Method for building integrated cantilever structure composite road adapted for precipitous mountainous area

A monolithic and mountainous technology, applied in the direction of roads, roads, infrastructure engineering, etc., can solve the problems of large number of masonry retaining wall projects, high height of cut slopes, difficulty in greening, etc., to protect the natural ecological environment and reduce land occupation area, to avoid the effect of accelerated weathering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, this embodiment is applicable to the case where the geological conditions are bedrock and mountains.

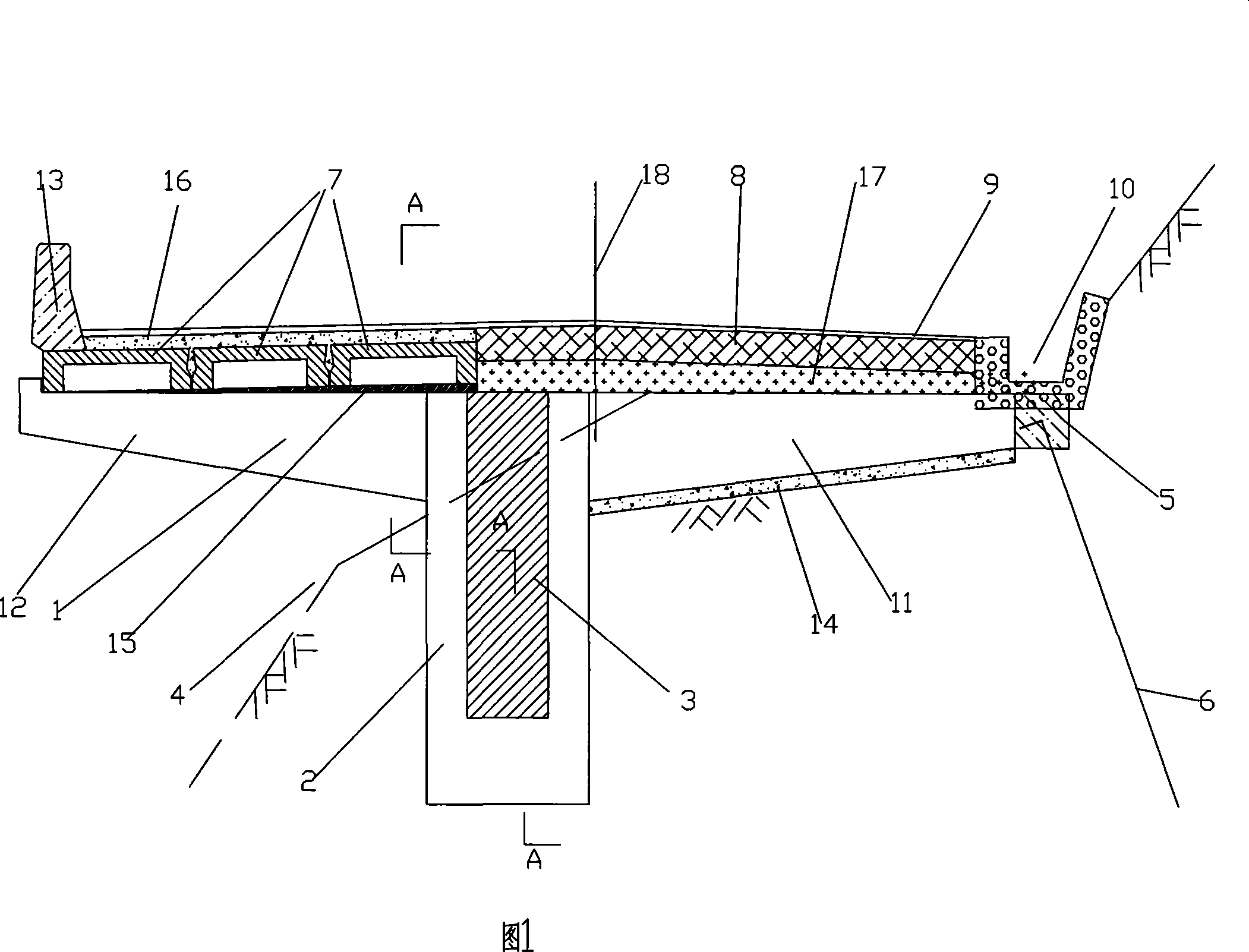

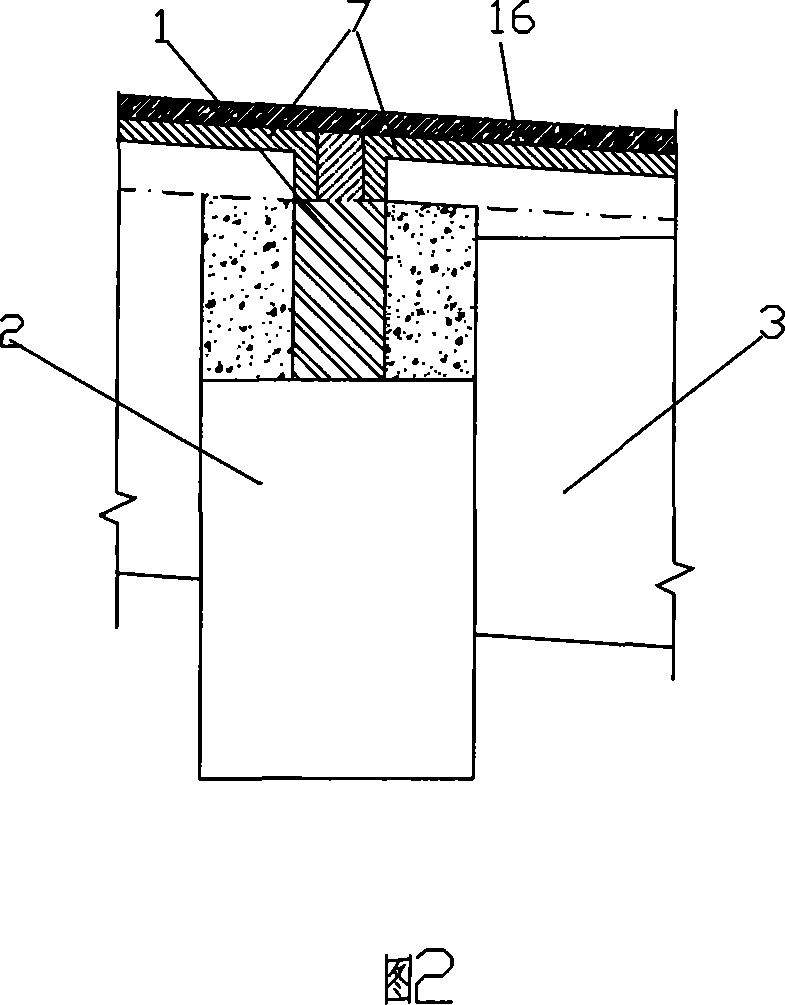

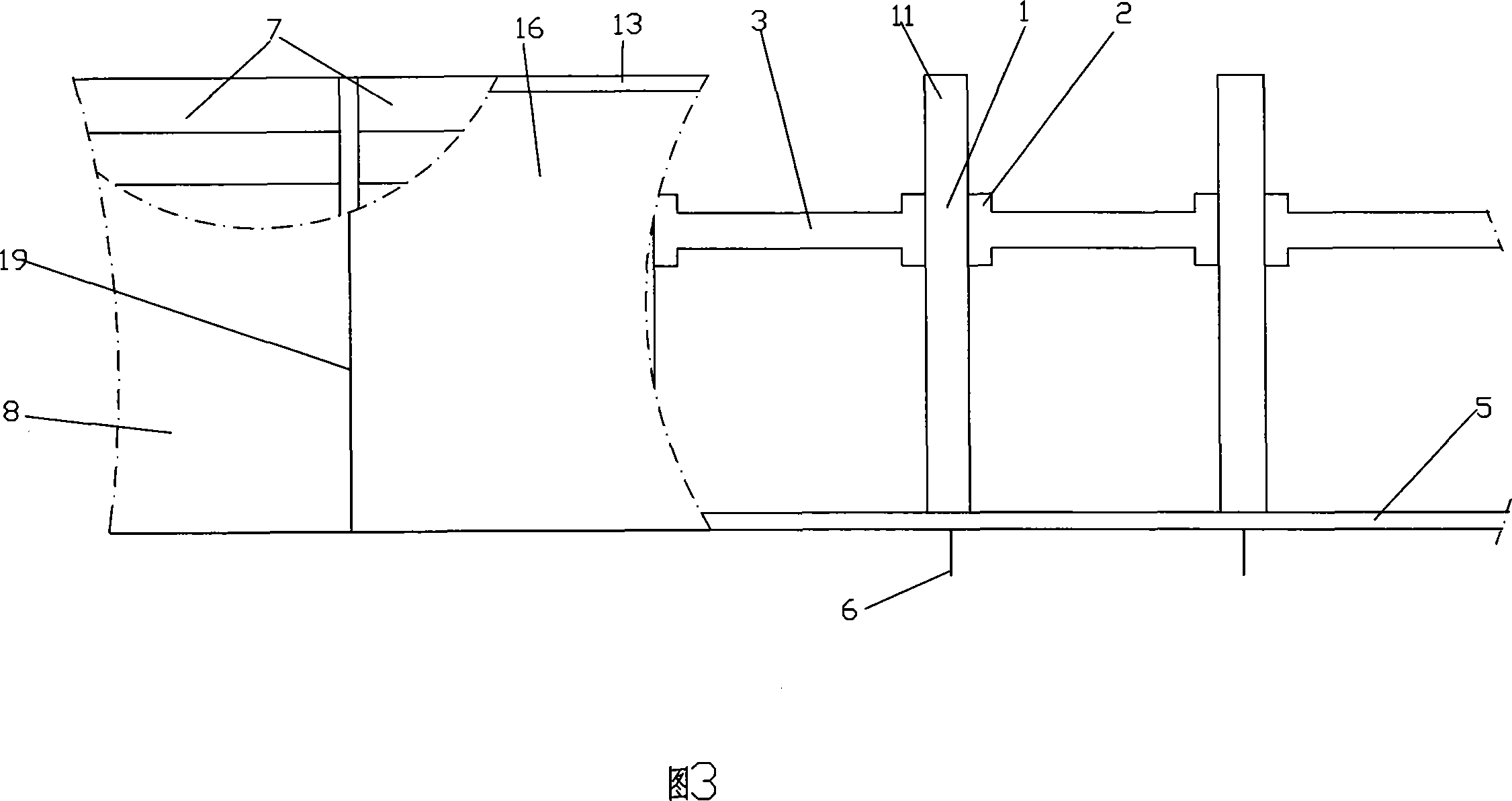

[0028] Fig. 1 is a schematic diagram of the structure of the present invention in use, Fig. 2 is a cross-sectional view along A-A of Fig. 1, and Fig. 3 is a top plan view of the present invention, as shown in the figure: the integral cantilever structure composite road suitable for steep mountainous areas of the present embodiment The construction method includes the following construction procedures:

[0029] a. Cast reinforced concrete columns 2 at set intervals along the road direction, cast in-situ reinforced concrete walls 3 between adjacent columns 2, and pour the walls 3 and the columns 2 into one body, and pour into one body with the bedrock of the mountain body 4;

[0030] b. Prefabricated reinforced concrete cantilever beam 1, the prefabricated cantilever beam 1 is arranged on the column 2 along the cross-sectional direction of the road and is p...

Embodiment 2

[0036] Embodiment 2. This embodiment is applicable to the situation where the geological conditions are non-bedrock mountains, and of course it can also be used for situations where the geological conditions are good.

[0037] Fig. 4 is a schematic structural diagram of Embodiment 2 of the present invention, as shown in the figure: the difference between this embodiment and Embodiment 1 is: a counterweight retaining wall 20 is built on the upper part of the longitudinal beam 5 and an anchor rod 6 is added for anchoring; one end of the anchor rod 6 is anchored In the mountain body 4, the other end is poured into the coupling body of the cantilever 1 and the longitudinal beam 5. Due to poor geological conditions, moment arm 19 and pouring counterweight retaining wall 20 are set to increase the anti-overturning moment of the structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com