Novel oil removal process for coal chemical industry wastewater

A coal chemical wastewater, a new technology, applied in the field of coal chemical industry, can solve the problems of difficult separation, poor oil-water separation effect of wastewater, etc., to achieve the effect of improving oil absorption effect, providing oil removal effect, and expanding the oil absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

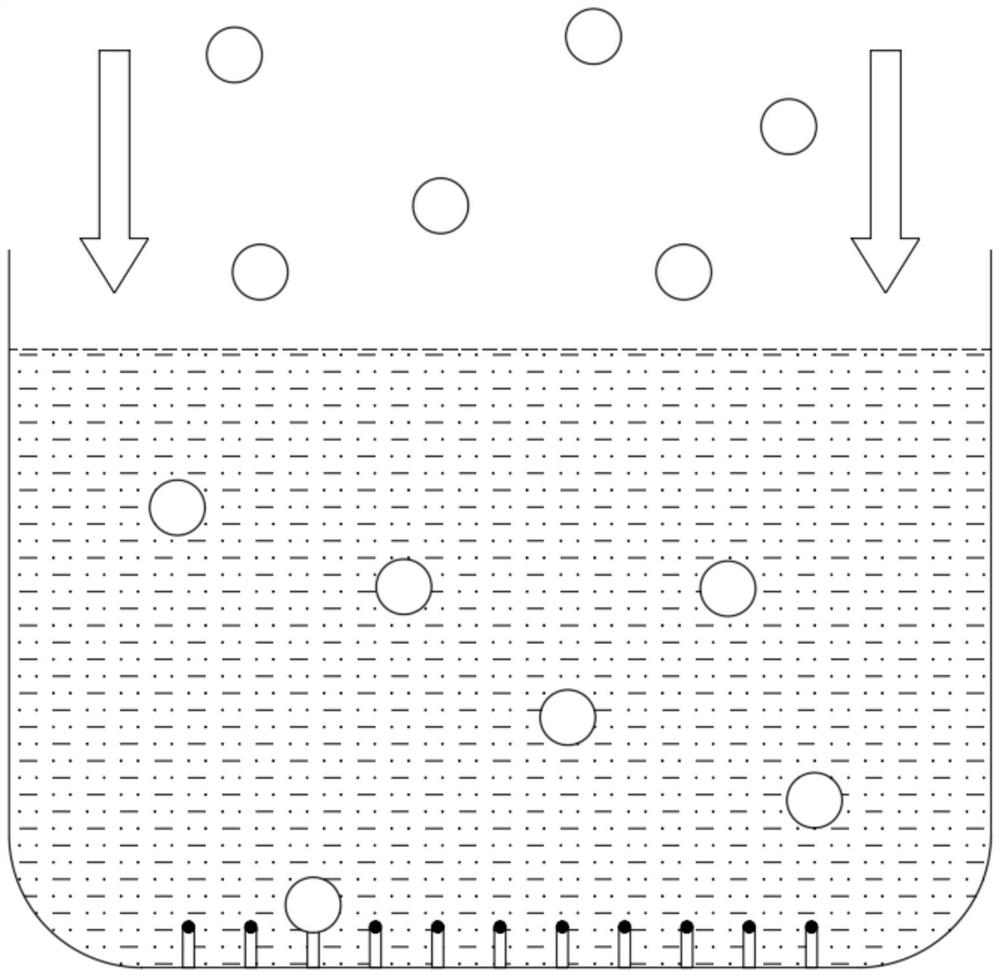

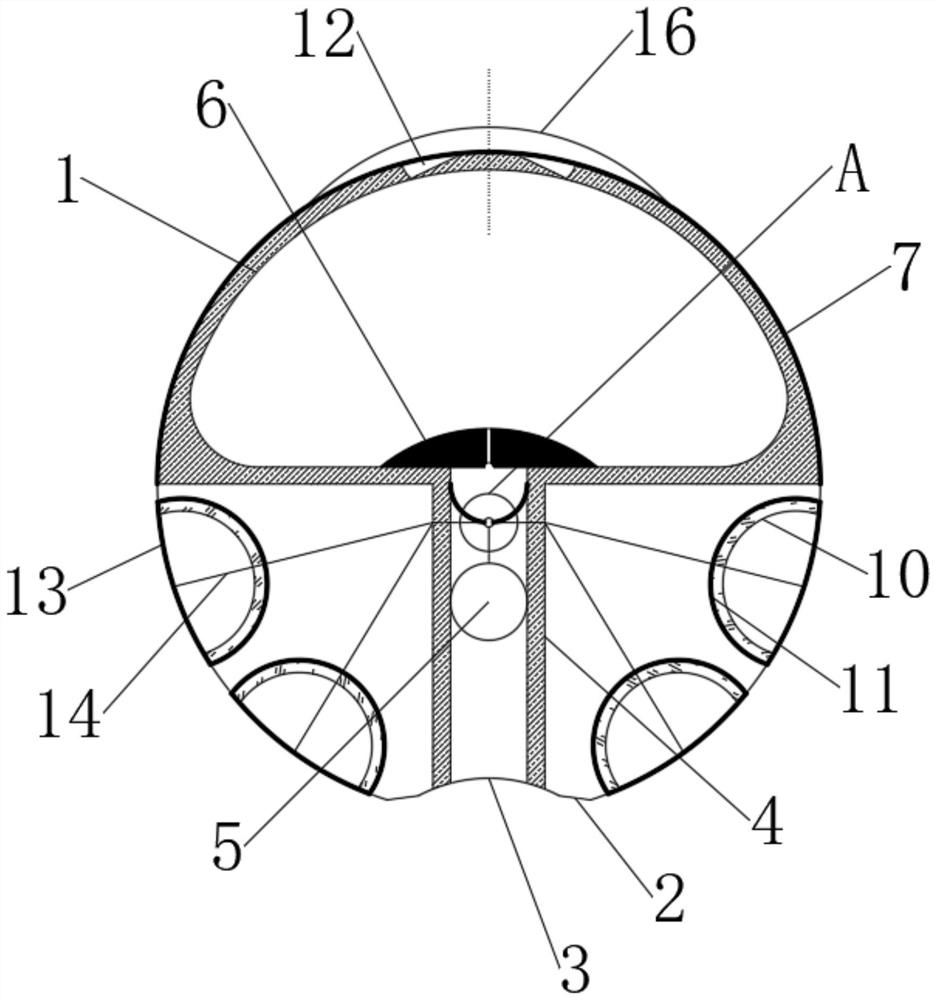

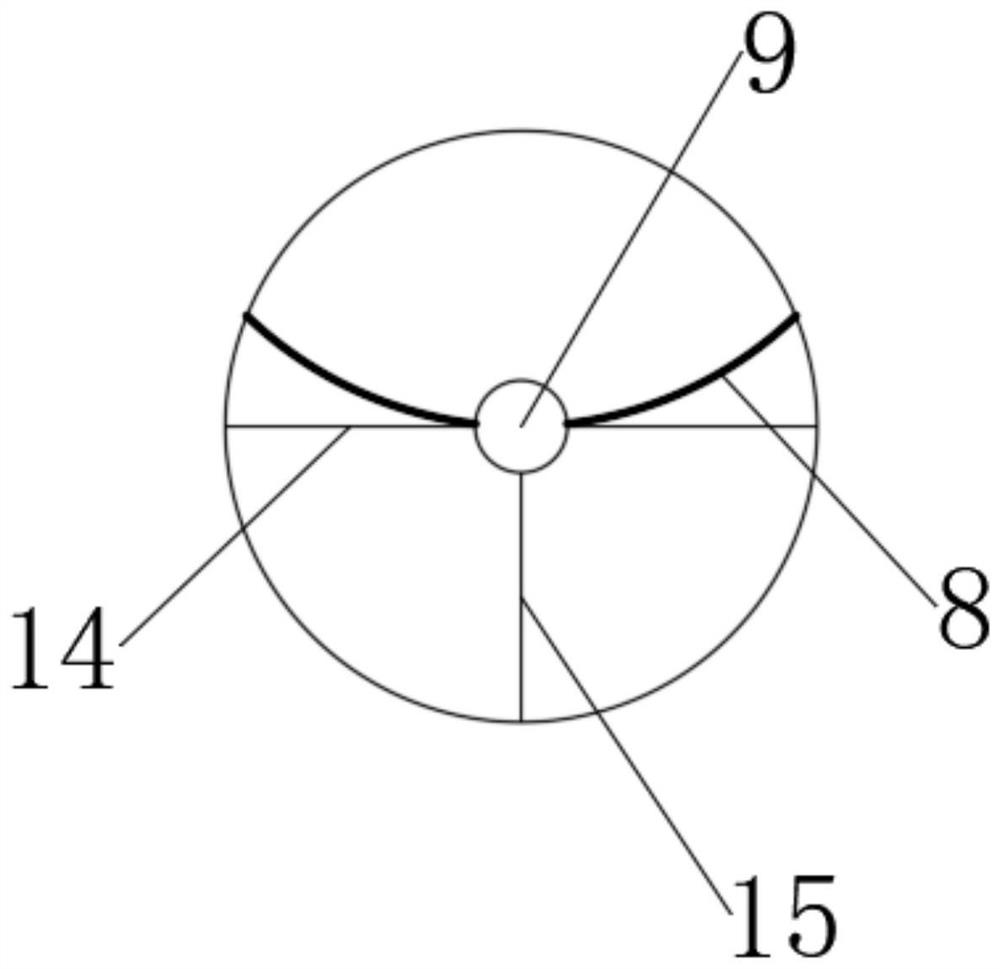

[0045] see figure 1 , a new oil removal process for coal chemical wastewater, comprising the following steps:

[0046] S1. First, use an oil-water separator to conduct preliminary oil-water separation of coal chemical wastewater, and then inject the wastewater with residual oil droplets into the degreasing tank;

[0047] S2. Before the waste water is injected, multiple evenly distributed trigger rods are installed in the degreasing tank, and the upper end of the trigger rod is inlaid and connected with a magnetic ball;

[0048] S3. Evenly throw a plurality of degreasing balls into the waste water in the degreasing pool, and the degreasing balls continuously absorb the residual oil droplets in the waste water during the sinking process;

[0049] S4. After the degreasing ball sinks until it combines with the magnetic ball and triggers the floating action, and then floats to the water surface, all are recovered;

[0050] S5. The oil stain absorbed in the degreasing ball is extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com