Coating for inner surface of sand mold of high-temperature alloy mold casting and using method

A high-temperature alloy and inner surface technology, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problems of high temperature coating outgassing, use, high temperature resistance, etc., to reduce thickening tension and achieve good finish , practical and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

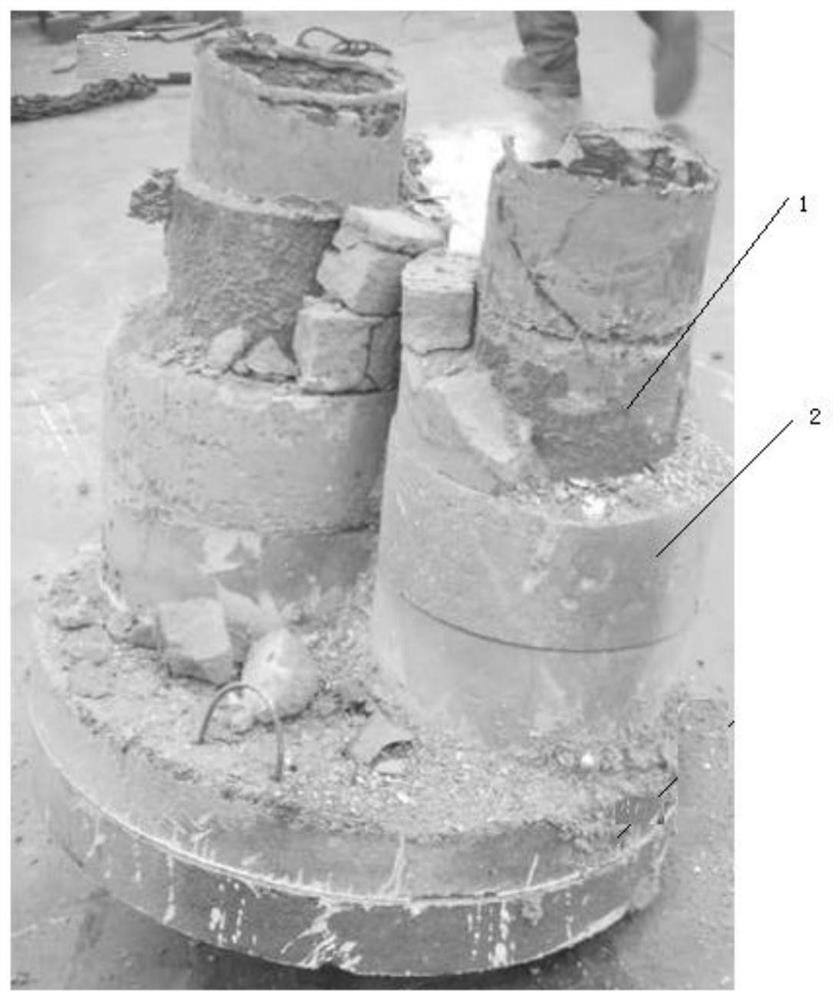

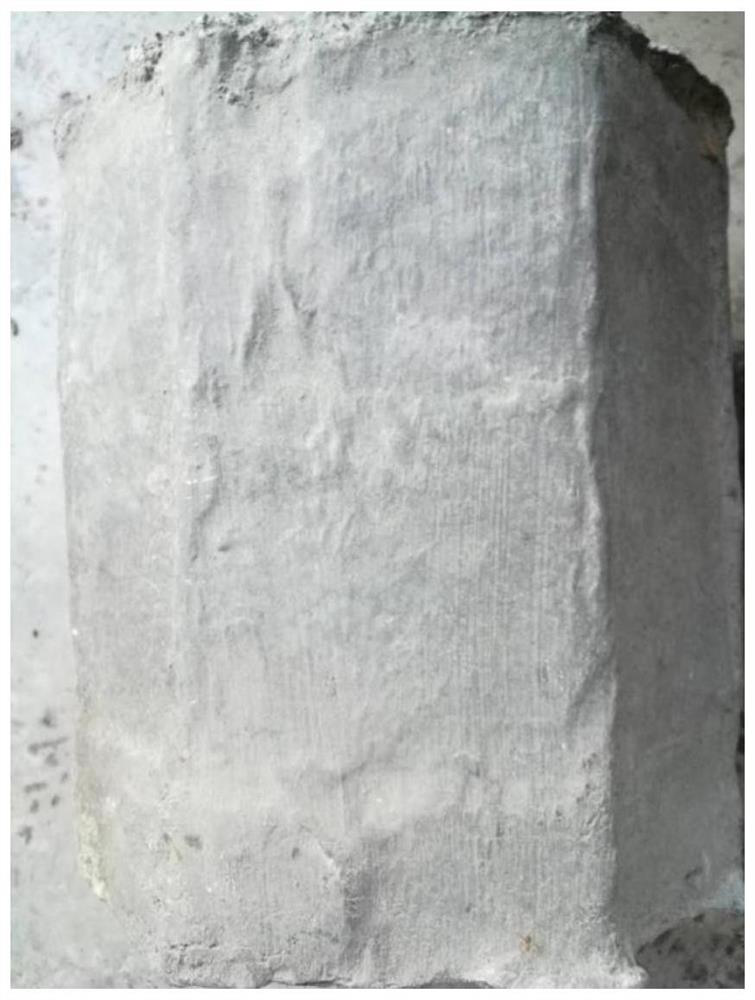

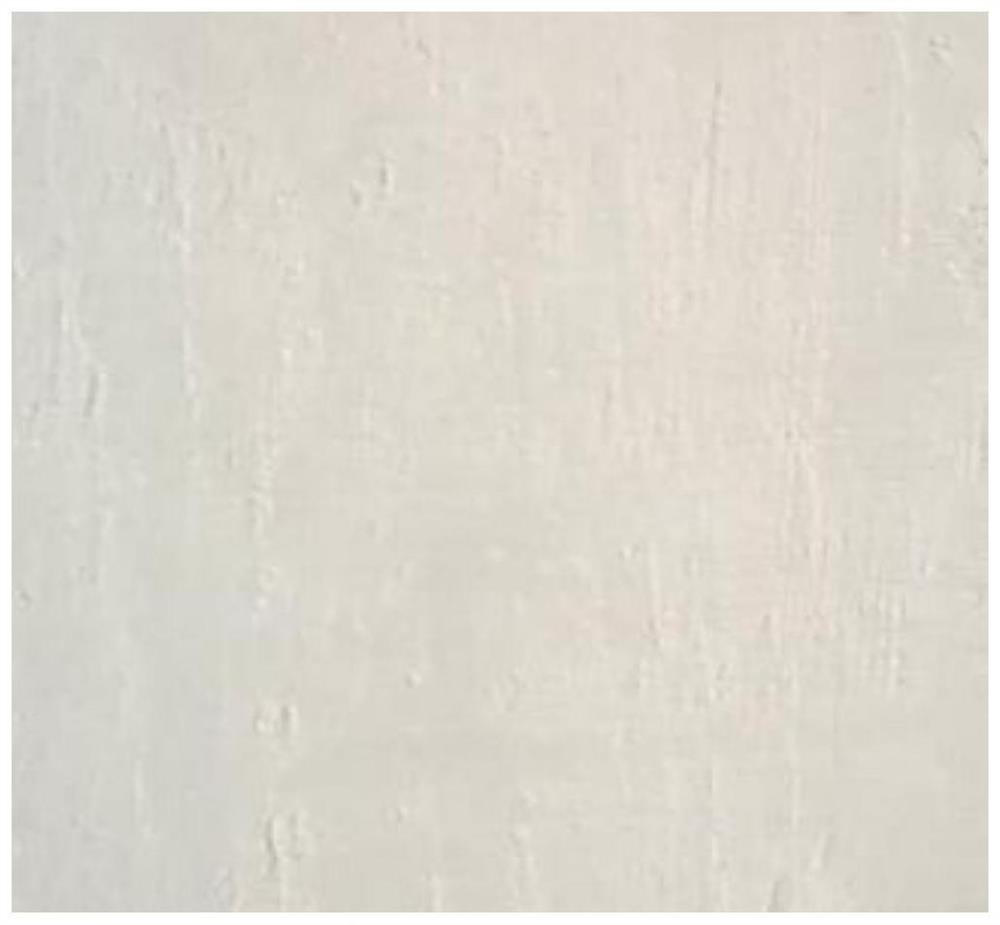

[0037] Such as figure 1 , figure 2 and image 3 As shown, the present invention is a sand mold inner surface coating for superalloy mold castings, consisting of the following components: 57 parts of zirconium powder;

[0038] 35 parts of aluminum oxide fine powder;

[0039] 40 parts of silica sol;

[0040] And aluminum sol 5 parts.

[0041] Use process: Stir 57 parts of zircon powder and 35 parts of aluminum oxide fine powder to obtain mixed powder; use a mesh sieve to sieve the mixed powder obtained above to obtain fine mixed powder, and fully stir the fine mixed powder after sieving It is convenient to use in the next step; 40 parts of silica sol and 5 parts of aluminum sol are mixed to obtain a colloidal mixture, and absolute alcohol is added to the colloidal mixture, stirred evenly, and reacted at room temperature for at least 4 hours to obtain a flocculent colloid, Stir evenly again; mix the fine mixed powder and the colloid evenly to obtain a qualified high-tempera...

Embodiment 2

[0044] Such as figure 1 , figure 2 and image 3 Shown, the present embodiment is based on embodiment 1, and the present invention is superalloy mold casting sand mold inner surface coating,

[0045] Composed of the following ingredients: 60 parts of zircon powder;

[0046] 34 parts of aluminum oxide fine powder;

[0047] 20 parts of silica sol;

[0048] And 10 parts of aluminum sol.

[0049]Use process: Stir 60 parts of zircon powder and 34 parts of aluminum oxide fine powder to obtain mixed powder; use a mesh sieve to sieve the mixed powder obtained above to obtain a fine mixed powder, and fully stir the fine mixed powder after sieving It is convenient to use in the next step; 20 parts of silica sol and 10 parts of aluminum sol are mixed to obtain a colloidal mixture, and absolute alcohol is added to the colloidal mixture, stirred evenly, and reacted at room temperature for at least 4 hours to obtain a flocculent colloid, Stir evenly again; mix the fine mixed powder an...

Embodiment 3

[0052] Such as figure 1 , figure 2 and image 3 Shown, present embodiment is based on embodiment 1 and 2, and the present invention is superalloy mold casting sand mold internal surface coating,

[0053] Composed of the following ingredients: 70 parts of zircon powder;

[0054] 24 parts of aluminum oxide fine powder;

[0055] 25 parts of silica sol;

[0056] And aluminum sol 7 parts.

[0057] Use process: Stir 70 parts of zircon powder and 24 parts of aluminum oxide fine powder to obtain a mixed powder; use a mesh sieve to sieve the mixed powder obtained above to obtain a fine mixed powder, and fully stir the fine mixed powder after passing the sieve It is convenient to use in the next step; 25 parts of silica sol and 7 parts of aluminum sol are mixed to obtain a colloidal mixture, and absolute alcohol is added to the colloidal mixture, stirred evenly, and reacted at room temperature for at least 4 hours to obtain a flocculent colloid, Stir evenly again; mix the fine mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com