Large size sleeve pipe optical rod assembling equipment

An assembly equipment and large-scale technology, which is applied in the field of optical rod and optical fiber processing, can solve the problems of complex processing equipment, high space height requirements, equipment erection and assembly difficulties, etc., and achieve low space height requirements, low consumption, and convenience The effect of disassembly and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

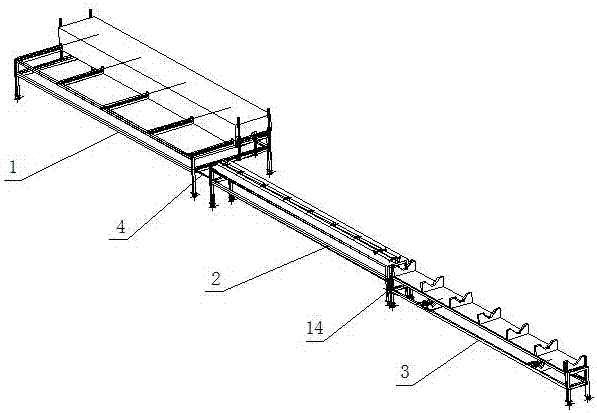

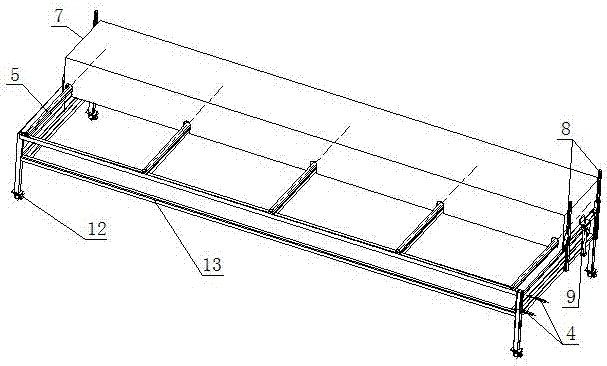

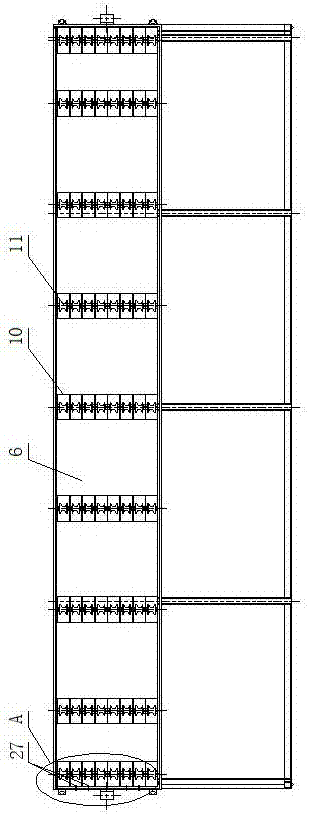

[0029] This large-size casing optical rod assembly equipment is composed of a mandrel storage device 1, a mandrel assembly device 2 and a sleeve assembly device 3. The left end of the mandrel assembly device 2 is equipped with a mandrel storage device 1 through a connector A4, and the mandrel The right end of the assembly device 2 is equipped with a casing assembly device 3 through a connector B14; the mandrel storage device 1 is composed of a mandrel storage rack 13, a slide rail 5, a slidable platform 6, a guide rod 8 and a lifting cylinder 9, and the mandrel The bottom of storage frame 1 is provided with adjustment roller A12, and adjustment roller A12 is used for adjusting the levelness of core rod storage frame 13; One side of the mandrel storage frame 13 is provided with a glass cover 7 through the guide rod 8 and the lifting cylinder 9, and the mandrel storage rack 13 is longitudinally evenly distributed with slide rails 5, and the slide rail 5 is slidably equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com