Solid insulation ring main unit main insulation module

A technology of solid insulation and ring network cabinets, which is applied in the direction of shields/shutters, switchgear, busbars/line layouts to prevent contact with contacts, and can solve the problem of large size, increased main insulation module size, and operation of solid insulation ring network cabinets Problems such as high height, to achieve the effect of reducing the operating height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

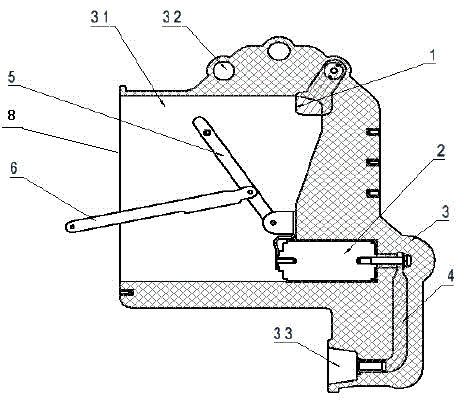

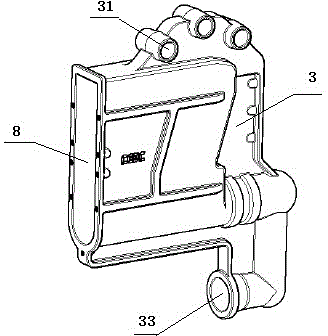

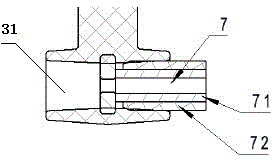

[0017] A main insulation module of a solid insulation ring network cabinet, including an epoxy body 3, an isolation knife 5, an isolation knife static contact 1, a vacuum interrupter 2 and a conductor 4, such as figure 1 with figure 2 , the vacuum interrupter 2 is poured horizontally in the epoxy body 3, the vacuum interrupter 2 and the conductor 4 are fixedly connected by bolts, the epoxy body 3 is provided with a cable joint connection hole 33, and the lower part of the main insulation module is provided with a cable joint connection Hole 33 for replacement of cable glands. The cable joint connection hole 33 is connected to the conductor 4 .

[0018] In order to reduce the operating height of the solid insulated ring network cabinet, the vacuum interrupter 2 is horizontally sealed in the epoxy body 3, so that the operating mechanism can be arranged at the front of the solid insulated ring network cabinet instead of the top. The vacuum interrupter 2 and the conductor 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com