Steel plate welding end positioning mechanism

A positioning mechanism and welding end technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficulty in improving the degree of automation of equipment, large deviation, and low production efficiency, so as to improve the degree of automation of equipment and ensure Quality, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

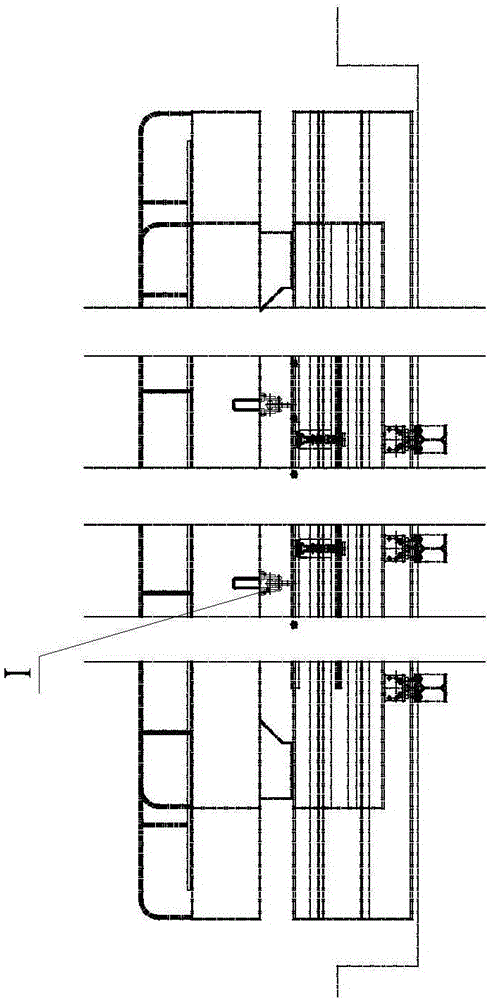

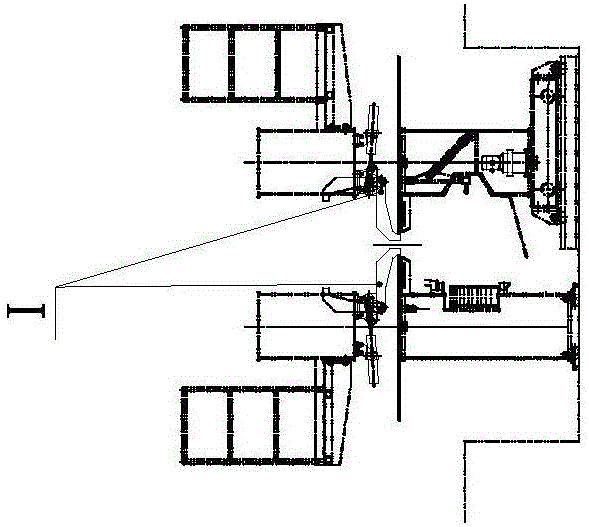

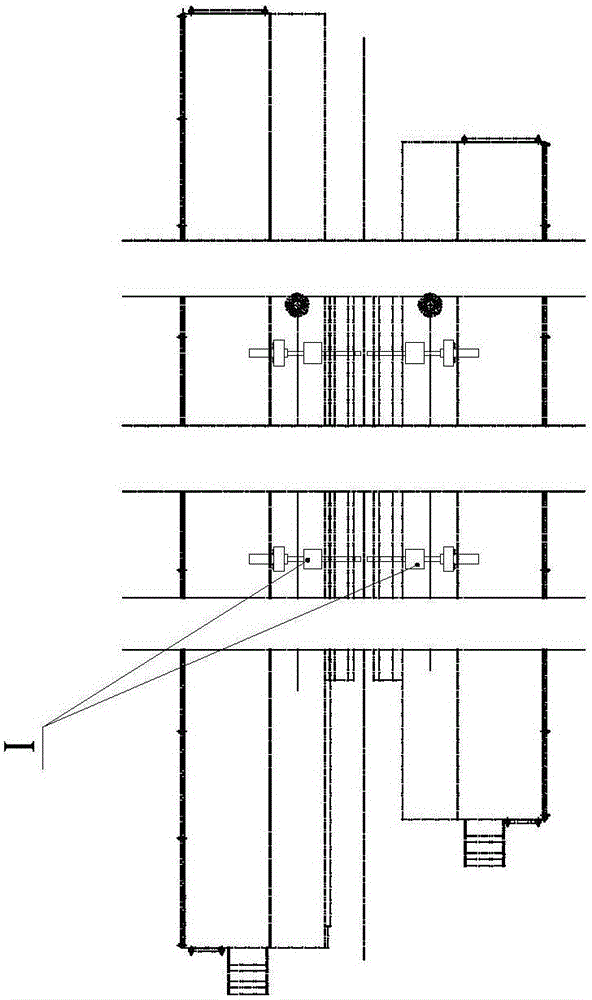

[0015] As shown in the figure: the end positioning mechanism of steel plate tailor welding in the embodiment mainly includes two positioning assemblies I arranged symmetrically facing each other; The positioning swing arm 4 is composed of the swing arm mounting base 3 fixed on the beam of the welding equipment during installation, the tail end of the positioning swing arm 4 is hinged on the swing arm mounting base 3, and the top of the positioning swing arm 4 is provided with a hinge seat 4a; the oil cylinder mounting seat 2 is arranged behind the swing arm mounting seat 3, and the oil cylinder mounting seat 2 is fixed on the beam of the welding equipment during installation, and the cylinder body of the hydraulic cylinder 1 is hinged on the oil cylinder mounting seat 2 with a pin Above, the piston rod end of the hydraulic cylinder 1 is hinged with the hinged s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com