Denitrification slow-release carbon source material for leaching type superimposed wetland and preparation method of denitrification slow-release carbon source material

A slow-release carbon source and denitrification technology, which is applied in chemical instruments and methods, anaerobic digestion treatment, special compound water treatment, etc., can solve the problems that the release cannot be effectively controlled, the scope of use is limited, and the mechanical strength is not high. , to achieve the effect of ensuring the water permeability efficiency of the wetland, ensuring the water permeability efficiency, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh the fruit shell and polycaprolactone in proportion, stir and mix, and the mixing time is 3 minutes to obtain a mixture; take the mixture, melt it at 60 ° C, continue stirring until the material is completely melted, and obtain a molten material; The molten material is poured into the mold and molded into a spherical structure to obtain the carbon source material.

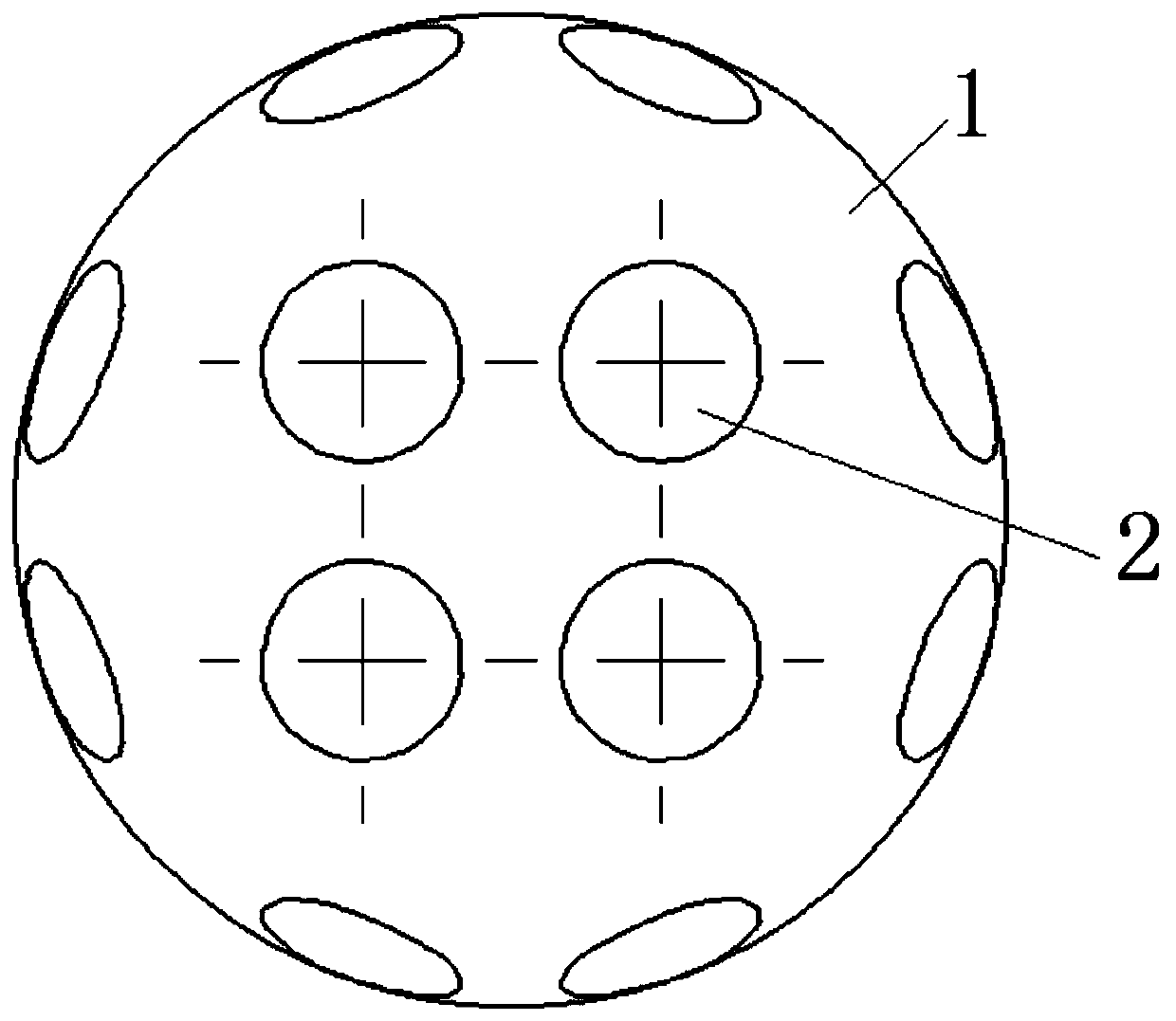

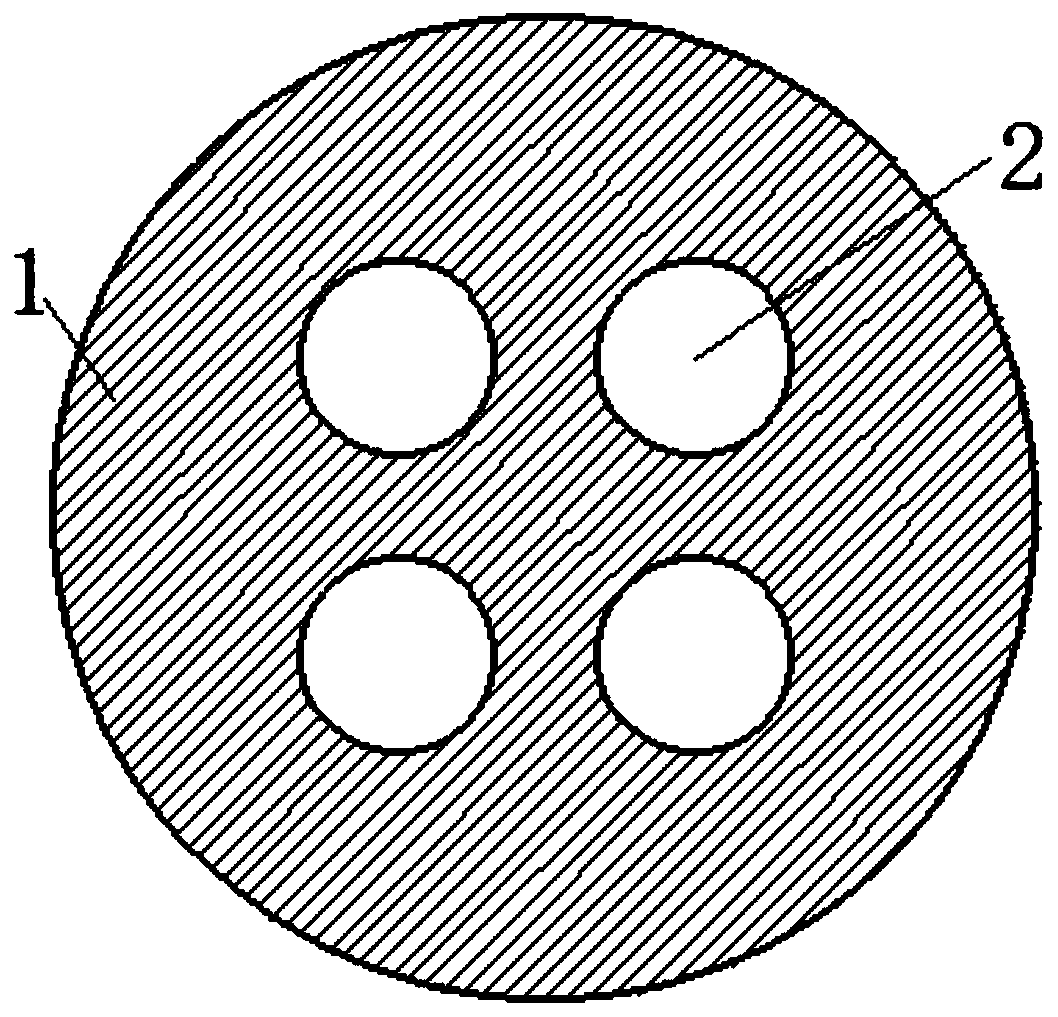

[0040] In this embodiment, the volume ratio of the fruit shell and polycaprolactone is 2:1; the fruit shell is walnut shell; the carbon source material is processed into a spherical structure 1, and the through holes 2 are arranged orthogonally to each other, and the through holes 2 The pore size of the spherical structure 1 is 7 mm, and the particle size of the spherical structure 1 is 30 mm.

Embodiment 2

[0042] Weigh the fruit shell and polycaprolactone in proportion, stir and mix, and the mixing time is 5min to obtain a mixture; take the mixture, melt it at 70°C, continue stirring until the material is completely melted, and obtain a molten material; The molten material is poured into the mold and molded into a spherical structure to obtain the carbon source material.

[0043] In this embodiment, the volume ratio of the shell and polycaprolactone is 2:1; the shell is macadamia husk; the carbon source material is processed into a spherical structure 1, and the through holes 2 are arranged orthogonally to each other, and the through holes 2 has a pore size of 8 mm, and the spherical structure 1 has a particle size of 40 mm.

Embodiment 3

[0045] Weigh the fruit shell and polycaprolactone in proportion, stir and mix, and the mixing time is 6 minutes to obtain a mixture; take the mixture, melt it at 80 ° C, continue stirring until the material is completely melted, and obtain a molten material; The molten material is poured into the mold and molded into a spherical structure to obtain the carbon source material.

[0046] In this embodiment, the volume ratio of the fruit shell and polycaprolactone is 2:1; the fruit shell is walnut shell; the carbon source material is processed into a spherical structure 1, and the through holes 2 are arranged orthogonally to each other, and the through holes 2 The pore size of the spherical structure 1 is 9 mm, and the particle size of the spherical structure 1 is 50 mm.

[0047]Structure: Observe that the carbon source materials prepared in Examples 1-3 have a particle size of 30-50 mm, the diameter of the through hole 2 of the spherical structure 1 is 7-9 mm, and the particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com