Nano porous starch-based material with high oil absorption rate and preparation method and application thereof

A nanoporous, high oil absorption technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., to achieve stable structure, high oil absorption effect, and good oil absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

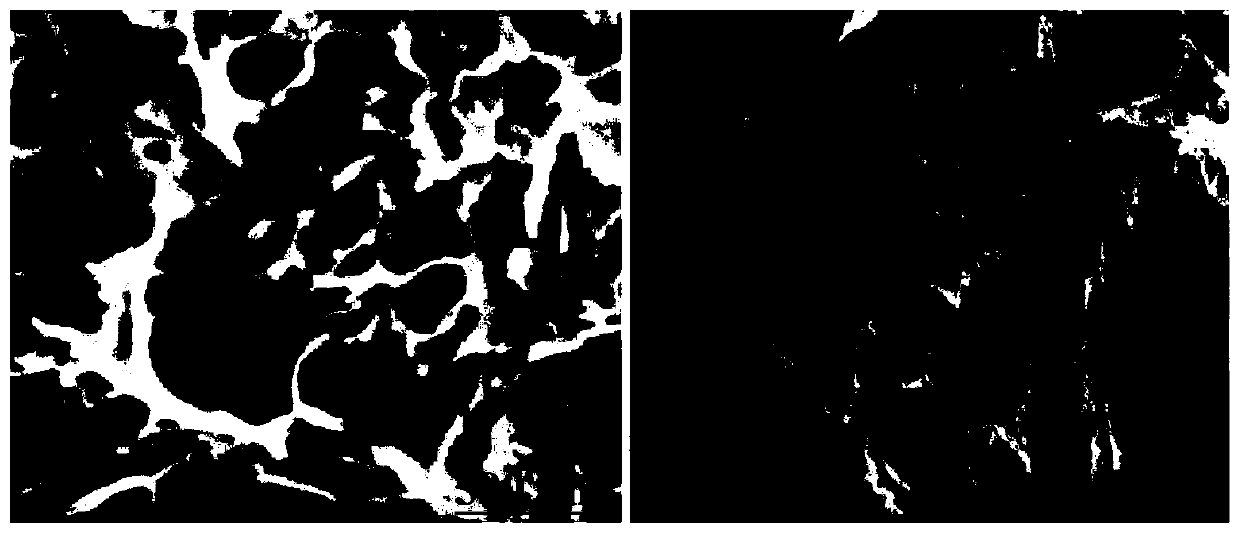

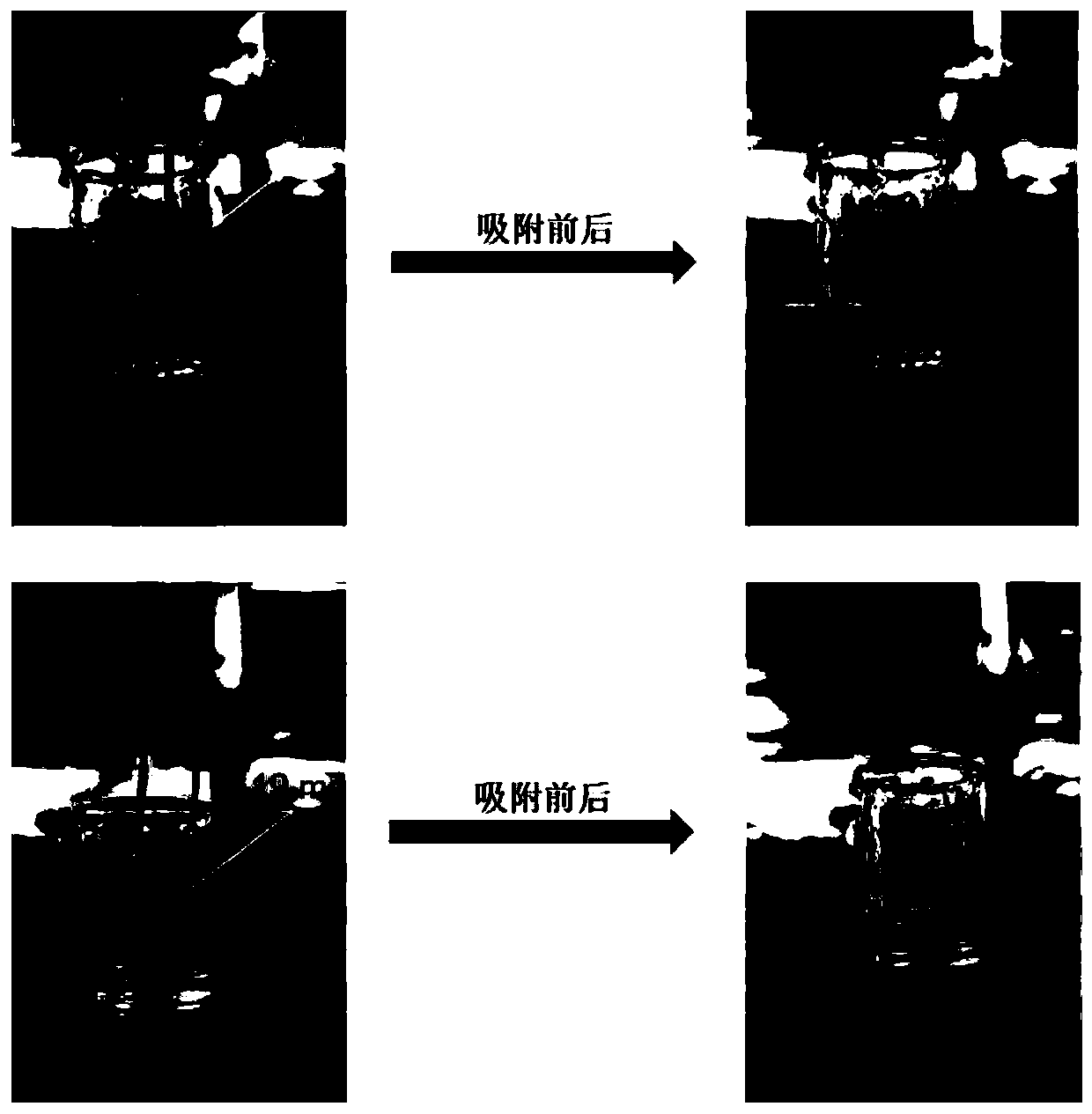

Image

Examples

Embodiment 1

[0039] A preparation method of nanoporous starch-based material with high oil absorption rate, comprising the following steps:

[0040] 1. Gelatinization treatment of starch: Take 100 g of starch and dissolve it in 10 L of distilled water, gradually raise the temperature to 95°C at a rate of 8°C / min and keep for 2 minutes, then cool to room temperature for later use;

[0041] 2. Add 2 g of calcium carbonate nanoparticles to step 1 and continue to stir for 20 min. Continue to stir overnight at 4°C. Centrifuge at 2500 r / min for 5 min. After washing with water three times, disperse in ethylenediaminetetraacetic acid (0.2 M pH=7.4, EDTA), stirred for 30 min, centrifuged and washed three times with ultrapure water. Repeatedly disperse EDTA, stir, centrifuge and wash;

[0042] Operation points and precautions: Calcium carbonate nanoparticles are dissolved in 10% ethanol water and ultrasonically mixed. When dissolving, ethanol can be added first to dissolve most of the nano-calcium ...

Embodiment 2

[0051] A preparation method of nanoporous starch-based material with high oil absorption rate, comprising the following steps:

[0052] 1. Gelatinization treatment of starch: Take 100 g of starch and dissolve it in 10 L of distilled water, gradually raise the temperature to 95 °C at a rate of 14 °C / min and keep for 4 min, then cool to room temperature for later use;

[0053]2. Add 4 g of calcium carbonate nanoparticles to step 1 and continue to stir for 20 min. Continue to stir overnight at 4°C. Centrifuge at 2500 r / min for 5-10 min. After washing with water three times, disperse in ethylenediamine Tetraacetic acid (0.2M pH=7.4, EDTA), stirred for 30-35 min, and centrifuged and washed three times with ultrapure water. Repeatedly disperse EDTA, stir, centrifuge and wash;

[0054] Operation points and precautions: Calcium carbonate nanoparticles are dissolved in 10% ethanol water and mixed ultrasonically. When dissolving, ethanol can be added first to dissolve most of the nano-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com