A trailer frame assembly assembly welding system

A welding system and component technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as potential safety hazards, frame component errors, and low weld strength, so as to avoid potential safety hazards and prevent The effect of knocking deformation and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

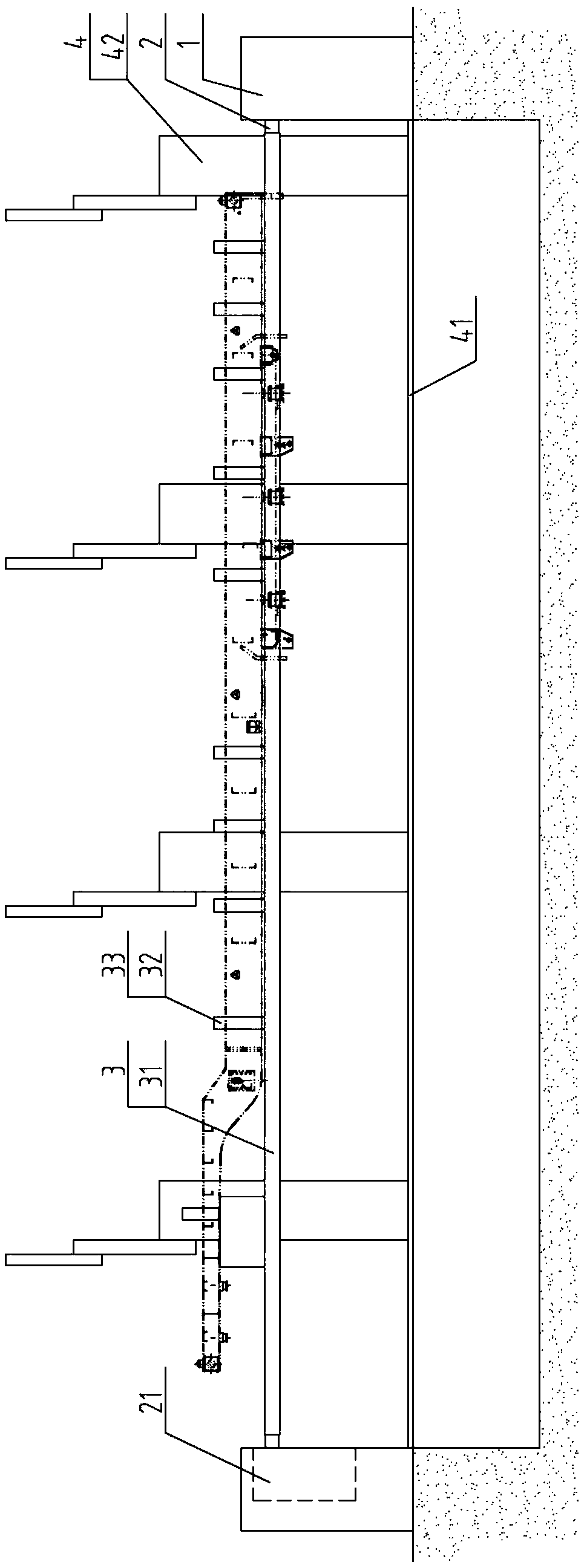

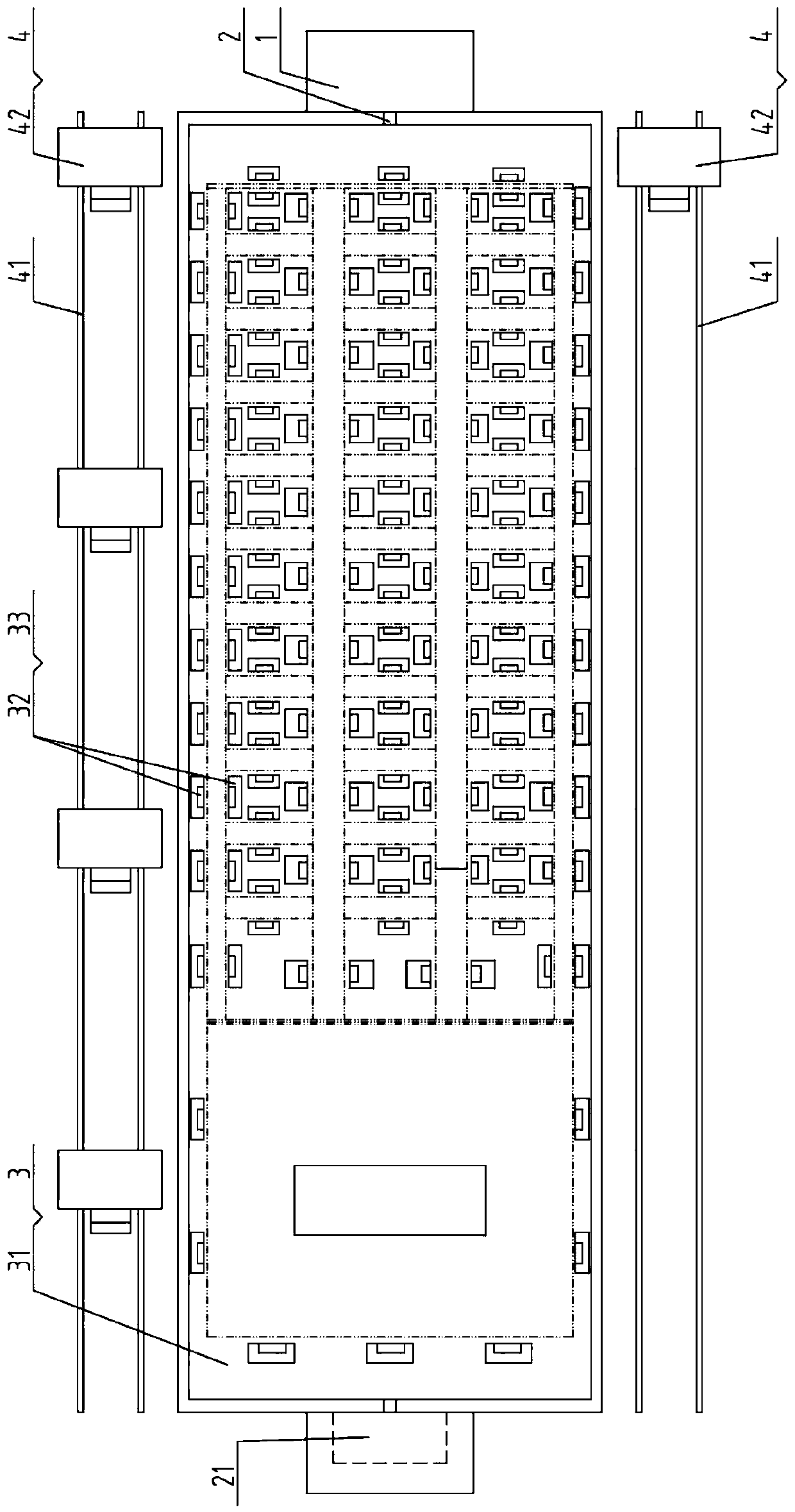

[0024] The present invention will be further described below in conjunction with accompanying drawing (be described ahead with the traction direction of tractor below).

[0025] Such as figure 1 , figure 2 As shown, the assembly and welding system of the trailer frame assembly includes a support frame 1, a turning shaft 2, a workpiece supporting part 3 and an electric control device.

[0026] The support frame 1 is symmetrically arranged in two pieces in the front and back directions, and is fixedly installed on the ground.

[0027] Described overturning shaft 2 is arranged as two pieces, and two overturning shafts 2 are concentrically arranged, and one end of two overturning shafts 2 is installed on the upper inner surface of support frame 1 through the bearing seat, and at least one overturning shaft 2 is provided with and installed The overturning drive device 21 on the support frame 1 or the ground can drive the overturning shaft 2 to rotate along its axis within at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com