Core material for vacuum heat insulating material formed from cured foam of melamine resin, vacuum heat insulating material using the same, and production method thereof

A vacuum insulation material, melamine technology, applied in heat exchange equipment, mechanical equipment, pipeline protection through heat insulation, etc., can solve the problems of reduced molding characteristics, reduced heat insulation performance, reduced durability, etc., and achieve the effect of preventing the reduction of vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

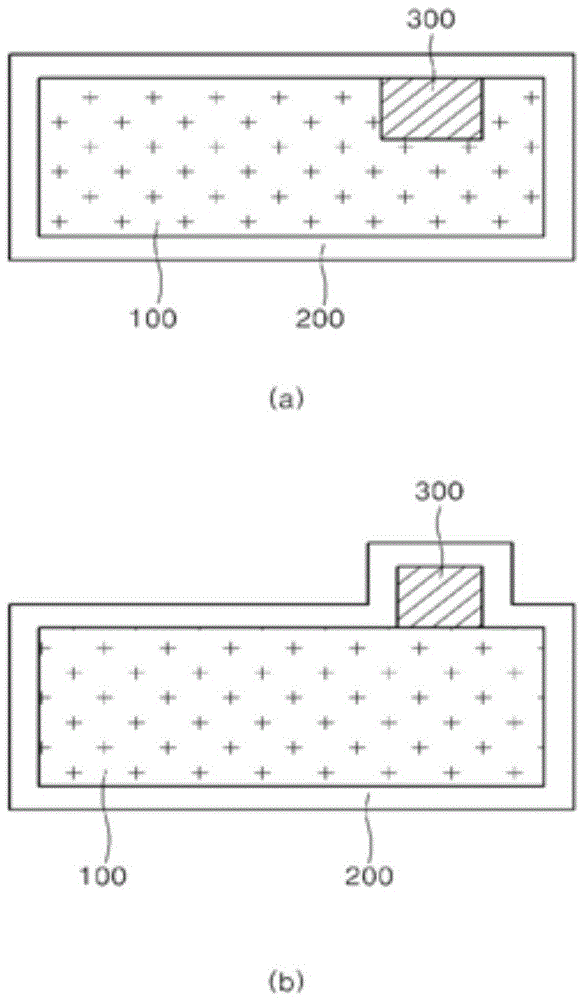

[0057] In another embodiment of the present invention, a method for preparing a vacuum thermal insulation material is provided, and the preparation method for the vacuum thermal insulation material includes the following steps: preparing a foam formed from a melamine resin cured foam with an open cell content (Open Cell Content) of more than 80% Steps of core material for vacuum insulation material; steps of removing residual substances by applying pressure of 0.5Pa to 10Pa for 10 minutes to 200 minutes at a temperature of 50°C to 250°C to the above-mentioned core material; and wrapping with a skin material The step of vacuum packaging is carried out after covering the above-mentioned core material.

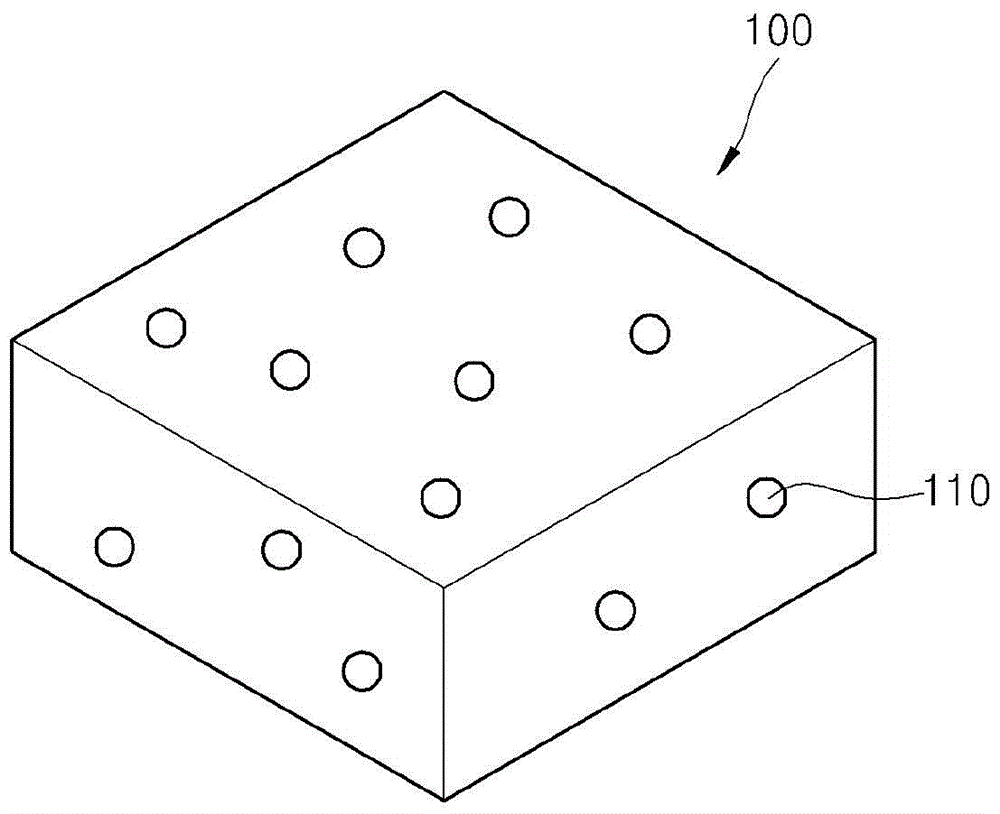

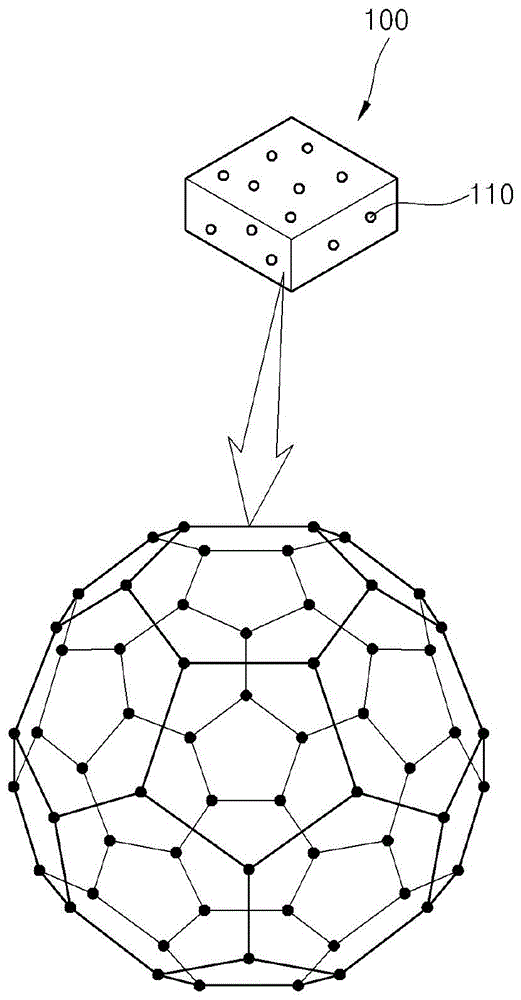

[0058] The core material formed by the above-mentioned melamine resin-cured foam is formed by mixing melamine-formaldehyde resin, curing agent, foaming agent and other additives at high speed and curing at a temperature above normal temperature, and As a product of the reaction, ...

Embodiment 1

[0063] The average particle diameter of the bubbles was 100 μm, the porosity was 95%, and the compressive strength was 1.5 kgf / cm 2 The melamine resin cured foam is made into a size of 8 × 190 × 250 mm (thickness × width × length) and used as a core material for vacuum insulation materials. Then, the outer skin is formed from the structure of polyvinylidene chloride (PVDC) / polyethylene terephthalate (PET) film (PET) 12 μm, nylon (Nylon) film 25 μm, aluminum foil 7 μm and linear low density polyethylene (LLDPE) film 50 μm structure Material. Next, 25 g of quicklime (CaO) having a purity of 95% was put into a pouch to prepare two absorbent materials and inserted on the surface of the core material. Then, under the temperature condition of 150°C, all residual gas of 5Pa was exhausted, the core material was inserted into the bag body, and then sealed in a vacuum state of 10Pa, thereby preparing the vacuum heat insulating material of the present invention.

Embodiment 2

[0065] Except that the average particle diameter of the bubbles is 100 μm, the porosity is 90%, and the compressive strength is 1.2 kgf / cm 2 The melamine resin cured foam was made into a size of 8×190×250mm (thickness×width×length) and used as a core material for vacuum insulation materials, and a vacuum insulation material was prepared according to the same conditions as in Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com