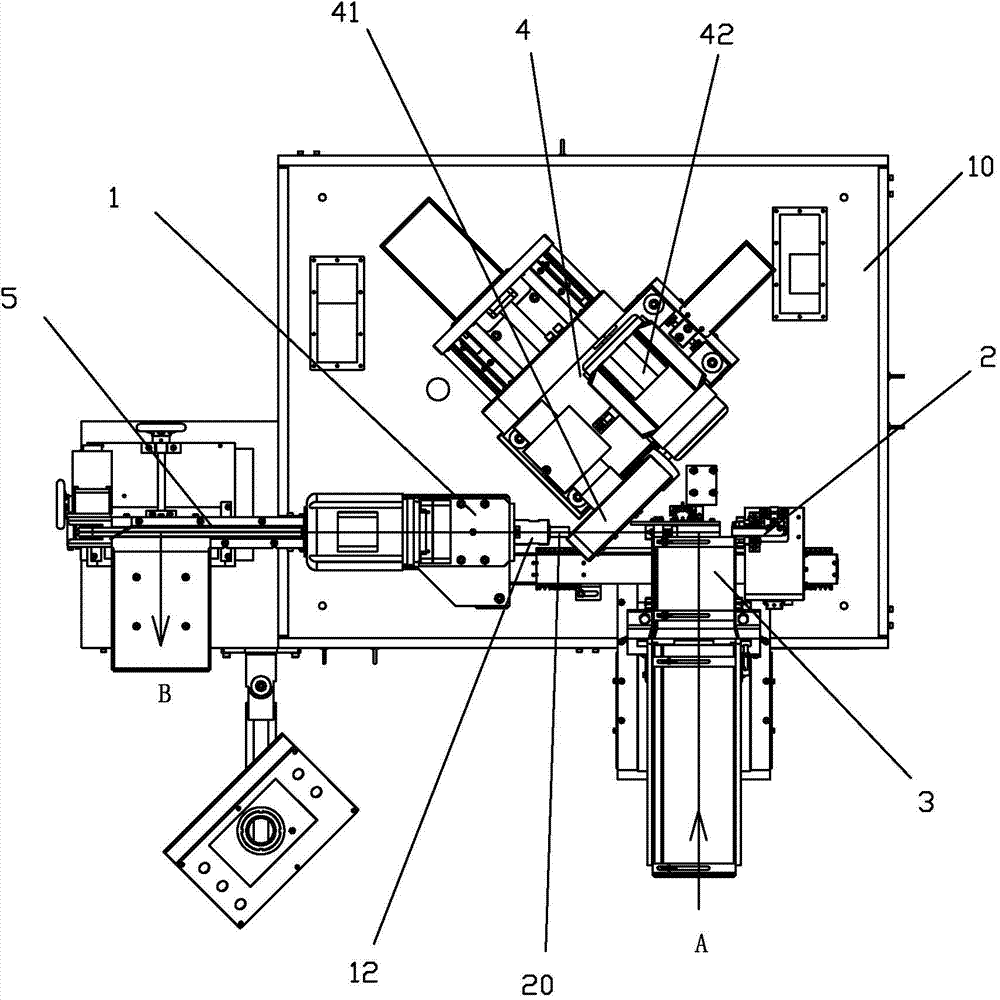

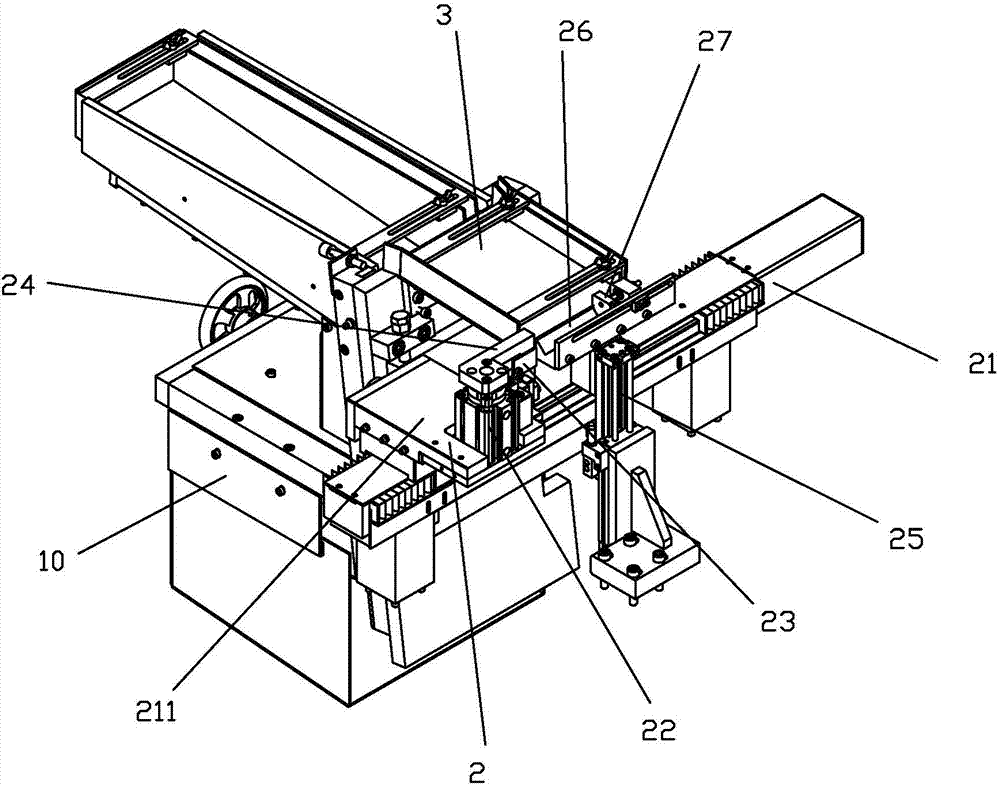

[0027] see Figure 1 to Figure 5 As shown, the linear feed-in and discharge mechanism of a kind of bar stock full-automatic chamfering machine of the present invention comprises:

[0028] A working head mechanism 1, the working head mechanism 1 includes a collet 11 that can be used to clamp the bar stock and a main shaft 12 that is used to drive the collet to rotate; the main shaft 12 is provided with a hollow inner chamber, so that the bar stock at the front end 20 send out to the rear end along the hollow inner cavity;

[0029] A feeding mechanism 2, the feeding mechanism 2 is arranged at a position adapted to the front end of the working head mechanism 1; the feeding mechanism 2 includes a linear feeding precision linear module 21 capable of rectilinear reciprocating motion, the linear The feeding precision linear module 21 is arranged at a position capable of reciprocating linearly along the axial direction of the main shaft of the working head mechanism, so as to be able...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com