Heat supply system for curing tobacco at three sections with solar energy

A solar heat collector, three-stage technology, applied in solar thermal power generation, solar thermal devices, tobacco, etc., can solve the problems of difficulty in ensuring the quality of flue-cured tobacco, inaccurate control, and excessive heat, so as to increase the temperature and reduce the workload , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

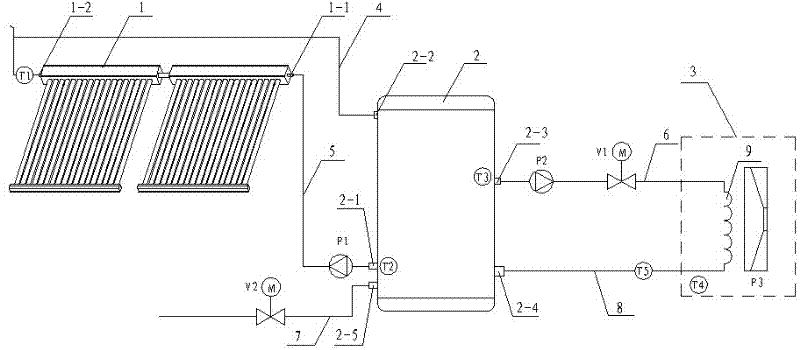

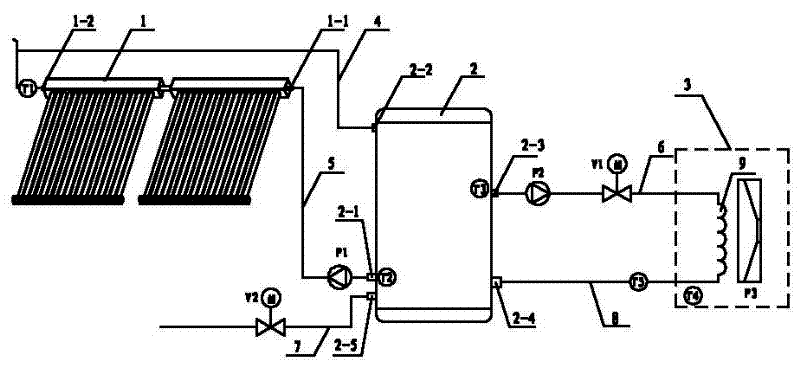

[0020] In this embodiment, the device for heating three-stage flue-cured tobacco using solar energy includes a solar heat collector 1, a hot water storage tank 2, a solar heat collecting circulation pump P1, a heating circulation pump P2, a fan heat exchanger P3, and a solenoid valve , temperature sensor, control cabinet 10. The ultra-clear tempered low-iron glass cover plate in the solar collector 1 has a transmittance ≥ 92%, and the metal heat absorber with a selective absorption coating in the heat collector 1, and the heat absorber can be a strip Or the whole board, the structure of the heat absorbing body is that there are fins at both ends of the tubular flow channel or fins on the upper part, and the material is copper or copper-aluminum composite material. The insulation material is rock wool, glass wool board or strip. The inlet 1-1 of the solar heat collector 1 is equipped with a pipeline 5 communicating with the lower circulation port 2-1 at the bottom of one side ...

Embodiment 2

[0039]The solar heat collector in this embodiment is a vacuum tube heat collector, including a vacuum tube, a header, a bottom bracket, a tailstock, and a tube head. The structure of the header is that there is an insulation layer on the shell between the inner tanks, and one side of the header (vertical insertion type) or two symmetrical sides (horizontal insertion type) have circular holes. One end of the vacuum tube opening is inserted into the row hole of the header and goes deep into the inner tank of the header. The other end of the vacuum tube is set on the tailstock and installed on the bottom bracket together. There is a bracket between the header and the bottom bracket. Other structures are the same as in Embodiment 1, and the control status setting of the control cabinet is also the same as in Embodiment 1.

[0040] During use, the heat supply pipe 9 of the present invention and the hot air blower or heat exchanger are contained in the flue-cured tobacco chamber 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com