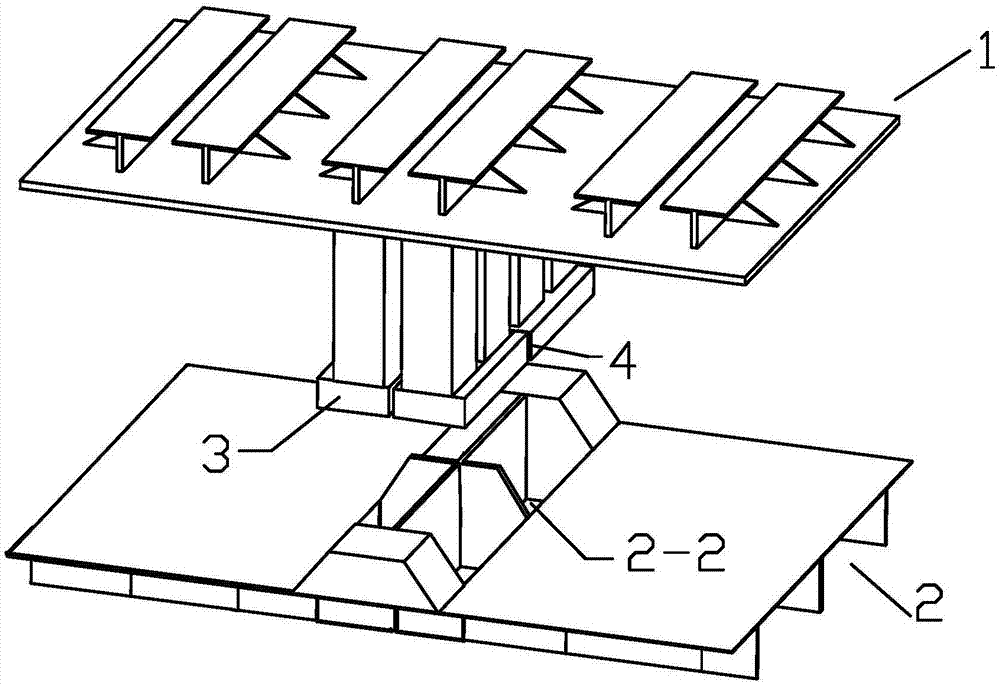

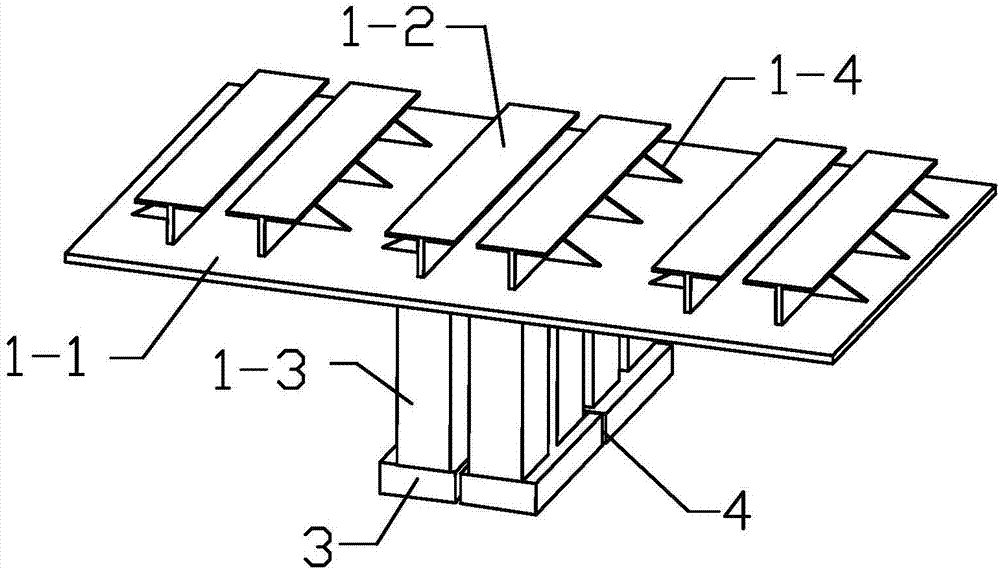

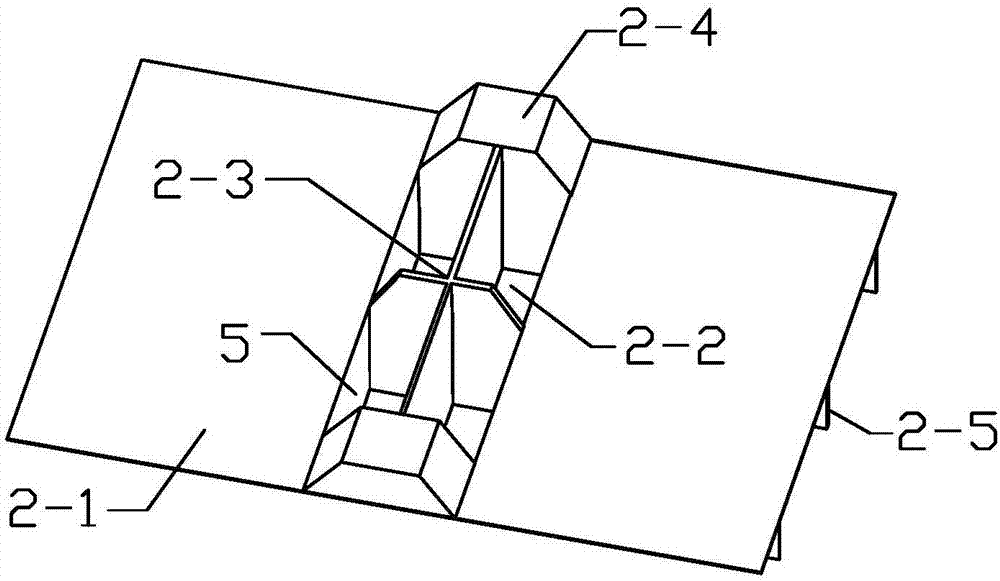

Environment-friendly water permeable brick as well as compression forming mould and preparation method for preparing environment-friendly water permeable brick

A technology of pressing and forming permeable bricks, which is applied in the field of building materials manufacturing, can solve the problems of ineffective removal of harmful substances, groundwater pollution, and low strength of permeable bricks, and achieve the effects of reducing the greenhouse effect, eliminating odors, and high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: a kind of method for preparing environment-friendly permeable brick, is characterized in that comprising the steps:

[0044] (1) Batching of permeable brick surface material and base material: Prepare two mixers, weigh 100 parts by weight of po.42.5 cement and 300 parts by weight of sand with a particle size of 10-20 mesh, and then add it to one of them In the mixer, add water to the mixer and stir evenly, wherein the mass percentage of cement and sand is 92%, and the amount of water added is 8%; simultaneously weigh 1800 parts of large stones with a particle size of 3-8mm and 400 parts of po. 42.5 Cement is added to another mixer, and 8% of the total base material water is added; at the same time, two mixers are turned on to stir the permeable brick surface material and the base material respectively, so that the mixing is uniform, and the mixer discharges the material and conveys it to the lower hopper;

[0045] (2) Cloth and press molding: the base mat...

Embodiment 2

[0048] Embodiment 2: a kind of method for preparing environment-friendly permeable brick, is characterized in that comprising the steps:

[0049] (1) Prepare the permeable brick surface material according to the following mass percentage: 75% surface layer solid material, 6% water, 4% mineral pigment, 7% epoxy resin, 6% activated carbon, 1.9% composite exterior Additives and 0.1% nano-scale titanium dioxide powder; wherein the surface layer solid material is composed of 300 parts by weight of sand with a particle size of 10-20 mesh and 100 parts by weight of cement; the composite external additive is composed of high-efficiency water reducer, organic silicon Aqua, diatomite and iron oxide are prepared according to the ratio of mass ratio 0.5:1.5:6:1; prepare permeable brick base solid material and water, wherein the base solid material includes 1800 parts by weight of a large particle size of 3-8mm Stones and 400 parts by weight of po42.5 cement, water accounts for 8% of the p...

Embodiment 3

[0055] Embodiment 3: a kind of method for preparing environment-friendly permeable brick, is characterized in that comprising the following steps:

[0056] (1) Prepare the permeable brick surface material according to the following mass percentage: 80% surface layer solid material, 8% water, 5% epoxy resin, 4% activated carbon, 2.02% composite external additive and 0.08% nano grade titanium dioxide powder; wherein the solid material of the surface layer is composed of 400 parts by weight of colored sand with a particle size of 10-20 mesh and 80 parts by weight of cement; Soil and iron oxide are prepared according to the ratio of mass ratio 1:0.5:5:0.6; prepare permeable brick base solid material and water, wherein the base solid material includes 1800 parts by weight of large stones with a particle size of 3-8mm and 400 parts by weight po42.5 cement, water accounts for 8% of the base material of the permeable brick;

[0057] (2) Prepare two mixers, add 80% surface layer solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Splitting tensile strength | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com