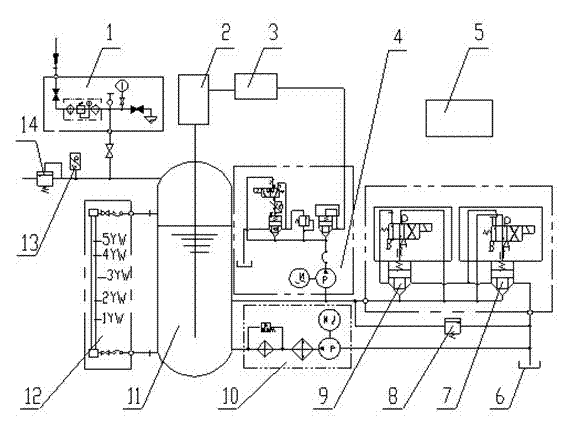

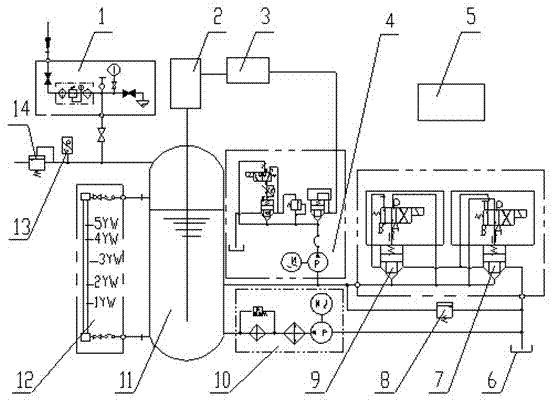

Automatic liquid supplementing and draining system with liquid filling tank

A liquid tank and liquid replenishment technology, which is used in pipeline systems, forging press driving devices, gas/liquid distribution and storage, etc. Effects of shock and vibration, increased service life, improved oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An automatic liquid filling and draining system for a liquid filling tank: at least including a liquid filling tank 11, an oil supply circuit connected to the liquid filling tank 11, an oil discharge circuit connected to the liquid filling tank 11 and a working mechanism for supplying working oil to the working cylinder 3 The oil circuit, the liquid filling tank 11 is connected with a liquid level sensor and a pressure charging circuit. During operation, the pressure charging circuit fills the liquid filling tank 11 with an air pressure of 0.3-0.5MPa, and the liquid level sensor detects the oil level of the liquid filling tank 11. When When the oil level is lower than the low oil level, the electric control unit 5 controls the oil supply circuit to supply oil to the liquid filling tank 11, so that the oil level of the liquid filling tank 11 handles the working oil level range. When it is higher than the high oil level point of the liquid filling tank 11, The operation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com