Preparation method of electrodes for sterilization and disinfection water generating device and product

A technology of sterilization, disinfection and generation device, which is applied in the fields of sterilization/microdynamic water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc. It can solve the problems of low efficiency and high cost, and achieve uniform fusion and good magnetic permeability. , the effect of stirring evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: This embodiment provides a method for preparing an electrode for a sterilizing water generating device, which includes the following steps:

[0035] (1) Prepare raw materials: soak electrolytic copper and silver ingots in a mixed solution formed by mixing sulfuric acid with a concentration of 20% and hydrofluoric acid with a concentration of 5%, after soaking for 20min to 40min, wash with pure water for subsequent use;

[0036] (2) Smelting: prepare a crucible with high magnetic permeability and high thermal conductivity, place electrolytic copper and silver ingots in the crucible according to weight percentage: electrolytic copper 91% to 99%, silver ingot: 1% to 9%, and place the crucible Placed in double vacuum smelting equipment with a constant electromagnetic field, at a vacuum degree of 10 -3 , at a temperature of 1000°C to 1200°C, rotate the crucible to form electromagnetic two-way stirring, and keep it warm for 100min to 150min to obtain a uniformly...

Embodiment 2

[0054] Embodiment 2: This embodiment provides a method for preparing an electrode for a sterilizing and disinfecting water generating device, the steps of which are basically the same as those in Embodiment 1, the difference being that

[0055] The preparation method of described crucible is as follows:

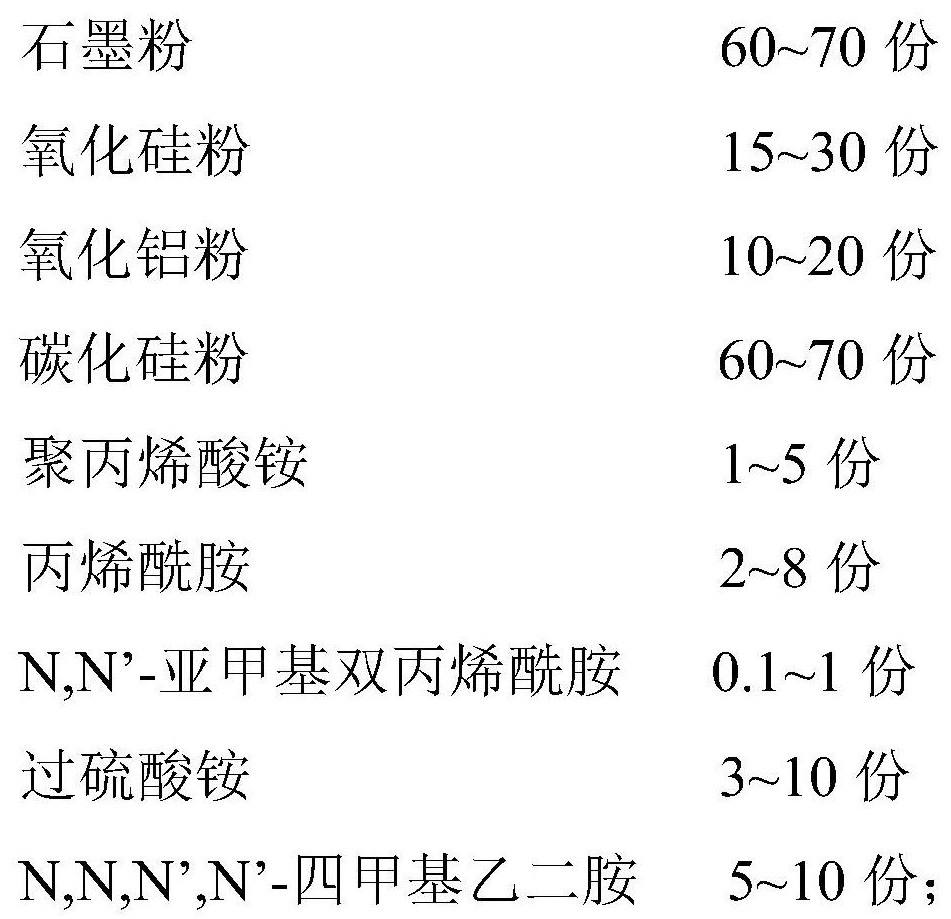

[0056] (1) prepare each component of following parts by weight:

[0057]

[0058] (2) acrylamide and N,N'-methylenebisacrylamide are mixed;

[0059] (3) Add ammonium polyacrylate to the mixed solution in step (2), and adjust the pH to 8 with concentrated ammonia water to obtain a premixed solution;

[0060] (4) Graphite powder, silicon oxide powder, aluminum oxide powder, silicon carbide powder and the premixed solution of step (3) are put into the ball milling tank, and the rotating speed is 60r / min, ball milling for 10h, then vacuumizing for 1h, Obtain mixed slurry;

[0061] (5) Add ammonium persulfate and N,N,N',N'-tetramethylethylenediamine to the mixed slurry in st...

Embodiment 3

[0063] Embodiment 3: This embodiment provides a method for preparing an electrode for a sterilizing and disinfecting water generating device, the steps of which are basically the same as those in Embodiments 1 and 2, the difference being that

[0064] The preparation method of described crucible is as follows:

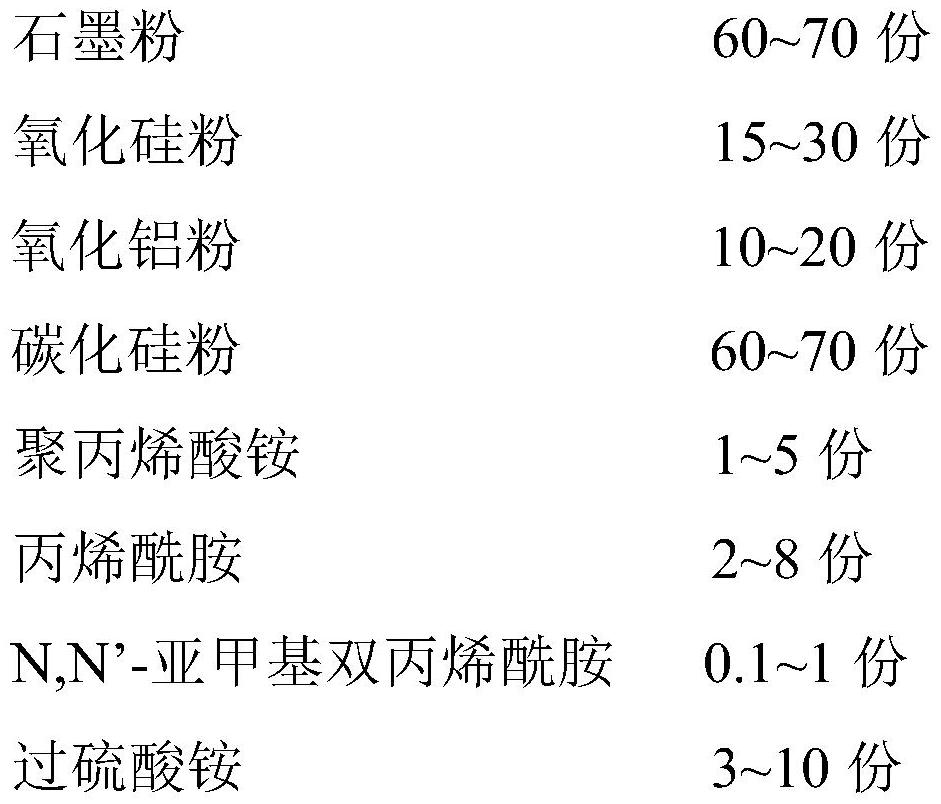

[0065] (1) prepare each component of following parts by weight:

[0066]

[0067] (2) acrylamide and N,N'-methylenebisacrylamide are mixed;

[0068] (3) Add ammonium polyacrylate to the mixed solution in step (2), and adjust the pH to 8 with concentrated ammonia water to obtain a premixed solution;

[0069] (4) Graphite powder, silicon oxide powder, aluminum oxide powder, silicon carbide powder and the premixed solution of step (3) are put into the ball mill tank, and the rotating speed is 70r / min, ball mill for 15h, and then vacuumize for 2h, Obtain mixed slurry;

[0070] (5) Add ammonium persulfate and N,N,N',N'-tetramethylethylenediamine to the mixed slurry in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com