Steel tower self-lifting installation method

An installation method and self-elevating technology, which is applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve the problems of inconvenient operation and many auxiliary facilities for installation, and achieve simple facilities, small operating height and ensure the quality of tailor welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

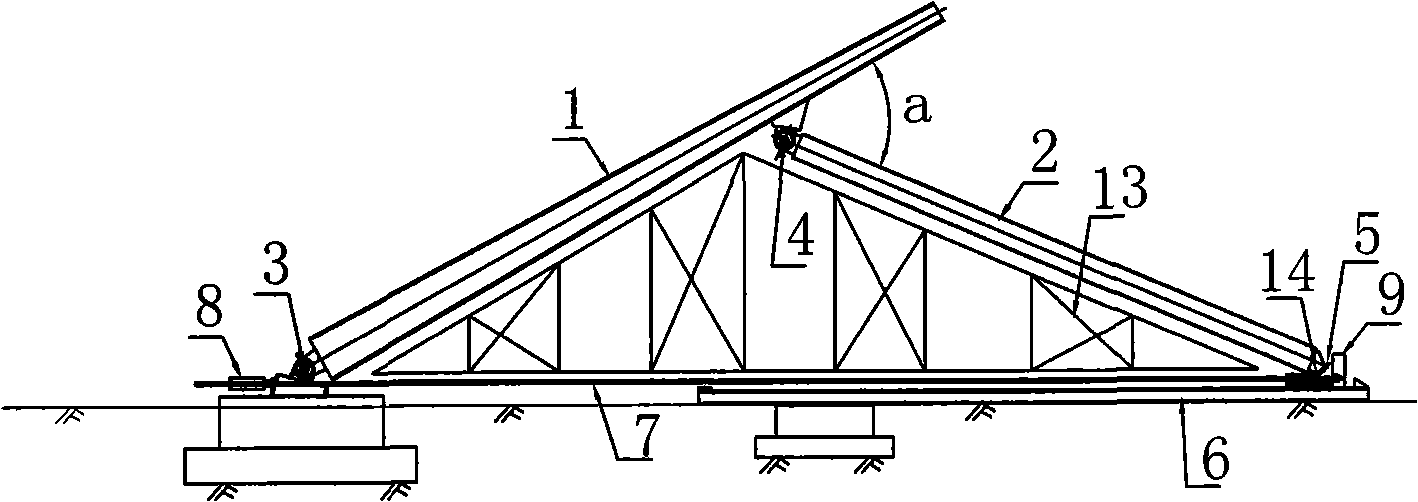

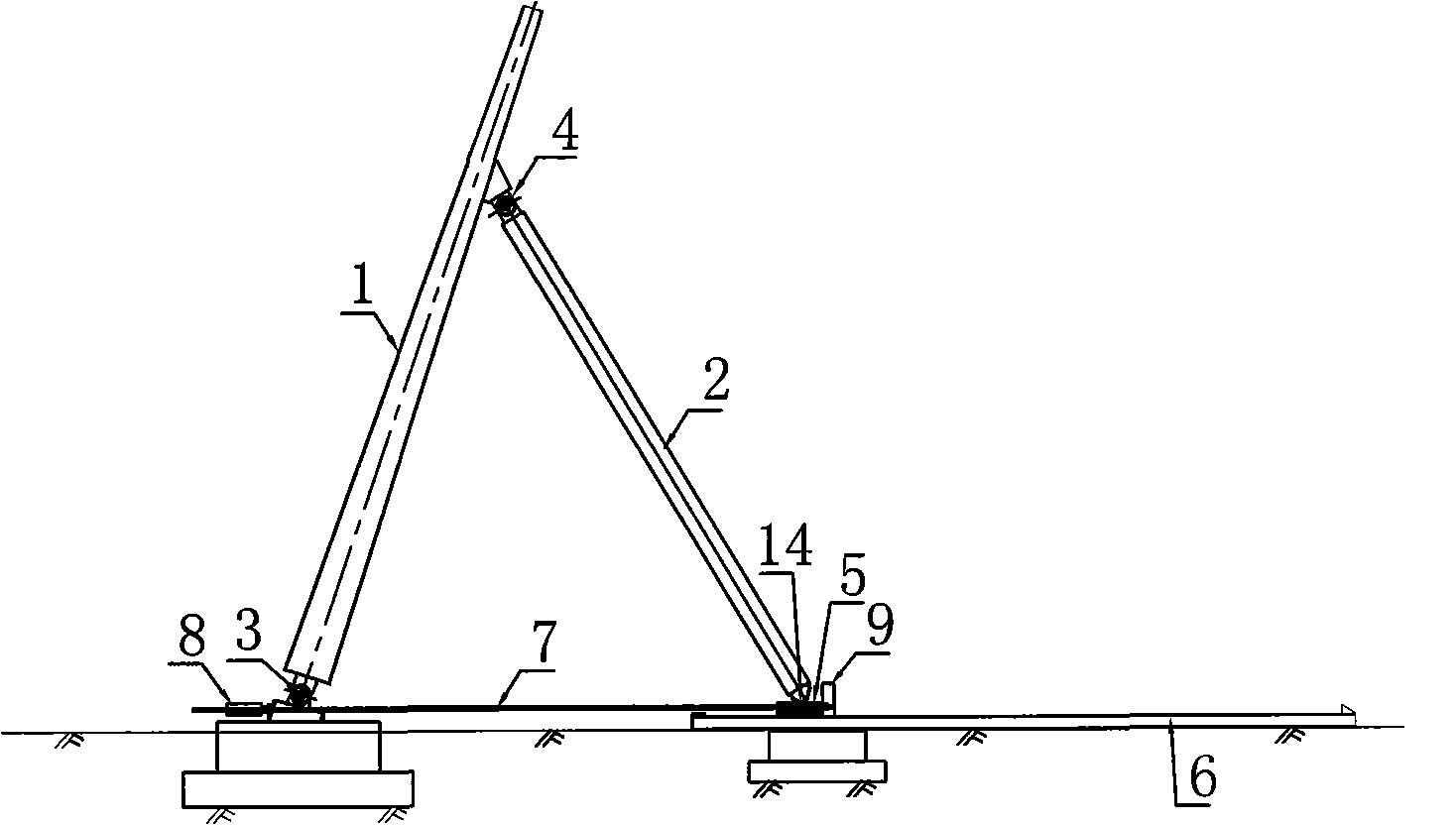

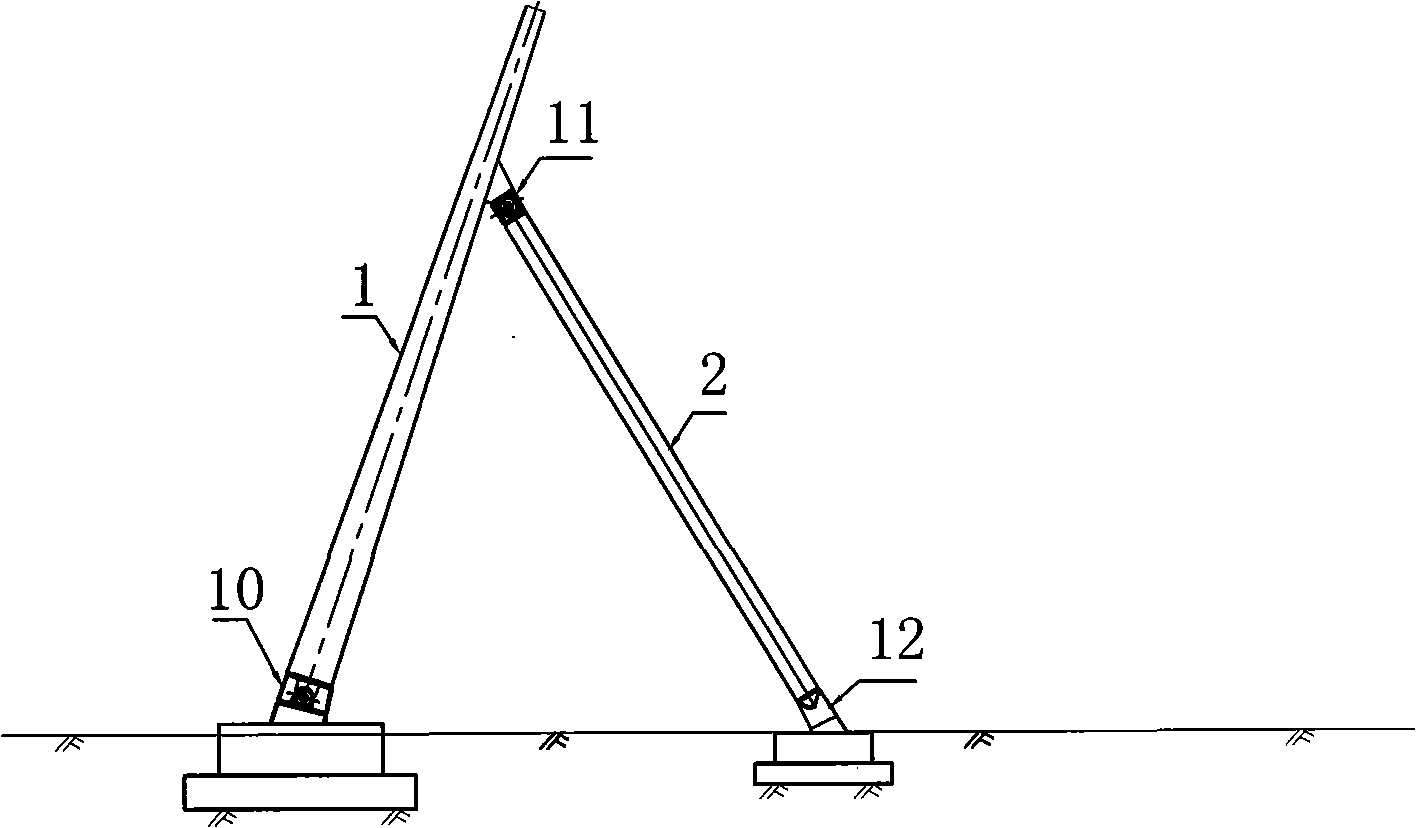

[0013] Such as figure 1 As shown, taking the construction of a "herringbone"-shaped steel tower as an example: first, set up a simple temporary support 13 under the steel tower 1 and the inclined legs 2, and make a certain angle a between the steel tower 1 and the inclined legs 2, and the steel tower 1 Can not overlap with the inclined leg 2 in parallel to avoid self-elevation difficulties, and then use the lifting equipment on the ground to tailor weld the steel tower 1 and the inclined leg 2 on the temporary support 13. Install the hinge 3 at the bottom of the steel tower; install the hinge 4 between the steel tower 1 and the inclined leg 2 (for the single-column steel tower, the auxiliary leg 2 can be set on the main body of the steel tower 1); install the slideway 6; install the inclined leg 2 Bottom ball boot 14 (or hinge) and slide plate 5, slide plate 5 is positioned on slideway 6; Then prestressed steel strand 7 is set between steel tower base and auxiliary leg bottom,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com