Phase-change-type boiler system

A boiler and phase change technology, applied in the field of boilers, can solve the problems of large fluctuations in conductivity, high operating water costs, and high operating height of personnel, and achieve the effect of large layout space, small footprint, and low operating height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

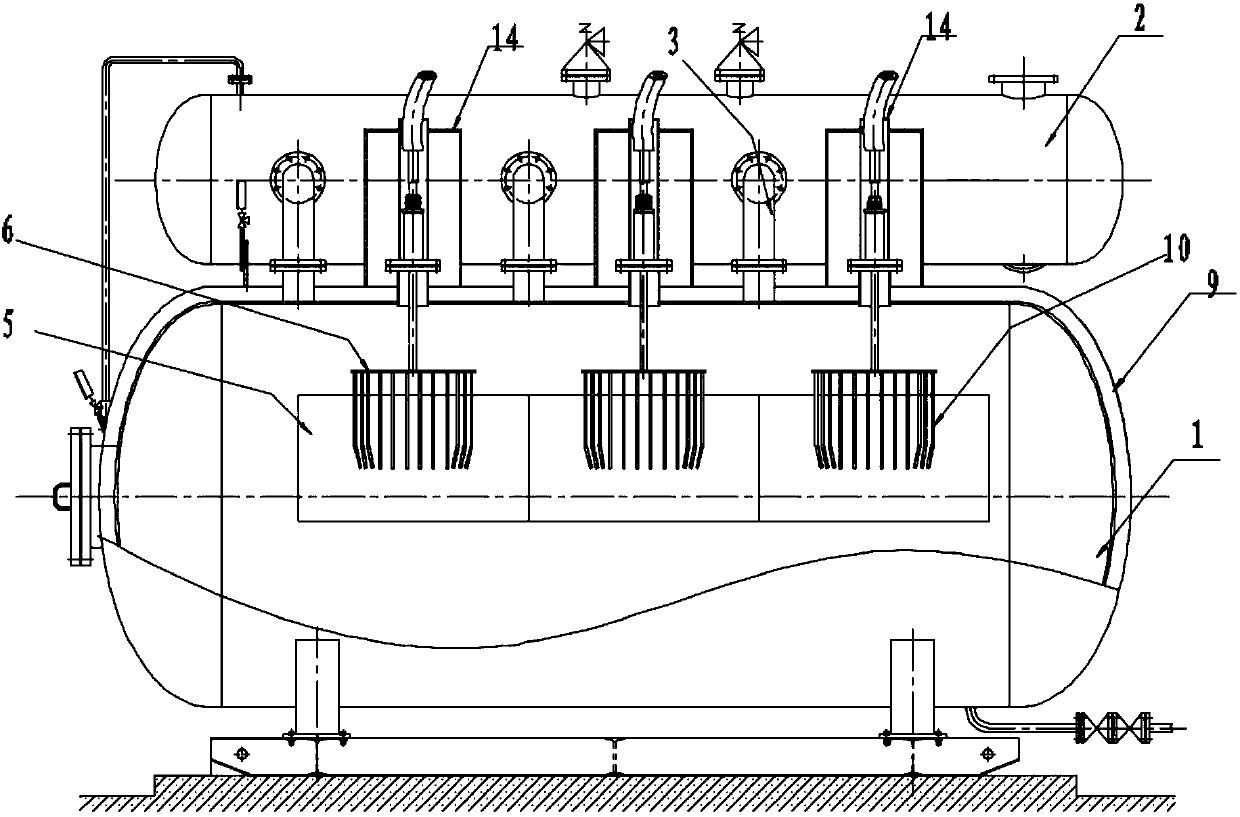

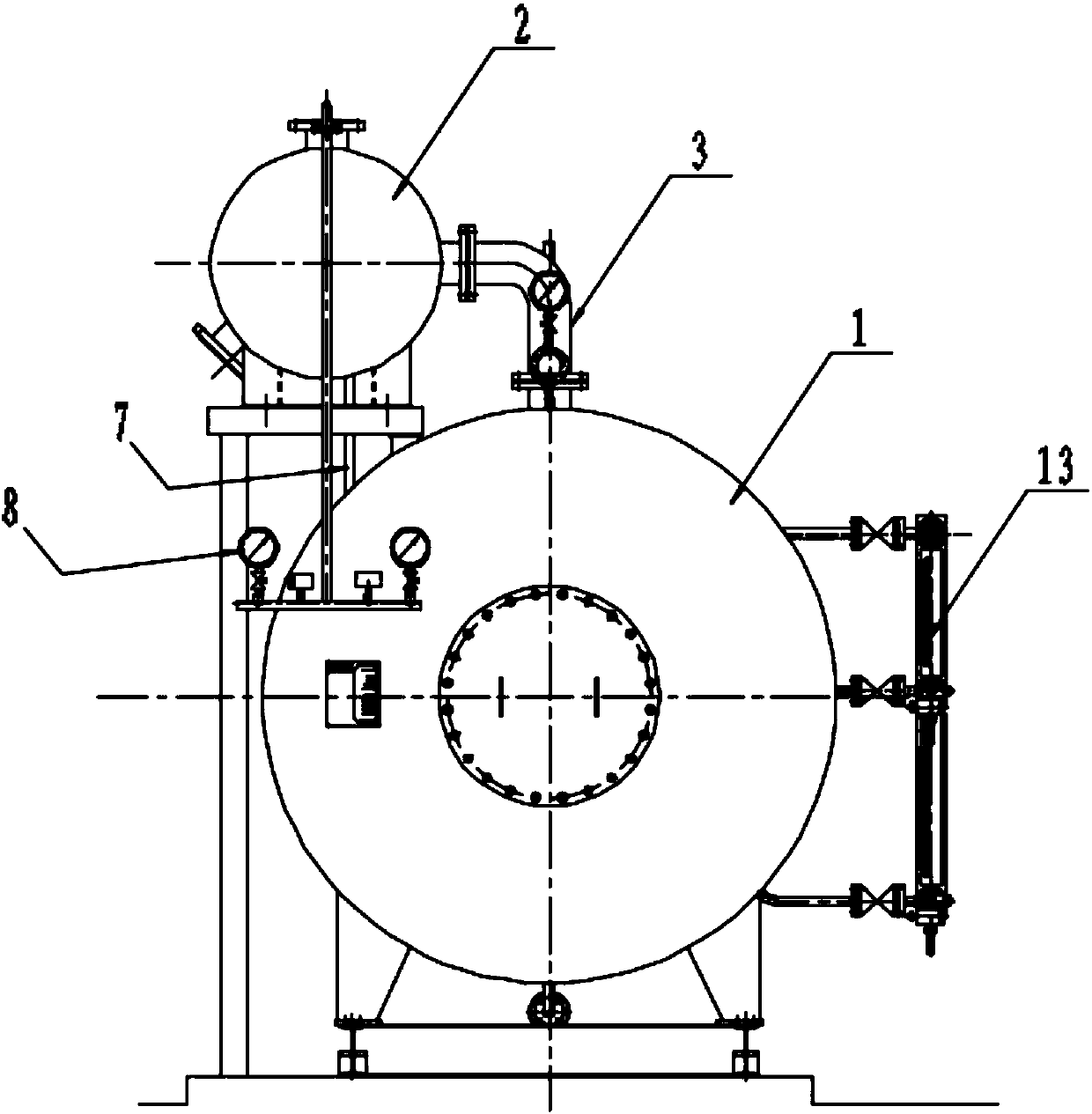

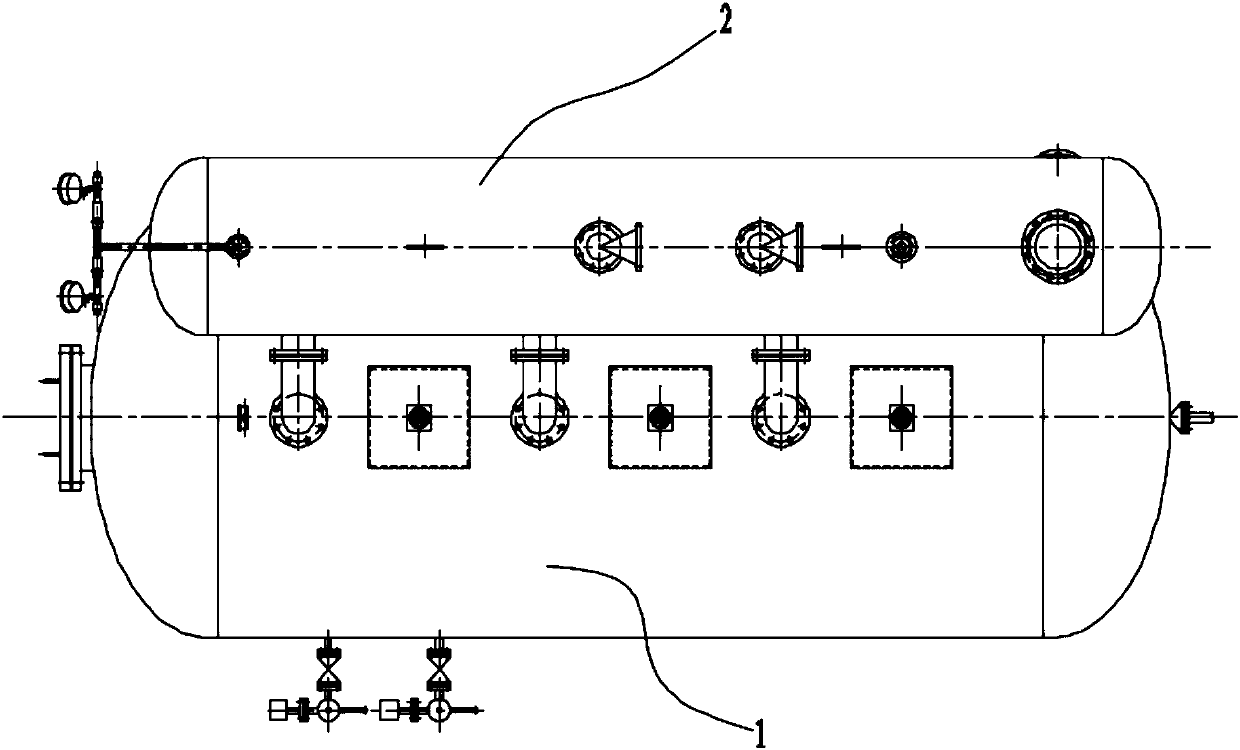

[0030] A phase change boiler system such as Figure 1-5 As shown, it includes a horizontal boiler shell 1 and a heat exchanger 2 located at the top of the boiler shell 1 . The boiler is arranged horizontally, specifically including two parts, the boiler shell 1 and the heat exchanger 2, and the heat exchanger 2 is arranged on the top of the boiler shell 1. Moreover, the boiler shell 1 and the heat exchanger 2 are connected through several steam channels 3 and the return pipe 4. Specifically, the top of the boiler shell 1 is connected with the heat exchanger 2 through the steam channels 3, and the bottom of the heat exchanger 2 is connected through the return pipe 4. The water pipe 4 is connected with the boiler shell 1; the upper opening of the steam passage 3 is connected with the side wall of the heat exchanger 2, and the lower opening of the return pipe 4 is connected with the bottom of the boiler shell.

[0031] The boiler shell 1 is covered with a thermal insulation pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com