Extractive distillation process in hydrofining process of crude benzene

A technology of hydrofining and extractive distillation, applied in the direction of distillation purification/separation, organic chemistry, etc., can solve problems such as insufficient heat supply, unfavorable operation of on-site employees, and unfavorable operation of extractive distillation tower height, so as to improve quality and facilitate operation , the effect of reducing the operating height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

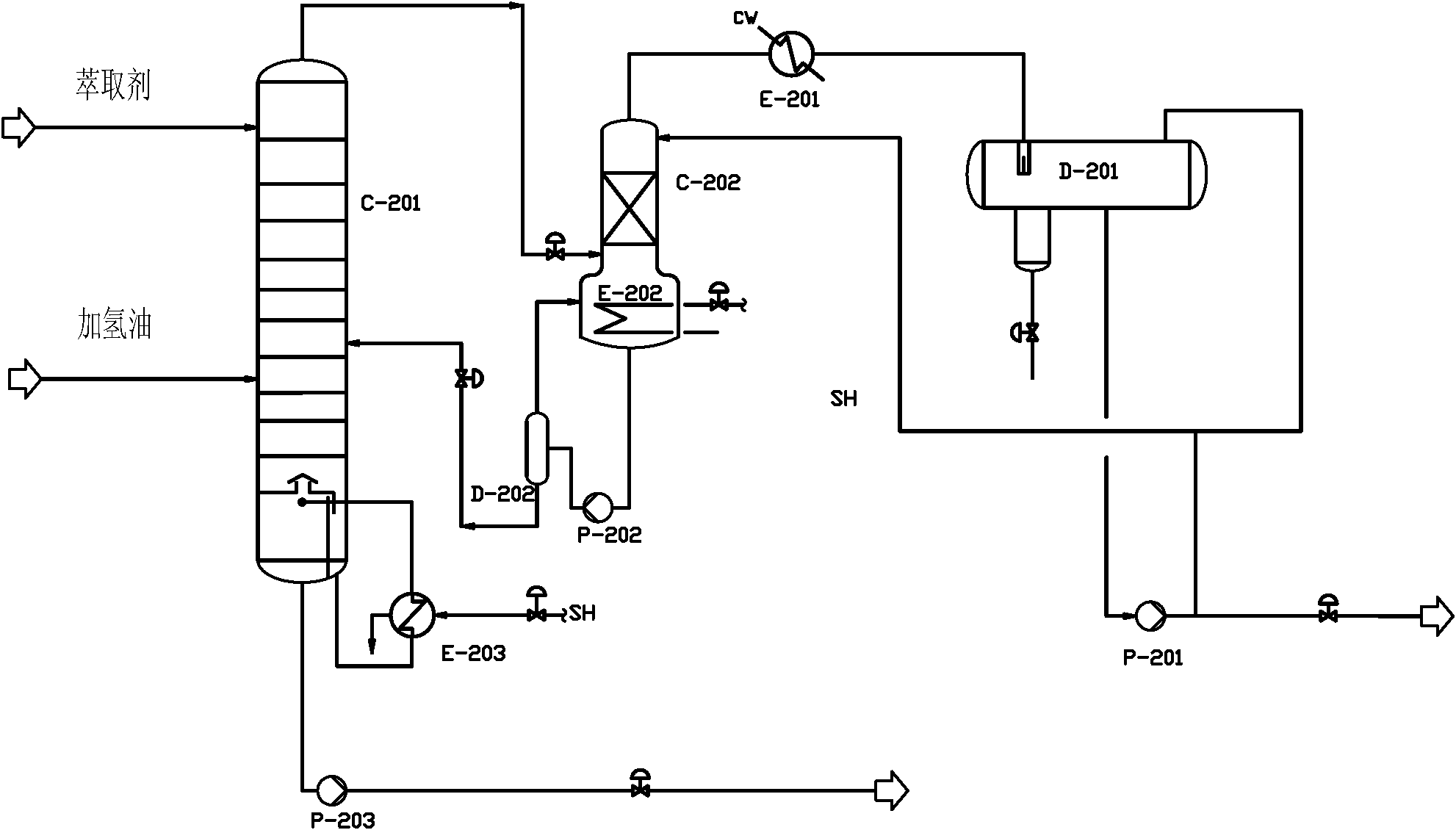

[0024] See figure 2 , an extractive distillation process in the hydrofining process of crude benzene, the equipment includes extractive distillation tower C-201, stripping tower C-202, liquid-liquid separation tank D-202, reflux tank D-201, tower top cooler E -201; the lower part of the stripping tower C-202 is provided with a kettle-type reboiler E-202, and the outlet at the top of the extractive distillation tower C-201 is connected to the side of the stripping tower C-202, and the lower part of the stripping tower C-202 is connected to the liquid The liquid separation tank D-202, the liquid-liquid separation tank D-202 is connected to the side of the extractive distillation tower C-201; the top of the stripping tower C-202 is connected to the top cooler E-201, and the top cooler E-201 The other end is connected to the reflux tank D-201, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com