High Performance Dam Portland Cement

A Portland cement, high-performance technology, applied in the field of cement, can solve the problems of increasing the cost of cement and being unfavorable to environmental protection, and achieve the effects of saving energy, being beneficial to environmental protection, and controlling cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with examples.

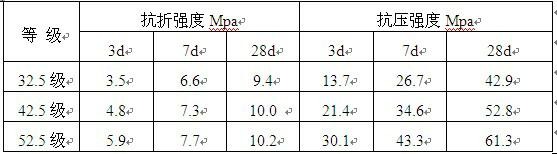

[0012] The present invention is divided into 32.5 grades, 42.5 grades and 52.5 grades according to cement strength grades. The specific implementation schemes and performance indicators of these three grades are given below.

[0013] 1. The cement formulations (%) of the three grades are:

[0014] grade Clinker fly ash Mineral powder + desulfurization gypsum natural plaster grinding aid Level 32.5 26.4 16.0 54.1 3.0 0.5 Level 42.5 35.0 11.5 50.0 3.0 0.5 Level 52.5 44.0 7.5 45.0 3.0 0.5

[0015] The quality requirements of each raw material are:

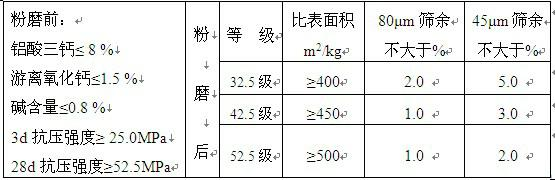

[0016] 1. General Portland cement clinker

[0017]

[0018] 2. Fly ash is required to reach grade II or above, in which the loss on ignition is ≤7.5%, the 28d compressive strength activity index is ≥75%, and the specific surface area after grinding is ≥750 m 2 / kg;

[0019] 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com