Flexible material used for modifying concrete as well as preparation process and application of flexible material

A flexible material and concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. Reuse, process and make easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this example,

[0031] In this example, the composition of the prepared flexible material by mass is: 35% rubber powder, 35% colloidal particles, 1% polypropylene fiber, 5% fly ash, and 24% mineral admixture. The mineral admixture is mineral powder. The rubber powder is a solid powder obtained by removing the zinc stearate contained on the surface of the rubber powder by a strong alkali solution, and the colloidal particle is a solid obtained by removing the zinc stearate contained on the surface of the rubber particles by a strong alkali solution particles. During actual preparation, the content of each component in the flexible material can be adjusted accordingly according to specific needs.

[0032]In actual preparation, the mineral admixture may also be slag powder.

[0033] In this embodiment, the particle size of the rubber powder is 40 mesh to 200 mesh, the particle size of the rubber particles is 0.45 mm to 5 mm, the length of the polypropylene fiber is 2...

Embodiment 2

[0071] In this example, the composition, proportion and preparation process of the prepared flexible material are the same as those in Example 1.

[0072] In this example, the difference between the prepared semi-rigid concrete and Example 1 is that the quality of the replaced fine aggregate is 30% of the total mass of the fine aggregate.

[0073] In this embodiment, the remaining components and proportions of the prepared semi-rigid concrete are the same as those in Embodiment 1.

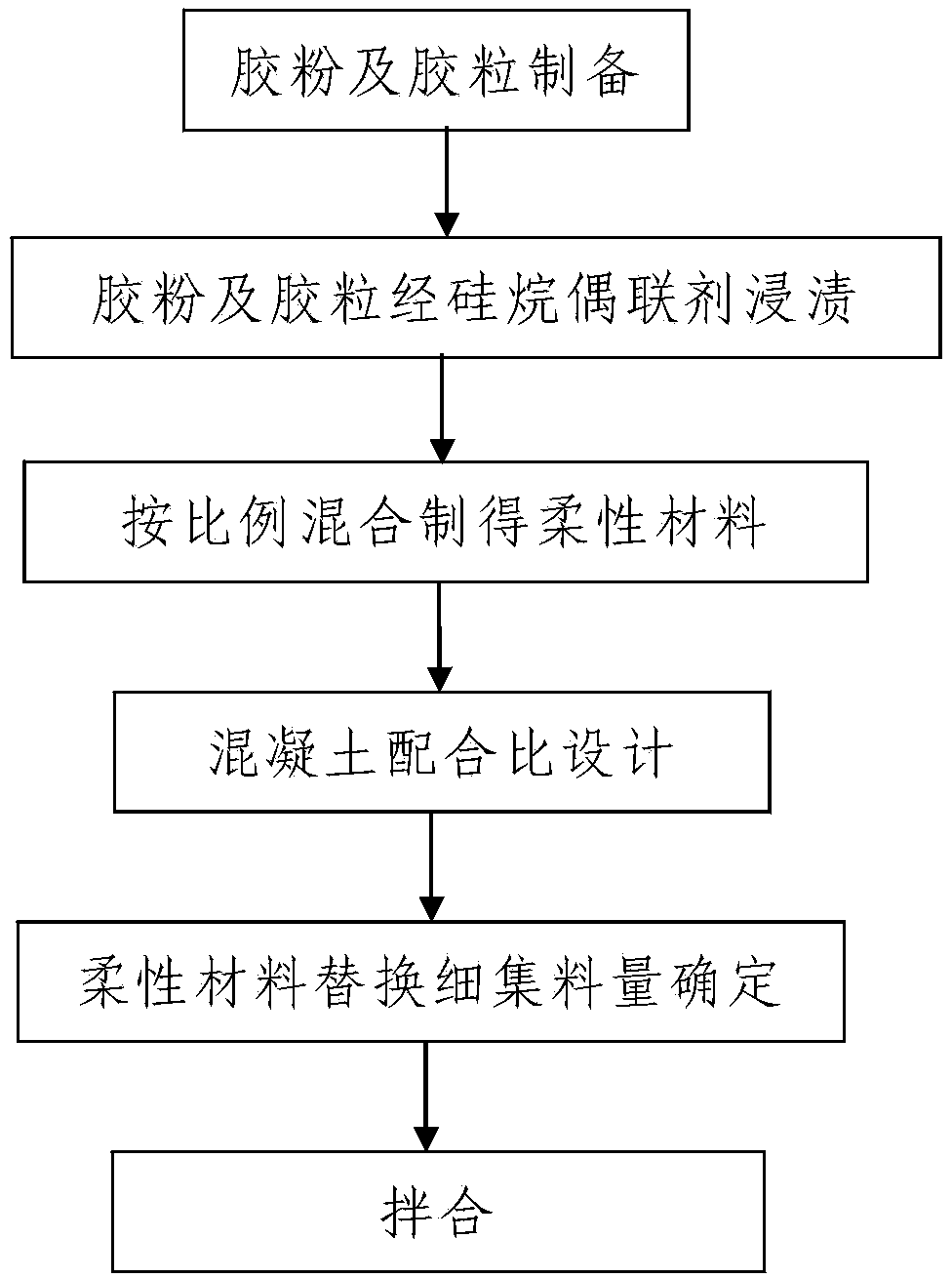

[0074] In this example, using figure 1 The preparation process shown is for the preparation of semi-rigid concrete, and the preparation process steps and process parameters adopted are the same as those in Example 1.

[0075] In the present embodiment, after the preparation of the semi-rigid concrete is completed, the slump and bulk density of the prepared concrete and the compressive strength of the constructed concrete structure are tested. The test results are as follows: the slump is 120mm, an...

Embodiment 3

[0077] In this example, the composition, proportion and preparation process of the prepared flexible material are the same as those in Example 1.

[0078] In this example, the difference between the prepared semi-rigid concrete and Example 1 is that the quality of the replaced fine aggregate is 45% of the total mass of the fine aggregate.

[0079] In this embodiment, the remaining components and proportions of the prepared semi-rigid concrete are the same as those in Embodiment 1.

[0080] In this example, using figure 1 The preparation process shown is for the preparation of semi-rigid concrete, and the preparation process steps and process parameters adopted are the same as those in Example 1.

[0081] In the present embodiment, after the preparation of the semi-rigid concrete is completed, the slump and bulk density of the prepared concrete and the compressive strength of the constructed concrete structure are tested. The test results are as follows: the slump is 130mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com