Methods for superplastic forming

A superplastic forming and preforming technology, applied in the field of manufacturing, can solve the problems of slow forming speed, affecting product yield, several times to tens of slowness, etc., to meet the requirements of reducing superplasticity, huge market promotion value, and broad application. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

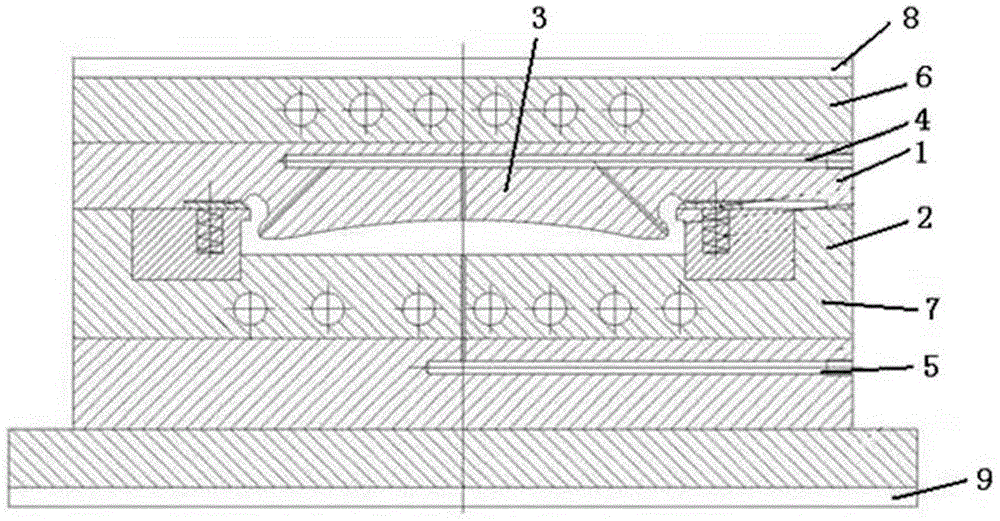

[0065] The following describes the design and preparation such as image 3 The mold shown.

[0066] reference image 3 with Figure 4 , First, use computer three-dimensional simulation software to pre-design the shape and structure of the preformed workpiece (prepared by S1 and S2) of the second step preform S2 that can push the thickness protection zone of the raw material to the four sides and four corners. Then reversely design the shape and structure of the punch 3 used in the first step of stamping forming S1 and the second step of preforming S2, and finally combined with a CNC lathe to prepare the mold.

Embodiment 2

[0068] The following describes the molding process of using the mold described in Example 1 to prepare the notebook shell with the 5083 aluminum alloy sheet as the raw material.

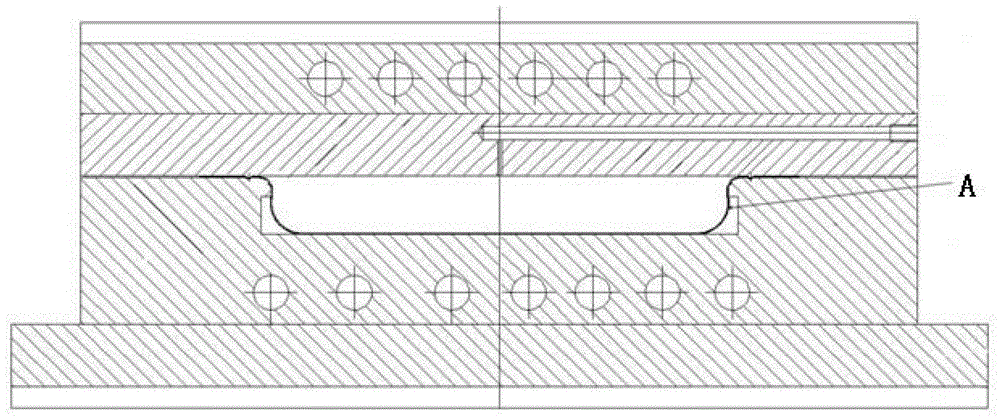

[0069] reference image 3 with Figure 4 , First spray the 5083 aluminum alloy plate with aqueous boron nitride, and then preheat it to 500 degrees Celsius. Through the action of a hydraulic press, the upper die 1 and the lower die 2 are closed and sealed, and the punch 3 of the upper die 1 presses the plate down. Press the sheet into the forming cavity of the lower die 2, perform the first step of stamping and forming S1, and then apply a positive air pressure of 0.1 to 1 MPa through the lower air inlet 5, and at the same time, apply a positive air pressure through the upper air inlet 4 in the opposite direction Small back pressure is used to suppress holes. The plate is gradually deformed after holding pressure for 1 to 5 minutes, and finally fits with the pre-formed cavity of the upper mold 2 to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com