Thermal design method for extra-planetary rotary cable bunch

A cable harness and thermal design technology, applied in the manufacture of wire harnesses, etc., can solve the problems of winding heating belts and difficulty in implementation, and achieve the effects of improving reliability, simplifying design, and achieving obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Extraterrestrial activity cable bundle, the cable bundle is C55 series wire, the wire specification is C55 / 012-22, and the power cable core cross section is 0.35mm 2 , the resistivity of the power cable core is 50.5Ω / km; when the cable bundle is working, the power current I=2A passing through the cable bundle is approximately considered to be 2A through the power cable core; in order to ensure that the cable bundle is in a cold space (-269 ℃), it is necessary to keep the temperature of the cable bundle at a level not lower than -25 ℃;

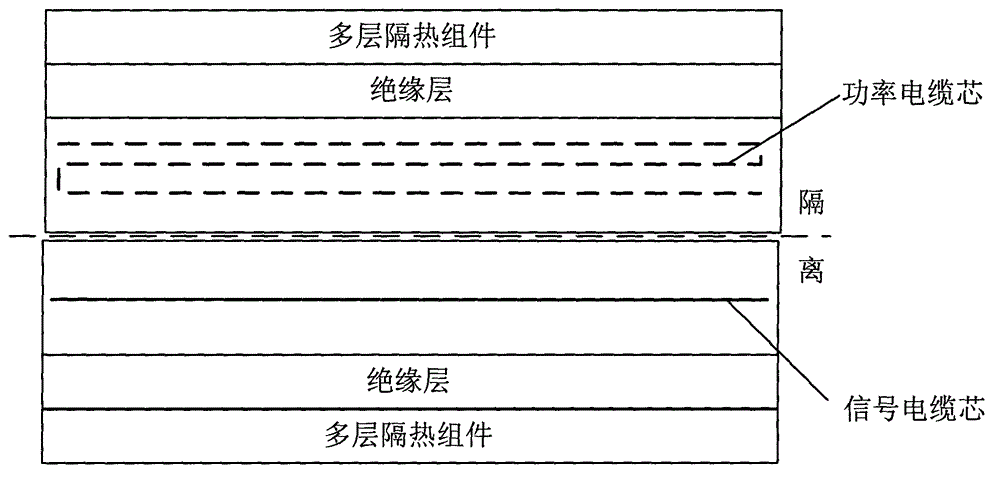

[0027] 1) First, design the extraterrestrial active cable bundle, that is, to isolate the power cable core and the signal cable core and cover the two with insulating layers and multi-layer heat insulation components, such as figure 1 As shown, the Thermal Desktop software is used to establish the thermal analysis model of the cable harness according to the track parameters in Table 1;

[0028] Orbital parameters in Table 1 Embodiment 1...

Embodiment 2

[0041] Extraterrestrial activity cable bundle, the cable bundle is C55 series wire, the wire specification is C55 / 011-20, and the power cable core cross section is 0.5mm 2 , the resistivity of the power cable core is 30.2Ω / km; when the cable bundle is working, the power current I=3A passing through the cable bundle is approximately considered to be 3A through the power cable core; in order to ensure that the cable bundle is in a cold space (-269 ℃), it is necessary to keep the temperature of the cable bundle at a level not lower than -15 ℃;

[0042] 1) First, design the extraterrestrial active cable bundle, that is, to isolate the power cable core and the signal cable core and cover the two with insulating layers and multi-layer heat insulation components, such as figure 1 As shown, the Thermal Desktop software and the track parameters in Table 2 are used to establish the thermal analysis model of the cable harness;

[0043] Orbit parameter in table 2 embodiment 2

[0044] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com