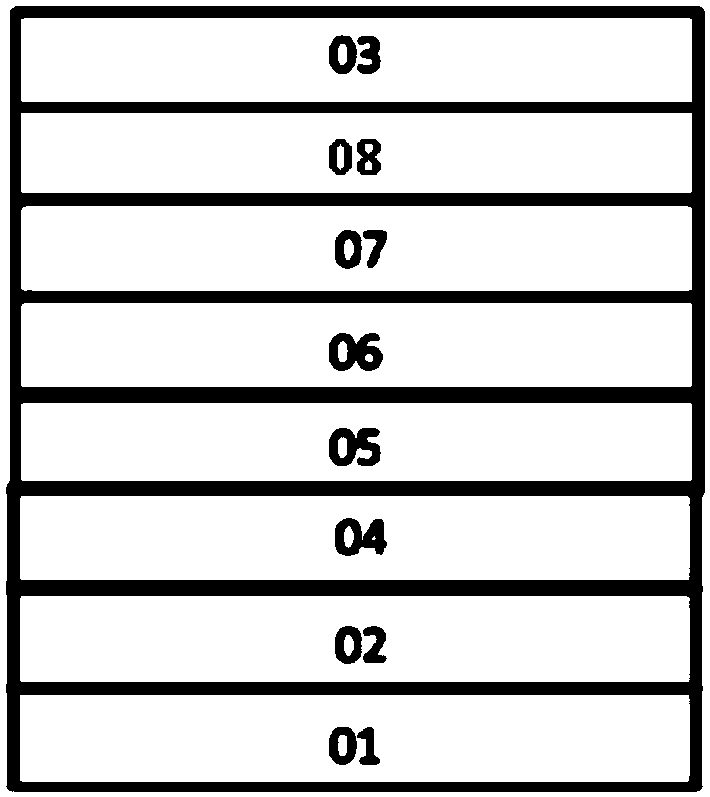

Patents

Literature

33results about How to "No outgassing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

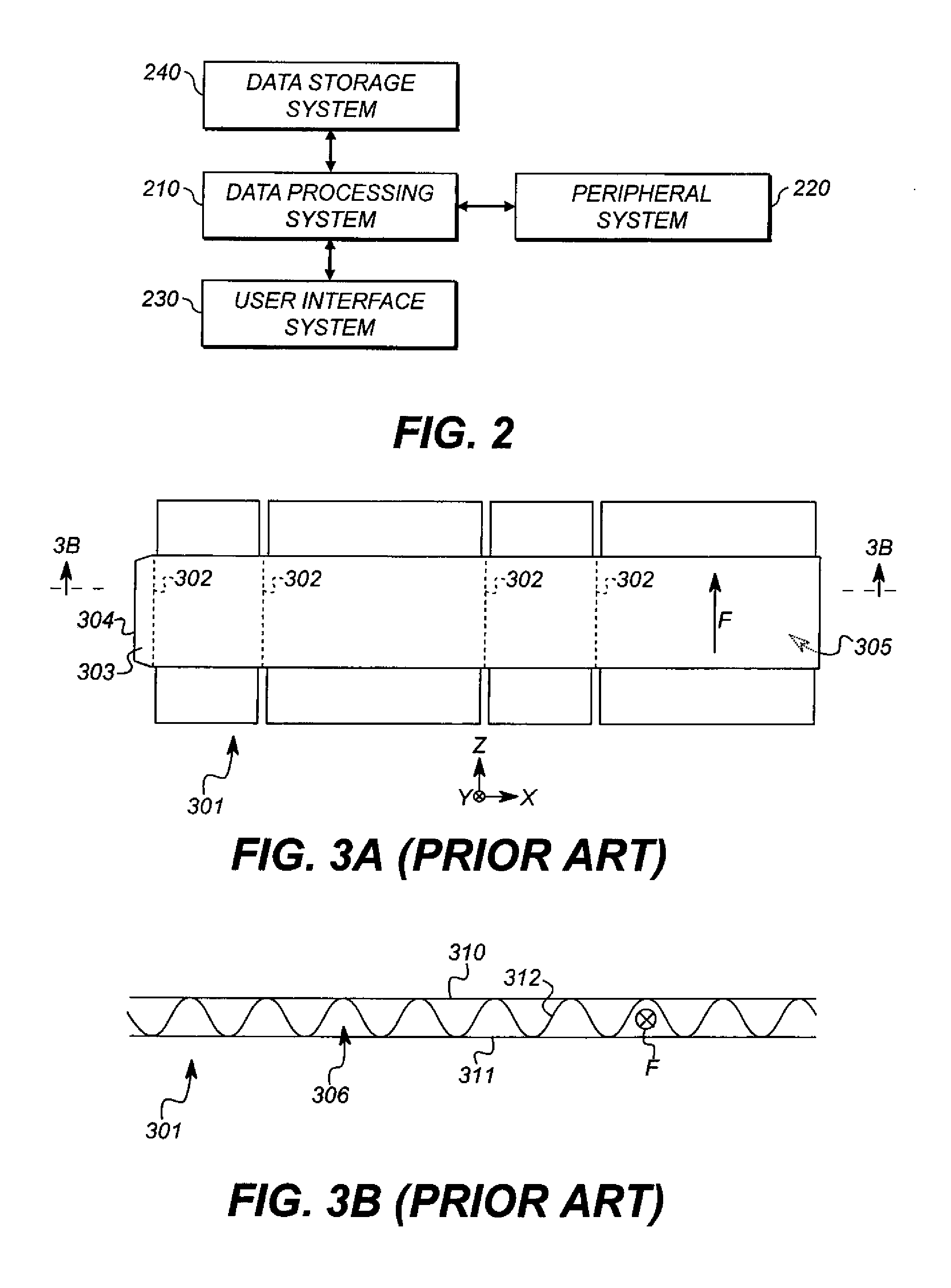

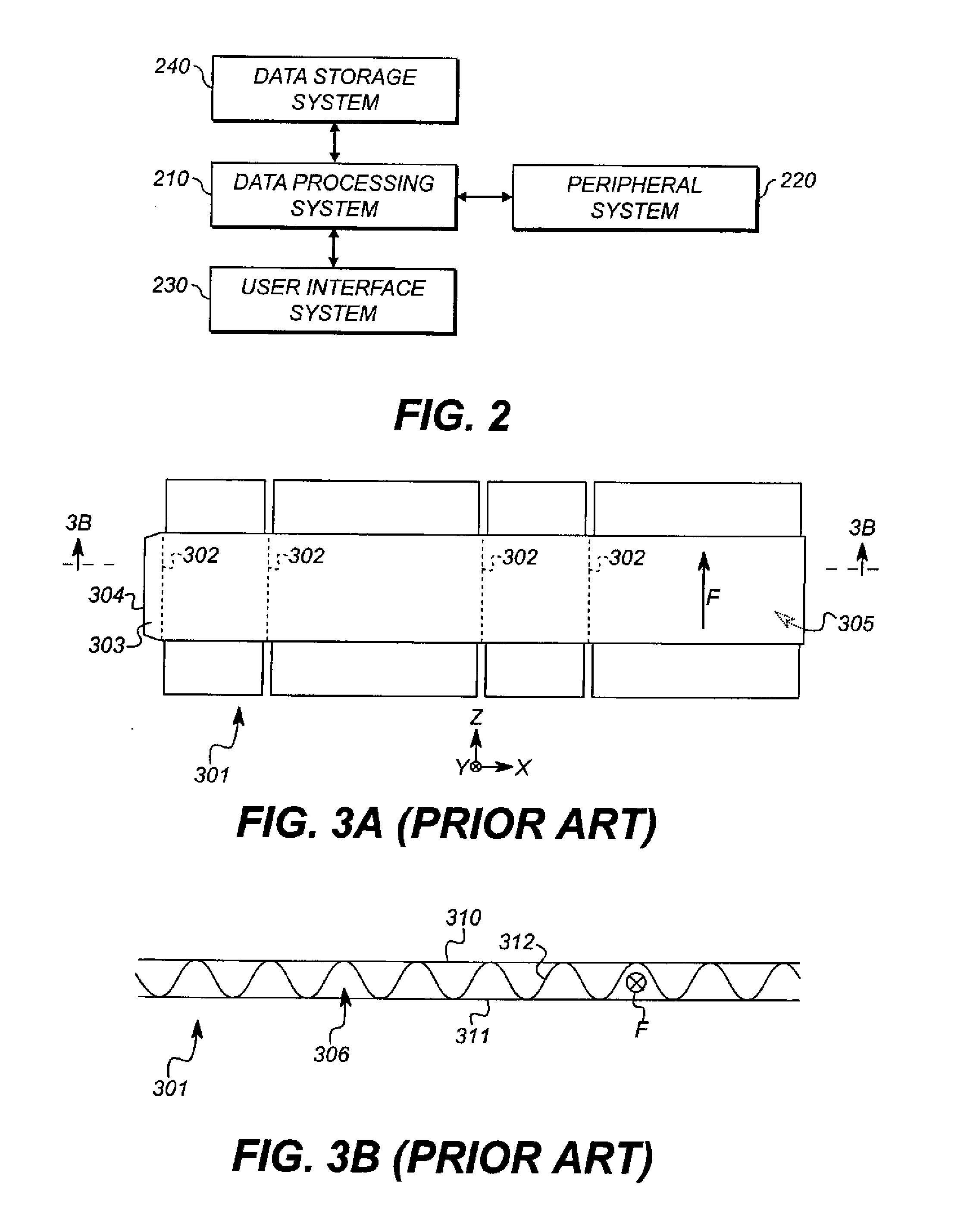

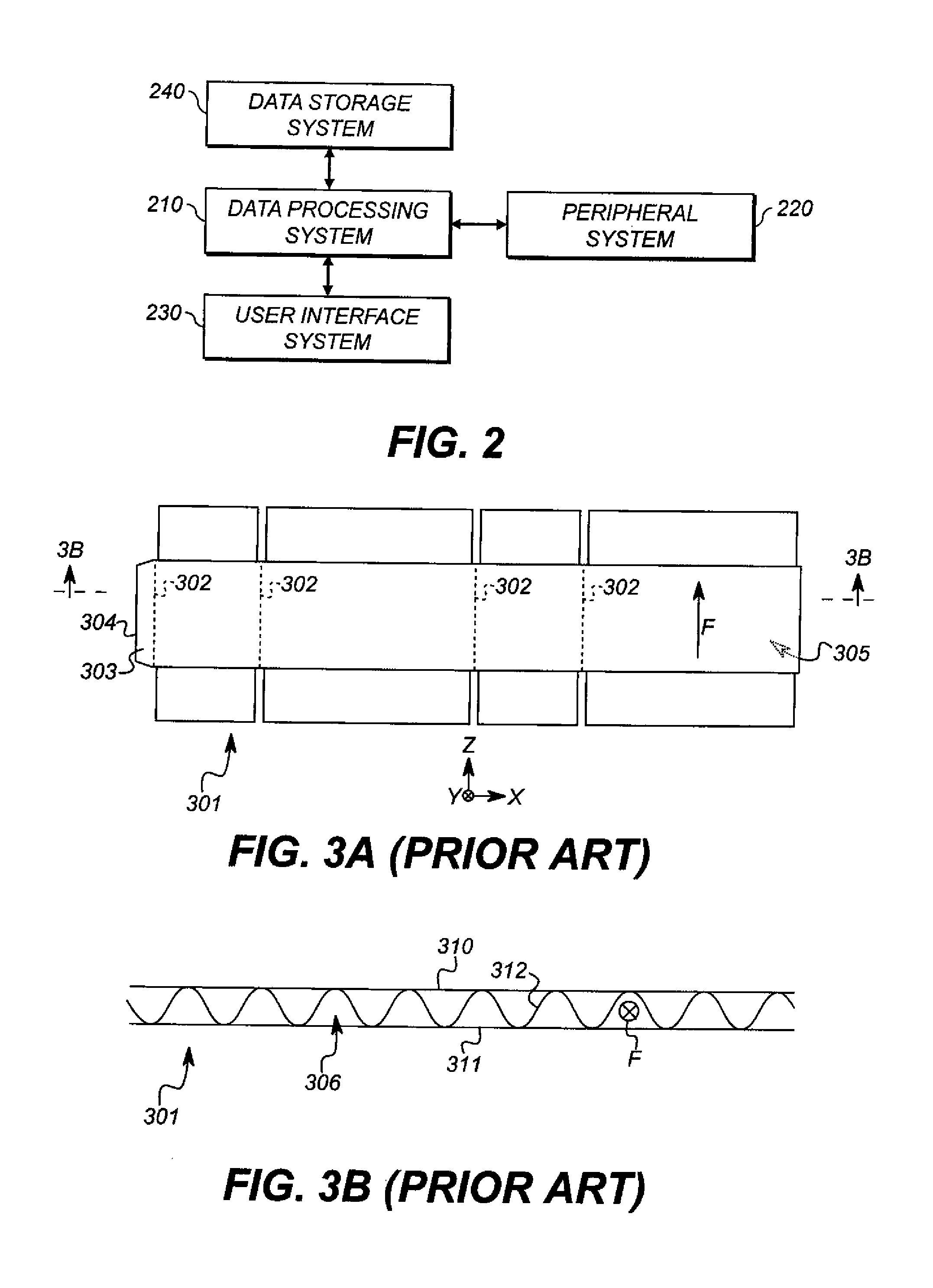

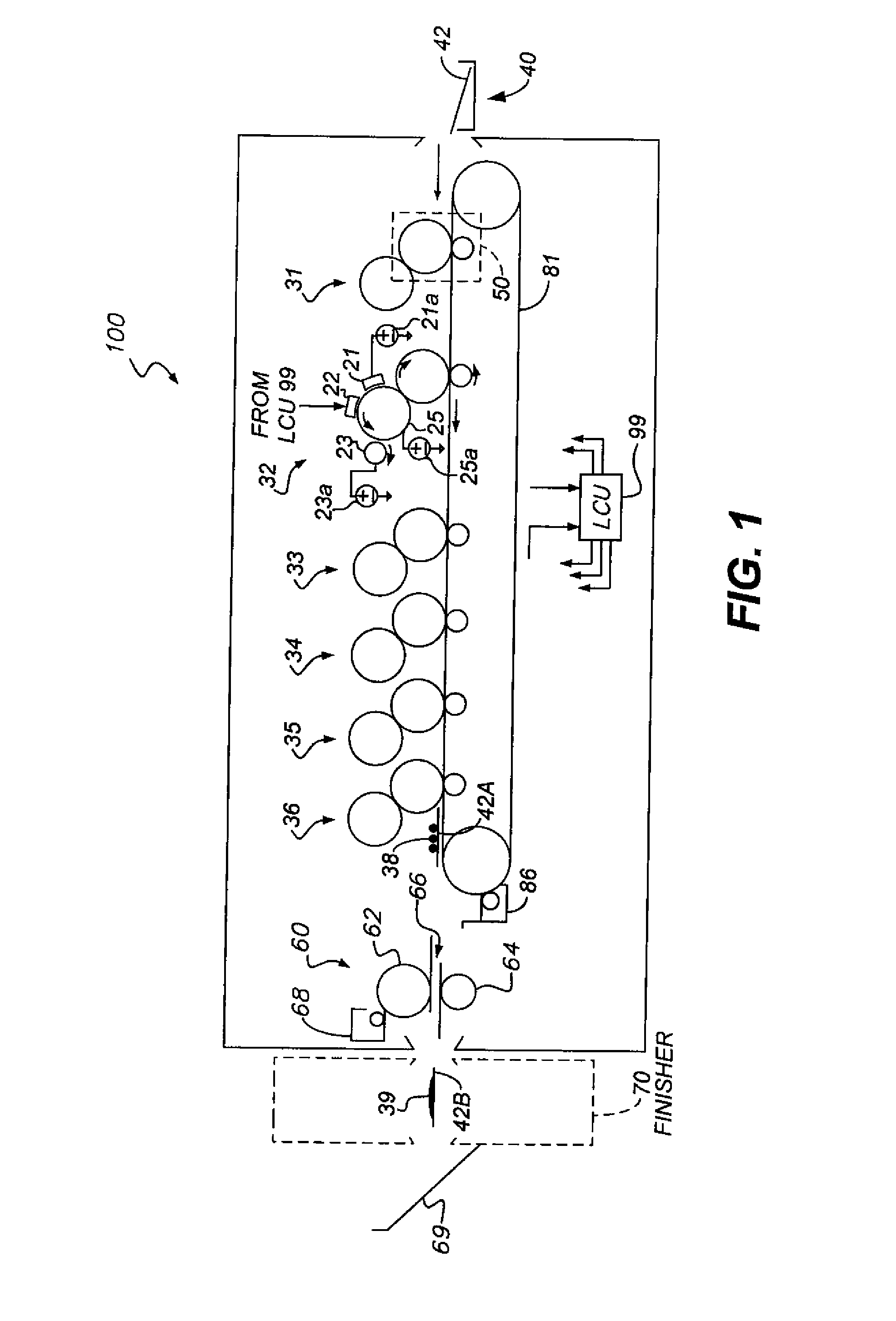

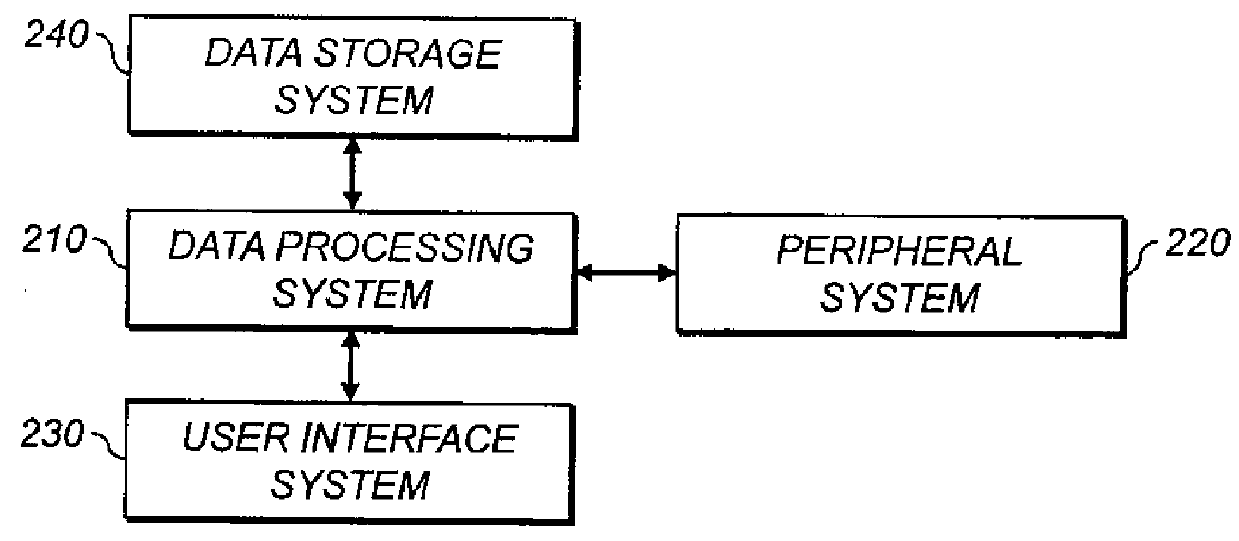

Forming three-dimensional structure from receiver

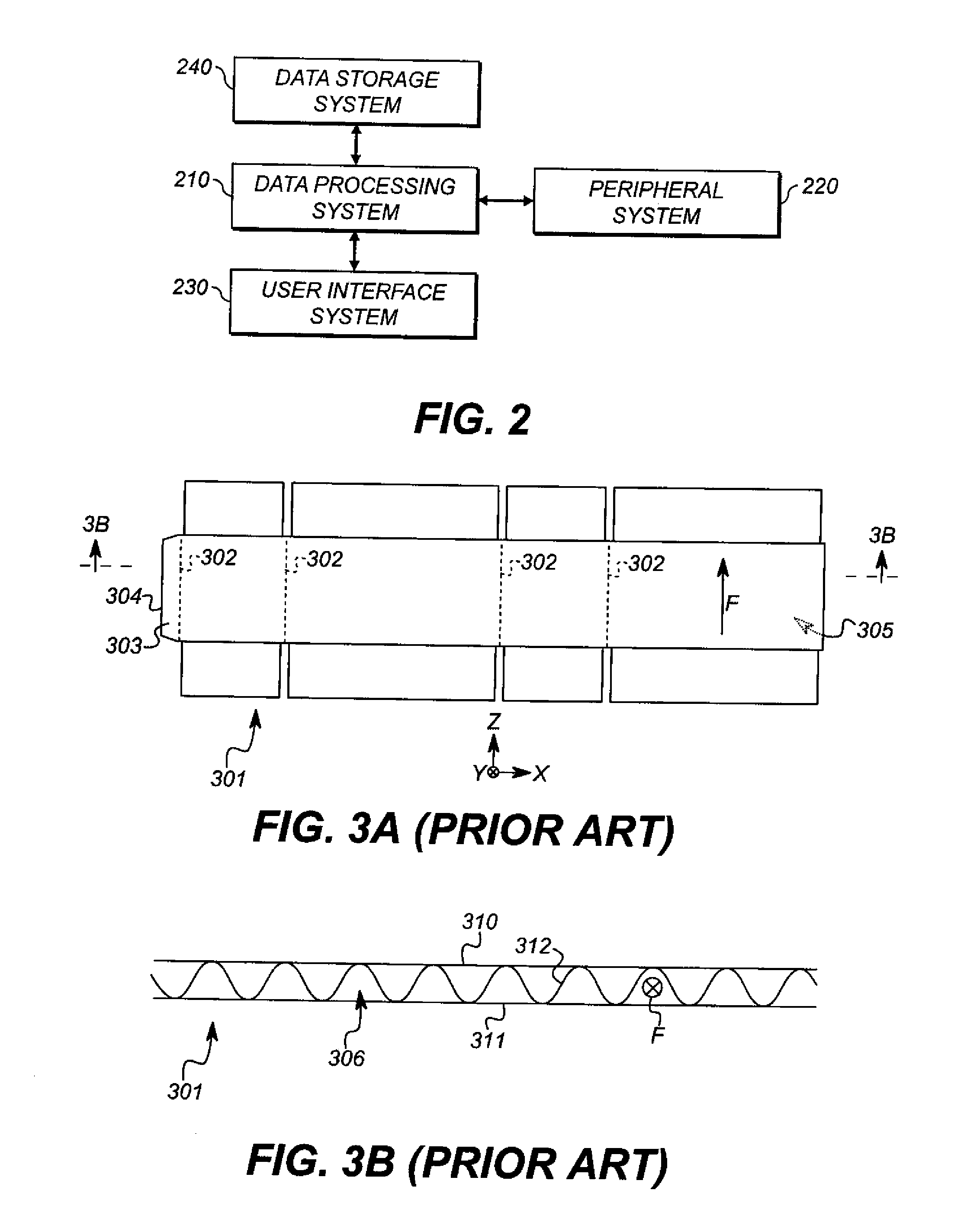

ActiveUS20140117588A1Precise positioningReduce quality problemsElectric discharge heatingBox making operationsElectrical and Electronics engineering

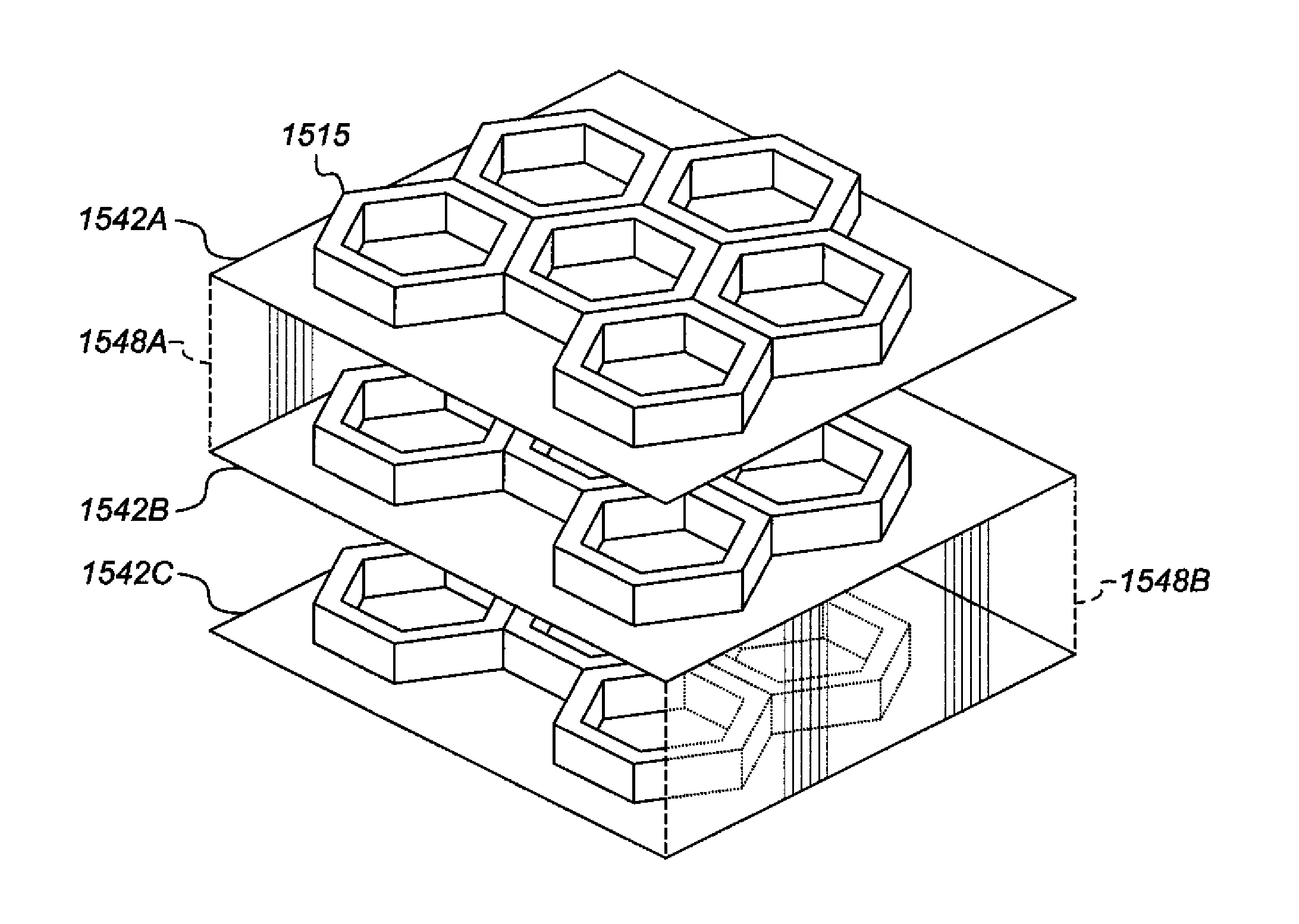

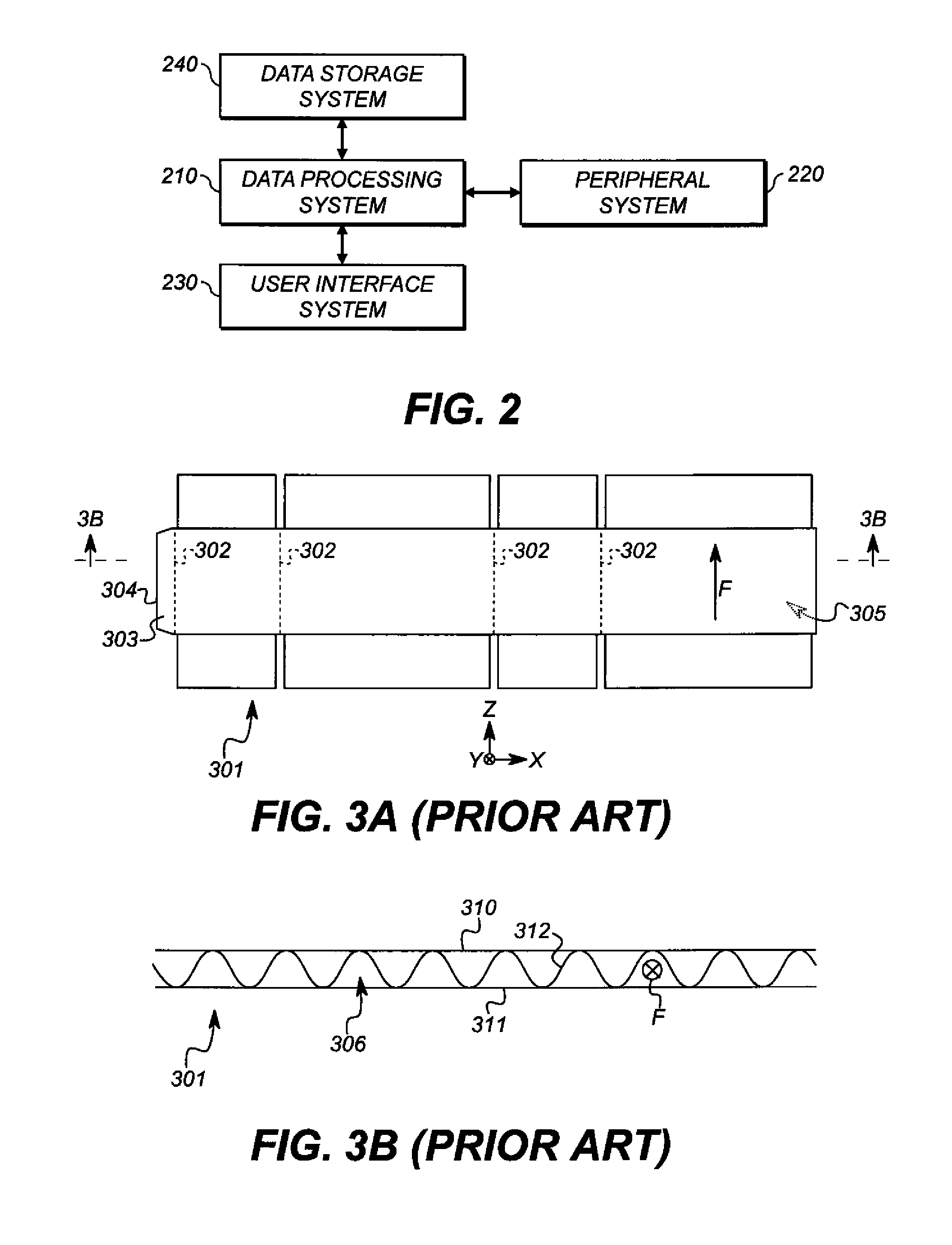

A method for forming a three-dimensional structure includes depositing a first pattern of thermoplastic toner particles onto a first surface of a receiver to form a plurality of spaced-apart stacks of toner particles that extend above the first surface of the receiver. The receiver is bent so that non-overlapping first and second portions of the receiver are defined. At least part of a surface of the receiver in the second portion is brought into contact with the deposited stacks of toner particles. The toner particles are fused to bind the second portion to the first portion and provide a selected spacing between the first portion and the second portion.

Owner:EASTMAN KODAK CO

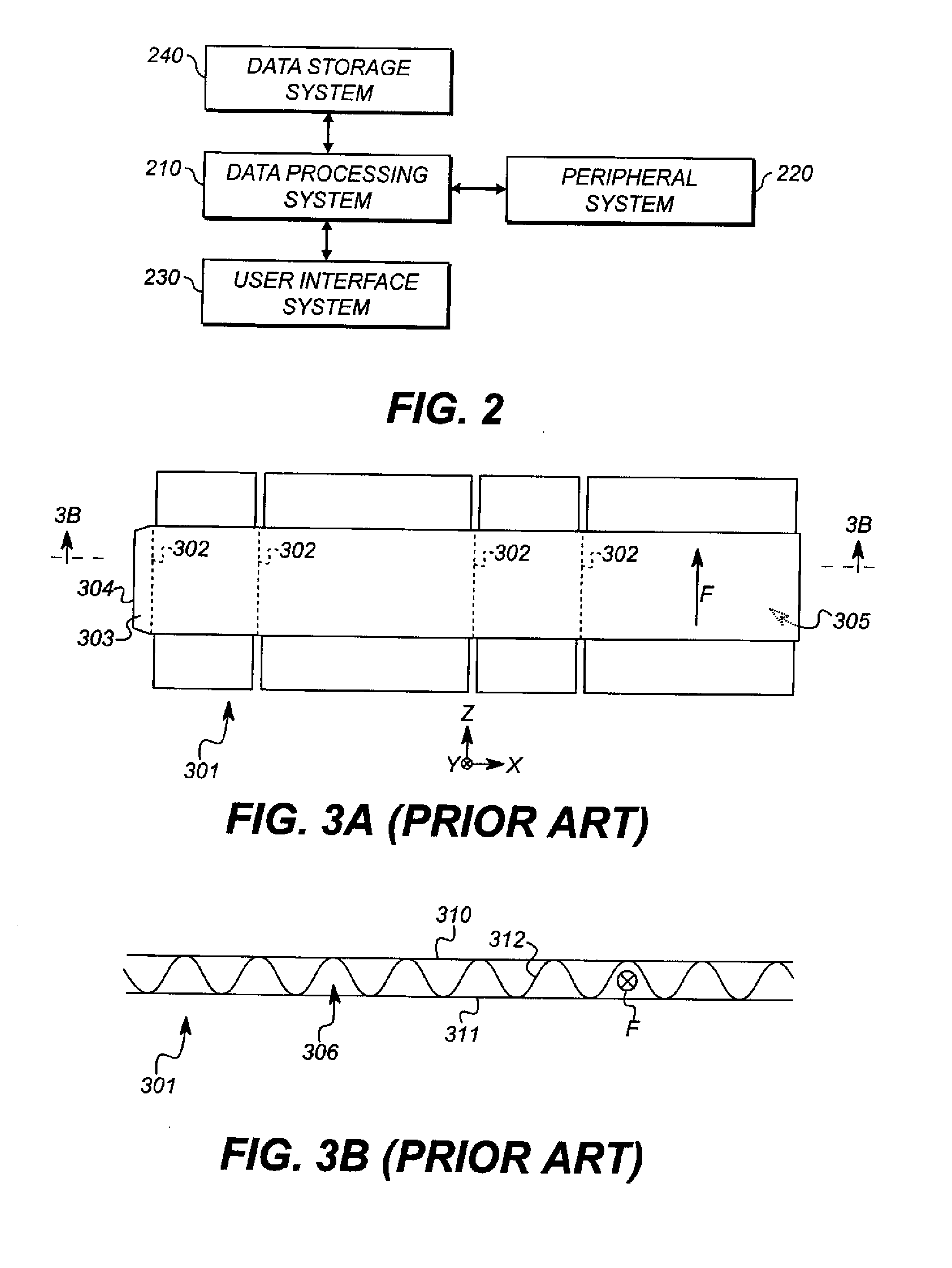

Forming a 3D structural element

InactiveUS20130292049A1Precise positioningReduce quality problemsLamination ancillary operationsLamination3d patterningBiomedical engineering

A structural element is formed. A 3D aim toner pattern is received. Using a processor, the 3D pattern is automatically sliced into a plurality of 2D aim toner patterns and corresponding thicknesses. A sheet is received. Toner corresponding to a selected one of the 2D aim toner patterns is deposited on the received sheet. The deposited toner is fixed to have substantially the thickness corresponding to the selected one of the 2D aim toner patterns. The receiving through fixing steps are repeated until each of the 2D aim toner patterns has been deposited onto a sheet. The sheets are fixed the together to form the structural element having toner corresponding to the 3D pattern.

Owner:EASTMAN KODAK CO

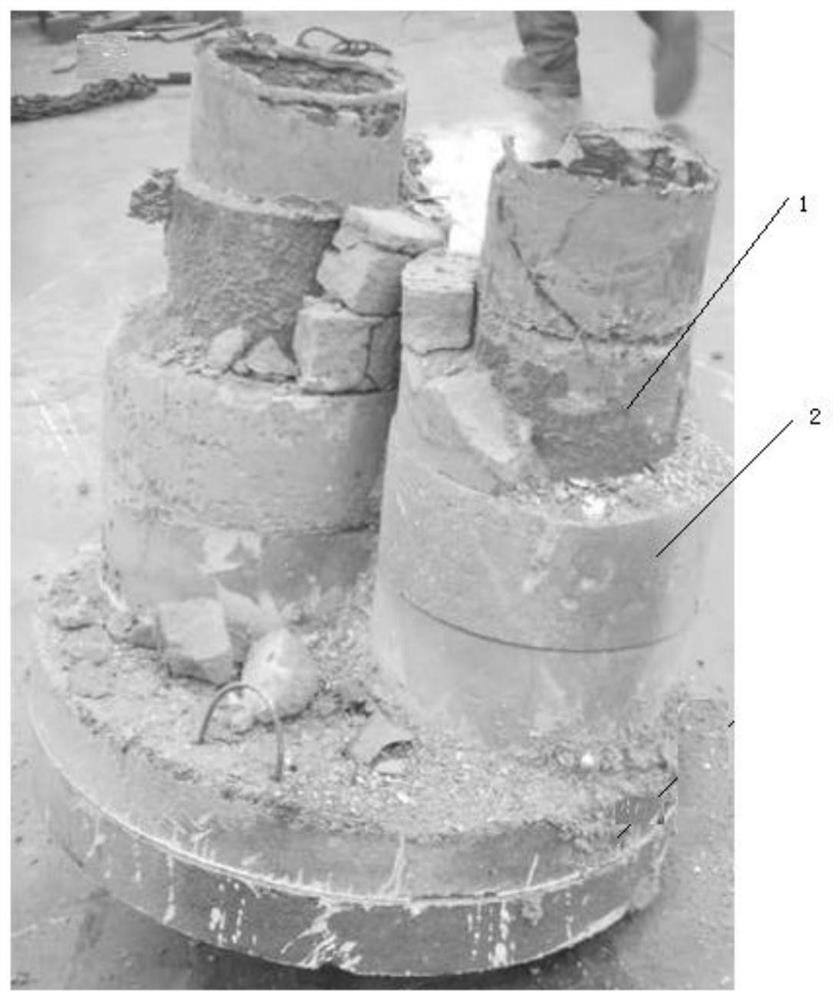

Casting method of wheel hub of wind turbine generator

InactiveCN102371346AGood adhesionImprove breathabilityFoundry mouldsFoundry coresAdhesiveCasting mold

The invention discloses a casting method of a wheel hub of a wind turbine generator. The method comprises the steps of preparing molding sand, preparing a casting mold, melting, pouring and performing knockout cleaning. In the method, resin sand is not adopted for molding, thereby fundamentally avoiding the impacts on a cast caused by surface sulfurization; in the method, the molding sand which is specially prepared for casting the wheel hub of the wind turbine generation is adopted, wherein bentonite and pottery clay are matched for being used as an adhesive, thereby having the advantages of high binding strength of the molding sand and good air permeability and being good in mold release property. The wheel hub prepared by adopting the method according to the invention is excellent in mechanical properties, the tensile strength is improved by 10-15% in comparison with the prior art, and the elongation rate is improved by 5-6% in comparison with the prior art.

Owner:辛培兴

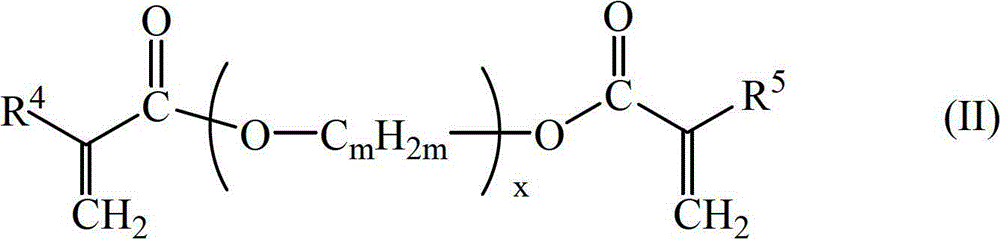

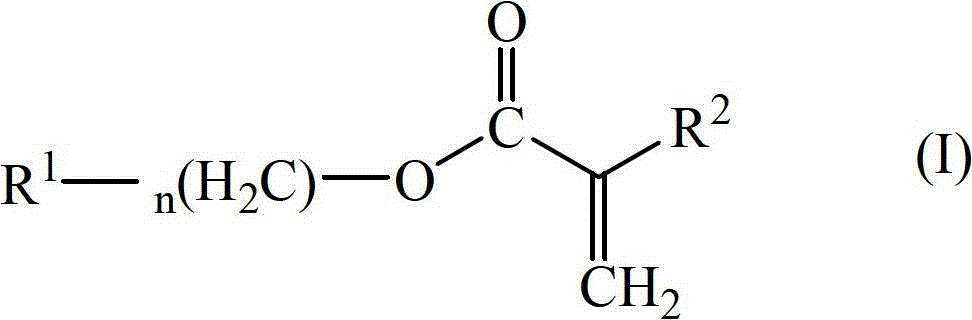

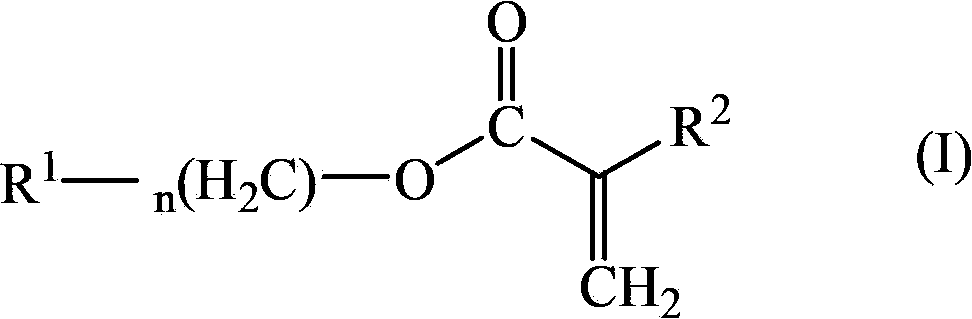

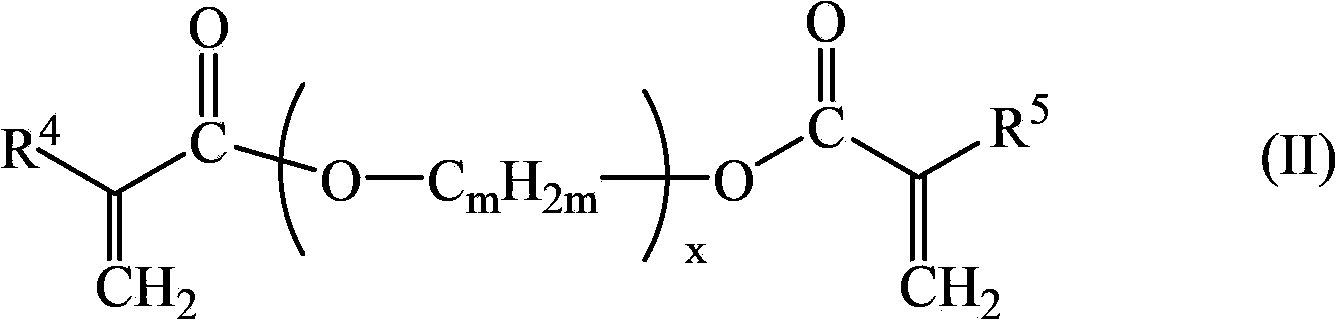

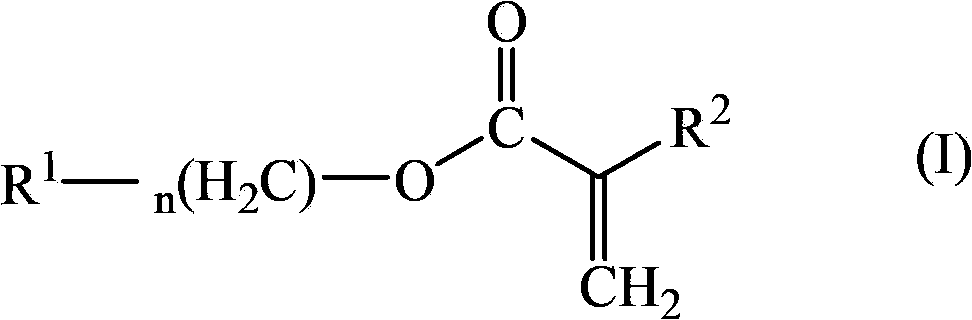

Photohardening resin composition and application thereof

ActiveCN102863908ANo outgassingImprove reliabilityAdhesive processesFilm/foil adhesivesPhotoinitiatorOligomer

A photohardening resin composition comprises (A) oligomer containing ethylenic bonds, (B) monomers containing at least one acrylate group, and (C) a photoinitiator, wherein (B) is selected from mono-acrylate monomers shown in formula (I), bis-acrylate monomers shown in formula (II) or a composition of the two, and the formula (I) and the formula (II) are defined in the specification and the claims. The invention also provides an adhesion layer formed by irradiation of the photohardening resin composition, a display element containing the adhesion layer, and a method for preparing the display element by using the photohardening resin composition. The hardening of the photohardening resin composition of the invention causes no gas release phenomenon, which further improves the reliability of the display element for subsequent application.

Owner:DAXIN MATERIALS

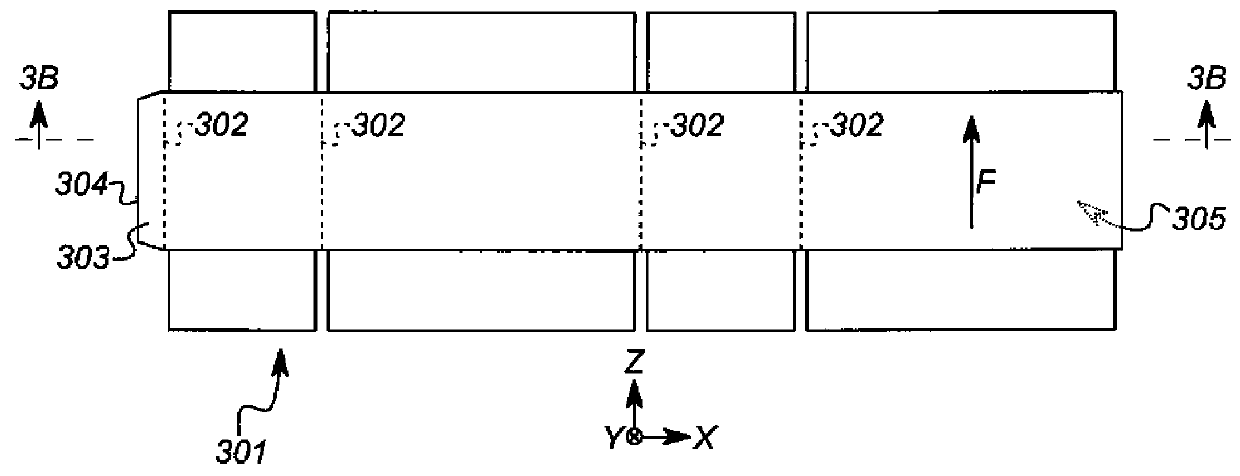

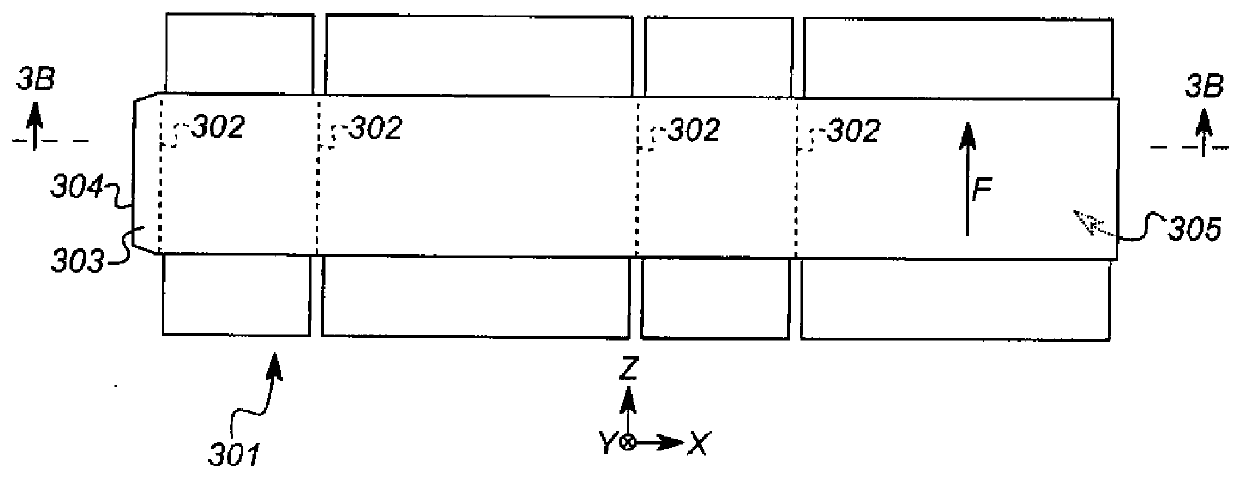

Forming a structural laminate that resists stress

ActiveUS20130292030A1Precise positioningReduce quality problemsLayered product treatmentBox making operationsEngineering

A structural laminate having a selected resistance to a first stress applied in a selected first stress direction relative to the laminate is formed from first and second sheets. A selected volume of toner is deposited on the first sheet to form a deposited toner pattern, the deposited toner pattern being disposed over a selected first surface area of the first sheet and extending normal to the first sheet by a selected first height. The second sheet, or toner thereon, is brought into contact with the deposited toner pattern. The deposited toner pattern is fixed to produce a fixed toner pattern that adheres the second sheet to the first sheet, in that way forming the laminate. The fixed toner pattern includes one or more first contiguous regions of toner extending in a direction within about 45° of the stress direction, so that the contiguous regions resist the applied stress.

Owner:EASTMAN KODAK CO

Addition-curable metallosiloxane compound

InactiveUS20130267653A1Satisfactory resistance to thermal yellowingNo outgassingSilicon organic compoundsCoatingsSilane compoundsPolymer science

Provided is a metallosiloxane compound (A) prepared by reacting a bifunctional silane compound (S1), a monofunctional silane compound (S2), a boron compound (M), and optionally H2O in a molar ratio of [the silane compound (S1)]:[the silane compound (S2)]:[the boron compound (M)]: [H2O] of n:m:k:a, where n, m, k, and a satisfy all conditions (i), (ii), and (iii), in which the metallosiloxane compound has at least one Si—H bond or C2-10 alkenyl group per molecule, and the conditions (i), (ii), and (iii) are expressed as follows:(i) n>0, m>0, k>0, a≧0;(ii) m / n≧0.5; and(iii) (n+m) / k≧1.8

Owner:DAICEL CHEM IND LTD

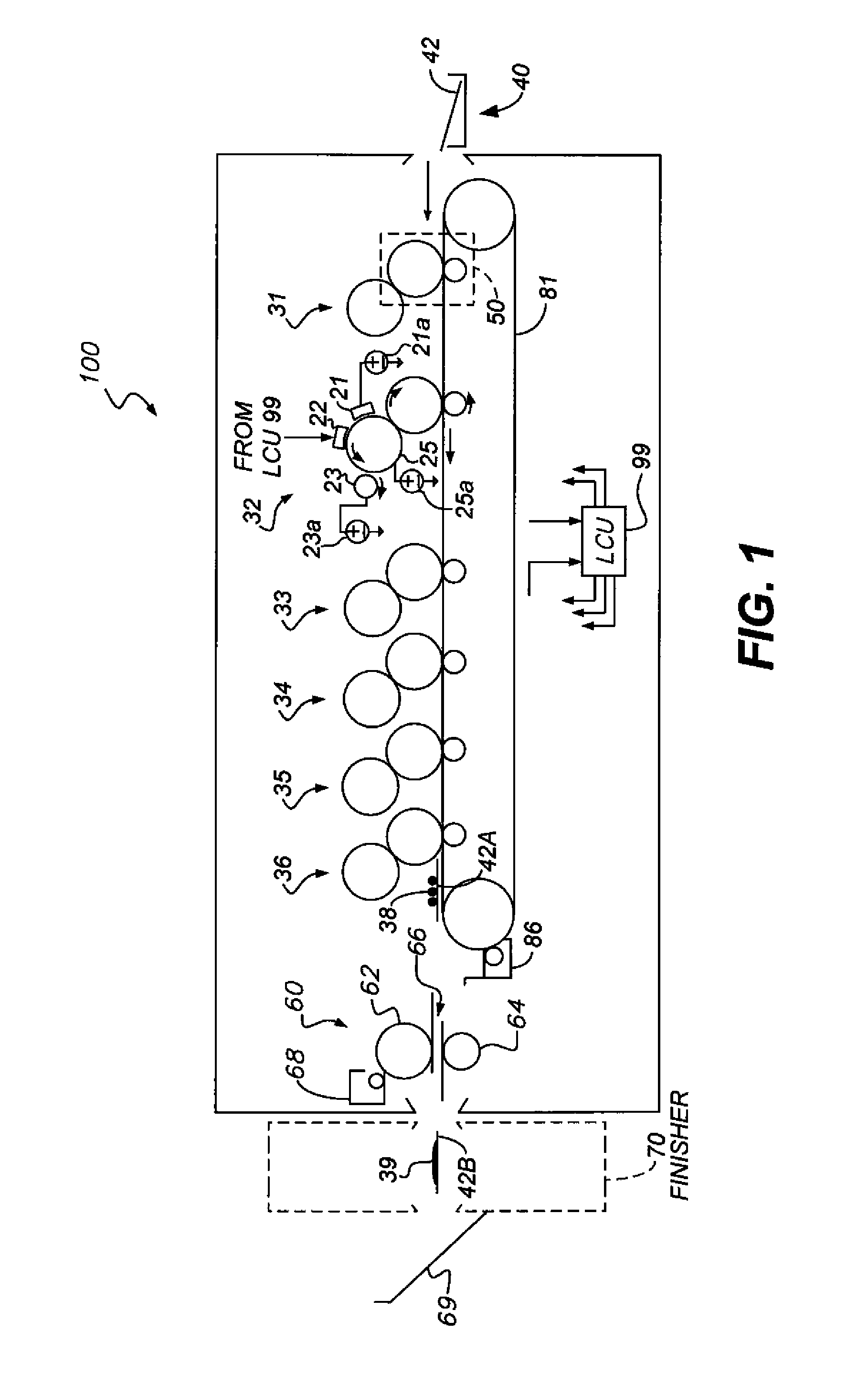

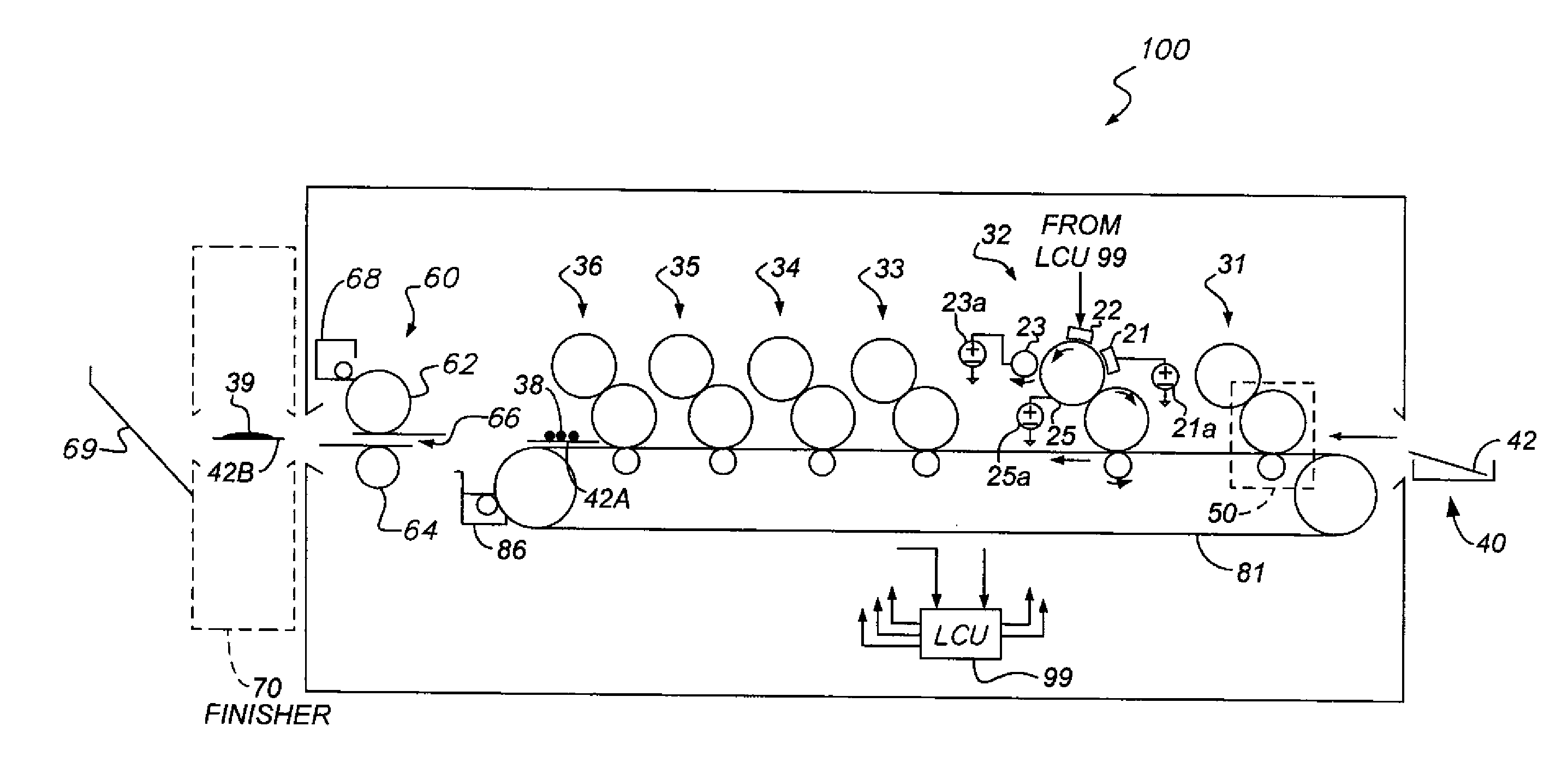

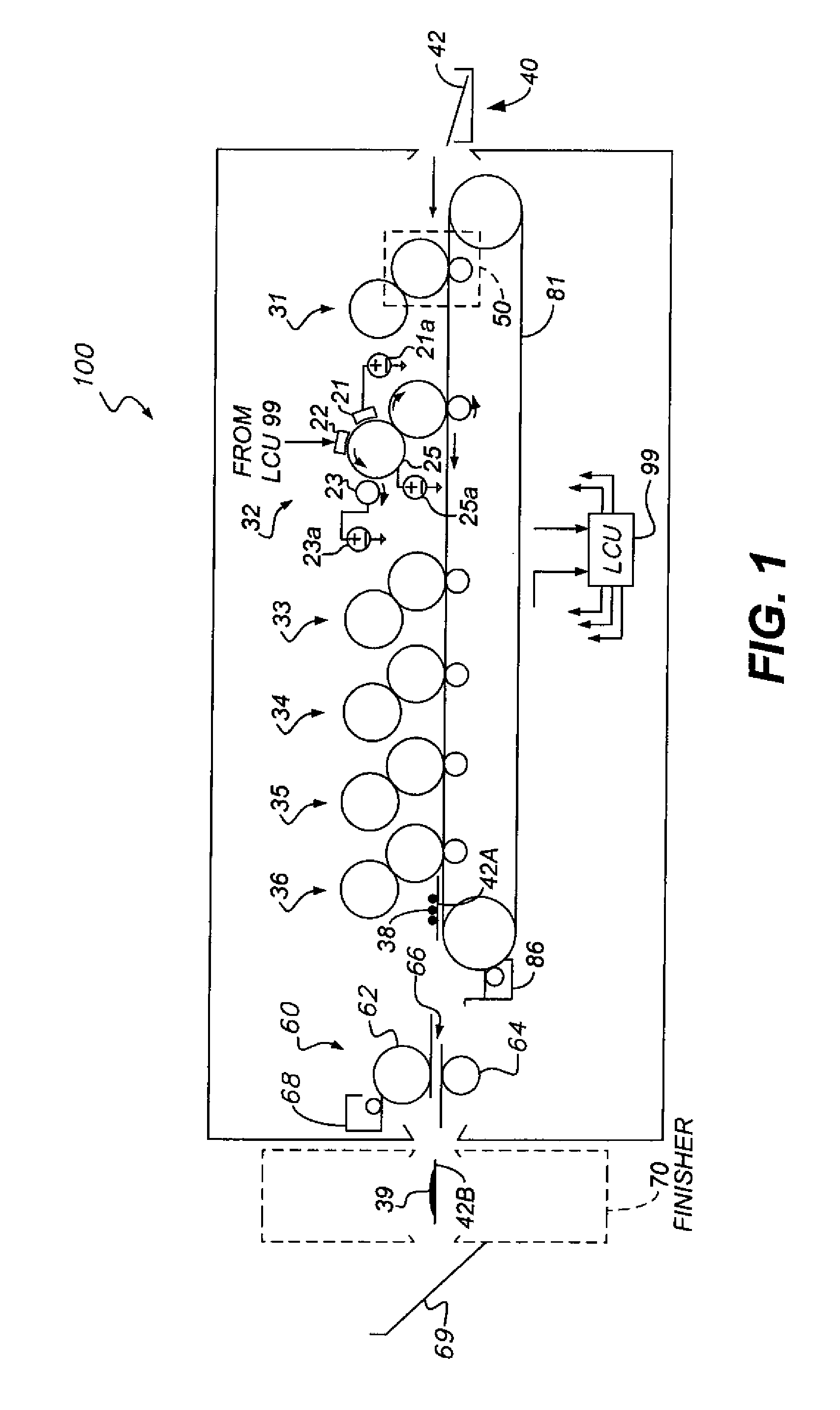

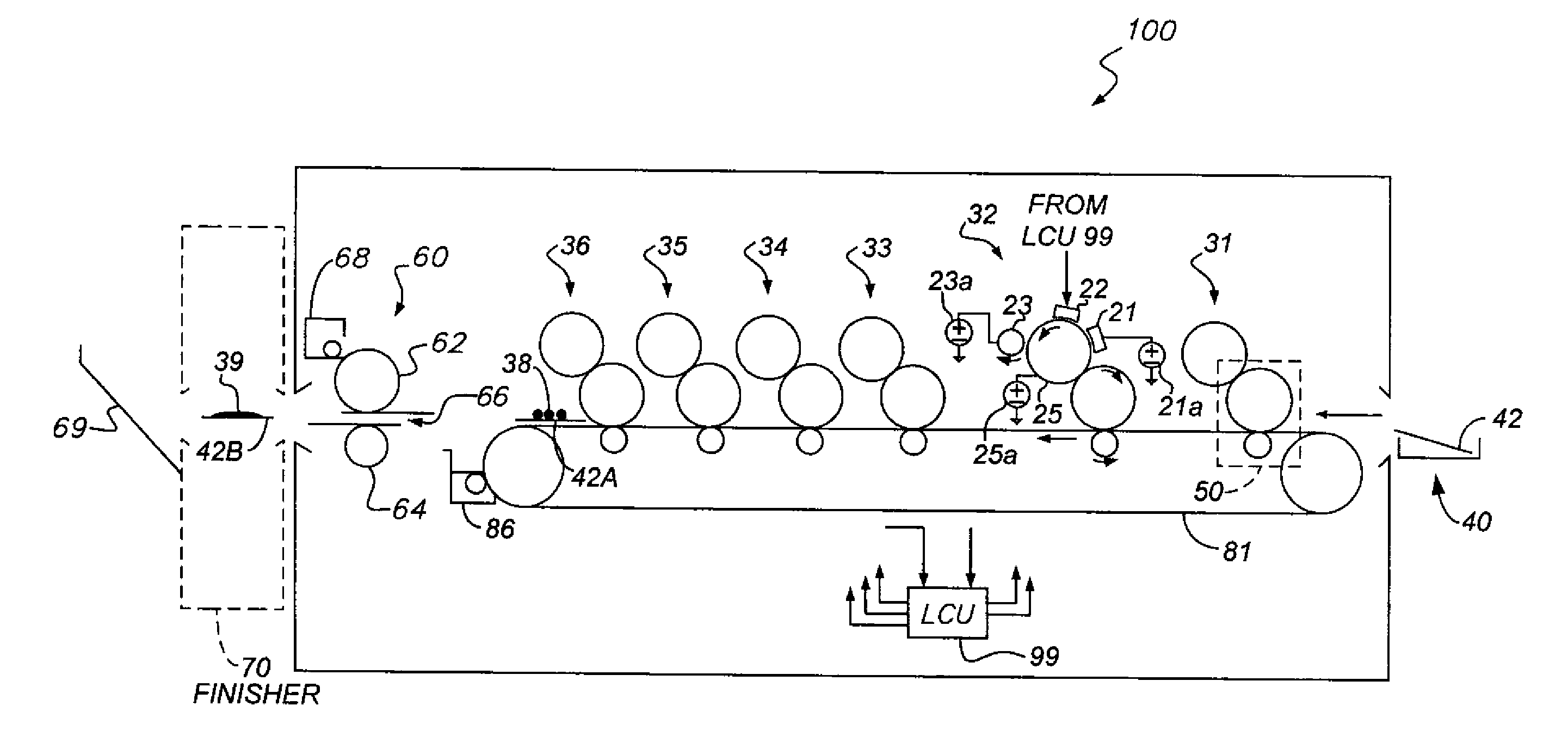

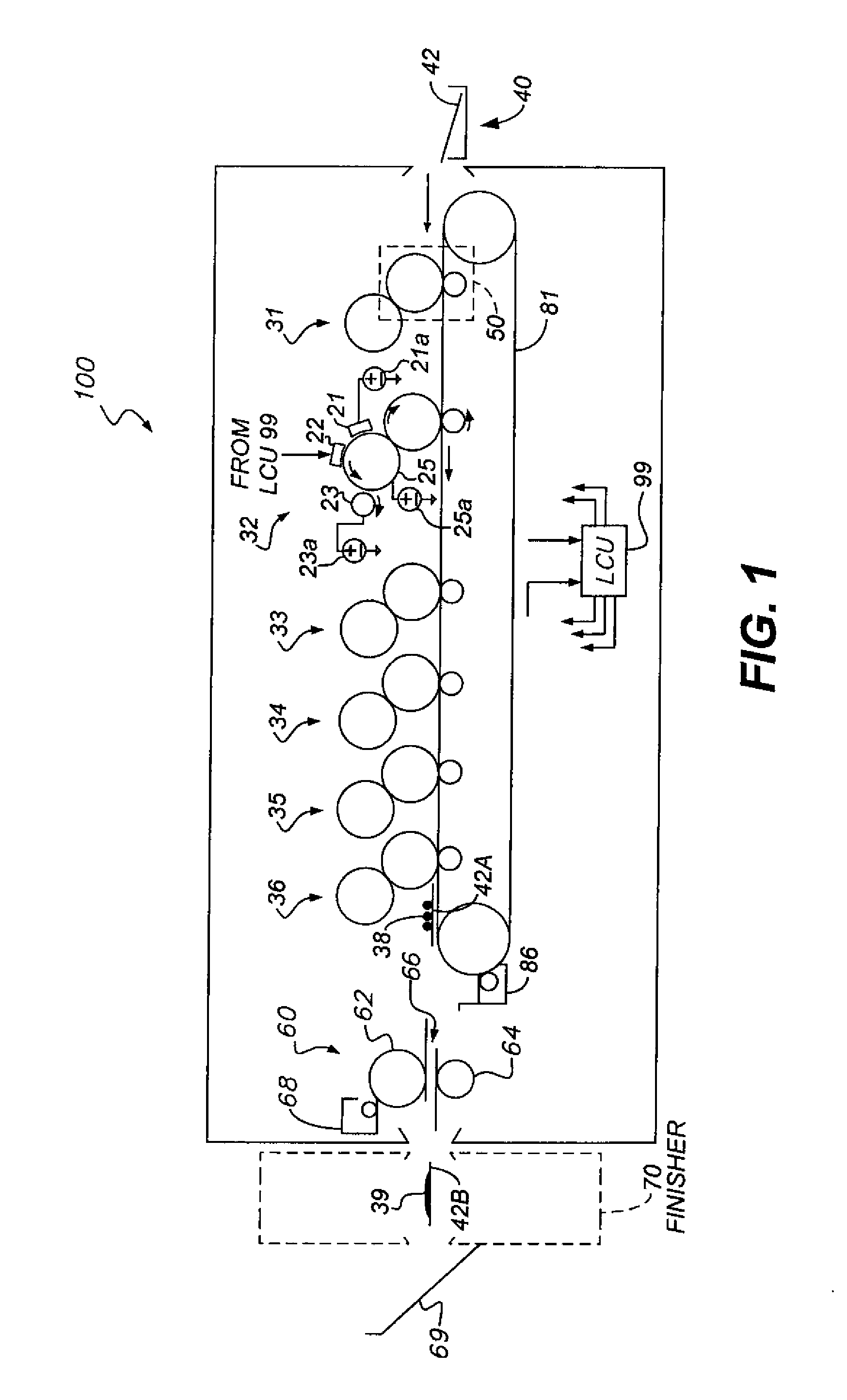

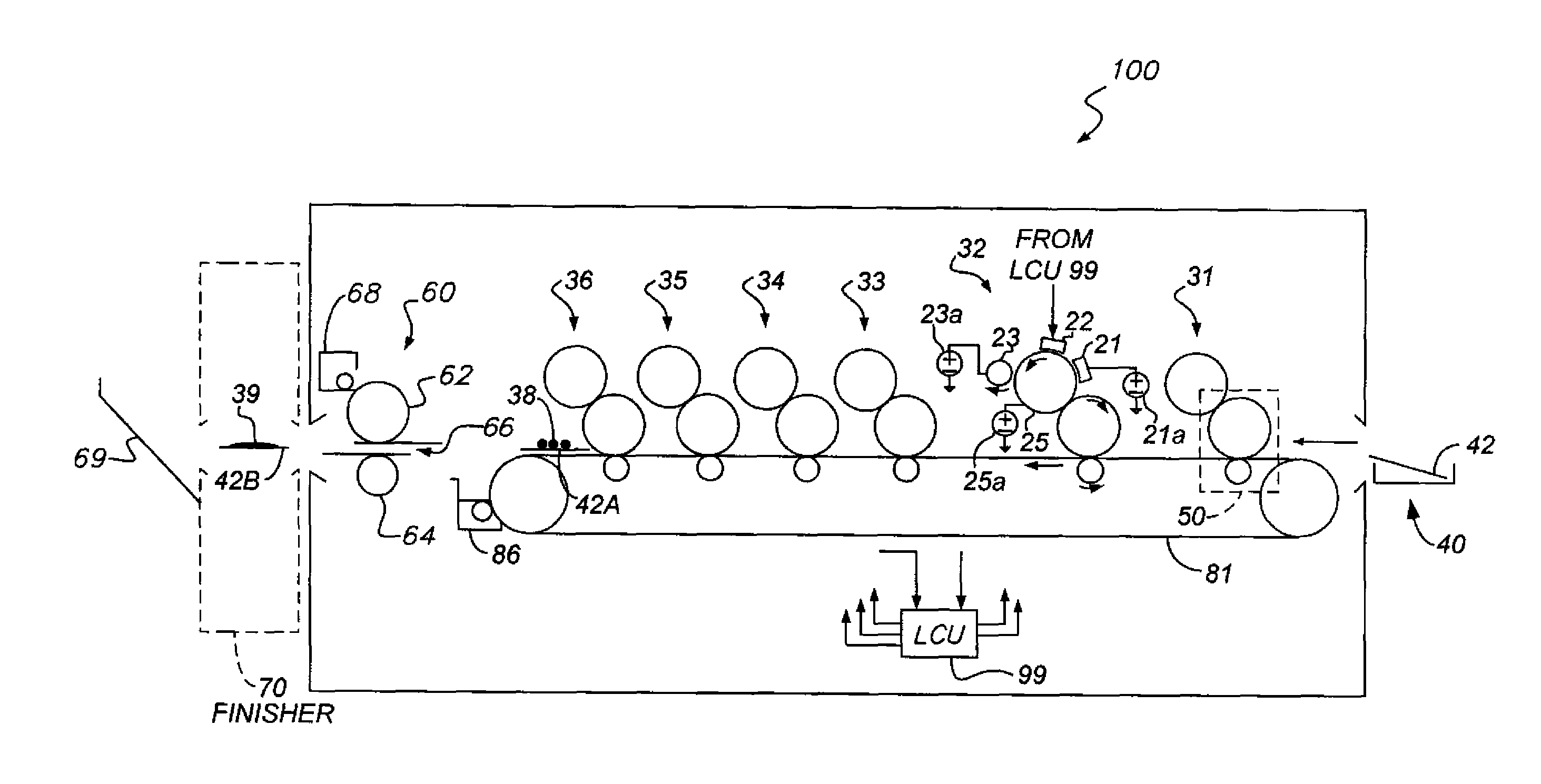

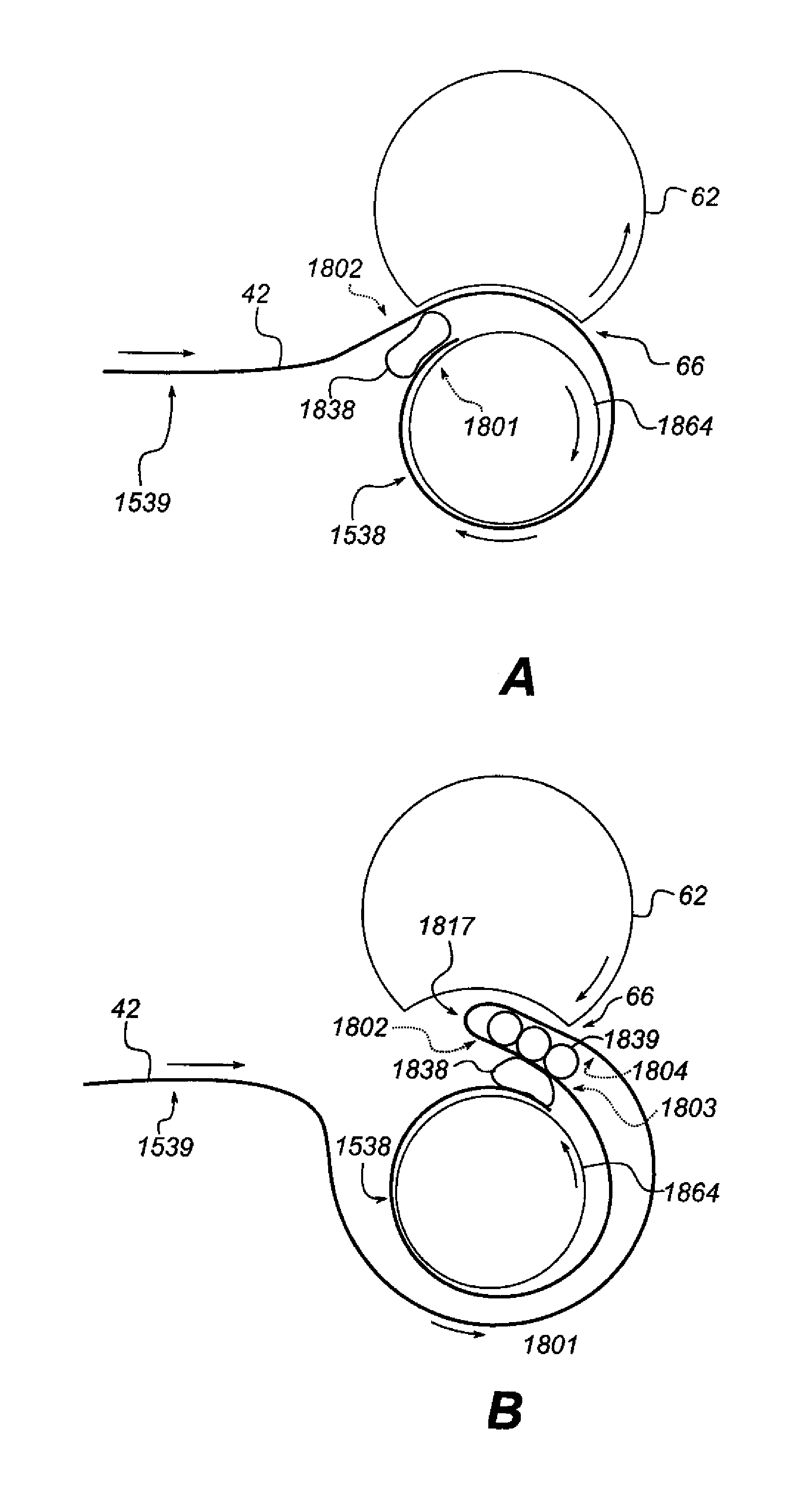

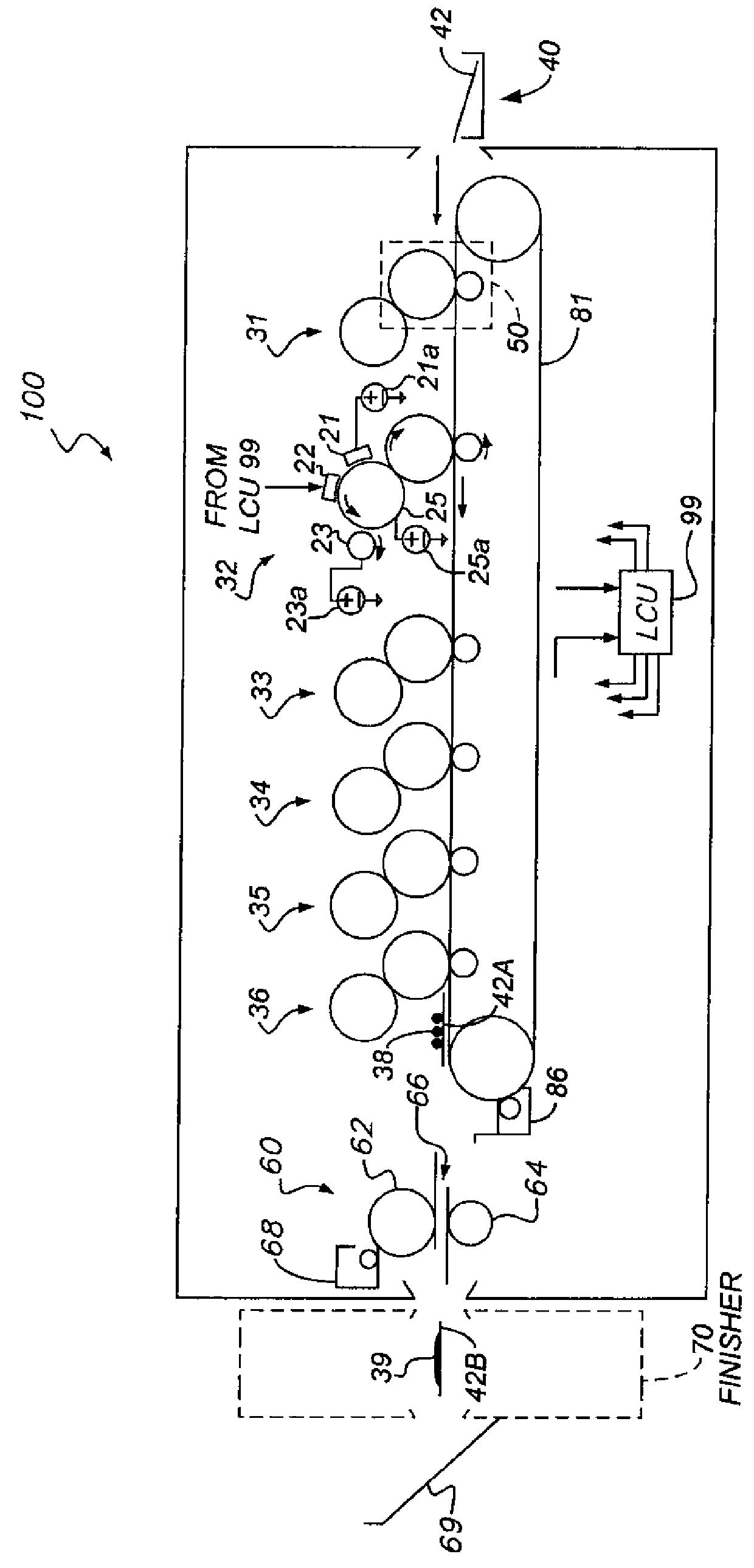

Z-folding three-dimensional-structure former

InactiveUS20140121092A1Precise positioningLow tensile strengthMechanical working/deformationElectrographic process apparatusEngineering

A device for producing a three-dimensional structure from a receiver includes a deposition unit that deposits toner on two surfaces of the receiver. That unit is controlled by a controller to produce a toner pattern on the first surface of the receiver. A softening device softens the toner. An automatic z-fold system makes a z-folded stack of separate portions of a length of the receiver, each portion being joined to at least one other portion in the z-folded stack by at least one of the z-folds. The z-fold system brings two separate portions of the same surface of the receiver into contact, at least one portion carrying softened toner.

Owner:EASTMAN KODAK CO

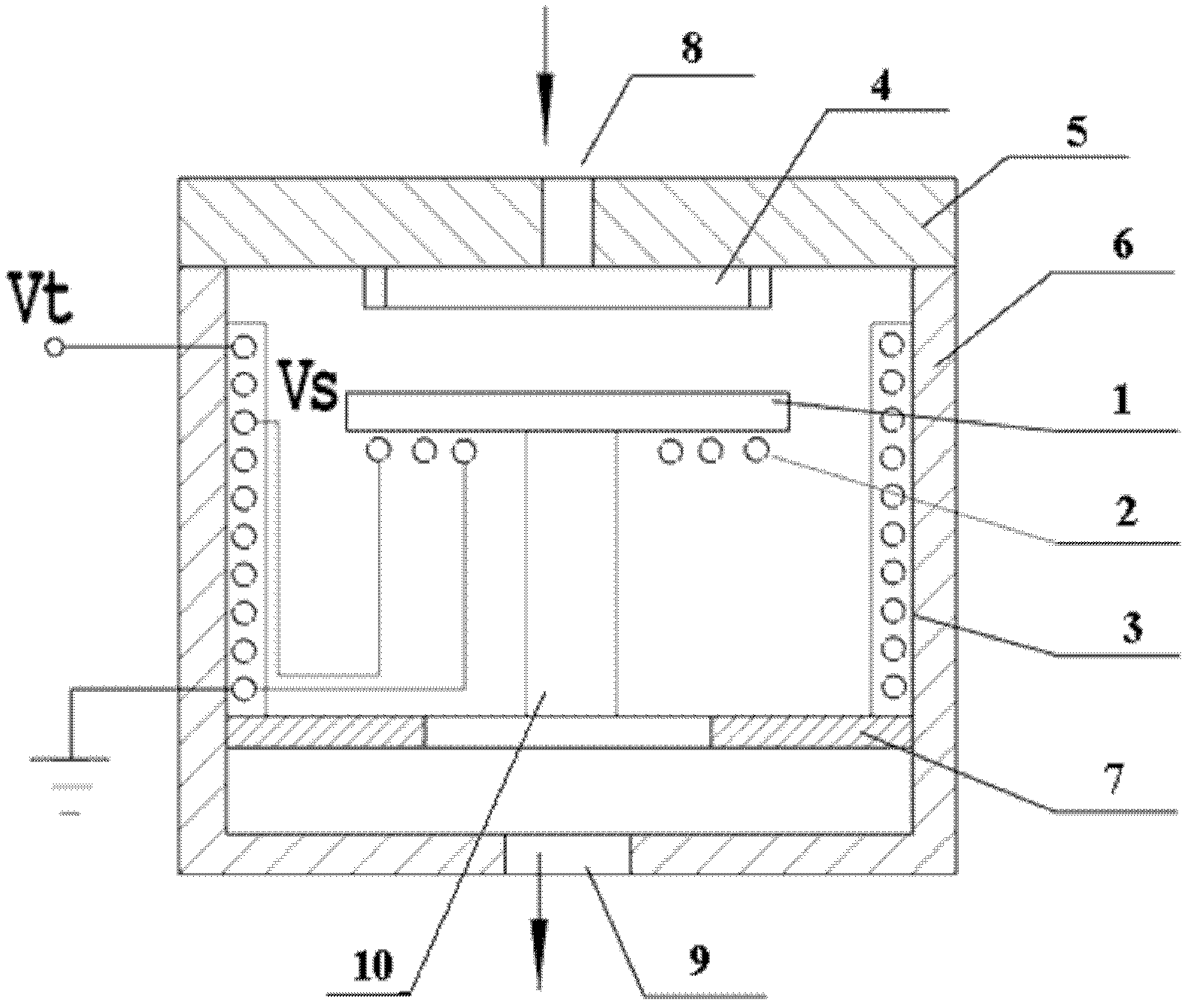

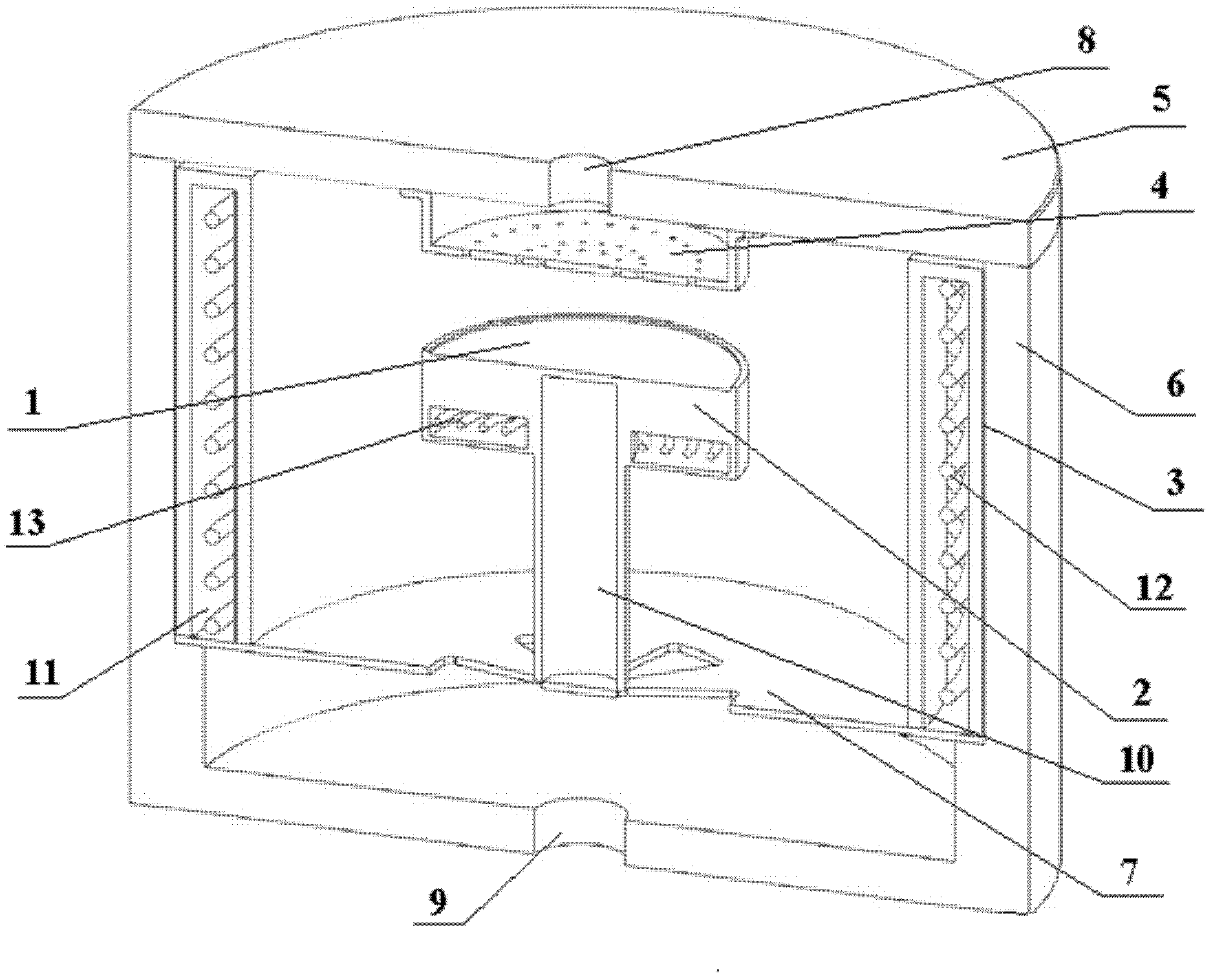

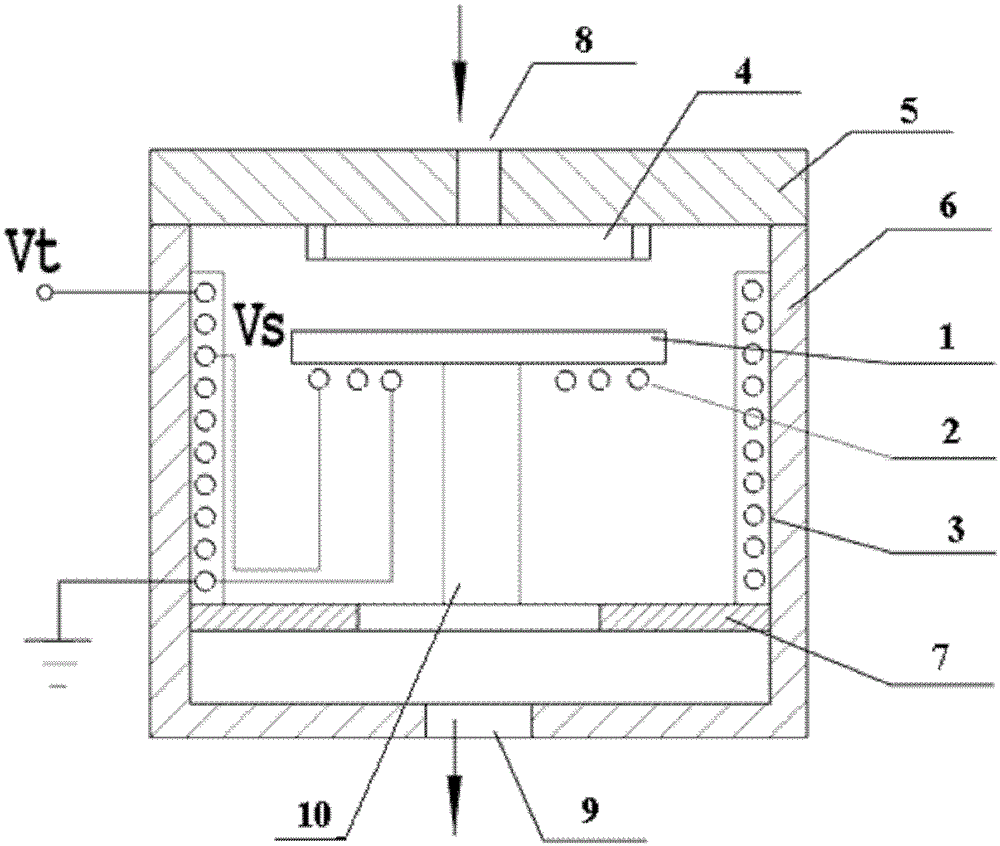

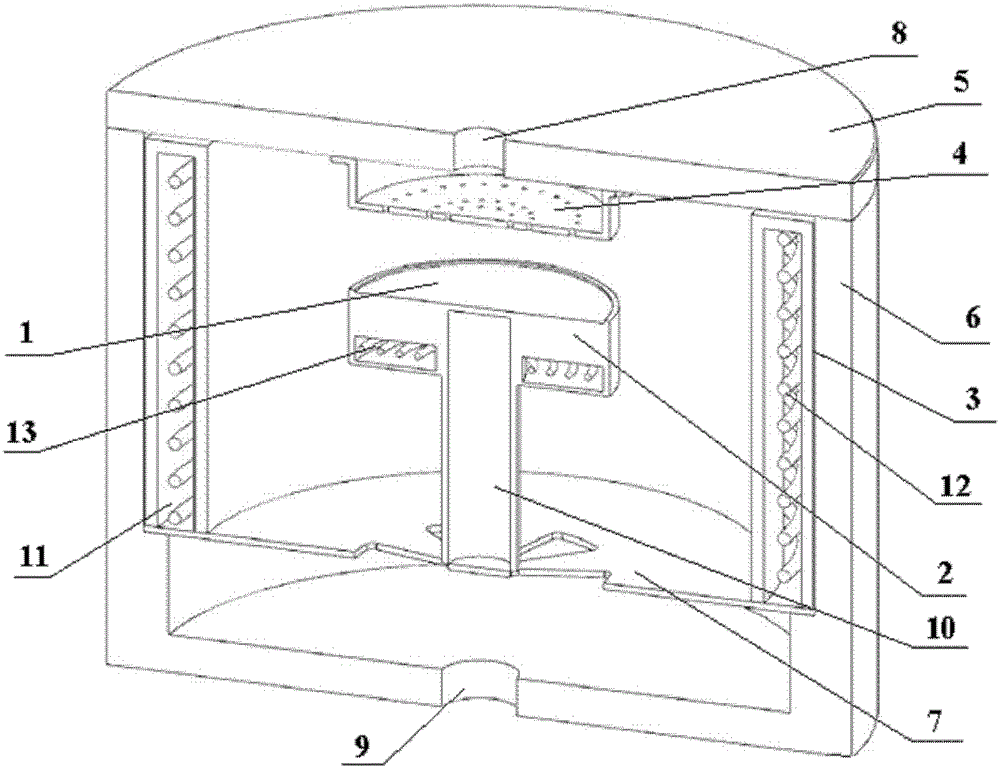

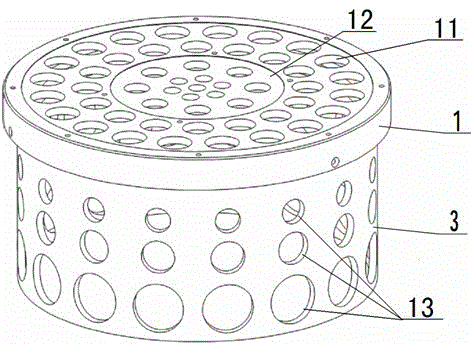

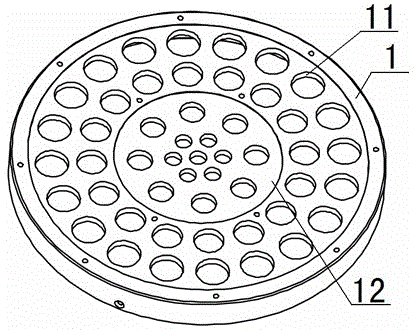

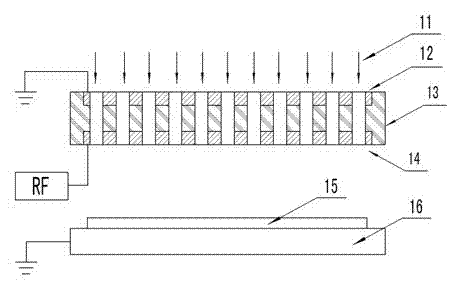

Cavity heating device

ActiveCN103208440ANo outgassingRequirements for maintaining vacuumElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringCavity wall

Disclosed is a cavity heating device. The cavity heating device comprises a cavity wall heating structure and / or a slide holder heating structure. The cavity wall heating structure is arranged on the inner wall of a reaction cavity. The slide holder heating structure is arranged at the bottom of a slide holder. The cavity heating device can reduce or avoid nonuniformity caused by the fact that plasma starting is unsymmetrical in structure in the plasma etching process. An electrode fixing structure is free of air discharge under the plasma starting condition and can meet requirement of a vacuum cavity for vacuum degree.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

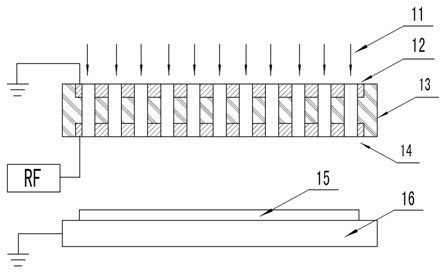

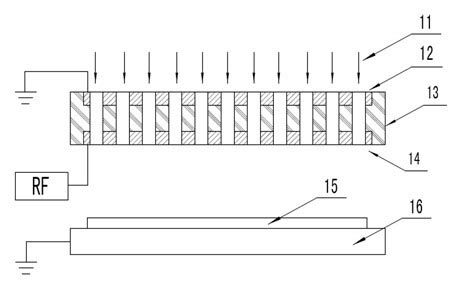

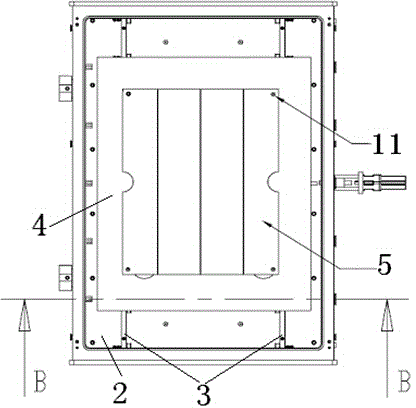

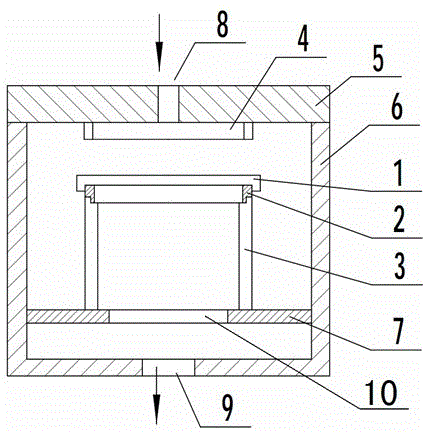

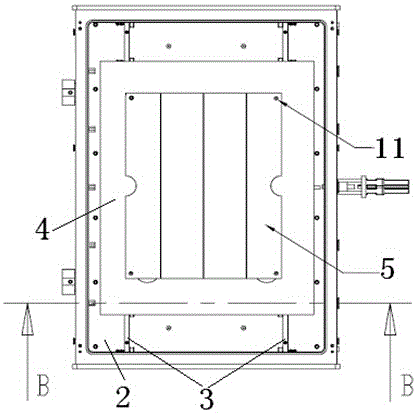

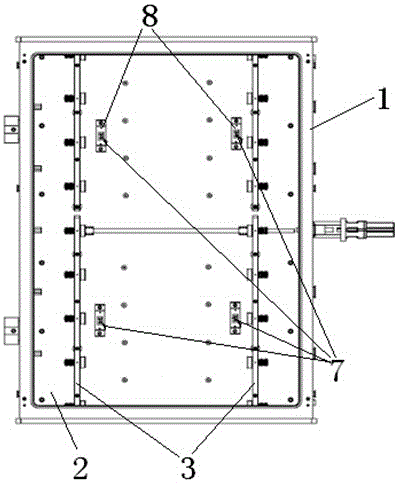

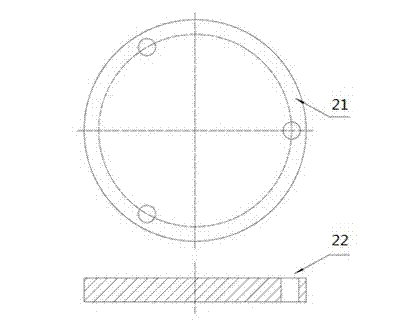

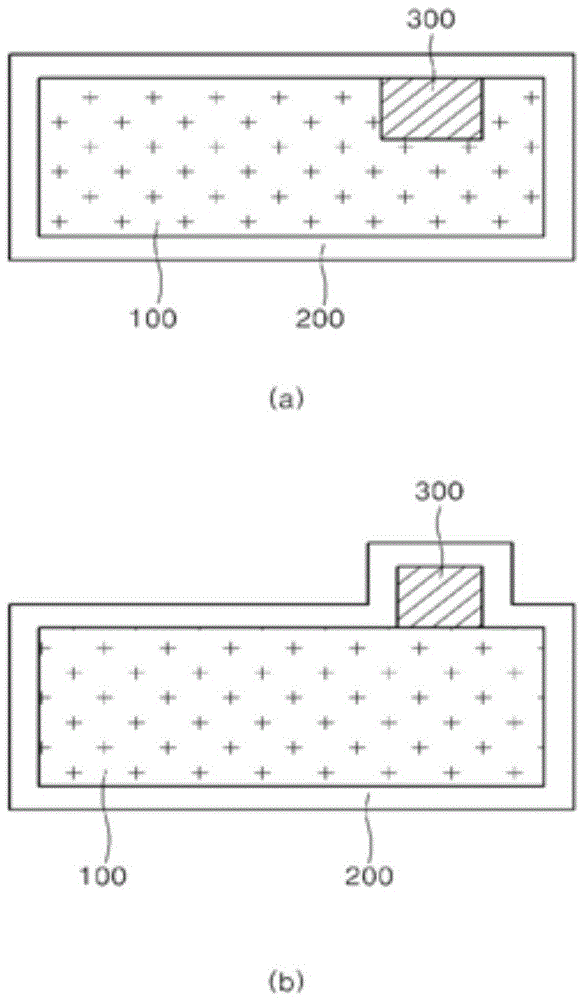

A flat plate electrode fixing structure

ActiveCN102290312ANo outgassingWide distribution of uniformityElectric discharge tubesEngineeringRadio frequency

The invention discloses a plate electrode fixing structure, belonging to the technical field of plasma etching. The plate electrode fixing structure comprises an insulating support, the insulating support is provided with a plurality of air inlets, and upper electrodes and lower electrodes are arranged around the air inlets. The insulating support is 5-1,000mm thick and is made of an insulating material such as ceramic, quartz, polytetrafluoroethylene or polycarbonate. The frequency of a radio-frequency power supply applied between the upper electrodes and the lower electrodes is 0-10GHz. Thedistance between the upper electrodes and the lower electrodes is 2-1,000mm. the area diameter of the upper electrodes and the lower electrodes is 20-3,000mm. By adopting the plate electrode fixing structure, the scope of uniform distribution of a plasma starter can be widened, and particularly good edge uniformity can be achieved. When the plasma starter is used, no air discharging can be causedby the plate electrode fixing structure, and a vacuum chamber can meet vacuum requirements.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

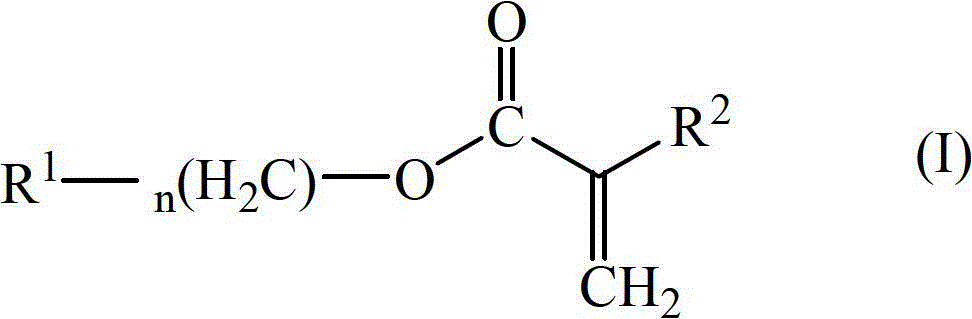

Incrementally forming three-dimensional structure from receiver

InactiveUS20140116604A1Precise positioningReduce quality problemsLamination ancillary operationsPaper/cardboard wound articlesEntry pointEngineering

A method for forming a three-dimensional structure includes depositing a first pattern of toner onto a receiver to form spaced-apart stacks of toner particles that extend above the receiver. The receiver is bent and part of it is brought into contact with the deposited toner. The toner is fused to bind two portions of the receiver together with a selected spacing between them. Fusing includes progressively wrapping the receiver around a rotatable support starting at an entry point defined with respect to the support while softening the toner at the entry point. More toner is then deposited on the first surface, at least part of a surface of the receiver in a fourth portion of the receiver is brought into contact with the toner, and the toner is fused. This is repeated to form the three-dimensional structure.

Owner:EASTMAN KODAK CO

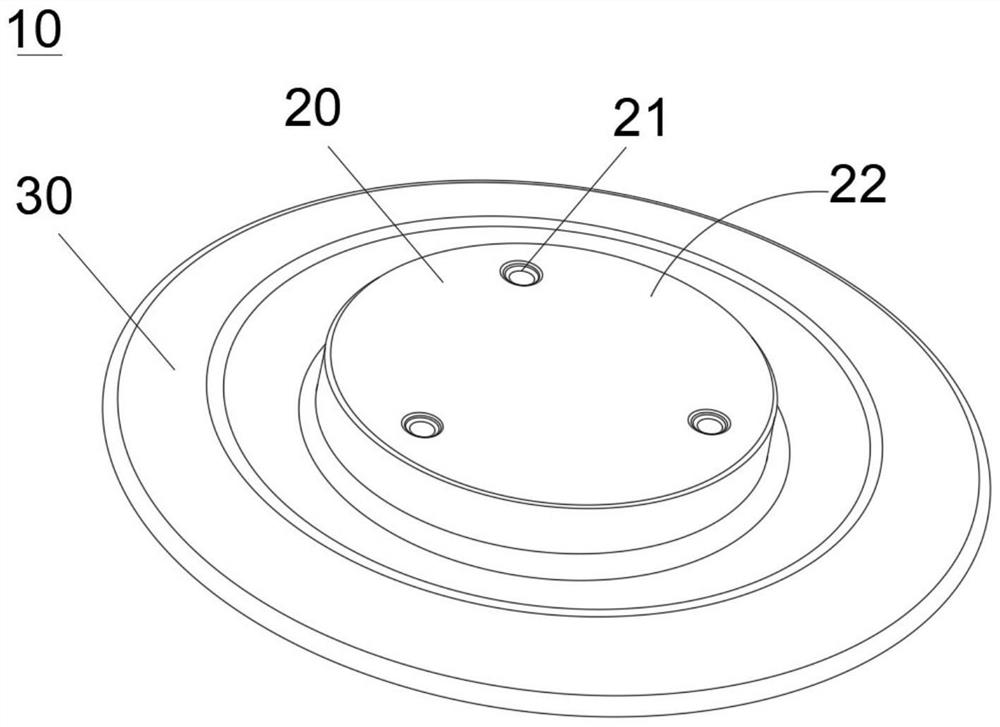

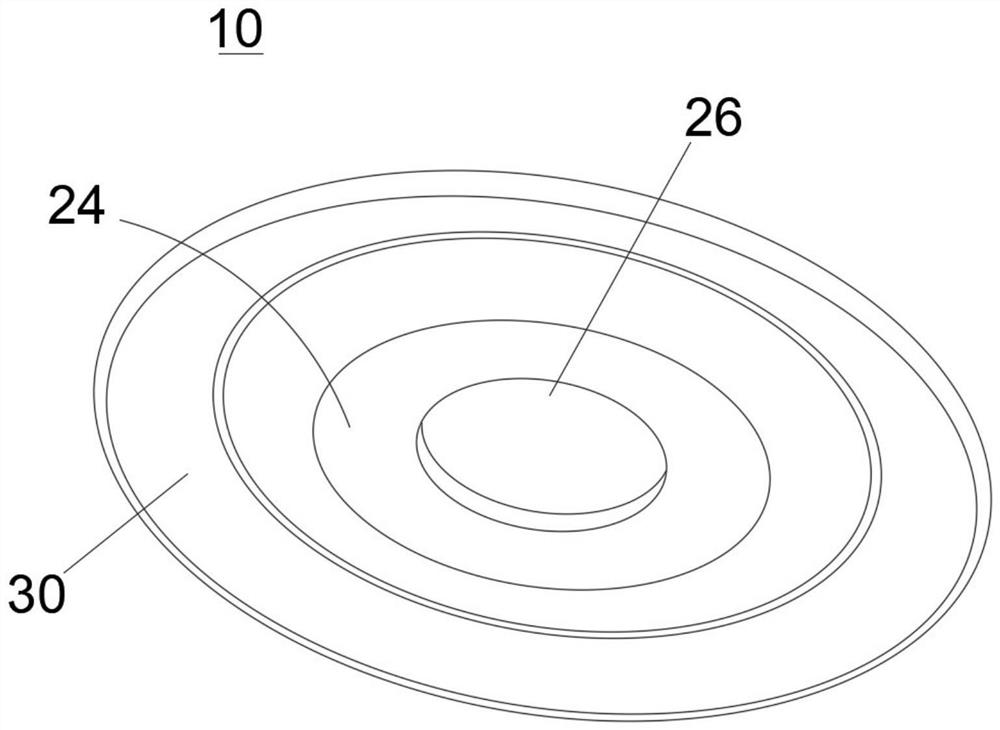

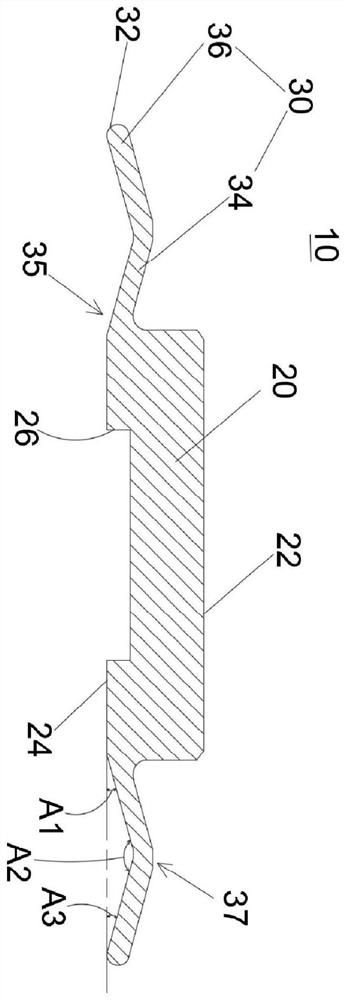

Sealing disc for vacuum sealing

PendingCN112268141AAchieve vacuum sealing effectHigh vacuum sealing effectEngine sealsLift valveMechanical engineeringVALVE PORT

A sealing disc for vacuum sealing is suitable for moving to an opening position or a closing position in a reciprocating mode to open or seal a valve port of an all-metal valve. A first sealing face is formed on a sealing plate of the sealing disc, and the first sealing face of the the sealing disc directly abuts against a valve port of the all-metal vacuum valve at the closing position . By meansof compensation movement and adjustment movement when the sealing faces made of metal abut against each other, the vacuum sealing performance can be improved, and the service life can be prolonged.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

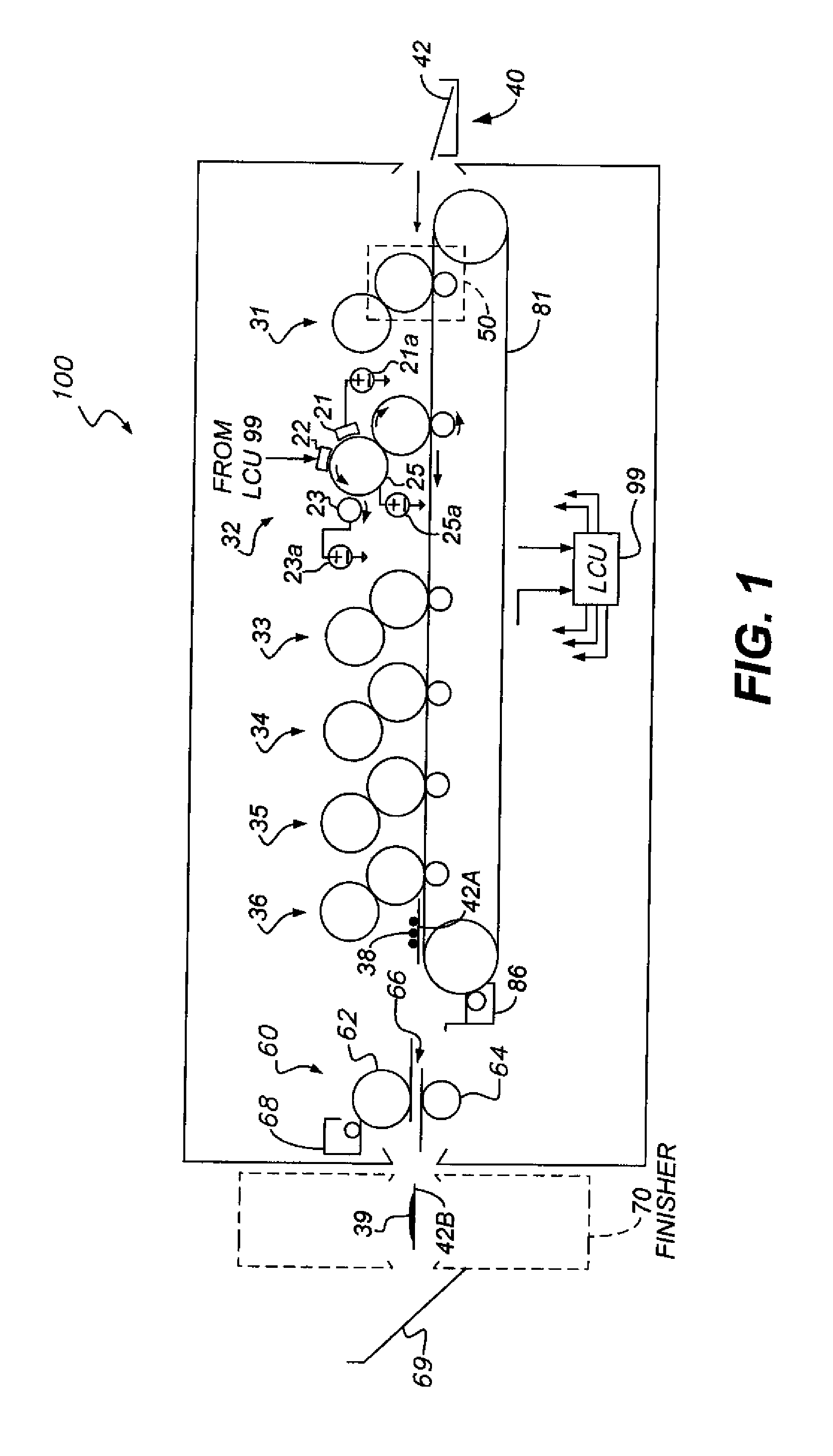

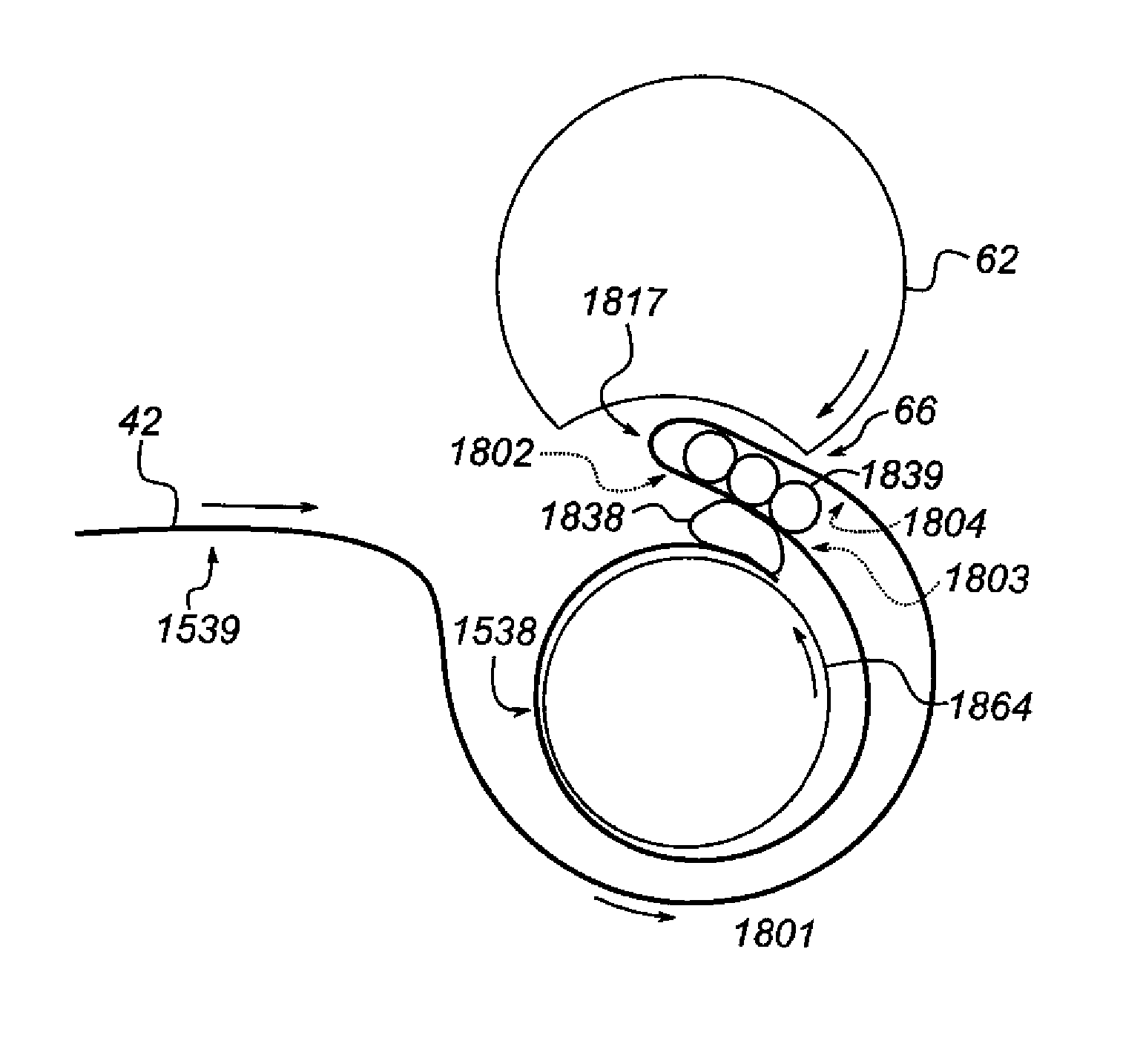

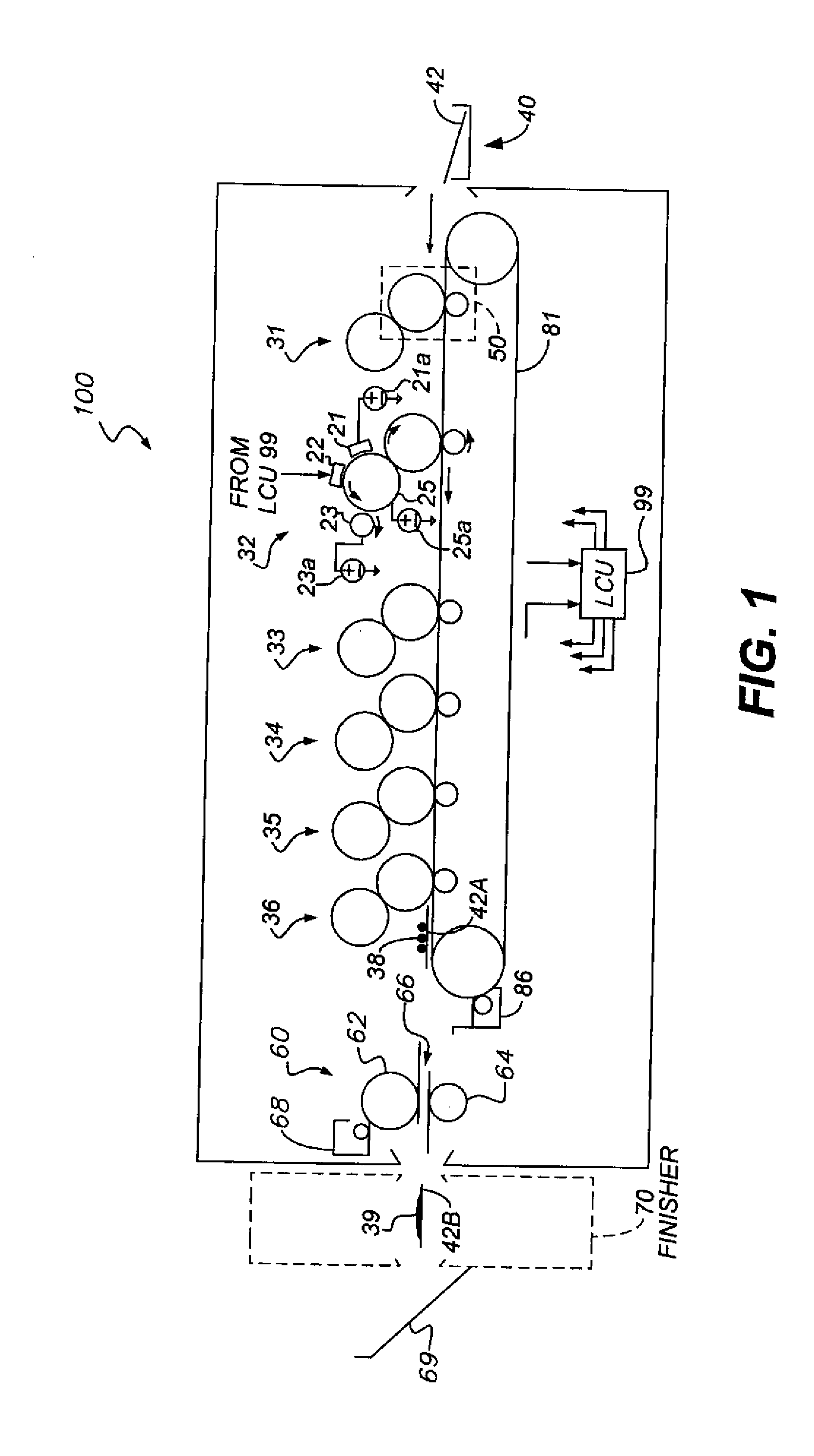

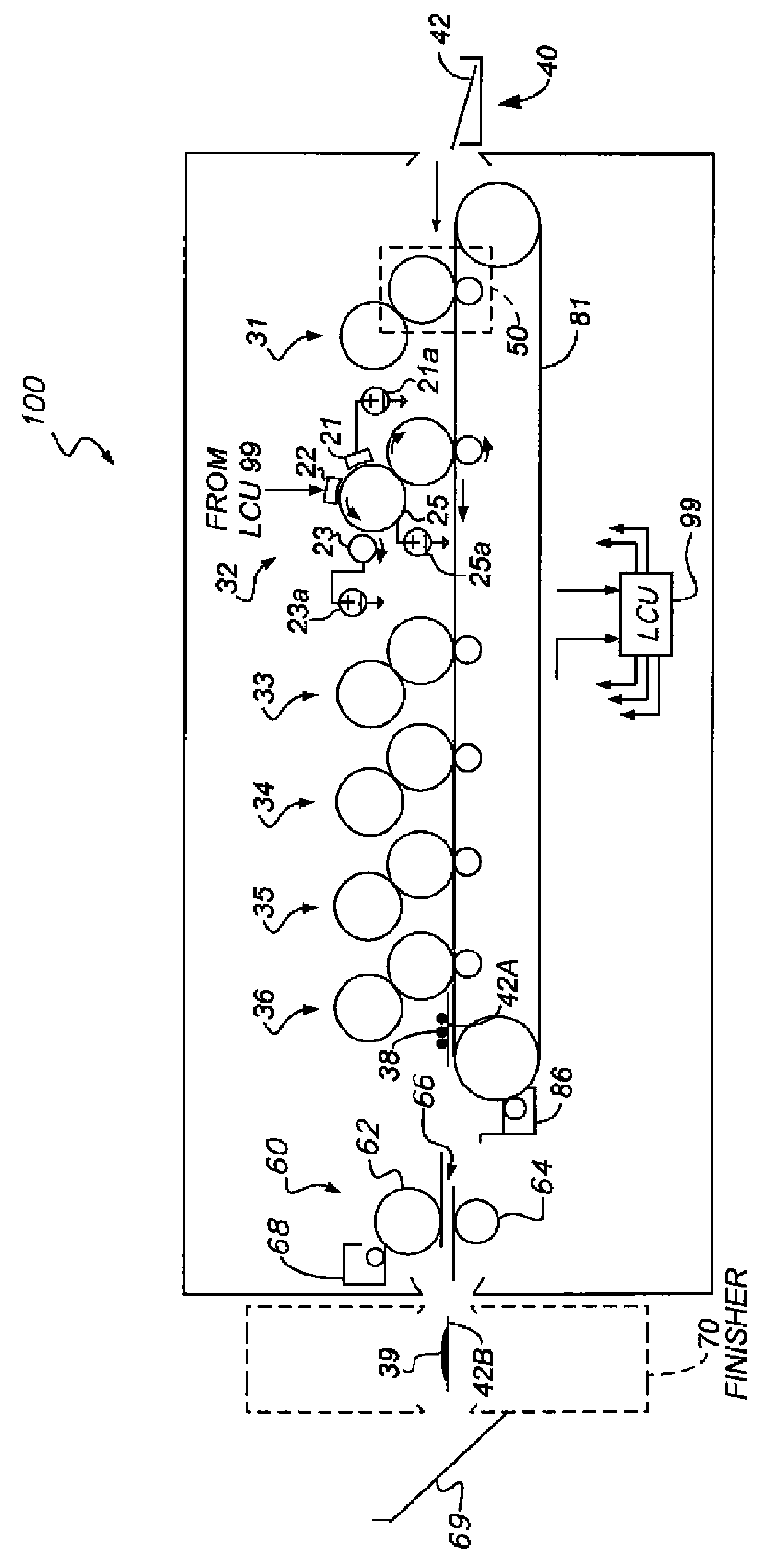

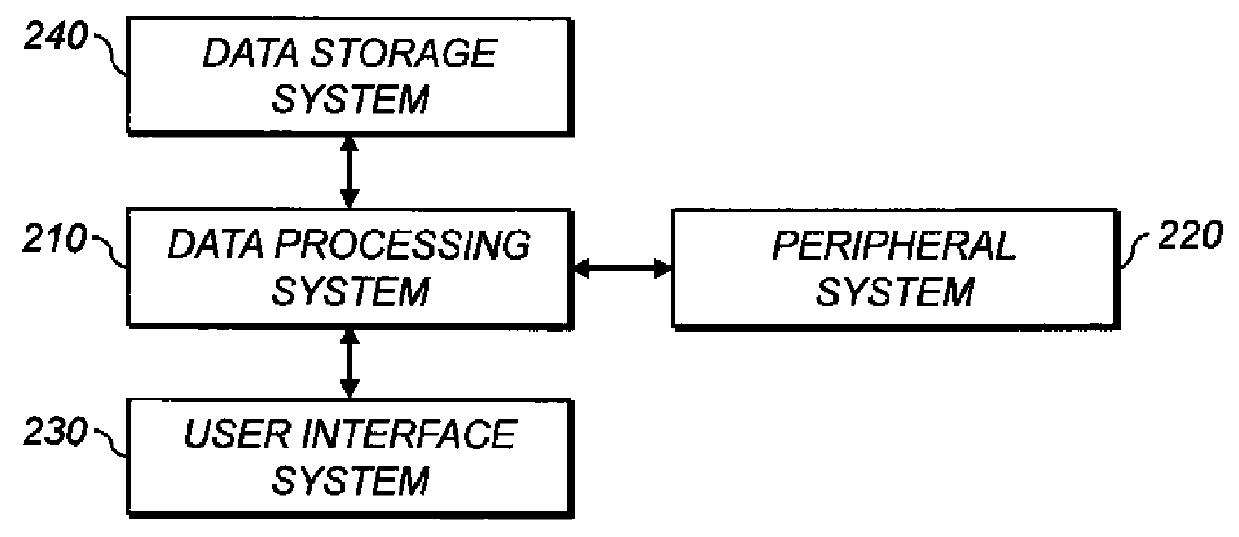

Three-dimensional-structure former

ActiveUS20140121088A1Precise positioningReduce quality problemsBoxes/cartons making machineryBox making operationsDirected UnitEngineering

A device for producing a three-dimensional structure from a receiver includes a deposition unit that deposits toner on the receiver. That unit is controlled by a controller to produce a toner pattern on the receiver. A fusing device includes first and second rotatable members having respective, different compliances and a mount that selectively retains the members with respect to each other to form a fusing nip and permits adjustment of respective forces between the members at each end. A directing unit entrains the receiver around the second member so that the receiver passes through the fusing nip. A softening device softens the toner of the toner pattern so that as the second member rotates through successive revolutions, corresponding layer areas of the receiver are defined and the softened toner in each layer area adheres to the second surface of the receiver in an adjacent layer area.

Owner:EASTMAN KODAK CO

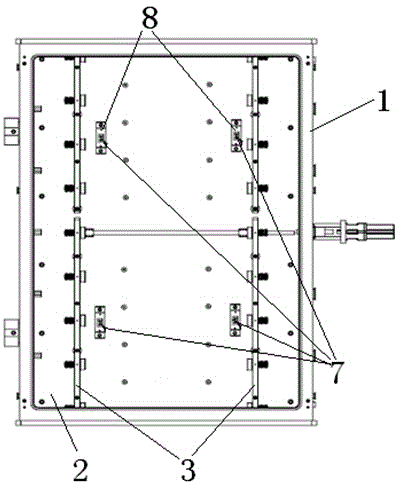

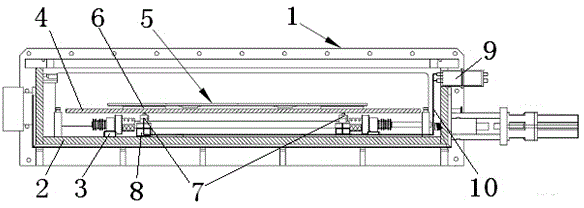

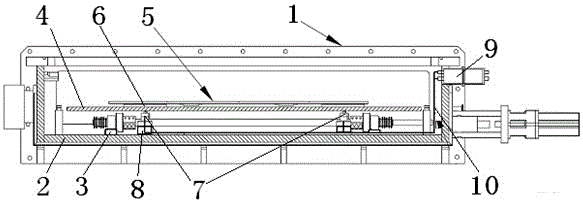

Horizontal continuous magnetron sputtering film plating machine online panel constant-temperature heating apparatus

ActiveCN104831247ALow costSimple mechanical structureVacuum evaporation coatingSputtering coatingElectrically conductiveElectricity

The present invention discloses a horizontal continuous magnetron sputtering film plating machine online panel constant-temperature heating apparatus, wherein a conveying base plate is horizontally provided with a copper conducting plate, the copper conducting plate is provided with an embedded thermocouple temperature measuring rod and a PTC constant-temperature low-voltage heating element, the embedded thermocouple temperature measuring rod and the PTC constant-temperature low-voltage heating element are respectively and correspondingly connected to the copper disk electrodes on the conveying base plate, the bottom portion of a vacuum chamber is provided with rotary electric conduction wheel electrodes, the rotary electric conduction wheel electrodes comprise a group of power supply electrodes and a group of temperature measuring electrodes, and when the copper disk electrodes and the rotary electric conduction wheel electrodes correspondingly contact and are electrically connected, real-time temperature detection and heating control are performed. With the apparatus of the present invention, the problem of the difficult heating on the panel to be plated in the vacuum chamber of the continuous magnetron sputtering film plating is overcome, the film plating qualities of the transparent electric conduction film, the antireflection film and the high reflection film of the plated display panel are increased, and the apparatus is suitable for increasing of the film plating quality of the transparent electric conduction film, the antireflection film and the high reflection film of the display panel.

Owner:赫得纳米科技(昆山)有限公司

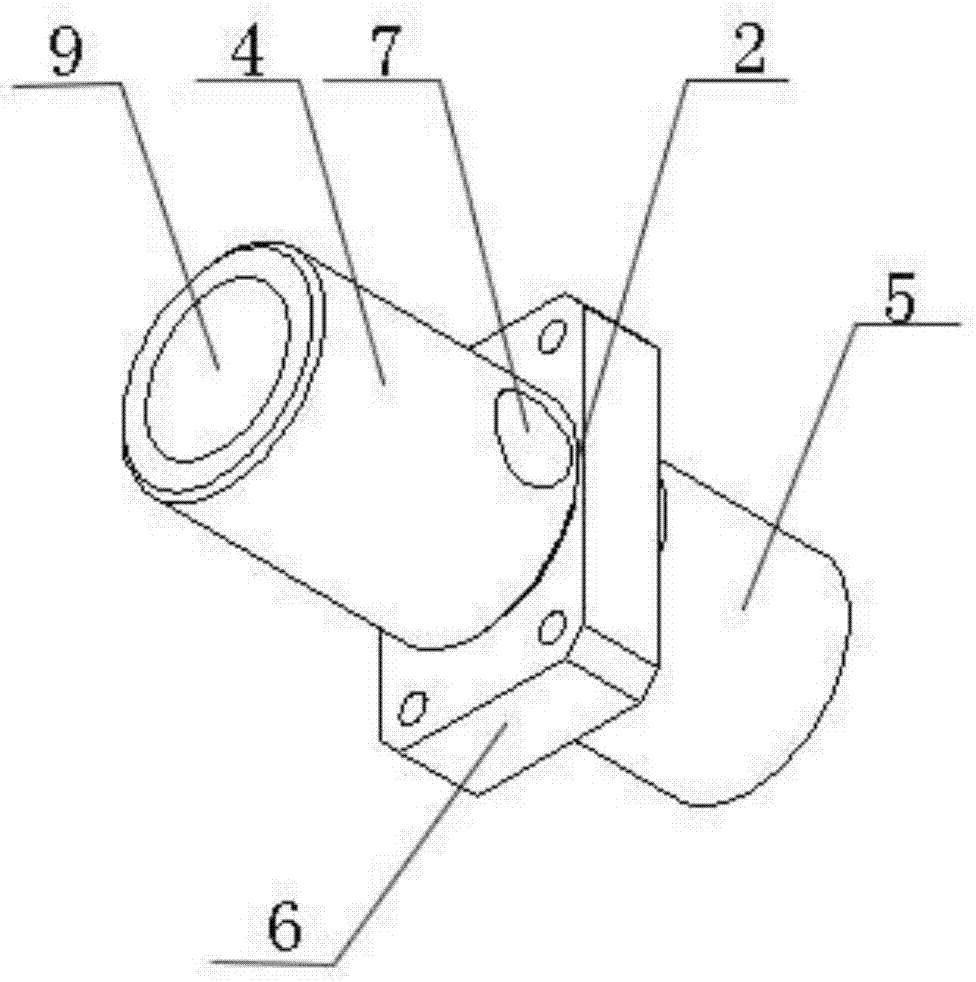

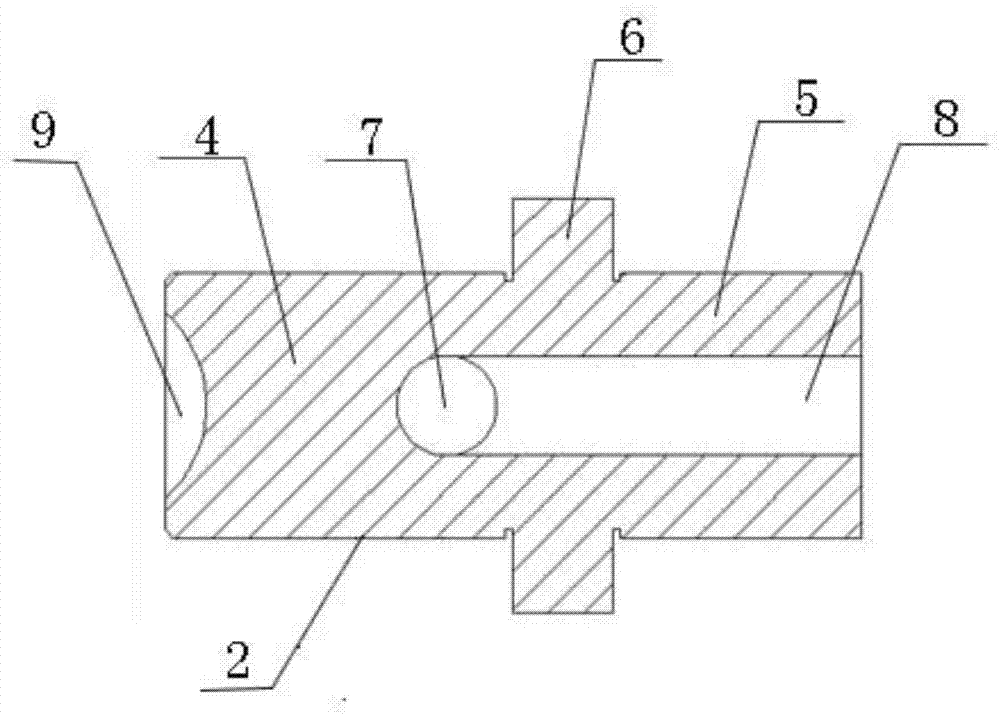

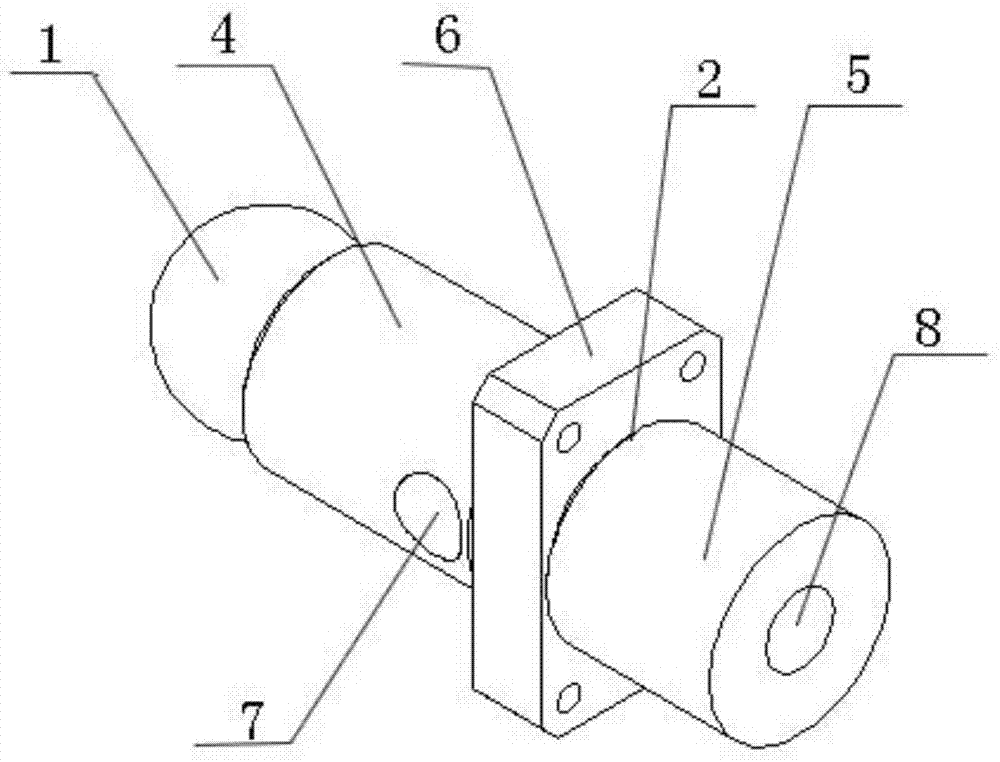

Device for accurate measurement of micro deformation of composite rod for space

The invention provides a device for accurate measurement of micro deformation of a composite rod for space, and relates to the field of aerospace. The device solves the problems that an existing measuring method is low in measurement accuracy and cannot be used for effectively measuring micro deformation of a composite rod for space. The device comprises a steel ball made of 16-level-accurcy stainless steel materials and a straight joint made of invar steel materials with the linear expansion coefficient being zero; the two ends of the straight joint are of a first cylindrical structure and a second cylindrical structure respectively, the middle of the straight joint is of a square structure, the end of the first cylindrical structure is provided with a spherical groove for fixing the steel ball, and the spherical groove is the same as the steel ball in diameter; the diameter of the second cylindrical structure is in clearance fit with the inner diameter of the composite material rod, and the composite material rod is installed on the second cylindrical structure in a sleeved mode and connected together with the second cylindrical structure in a cementing mode. When the device is used for measuring the micro deformation of the composite rod, the repeatability is within 0.5 micrometer, and the measuring accuracy is high.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

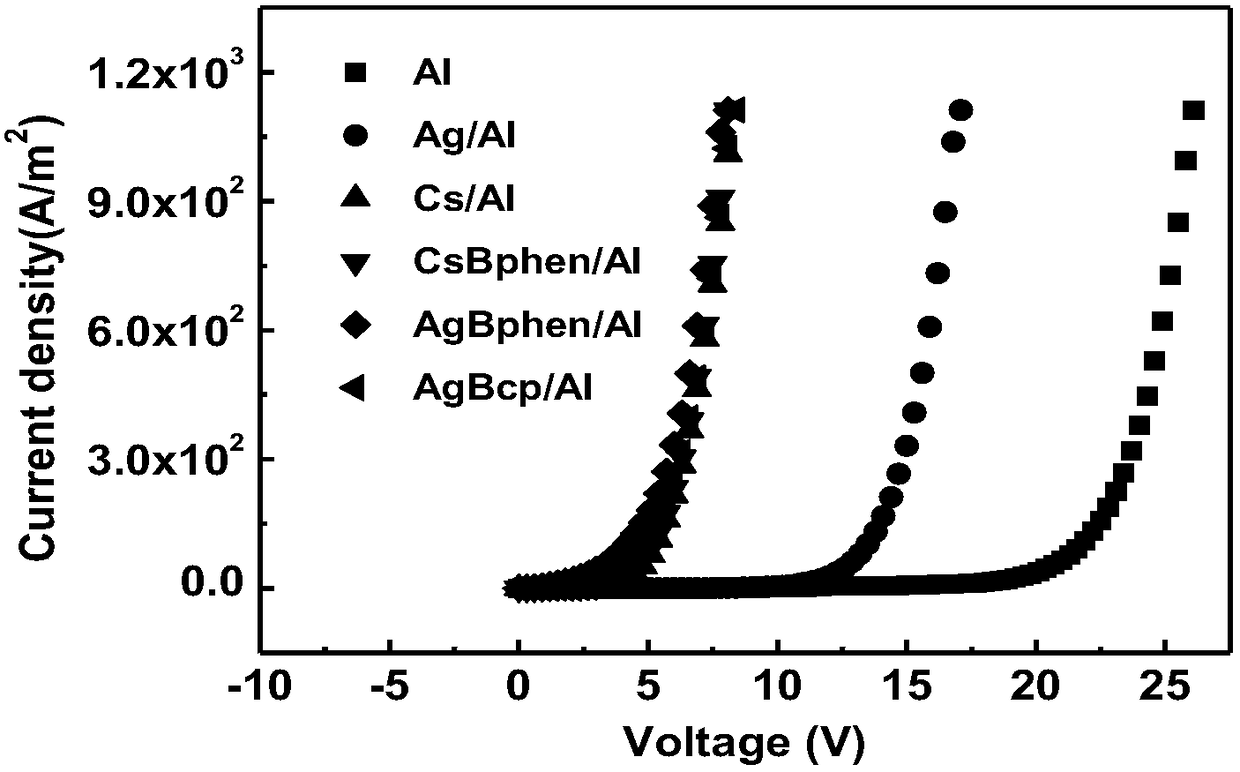

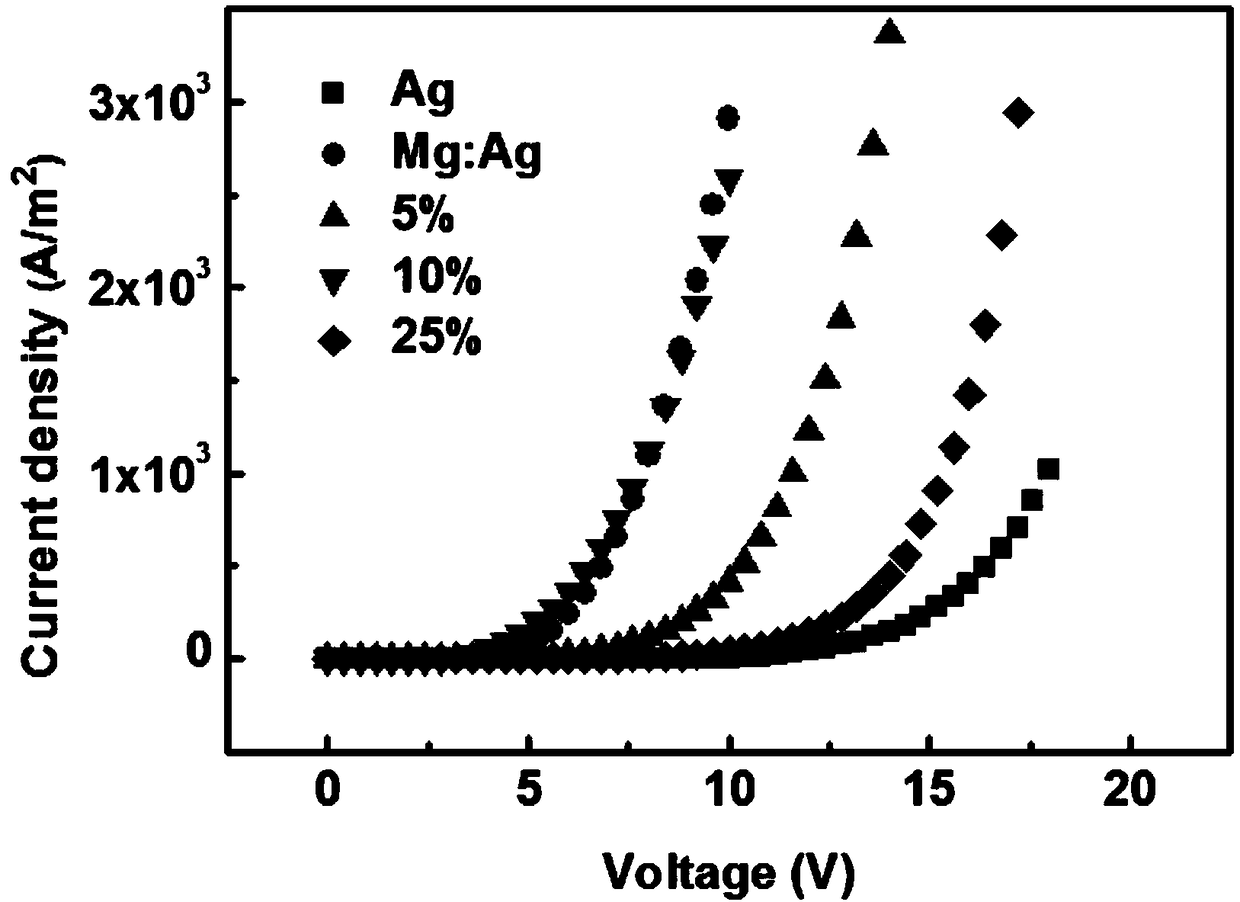

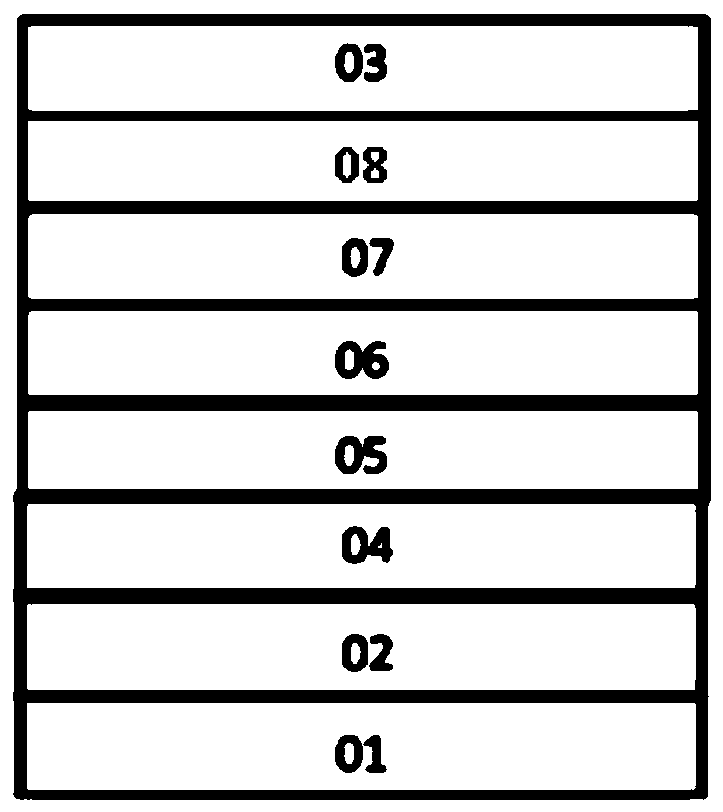

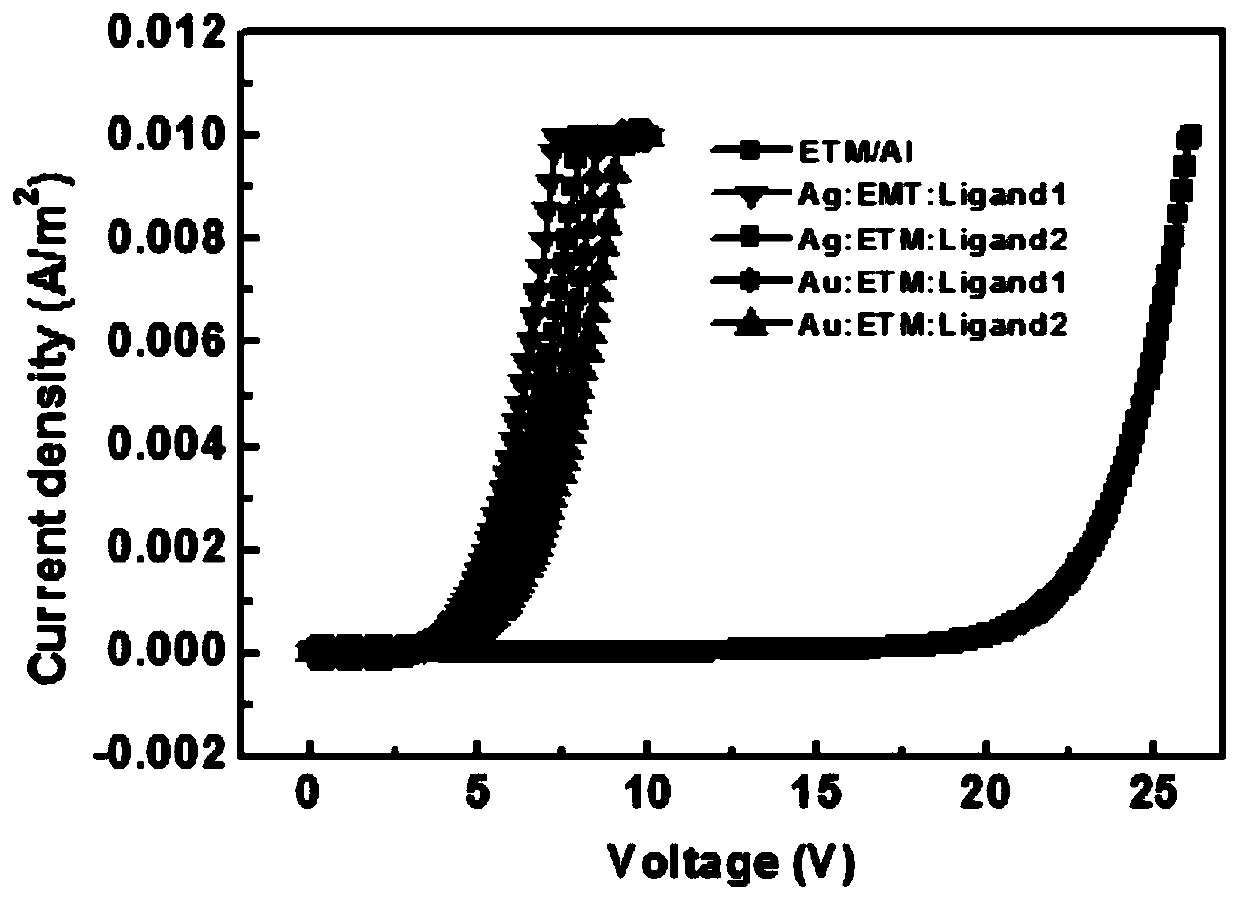

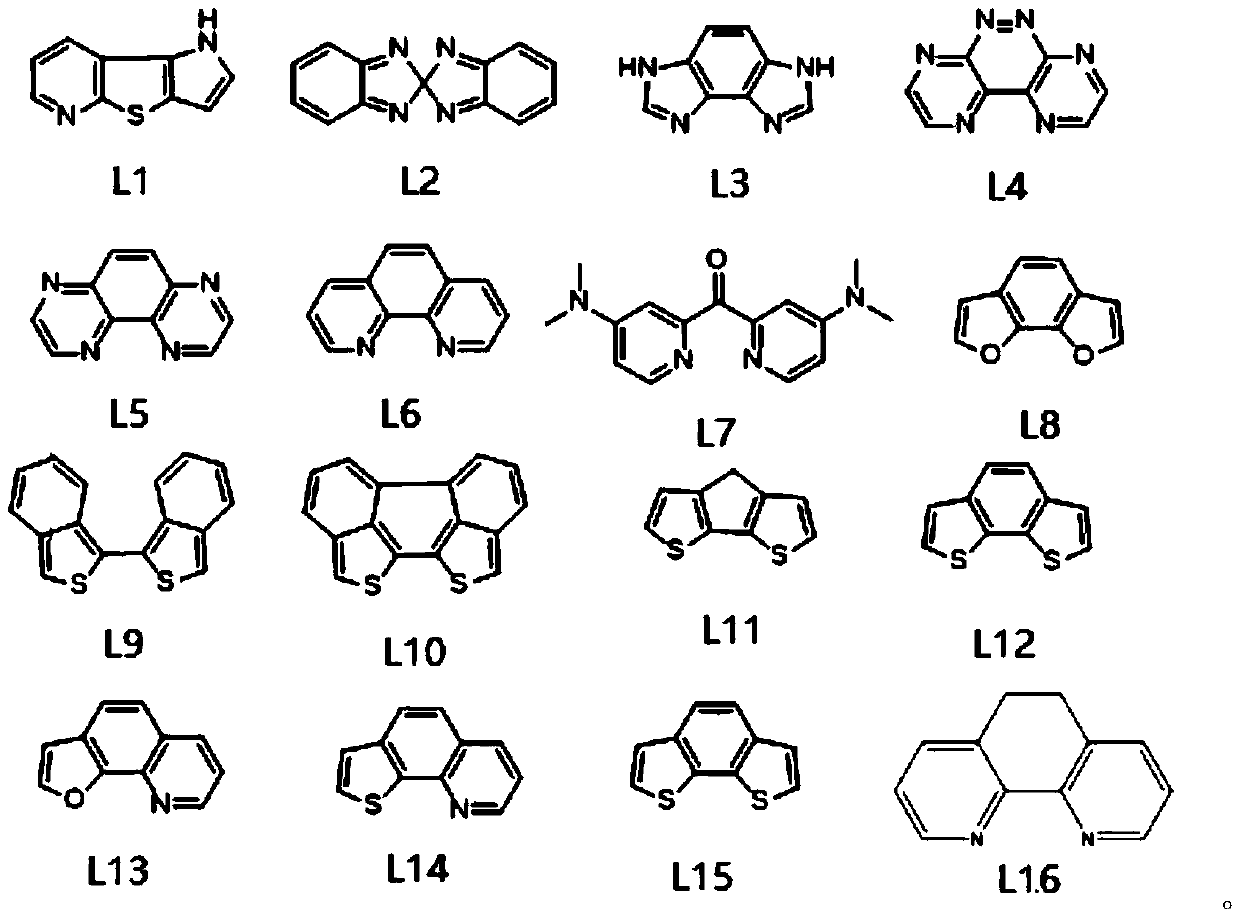

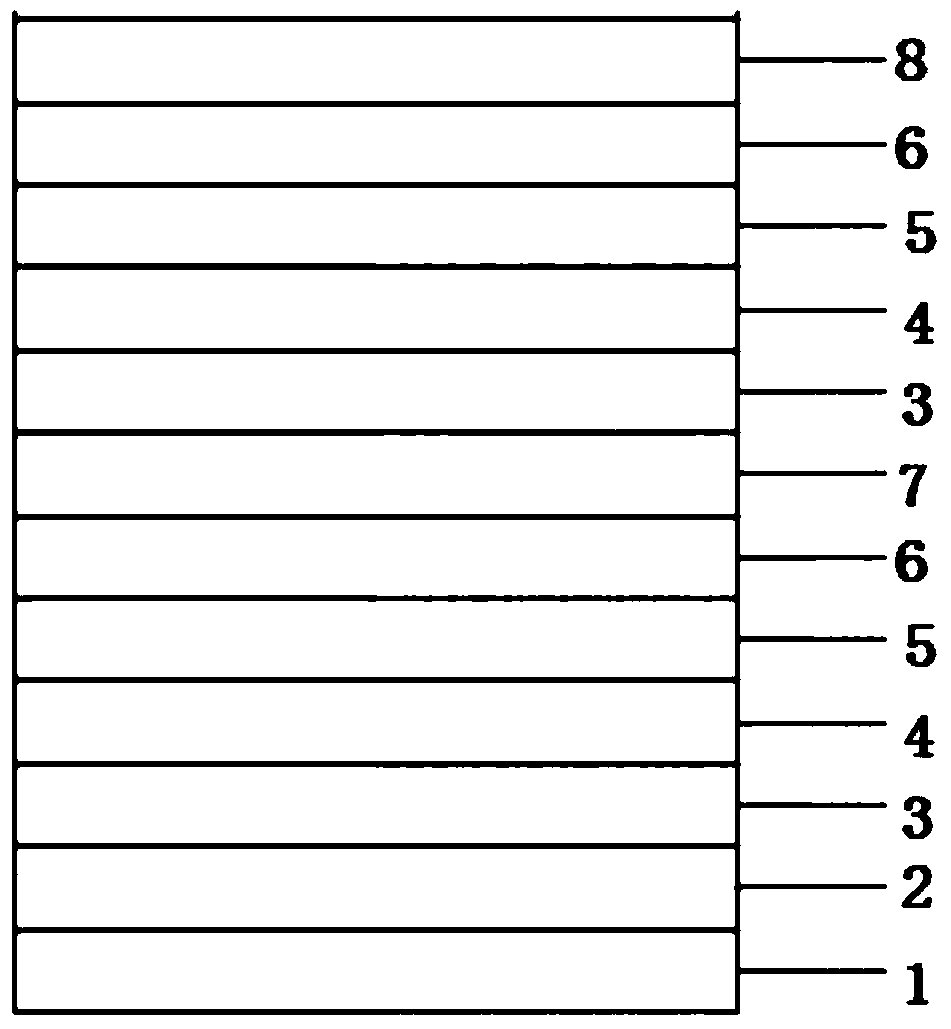

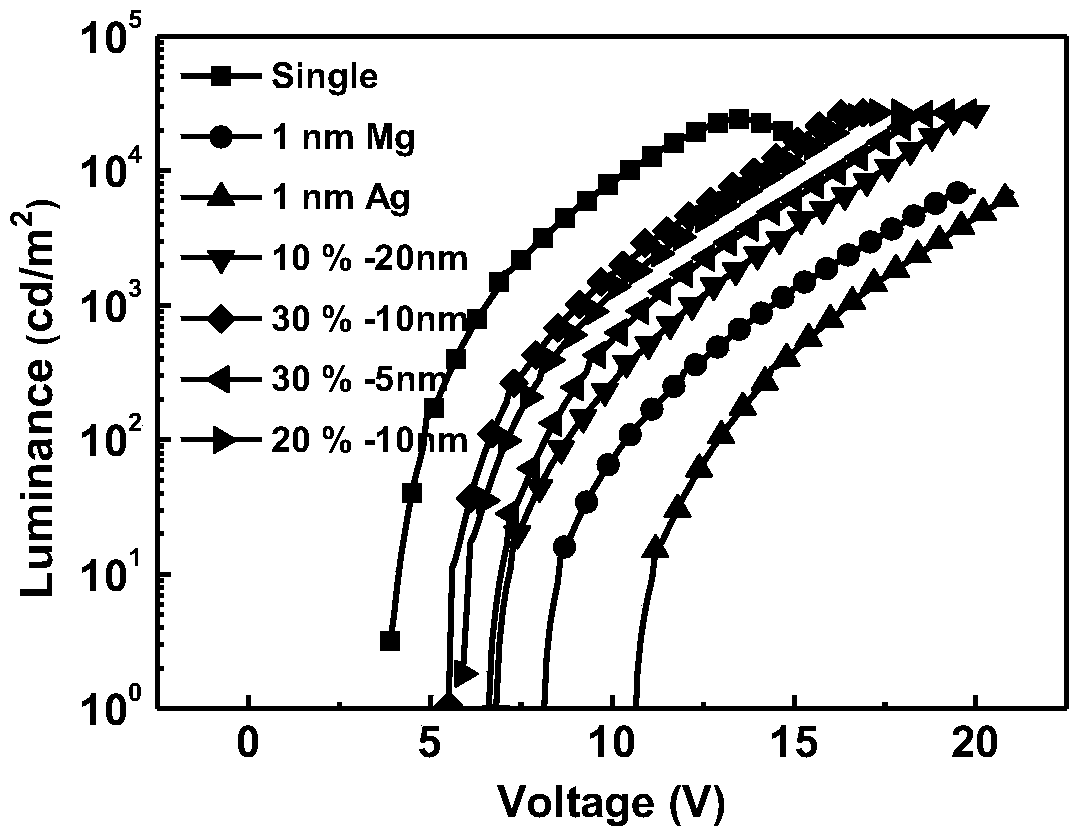

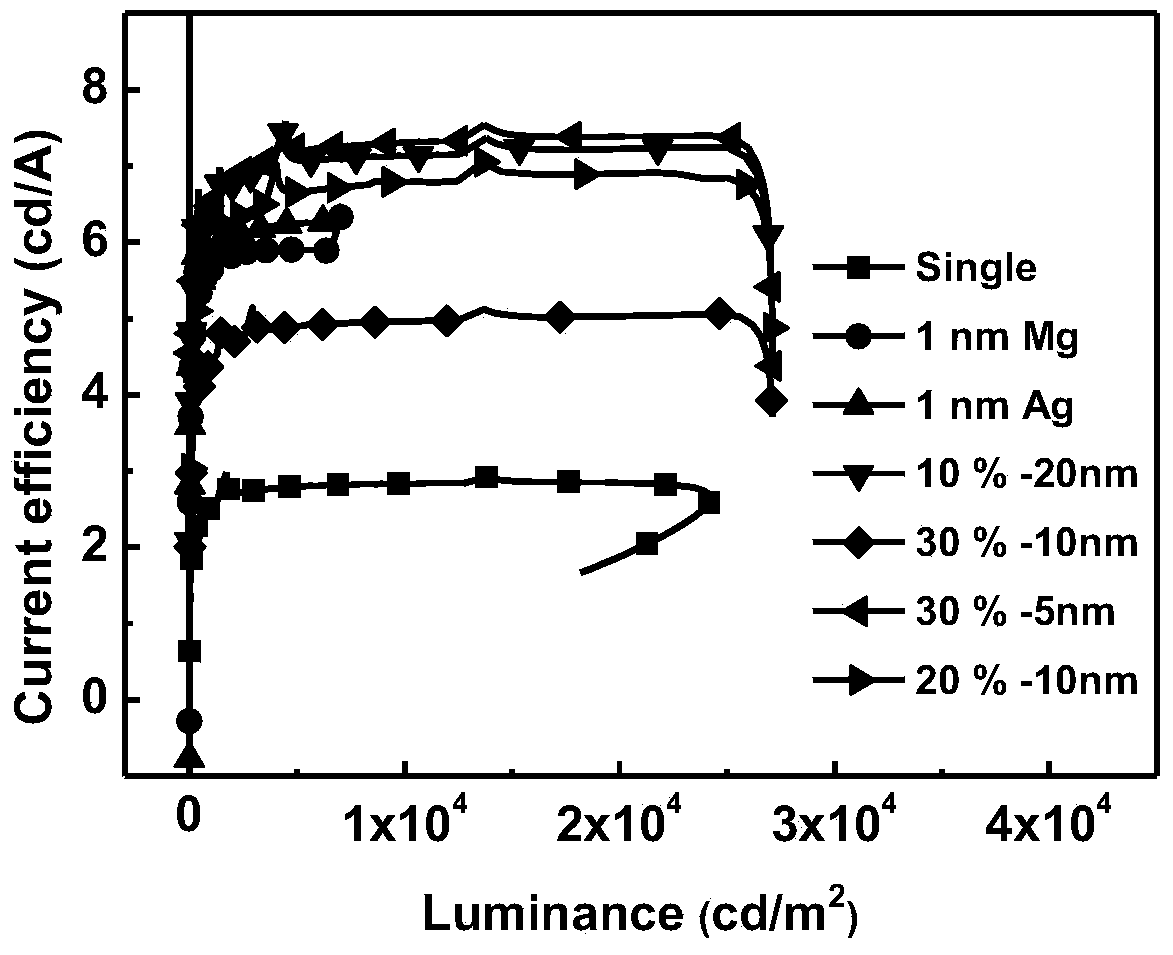

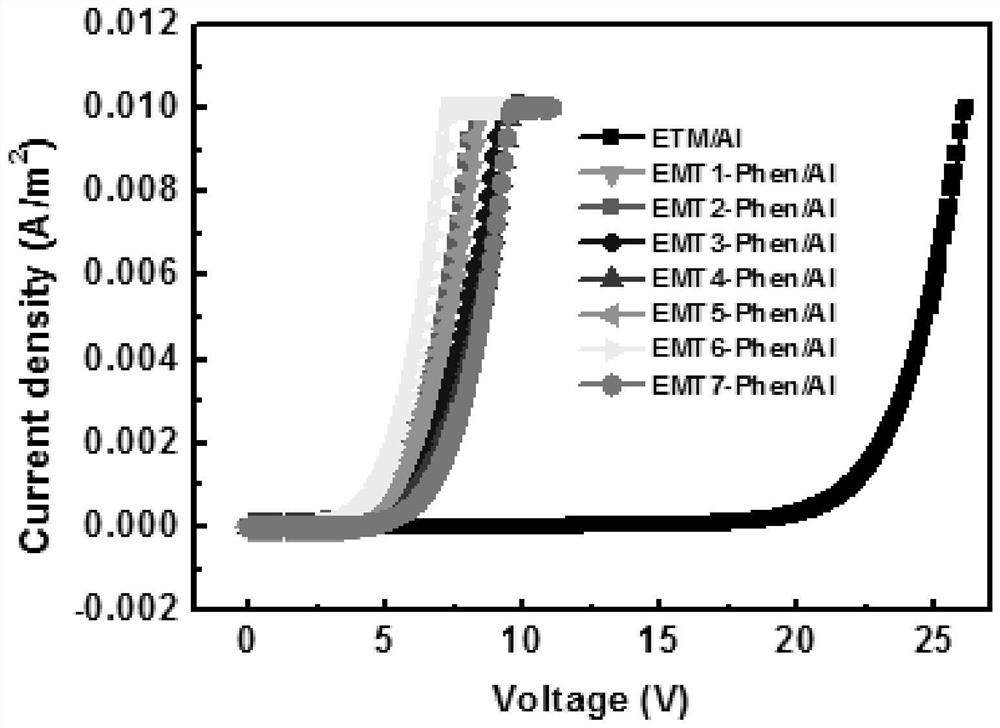

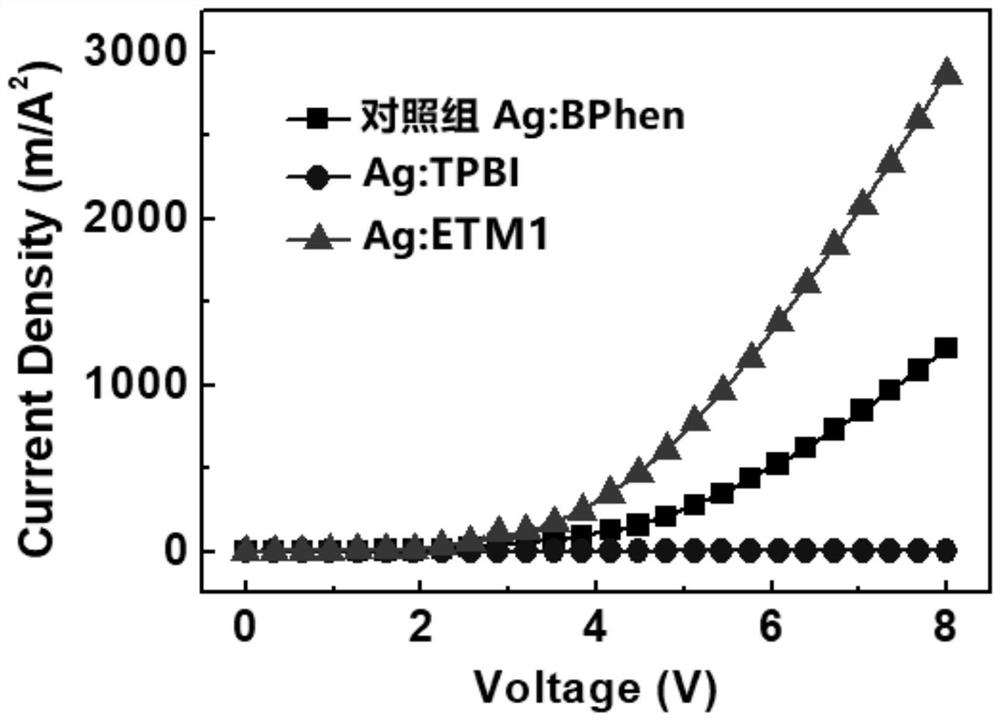

An organic electroluminescent device

ActiveCN107464885BLower injection barrierReduce usageSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerMaterials science

The present invention relates to an organic electroluminescence device, comprising a substrate, and a light-emitting device sequentially formed on the substrate, the light-emitting device comprising a first electrode layer, a hole injection layer, a hole transport layer, a light-emitting layer, a hole A hole blocking layer, an electron transport layer and a second electrode layer, the electron transport layer includes an electron transport host material with coordination ability and an inert metal doped in the electron transport host material; the electron transport host material is Electron transport materials with coordination properties can undergo coordination reactions with inert metal cations to promote the process of inert metals losing electrons, thereby reducing the work function of inert metals and enabling inert metals to achieve n-type doping similar to active metals The effect is to reduce the LUMO energy level of the electron transport material, thereby promoting the injection of electrons, thereby significantly reducing the driving voltage of the device and improving the efficiency of the device.

Owner:TSINGHUA UNIV

chamber heating device

ActiveCN103208440BNo outgassingRequirements for maintaining vacuumElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringCavity wall

Disclosed is a cavity heating device. The cavity heating device comprises a cavity wall heating structure and / or a slide holder heating structure. The cavity wall heating structure is arranged on the inner wall of a reaction cavity. The slide holder heating structure is arranged at the bottom of a slide holder. The cavity heating device can reduce or avoid nonuniformity caused by the fact that plasma starting is unsymmetrical in structure in the plasma etching process. An electrode fixing structure is free of air discharge under the plasma starting condition and can meet requirement of a vacuum cavity for vacuum degree.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

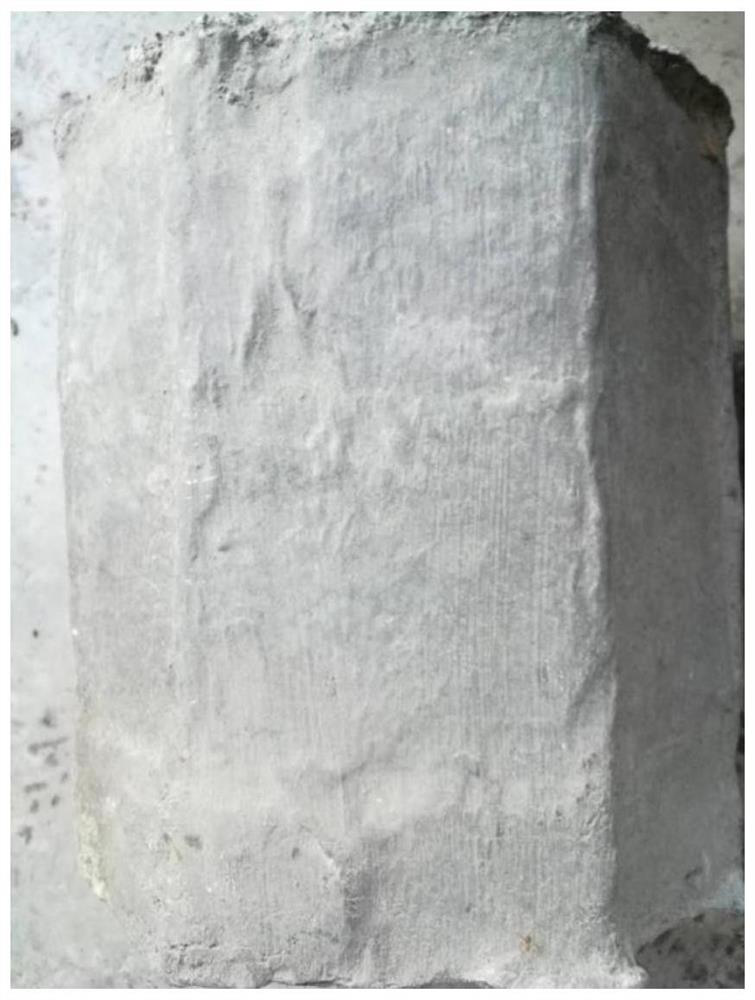

Coating for inner surface of sand mold of high-temperature alloy mold casting and using method

PendingCN112045147AControl crackingControl microcracksFoundry mouldsFoundry coresSurface finishSuperalloy

The invention discloses a coating for the inner surface of a sand mold of a high-temperature alloy mold casting and a using method. The coating comprises the following components of zircon powder, aluminum oxide micro powder, silica sol and aluminum sol. The coating and the using method have the advantages that the strength at low temperature is high, the high temperature resistance at high temperature is realized, and the molten steel scouring resistance at high temperature is realized; after the inner surface of the sand mold is coated with the coating for the isothermal forging inner surface of the sand mold of the high-temperature alloy mold casting, the inner surface of the sand mold is good in smoothness and free of air holes; and the coating can be used in a vacuum environment.

Owner:王成富

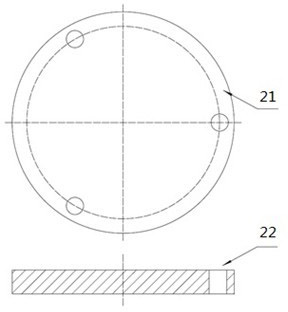

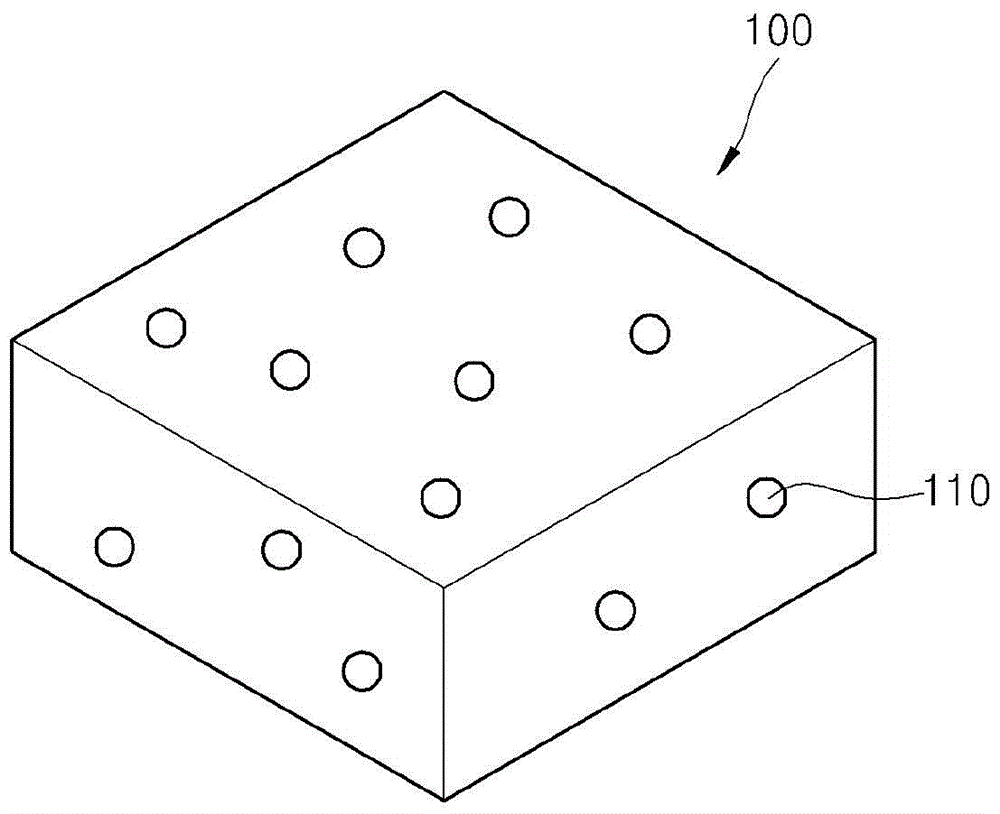

a slide deck

ActiveCN103208409BNo outgassingRequirements for maintaining vacuumElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringChip carrier

The invention discloses a chip carrier and belongs to the technical field of plasma body processes. The chip carrier comprises a cavity, a cavity upper cover, an electrode, a chip fixing disc, a fixing disc supporting ring and a supporting disc. A chip fixing structure of the chip carrier comprises the chip fixing disc and the fixing disc supporting ring. An unevenness phenomenon caused by an asymmetric structure when a plasma body is started can be reduced or avoided, and a gas homogenizing structure is simplified. Under the starting condition of the plasma body, the chip carrier does not cause a gas escape phenomenon, so that the requirement of a chip for the cavity vacuum degree can be kept.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

A kind of inert metal n-type dopant and its application in organic electroluminescent devices

ActiveCN109473558BGood coordination functionLower injection barrierSolid-state devicesSemiconductor/solid-state device manufacturingDopantChemical physics

The invention belongs to the technical field of organic electroluminescent devices, in particular to an n-type dopant based on an inert metal, and further discloses its application as an electron transport material dopant and its application in organic electroluminescent devices application. The n-type dopant based on the inert metal of the present invention includes an inert metal and a ligand compound with a coordination function, and the dopant is doped in a conventional electron transport host material, which can effectively reduce the electron transport material LUMO energy level, and then promote the injection of electrons, thereby significantly reducing the driving voltage of the device and improving the efficiency of the device.

Owner:TSINGHUA UNIV

Addition-curable metallosiloxane compound

InactiveUS8791221B2Satisfactory resistance to thermal yellowingNo outgassingSilicon organic compoundsCoatingsSilane compoundsSilanes

Provided is a metallosiloxane compound (A) prepared by reacting a bifunctional silane compound (S1), a monofunctional silane compound (S2), a boron compound (M), and optionally H2O in a molar ratio of [the silane compound (S1)]:[the silane compound (S2)]:[the boron compound (M)]:[H2O] of n:m:k:a, where n, m, k, and a satisfy all conditions (i), (ii), and (iii), in which the metallosiloxane compound has at least one Si—H bond or C2-10 alkenyl group per molecule, and the conditions (i), (ii), and (iii) are expressed as follows:(i) n>0, m>0, k>0, a≧0;(ii) m / n≧0.5; and(iii) (n+m) / k≧1.8.

Owner:DAICEL CHEM IND LTD

Horizontal continuous magnetron sputtering coating machine online panel constant temperature heating device

ActiveCN104831247BNo outgassingImprove thermal conductivityVacuum evaporation coatingSputtering coatingElectricitySputtering

The present invention discloses a horizontal continuous magnetron sputtering film plating machine online panel constant-temperature heating apparatus, wherein a conveying base plate is horizontally provided with a copper conducting plate, the copper conducting plate is provided with an embedded thermocouple temperature measuring rod and a PTC constant-temperature low-voltage heating element, the embedded thermocouple temperature measuring rod and the PTC constant-temperature low-voltage heating element are respectively and correspondingly connected to the copper disk electrodes on the conveying base plate, the bottom portion of a vacuum chamber is provided with rotary electric conduction wheel electrodes, the rotary electric conduction wheel electrodes comprise a group of power supply electrodes and a group of temperature measuring electrodes, and when the copper disk electrodes and the rotary electric conduction wheel electrodes correspondingly contact and are electrically connected, real-time temperature detection and heating control are performed. With the apparatus of the present invention, the problem of the difficult heating on the panel to be plated in the vacuum chamber of the continuous magnetron sputtering film plating is overcome, the film plating qualities of the transparent electric conduction film, the antireflection film and the high reflection film of the plated display panel are increased, and the apparatus is suitable for increasing of the film plating quality of the transparent electric conduction film, the antireflection film and the high reflection film of the display panel.

Owner:赫得纳米科技(昆山)有限公司

A stacked organic electroluminescent device

ActiveCN107464884BFacilitate transmissionEasy to separateSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeChemical physics

The present invention relates to a laminated organic electroluminescent device, comprising a substrate, and a light-emitting device sequentially formed on the substrate, the light-emitting device comprising a first electrode layer, a hole injection layer, a hole transport layer, and a light-emitting layer , an electron transport layer, an electron generation layer, a hole injection layer, a hole transport layer, a light emitting layer and an electron transport layer second electrode layer, the electron generation layer includes an electron transport material with coordination ability and doped in the Inert transition metals in electron transport materials; electron transport materials with coordination ability can form complexes with inert metal ions to reduce the work function of inert metals, so that they can achieve n-type doping effects similar to active metals and improve free current carrying Subconcentration, reduce the LUMO energy level of the electron transport material, used as the electron generation layer of the laminated device, promote the generation of electrons and enhance the separation of electrons, so that the driving voltage of the device can be significantly reduced, and the device efficiency can be improved.

Owner:TSINGHUA UNIV

Method and application of n-type doping of electron transport materials based on inert metals

ActiveCN109524571BLower injection barrierEasy injectionSolid-state devicesSemiconductor/solid-state device manufacturingChemical physicsWork function

The invention belongs to the technical field of organic electroluminescent devices, in particular to a method for realizing N-type doping of electron transport materials based on inert metals, and further discloses the application of the method in preparing organic electroluminescent devices. The method for N-type doping of electron transport materials based on inert metals in the present invention uses ligand compounds with coordination functions to connect with existing general electron transport materials, so that the general electron transport materials increase some The performance of the group, and make it have a coordination function, and then can use its coordination with M n+ Coordination occurs to promote the inert metal M to lose electrons and reduce its work function, so that the inert metal can achieve the N-type doping effect similar to the active alkali metal, improve the transmission characteristics of the electron transport material, reduce the injection barrier of electrons, and enhance the electron density. injection.

Owner:TSINGHUA UNIV

Photohardening resin composition and application thereof

ActiveCN102863908BNo outgassingImprove reliabilityAdhesive processesFilm/foil adhesivesDiacrylate esterIrradiation

A photohardening resin composition comprises (A) oligomer containing ethylenic bonds, (B) monomers containing at least one acrylate group, and (C) a photoinitiator, wherein (B) is selected from mono-acrylate monomers shown in formula (I), bis-acrylate monomers shown in formula (II) or a composition of the two, and the formula (I) and the formula (II) are defined in the specification and the claims. The invention also provides an adhesion layer formed by irradiation of the photohardening resin composition, a display element containing the adhesion layer, and a method for preparing the display element by using the photohardening resin composition. The hardening of the photohardening resin composition of the invention causes no gas release phenomenon, which further improves the reliability of the display element for subsequent application.

Owner:DAXIN MATERIALS

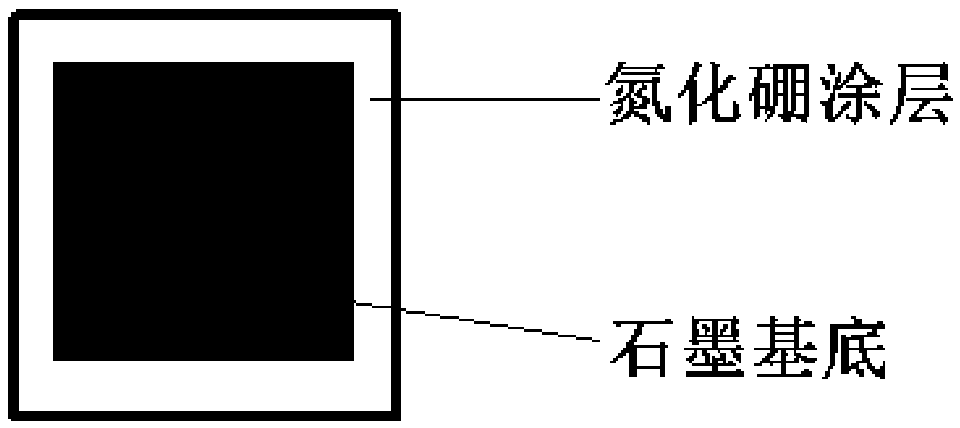

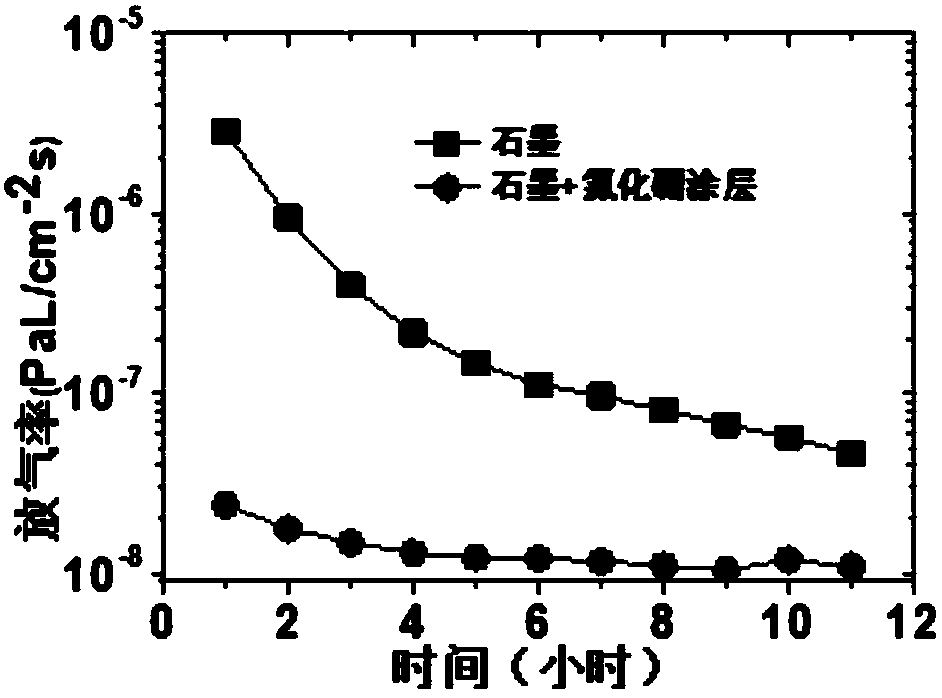

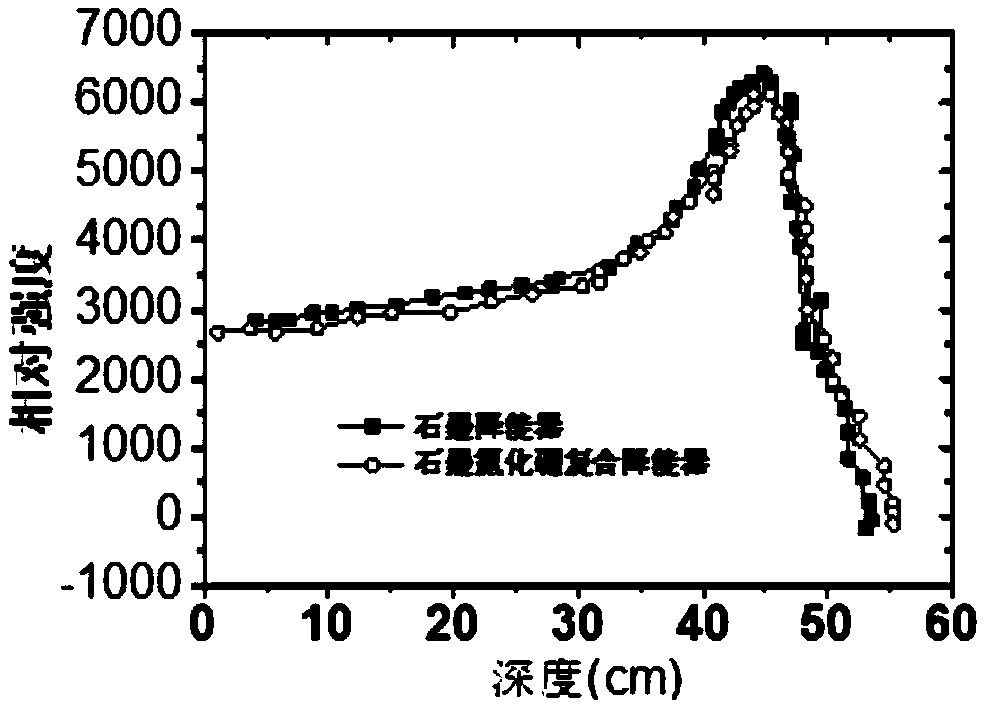

Energy-reducing device for high-energy particles and its preparation method

ActiveCN107863173BImprove adhesionPut an end to deflationRadiation/particle handlingVacuum evaporation coatingBeam energyBoron nitride

The invention discloses a high-energy particle energy-reducing device and a preparation method thereof. The energy-reducing device is a graphite substrate covered with a dense boron nitride coating, and the thickness of the dense boron nitride coating is 5-800[mu]m; the preparation method adopts a vapor deposition method, and comprises the following steps: firstly, placing a graphite substrate into a vacuum chamber, then mixing an ammonia gas, a boron chloride gas and a nitrogen gas according to the volume ratio of the ammonia gas to the boron chloride gas to the nitrogen gas of (0.8-1.2):(0.8-1.2):(40-60) to obtain a mixed gas, then firstly raising the temperature in the vacuum chamber to 500-2000 DEG C, and finally introducing the mixed gas with a flow quantity of 10-100sccm into the vacuum chamber for 12-36h to obtain the target product. According to the high-energy particle energy-reducing device provided by the invention, the degassing rate is much lower than that of a graphite energy-reducing device, a high-energy particle beam has good penetrating performance on the high-energy particle energy-reducing device and the graphite energy-reducing device, and the high-energy particle energy-reducing device can be easily, widely and commercially applied to the fields of high-precision and high-energy particle beam energy reduction of a cyclotron.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

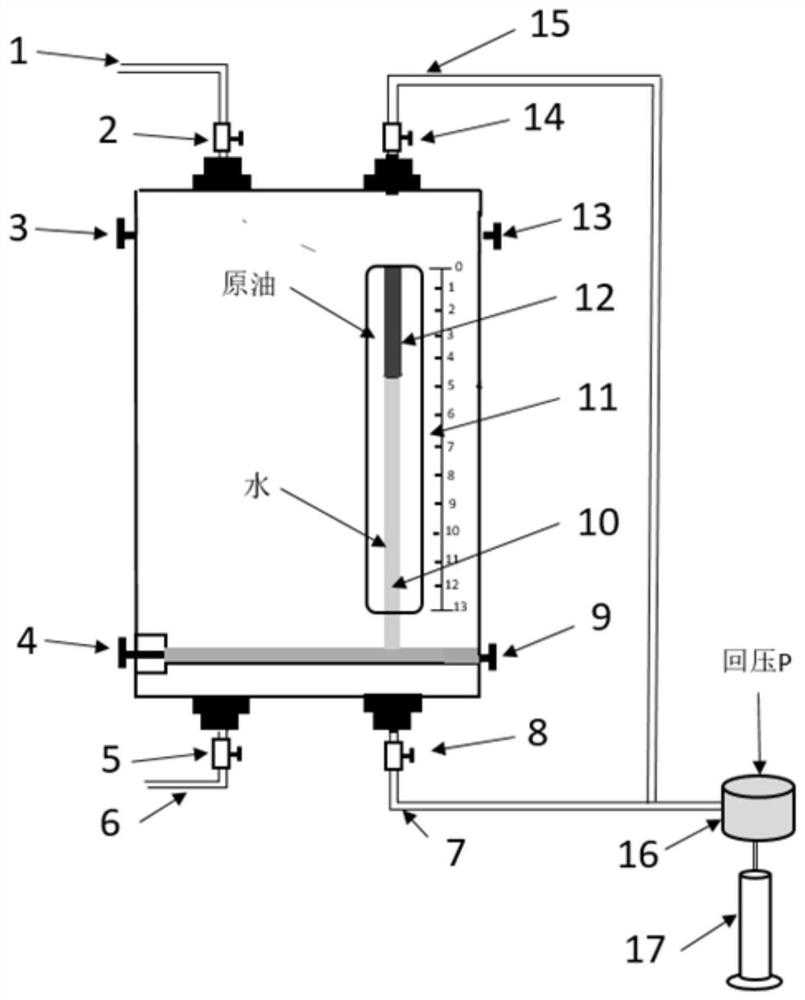

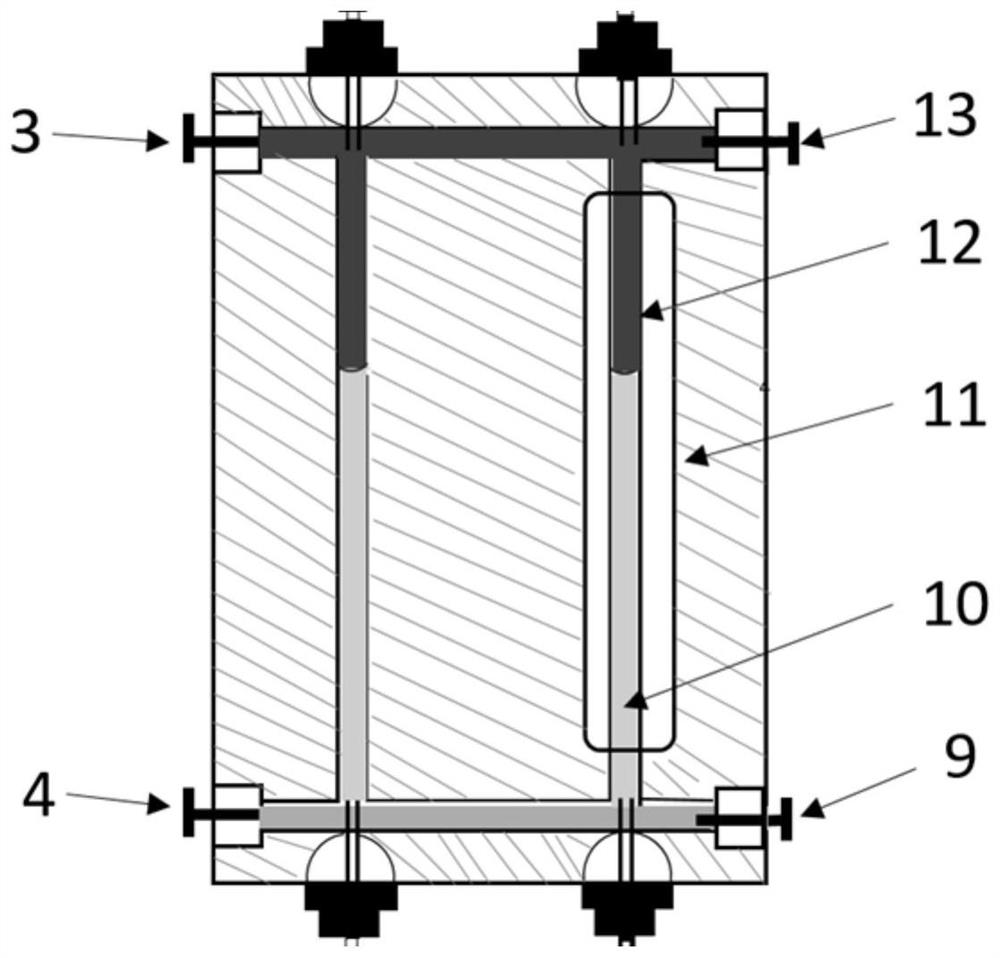

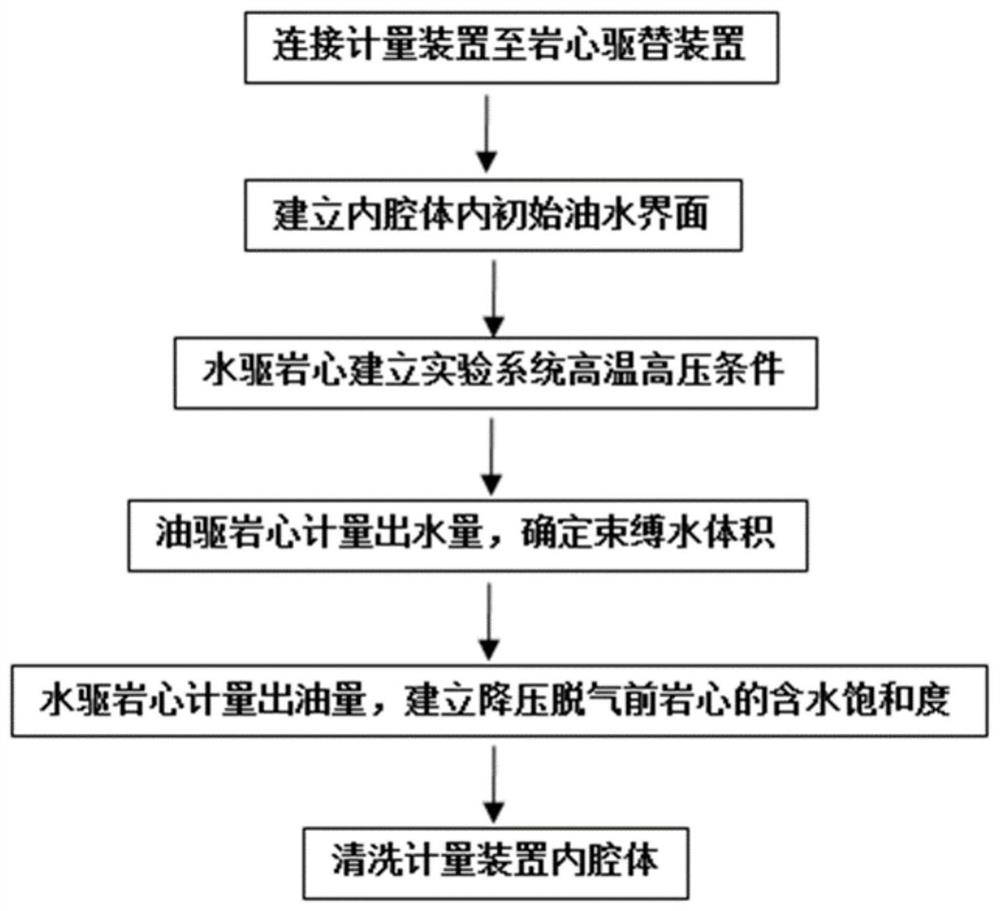

High-temperature and high-pressure visual oil-water metering device and method

PendingCN113933478ANo outgassingGuaranteed gas stateEarth material testingPermeability/surface area analysisRock coreOil water

The high-temperature and high-pressure visual oil-water metering device comprises a metering main body, the metering main body is provided with a metering cavity, the metering cavity is a #-shaped channel inner cavity which is communicated with one another, and the #-shaped channel inner cavity comprises an upper transverse metering channel, a lower transverse metering channel, a left longitudinal metering channel and a right longitudinal metering channel. The #-shaped inner cavity in the structural design plays a role of a U-shaped pipe in the experiment process, the physical phenomenon of automatic gravity differentiation of oil and water due to density difference is fully utilized, high-pressure gas-containing crude oil is metered at the upper part of the inner cavity, and high-temperature and high-pressure water is metered at the lower part of the inner cavity. The pressure of the high-pressure gas-containing crude oil and the high-temperature and high-pressure water outlet pipe is controlled to be the simulated oil reservoir pressure through the back-pressure valve, so that the pressure of the whole metering system is always higher than the gas bubble point pressure, the crude oil degassing phenomenon is avoided, the crude oil in the rock core is always kept in a gas-containing state, and a guarantee is provided for the subsequent rock core depressurization and degassing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Forming three-dimensional structure from receiver

ActiveUS9248619B2Easy to produceWeight and mass can be reducedLayered product treatmentBox making operationsEngineeringElectrical and Electronics engineering

A method for forming a three-dimensional structure includes depositing a first pattern of thermoplastic toner particles onto a first surface of a receiver to form a plurality of spaced-apart stacks of toner particles that extend above the first surface of the receiver. The receiver is bent so that non-overlapping first and second portions of the receiver are defined. At least part of a surface of the receiver in the second portion is brought into contact with the deposited stacks of toner particles. The toner particles are fused to bind the second portion to the first portion and provide a selected spacing between the first portion and the second portion.

Owner:EASTMAN KODAK CO

Forming a structural laminate that resists stress

ActiveUS9248636B2Easy to produceImprove mechanical propertiesLamination ancillary operationsLayered product treatmentEngineeringSheet material

A structural laminate having a selected resistance to a first stress applied in a selected first stress direction relative to the laminate is formed from first and second sheets. A selected volume of toner is deposited on the first sheet to form a deposited toner pattern, the deposited toner pattern being disposed over a selected first surface area of the first sheet and extending normal to the first sheet by a selected first height. The second sheet, or toner thereon, is brought into contact with the deposited toner pattern. The deposited toner pattern is fixed to produce a fixed toner pattern that adheres the second sheet to the first sheet, in that way forming the laminate. The fixed toner pattern includes one or more first contiguous regions of toner extending in a direction within about 45° of the stress direction, so that the contiguous regions resist the applied stress.

Owner:EASTMAN KODAK CO

Plate electrode fixing structure

ActiveCN102290312BNo outgassingWide distribution of uniformityElectric discharge tubesEngineeringPolycarbonate

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Core material for vacuum heat insulating material formed from cured foam of melamine resin, vacuum heat insulating material using the same, and production method thereof

InactiveCN104838196BSave the unit price of preparationImprove long-term durabilityThermal insulationSynthetic resin layered productsMelamineMelamine resin

Owner:LG HAUSYS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com