Technological method for manufacturing ultra-wide titanium plate

A process method, the technology of titanium plate, applied in the direction of metal rolling, etc., can solve the problems of titanium plate width not meeting the use requirements, low production efficiency, and low comprehensive yield, so as to shorten the process cycle, improve processing efficiency, reduce The effect of material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

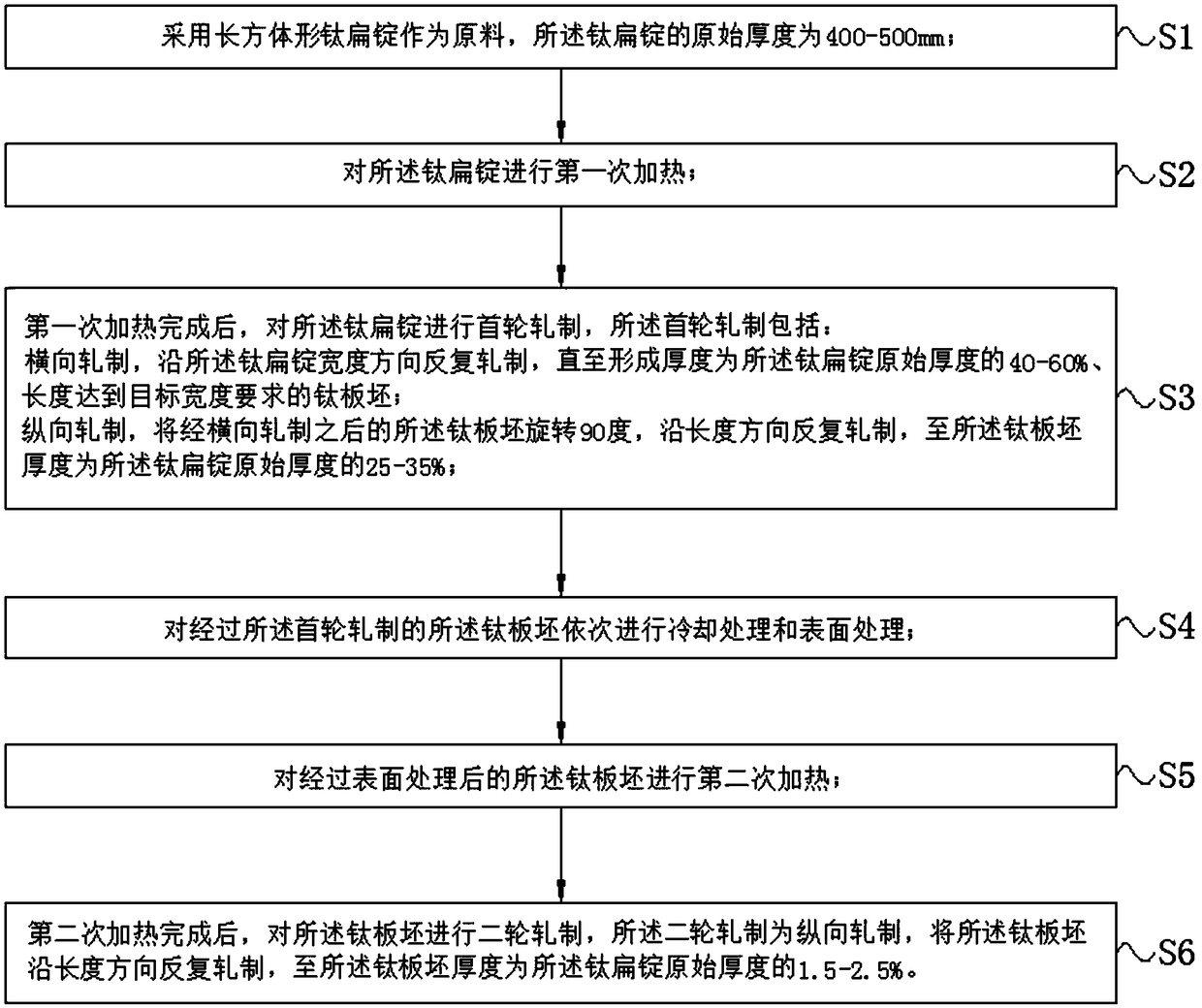

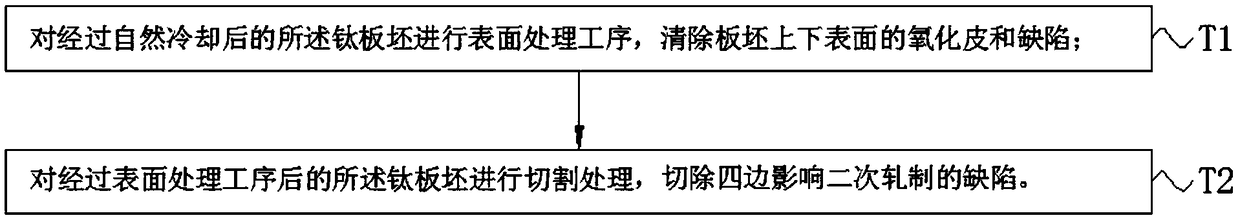

[0034] Please refer to the attached figure 1 , which shows the flow of a process for producing an ultra-wide titanium plate provided in an embodiment of the present application.

[0035] A kind of processing method of producing ultra-wide titanium plate, described processing method comprises:

[0036] S1 uses a rectangular parallelepiped titanium slab as a raw material, and the original thickness of the titanium slab is 400-500 mm.

[0037] When the traditional process is used to process titanium plates, the titanium round ingot melted in the vacuum consumable electric arc furnace is used as the raw material. Before rolling the coil, it must be forged, and the titanium round ingot is forged into a square with a thickness of about 200mm. ingot. However, forging needs to be carried out at high temperature, and the heat loss is serious; moreover, after forging, the oxide skin on the surface of the titanium ingot is thick, and the surface quality is poor, so it needs to be plane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com