Magnetic bearing device

A technology of magnetic bearings and rolling bearings, applied in bearings, shafts and bearings, rolling contact bearings, etc., can solve the problems of unstable magnetic bearing control system and complicated controller, and achieve simplified structure, stable control objects, and reduced heat generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

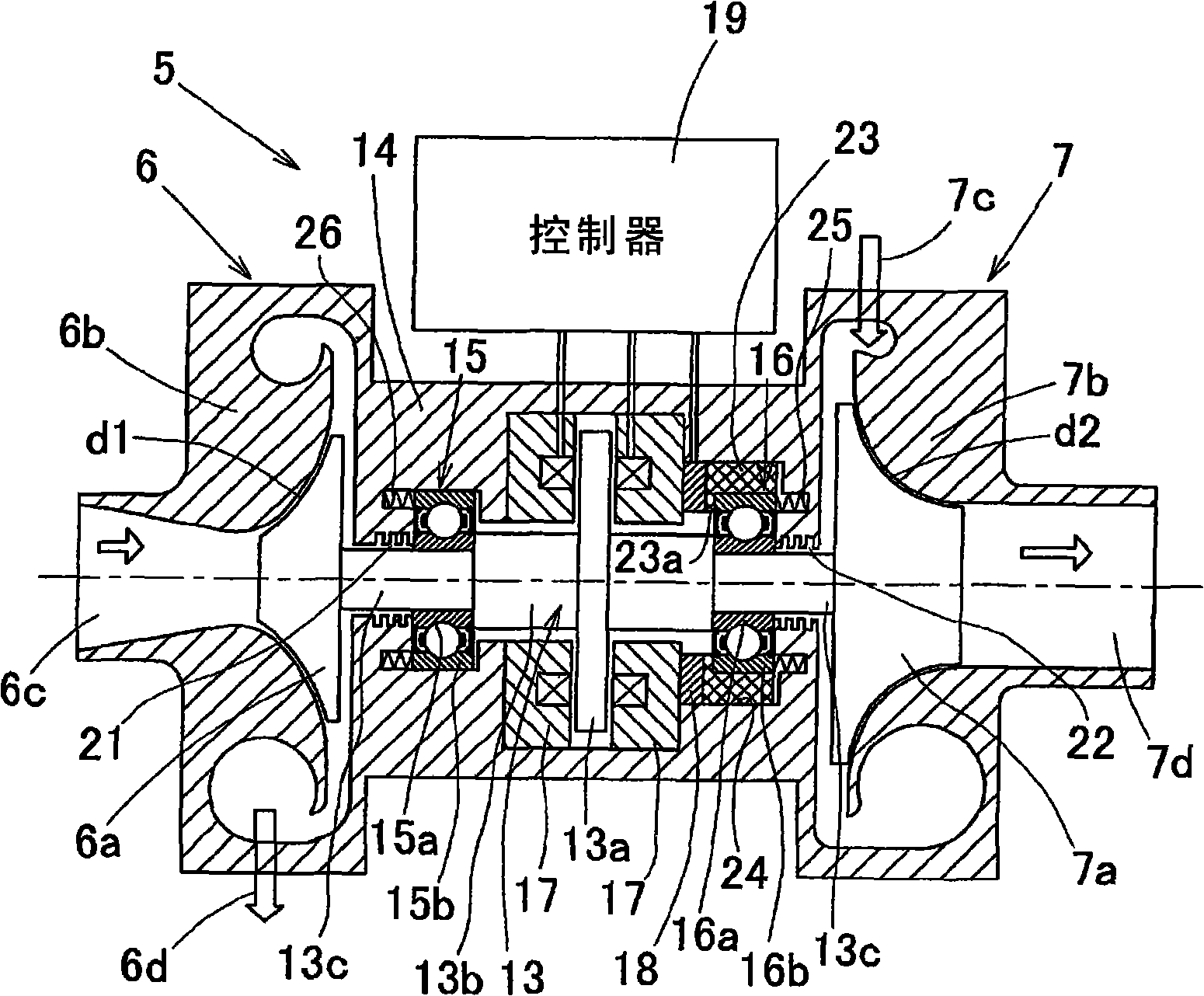

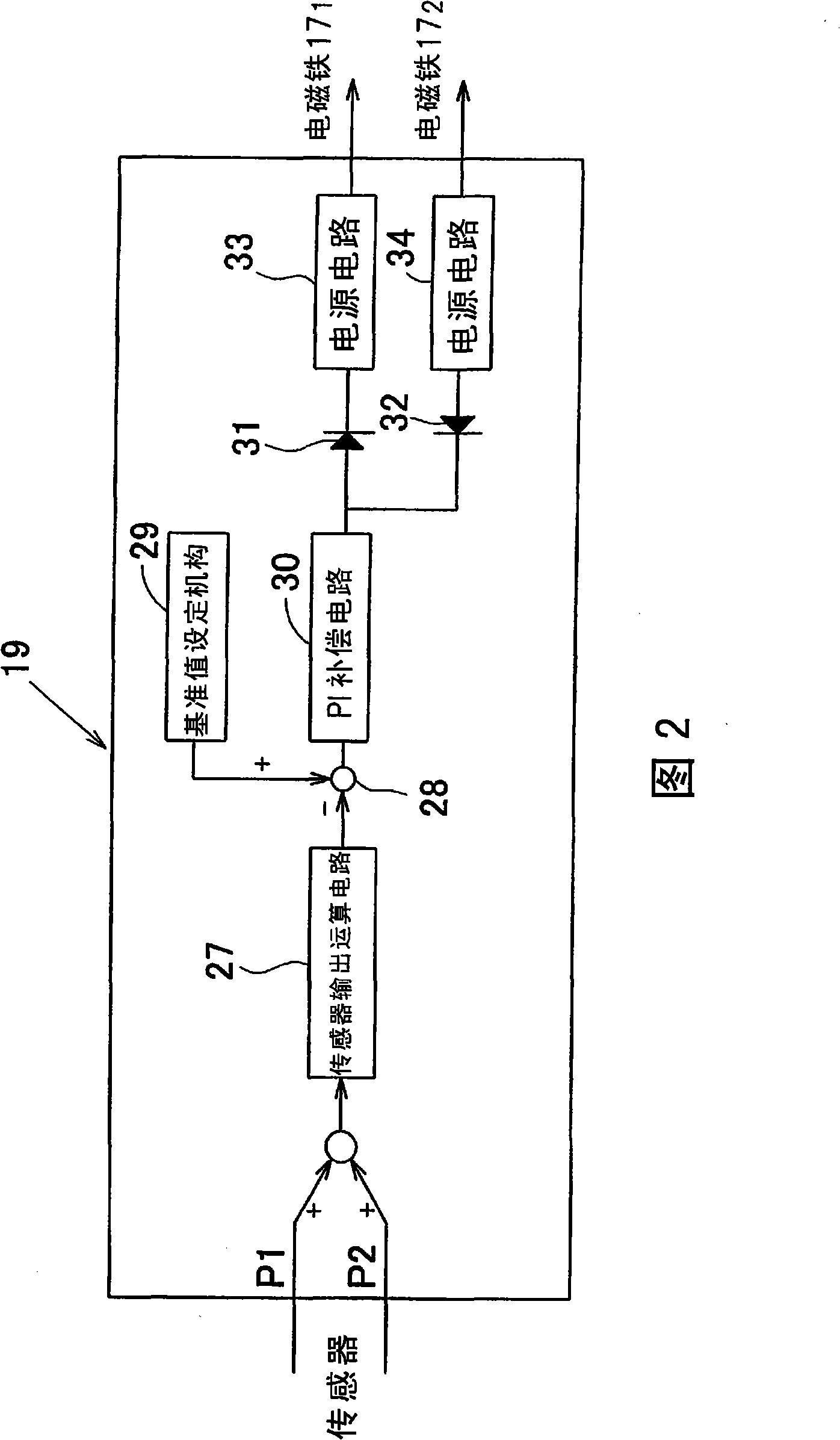

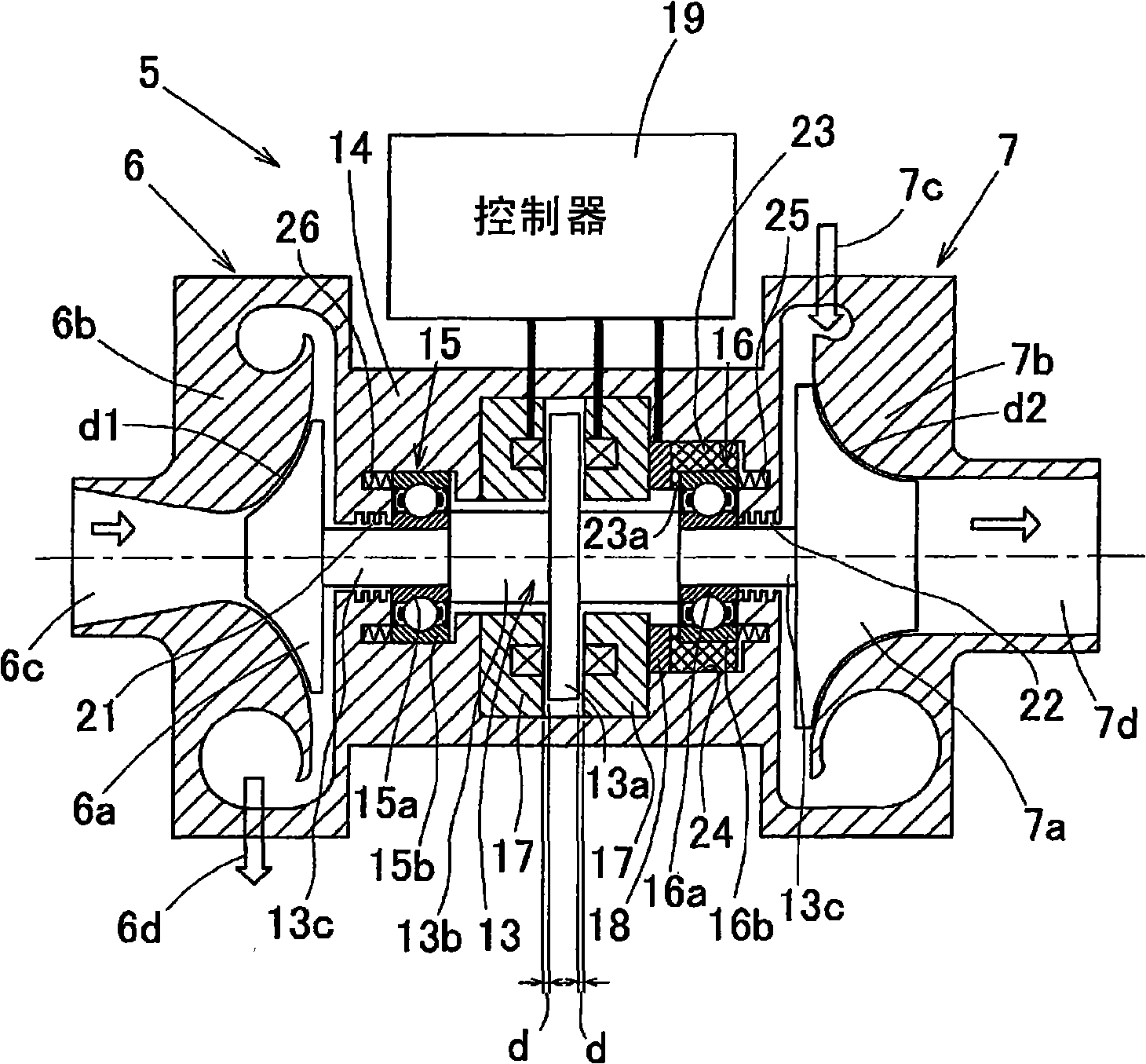

[0048] combine figure 1 A first embodiment of the present invention will be described with reference to FIG. 2 . figure 1 A sectional view showing a turbine assembly 5 incorporating the magnetic bearing device of the present invention. The turbine assembly 5 constitutes a compression-expansion turbine system, which includes a compressor 6 and an expansion turbine 7 , the compressor blades 6 a of the compressor 6 and the turbine blades 7 a of the expansion turbine 7 are mounted on both ends of the main shaft 13 . In addition, the compressor blade 6a is driven by power generated by the turbine blade 7a, and no separate drive source is provided.

[0049] The compressor 6 includes a casing 6b facing the compressor blade 6a through a small gap d1, and the air sucked in the axial direction from the suction port 6c in the center is compressed by the compressor blade 6a, and the air sucked in the axial direction from the suction port 6c in the center is compressed, not shown), disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com