Huadian type process and device for dry distillation of oil shale

A technology of oil shale and dry distillation, which is applied in special forms of dry distillation, petroleum industry, direct heating dry distillation, etc. It can solve the problems of expensive imported equipment, ineffective use of semi-coke, and small daily processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

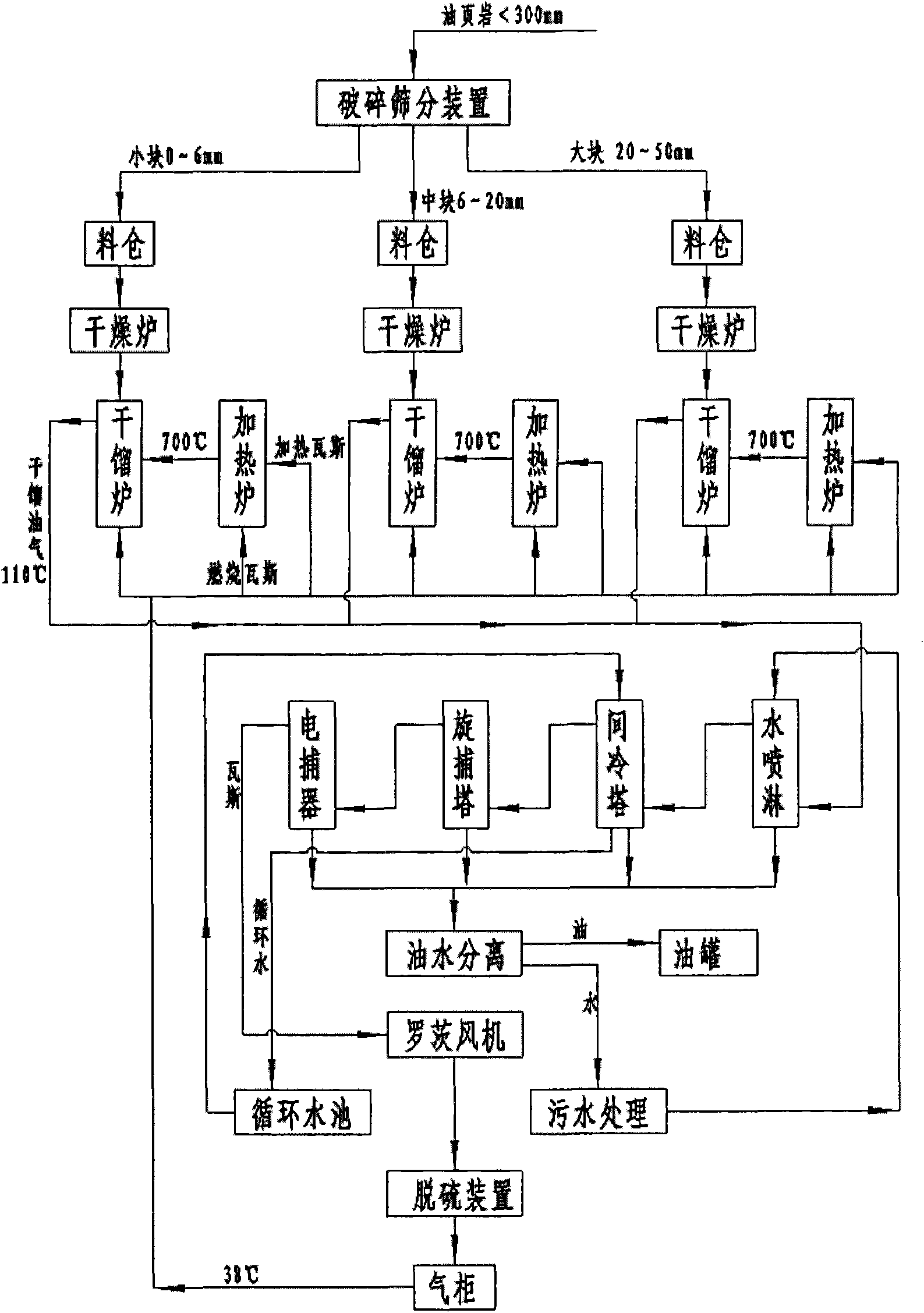

[0064] Process flow of the present invention such as figure 1 As shown in the figure, the flow of this new process is mainly reflected in the figure, which are: ore crushing and screening, grading and siloing, drying and preheating, grading dry distillation, condensation recovery, gas desulfurization, and gas heating. Different grades of oil shale are sent to dry distillation furnaces of different specifications for dry distillation; the full cycle process of gas and the condensation recovery system of oil and gas are clearly reflected. Specifically include the following steps:

[0065] 1. Crushing and screening: The oil shale less than 300mm mined from the mine is crushed by crushing and screening equipment into three different specifications: small, medium and large. As a result, the specific specifications should ensure that the ratio of sieved products is: small: medium: large = 1:2:2. In actual operation, it can be realized by adjusting the aperture of the sieve plate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com