A high-toughness and atmospheric corrosion-resistant flux-cored welding wire and its preparation method

An atmospheric corrosion-resistant, flux-cored welding wire technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as large welding spatter, corrosion of vehicle steel structures, and high spattering work intensity, and achieve reasonable component design and durability. The effect of excellent atmospheric corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

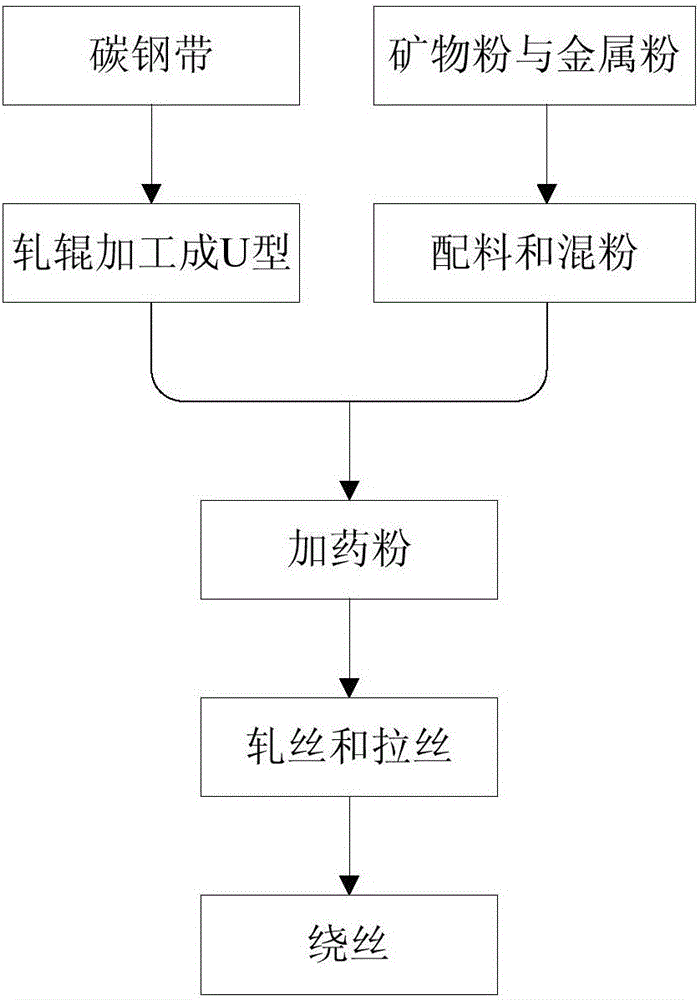

Method used

Image

Examples

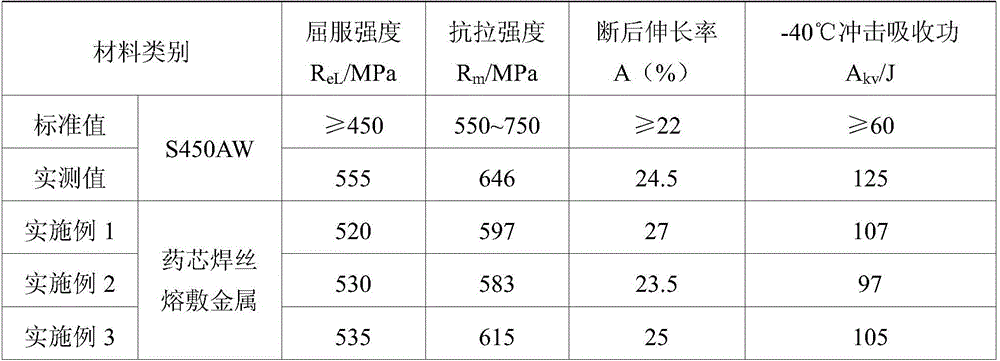

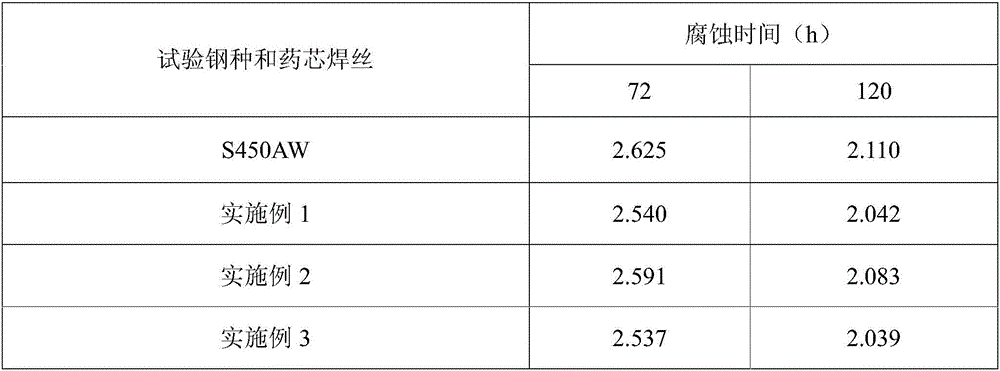

Embodiment 1

[0040] The drug core composition of embodiment 1:

[0041]35.0% rutile, 4.0% quartz sand, 1.5% magnesia, 6.0% aluminosilicate, 3.0% sodium fluoride, 1.5% sodium oxide, 10.0% low carbon ferromanganese, 4.0% ferrosilicon, 5.0% Ni, 4.0% Cr, 2.0% Cu, 3.5% ferro-titanium, a total of 1.5% ferromolybdenum and ferro-vanadium, 19% iron powder.

Embodiment 2

[0042] The drug core composition of embodiment 2:

[0043] 32.0% rutile, 5.0% quartz sand, 2.0% magnesia, 8.0% aluminosilicate, 2.5% sodium fluoride, 2.0% sodium oxide, 9.0% low carbon ferromanganese, 3.5% ferrosilicon, 4.0% Ni, 3.5% Cr, 1.5% Cu, 2.5% ferro-titanium, a total of 1.0% ferromolybdenum and ferro-vanadium, 23.5% iron powder.

Embodiment 3

[0044] The drug core composition of embodiment 3:

[0045] 30.0% rutile, 6.0% quartz sand, 2.5% magnesia, 10.0% aluminosilicate, 2.0% sodium fluoride, 2.5% sodium oxide, 8.0% low carbon ferromanganese, 5.0% ferrosilicon, 4.5% Ni, 4.5% Cr, 2.5% Cu, 3.0% ferro-titanium, a total of 1.5% ferromolybdenum and ferro-vanadium, 18% iron powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com