Driving belt vulcanizing boiler

A vulcanization tank and transmission belt technology, which is applied to belts, other household appliances, household appliances, etc., can solve the problems of high steam pressure requirements, uncontrollable external cavity temperature, and influence on normal vulcanization, so as to save steam consumption and avoid steam loss , Reduce the effect of vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

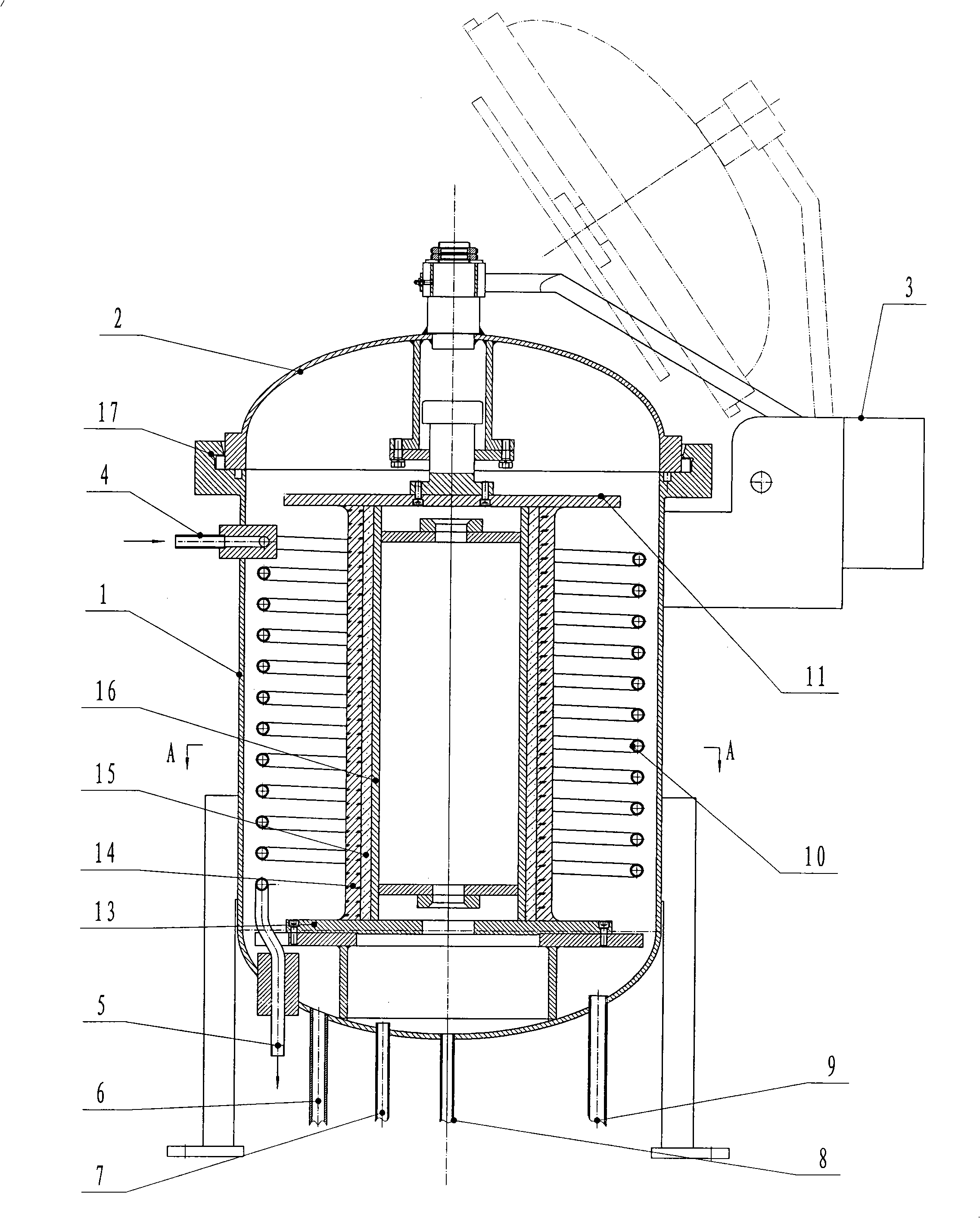

[0013] The embodiment in the figure is a rubber V-belt vulcanization tank. Between the rubber sleeve 14 and the cover plate 11 and the supporting plate 13 is an inner cavity, between the rubber sleeve 14 and the transmission belt vulcanization tank body 1, and the tank cover 2 is an outer cavity, and the lower part of the outer cavity has an outer cavity pressure air outlet 6 and an outer cavity The pressure air inlet 9, the inner cavity is connected to the inner cavity steam inlet 7 and the inner cavity steam outlet 8, the inner cavity steam inlet 7 and the inner cavity steam outlet 8 are connected to the steam pipeline, and the inner cavity steam inlet 7 is also connected to the vacuum pipeline through a three-way valve , the three-way valve is connected to the inner cavity steam inlet 7, the steam pipeline, and the vacuum pipeline. The high-temperature steam heating pipe 10 in the outer cavity is in a spiral shape, surrounds the rubber sleeve 14, and contains a high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com