Ventilation chassis with pagoda structure and application of ventilation chassis in fluidized coating machine

A pagoda and chassis technology, which is applied in the fields of food equipment, chemical industry, medicine, and materials, can solve the problems of uneven coating thickness of particles, uneven thickness of irregular surfaces, and easy adhesion of powder, so as to improve drying efficiency, The effect of reducing energy consumption and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

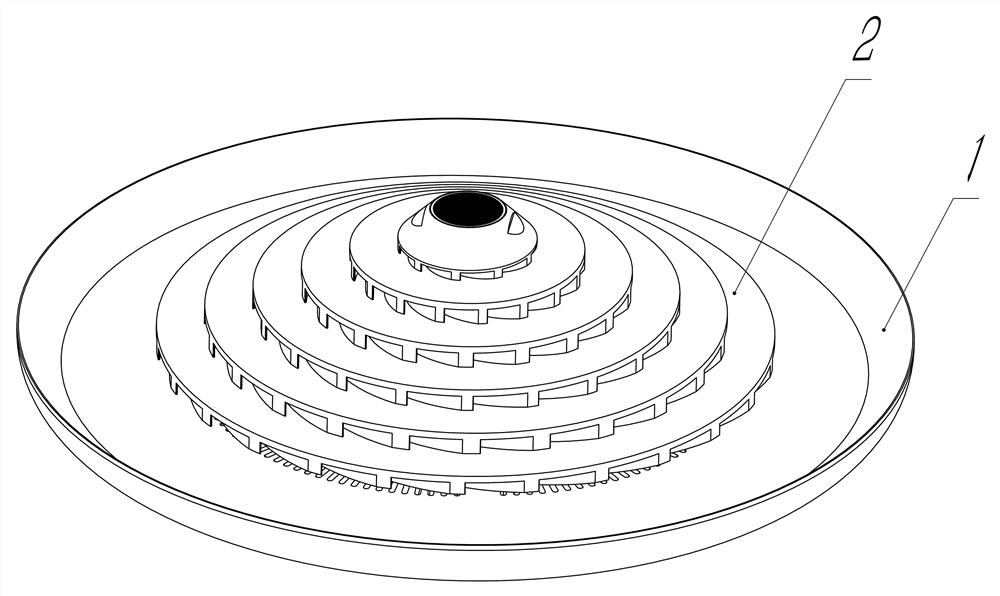

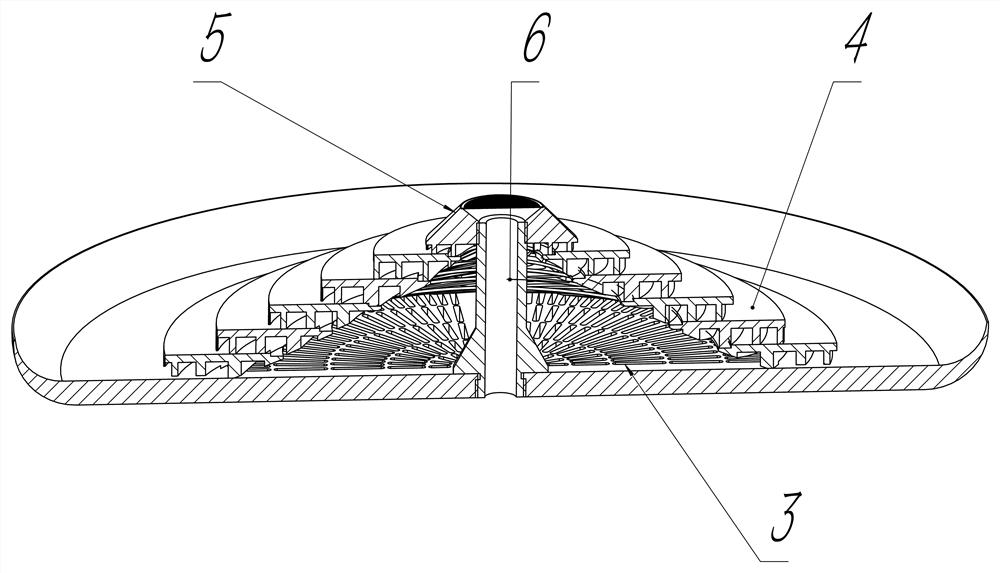

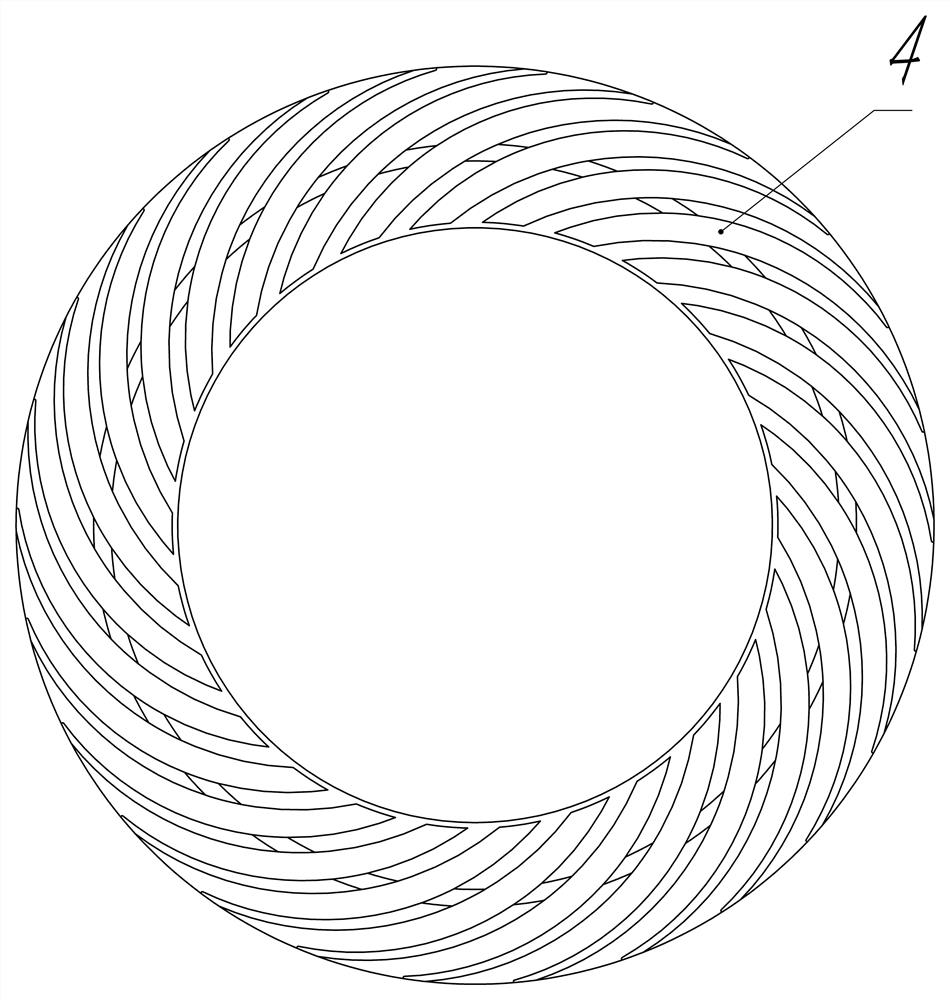

[0019] like figure 1 As shown, the present invention provides a ventilation chassis device with a pagoda structure, which is composed of chassis 1 and pagoda structure 2. figure 2 As shown, a ventilation hole 3 is opened in the annular area around the center of the chassis 1; the pagoda 2 is composed of a plurality of pagoda rings 4, a pagoda cap 5 and a connecting rod 6.

[0020] The center of chassis 1 is solid, and the center radiates several solid central shafts. The area between the central shafts is divided into slotted ventilation holes 3. The annular area between the ventilation holes 3 and the edge of the chassis 1 is a solid part, and the edge of the chassis is designed with an R angle. The number and width of the central axis are designed according to the load of the disc, and the length, width and ventilation area of the ventilation holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com