Construction method for tying and lacing main body structure and filler wall

A technology of the main structure and construction method, which is applied in the direction of walls, building components, building structures, etc., can solve the problems that the block modulus of the infill wall cannot be satisfied, the decoration stage is not considered, and the precision requirements are high, so as to improve construction efficiency and reduce The process of welding steel bars and the effect of strengthening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A method for constructing a tie bar for a main structure and a filled wall, comprising the following steps:

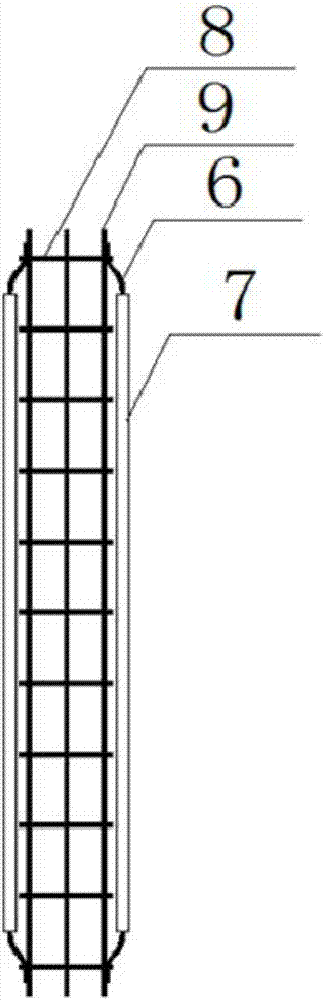

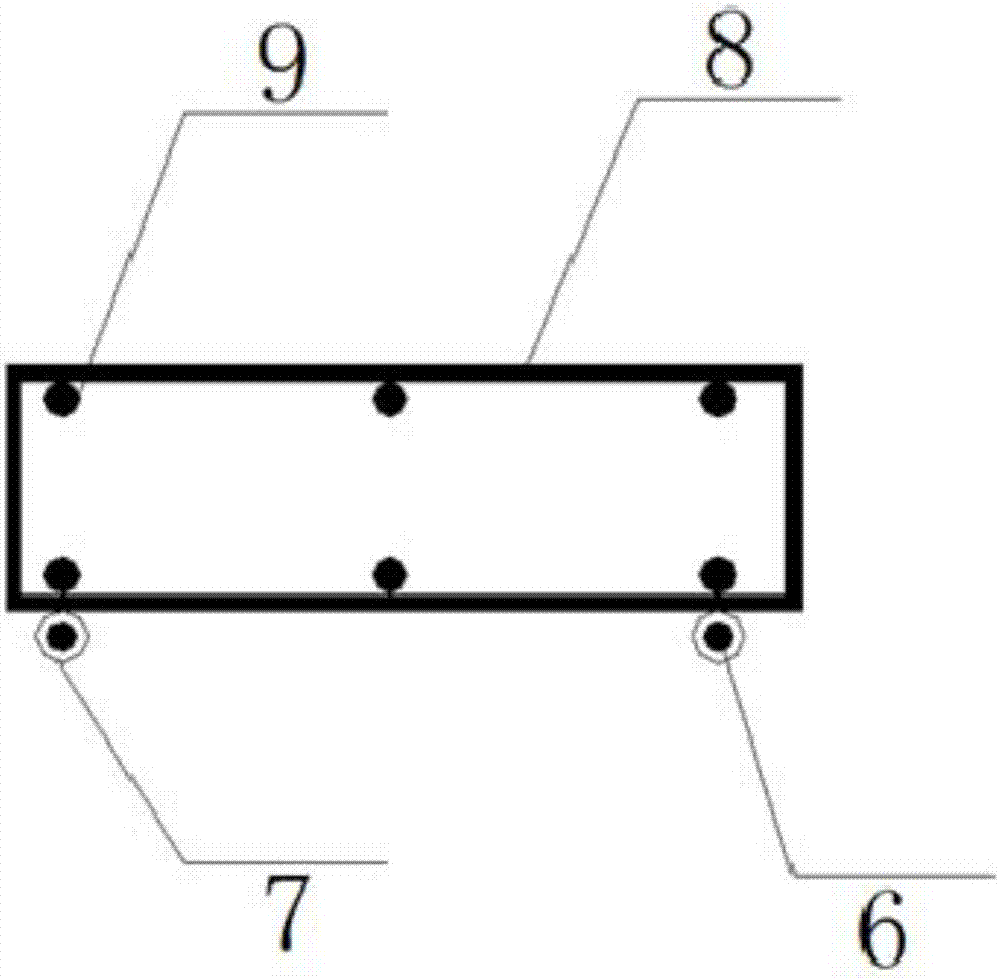

[0041] 1)—4) steps, such as figure 2 with image 3 Shown: 1) Carry out reinforcement blanking according to the height of the wall, and process pre-embedded reinforcement 6 in the shape of "Ji";

[0042] 2) Set the pearl cotton tube 7 on the straight section of the pre-embedded steel bar 6, and seal the two ends with adhesive tape;

[0043] 3) Welding the bent section of the pre-embedded reinforcement 6 with the horizontal stirrup 8 and the vertical reinforcement 9 of the main structural reinforcement;

[0044] 4) install the main structure formwork, make the pearl cotton tube 7 close to the formwork, and pour the main structure concrete;

[0045] 5) The concrete strength grade of the main structure meets the design requirements, and the formwork is removed to prepare for the next step of masonry filling walls;

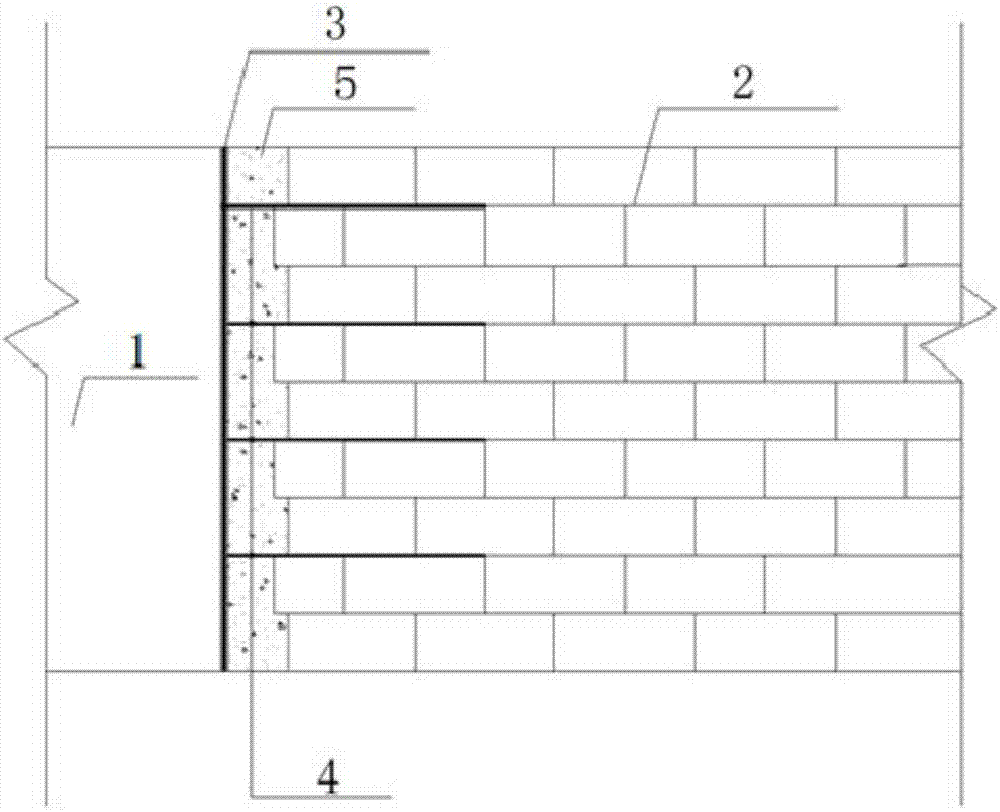

[0046] 6) If figure 1 As shown in the drawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com