Patents

Literature

69results about How to "Good long-term durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

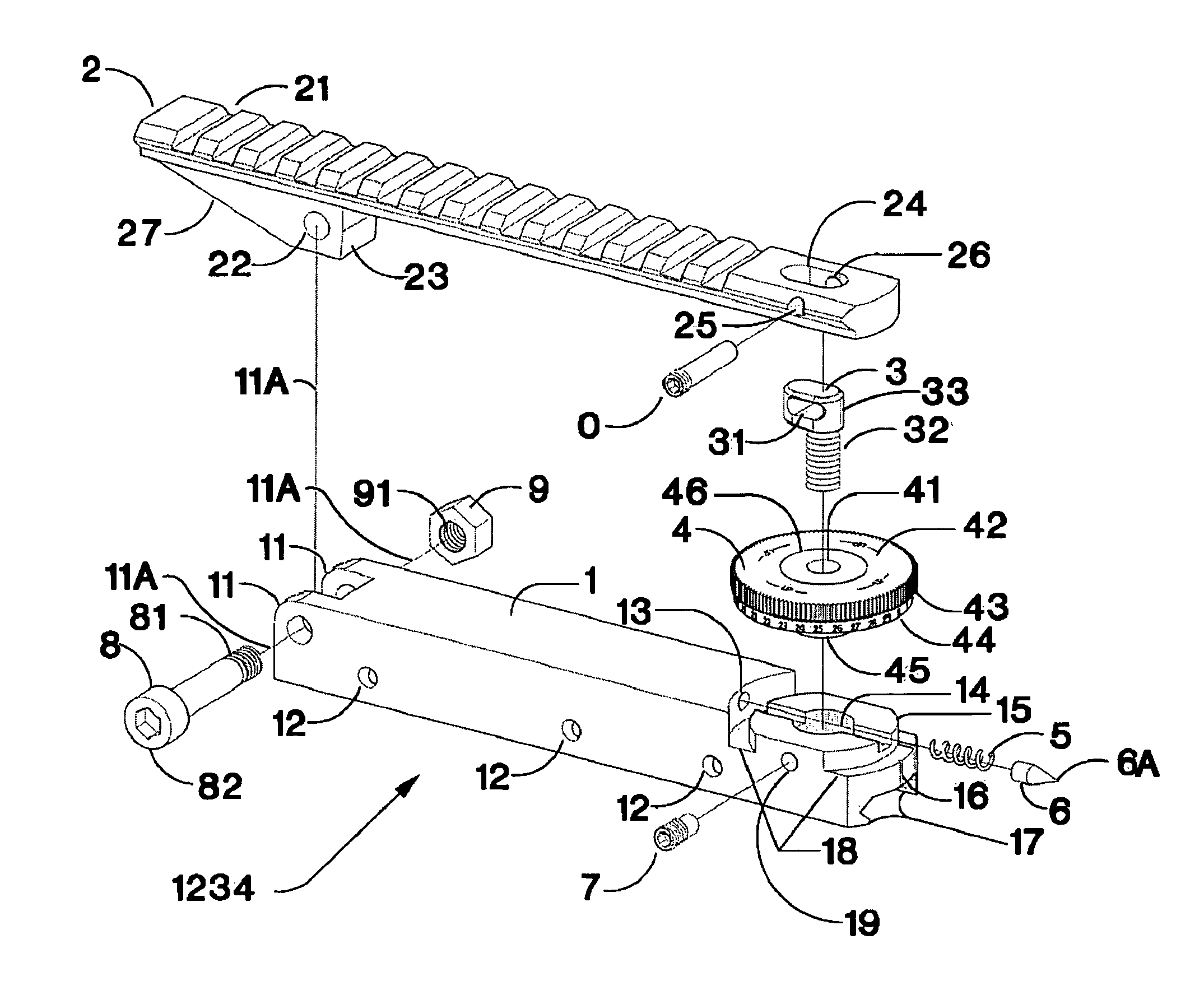

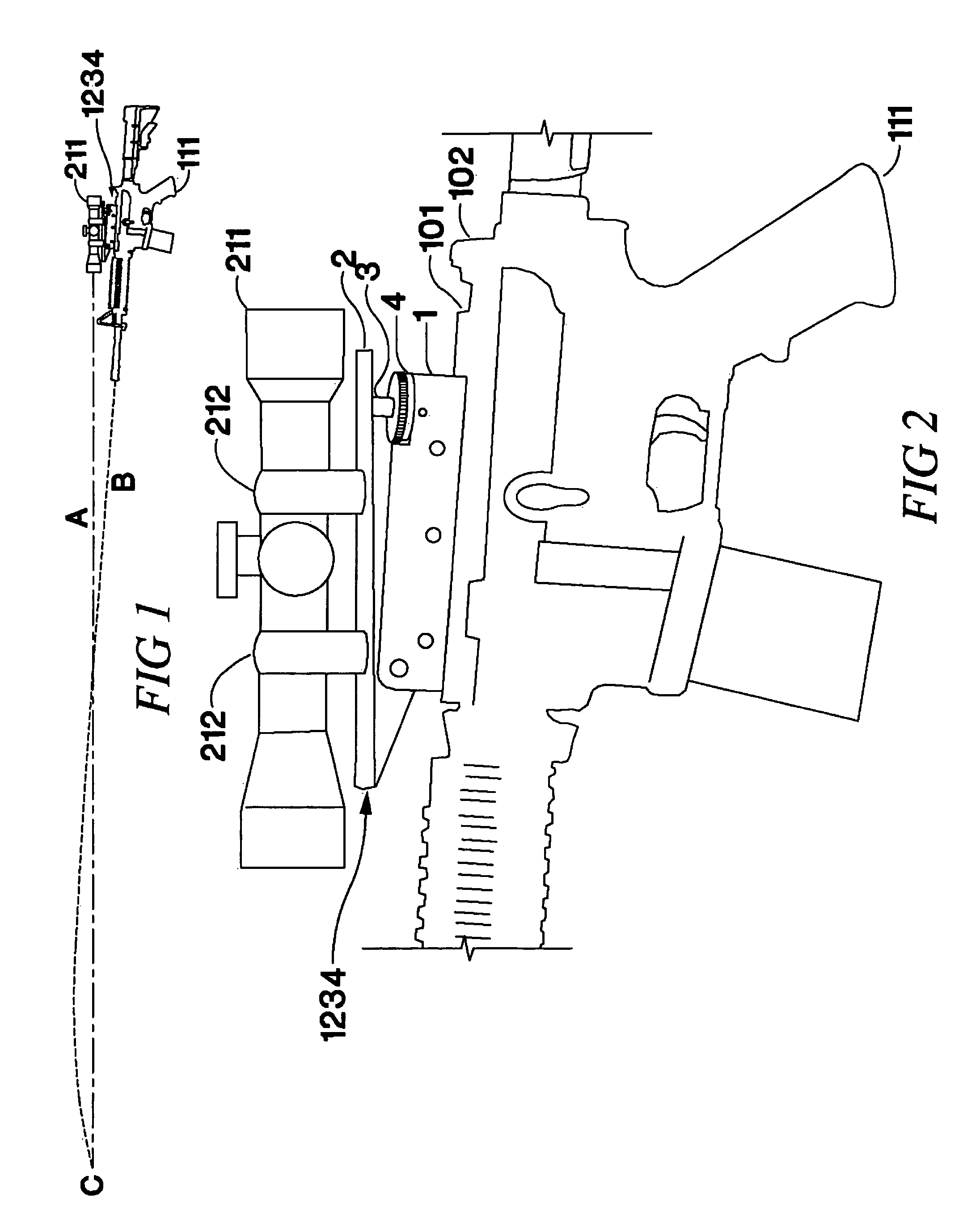

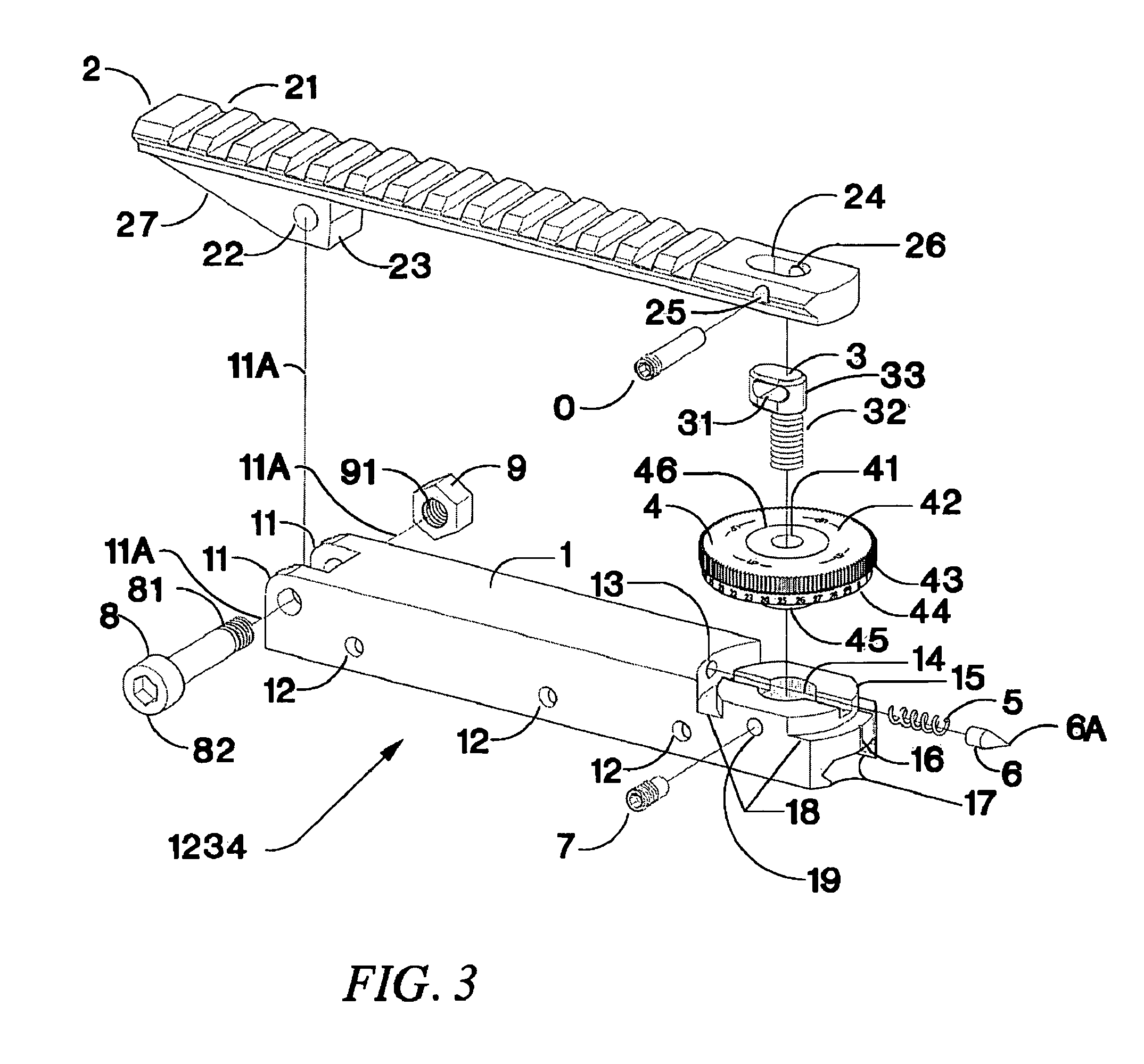

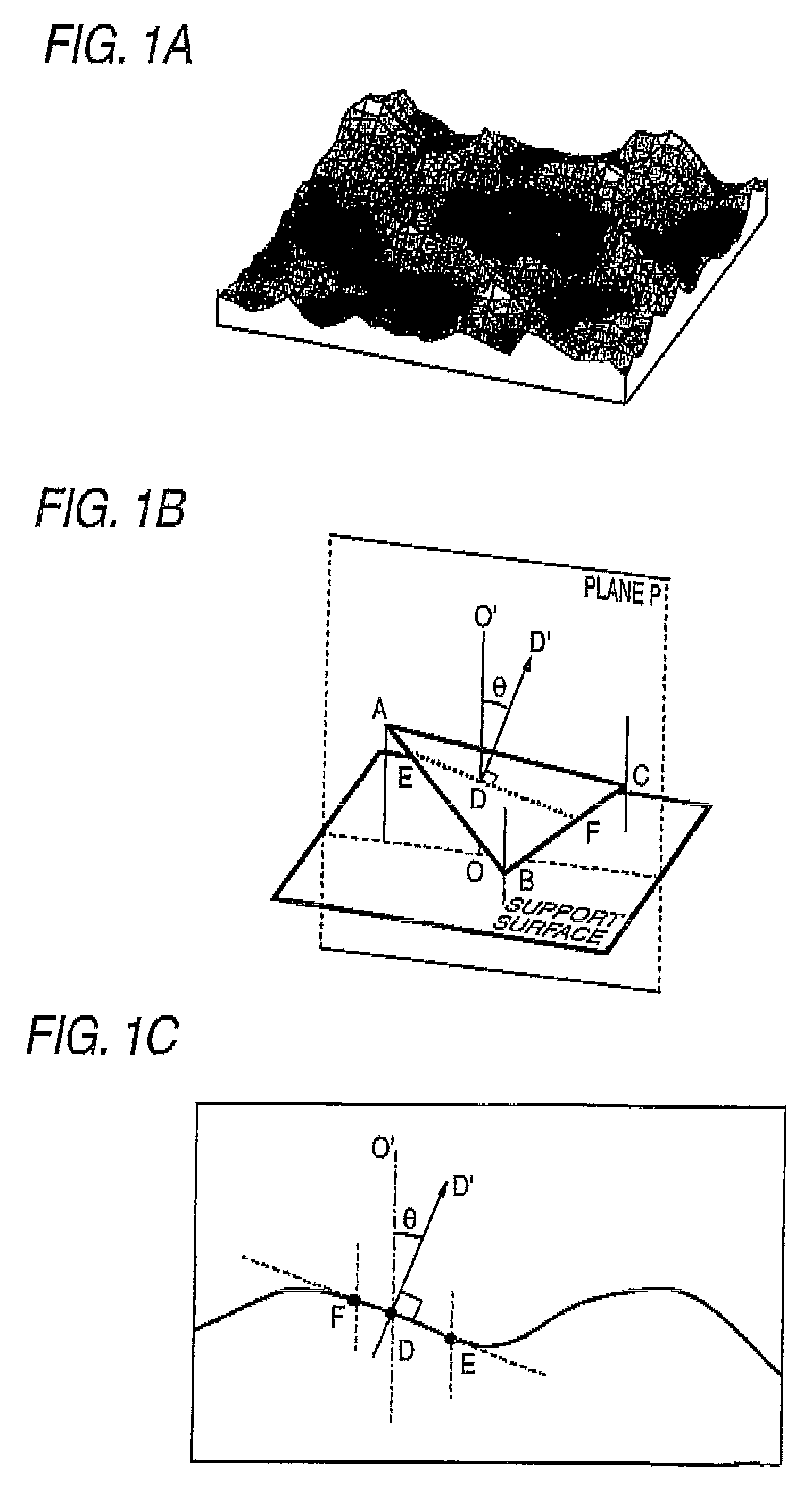

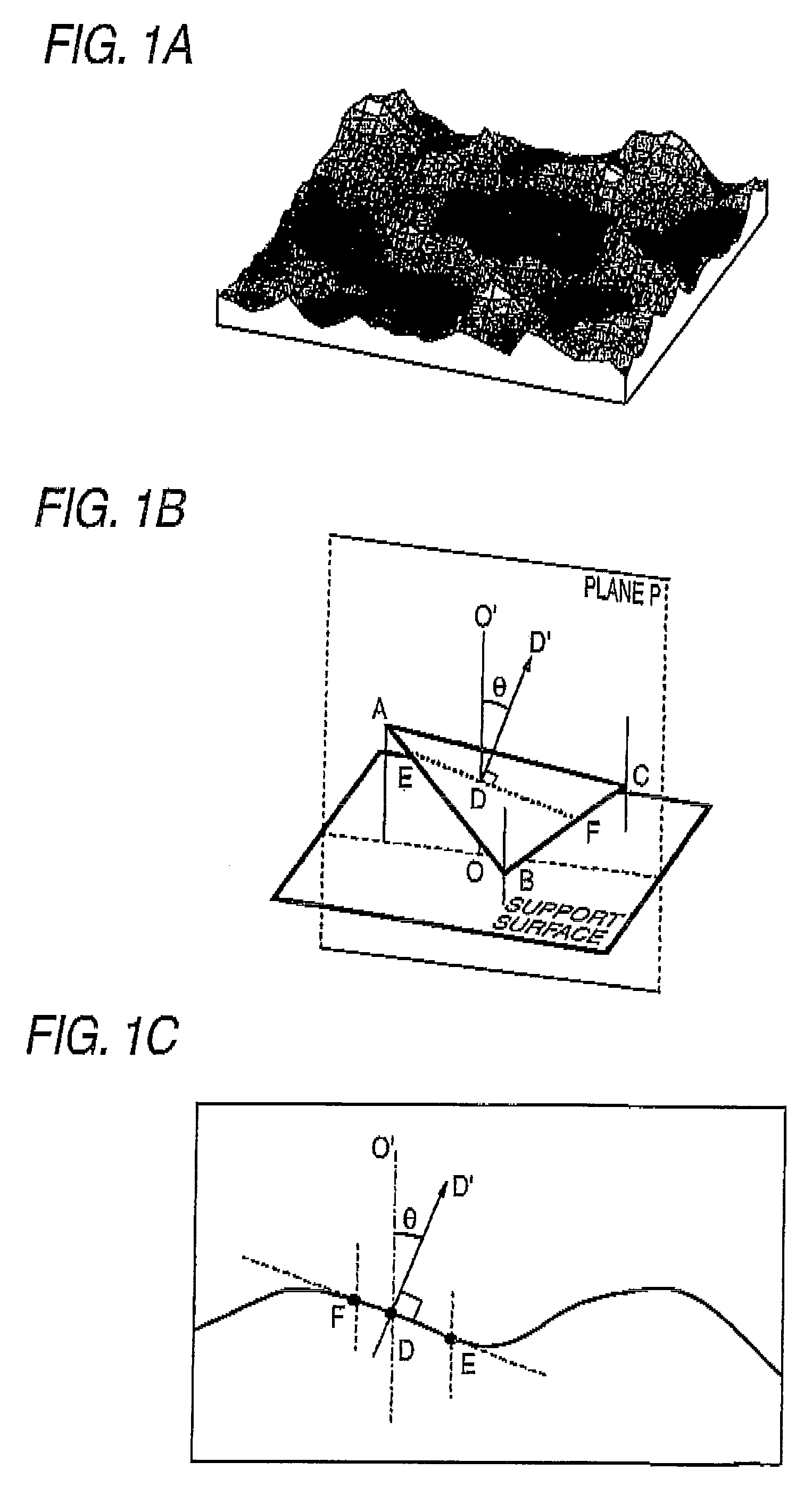

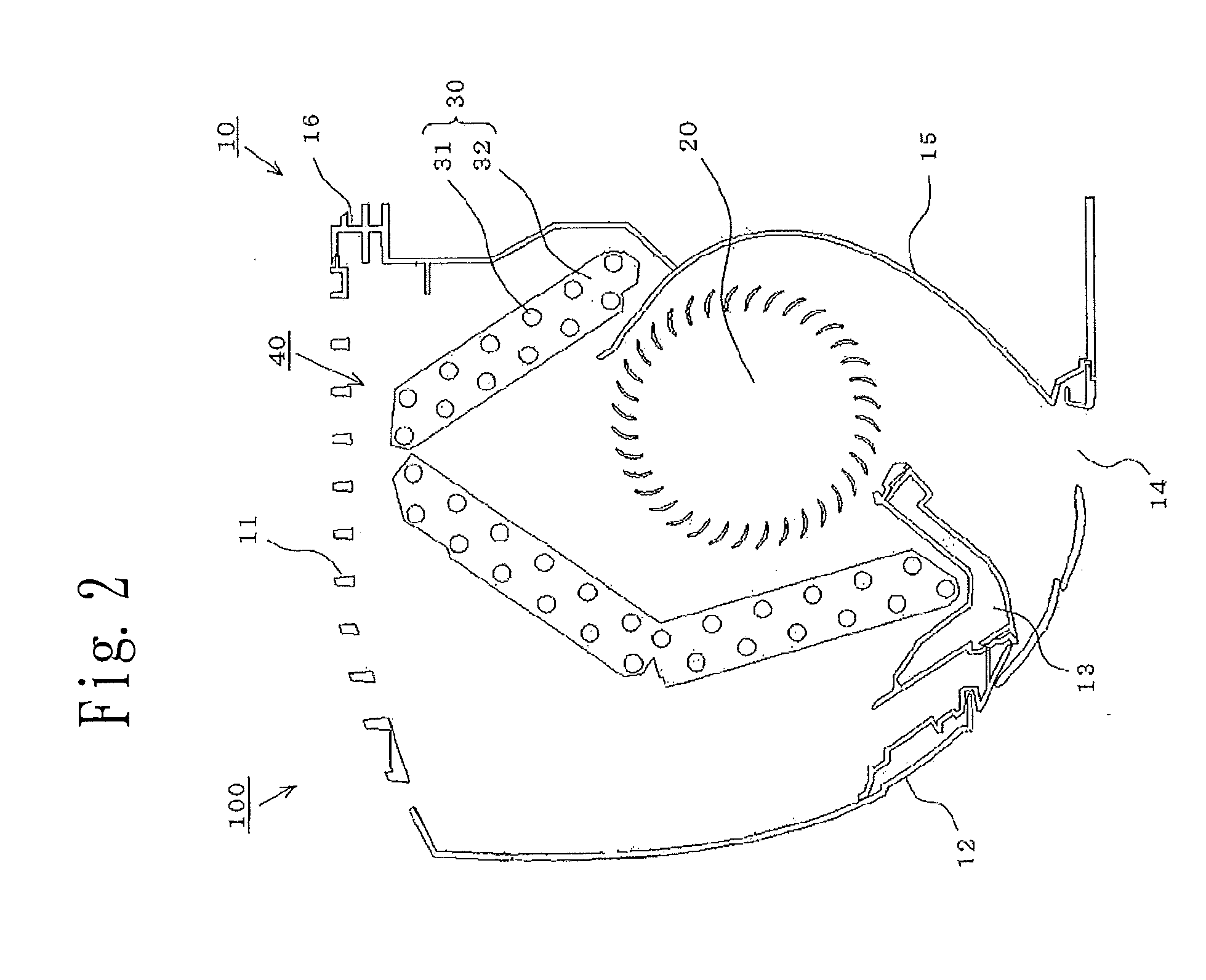

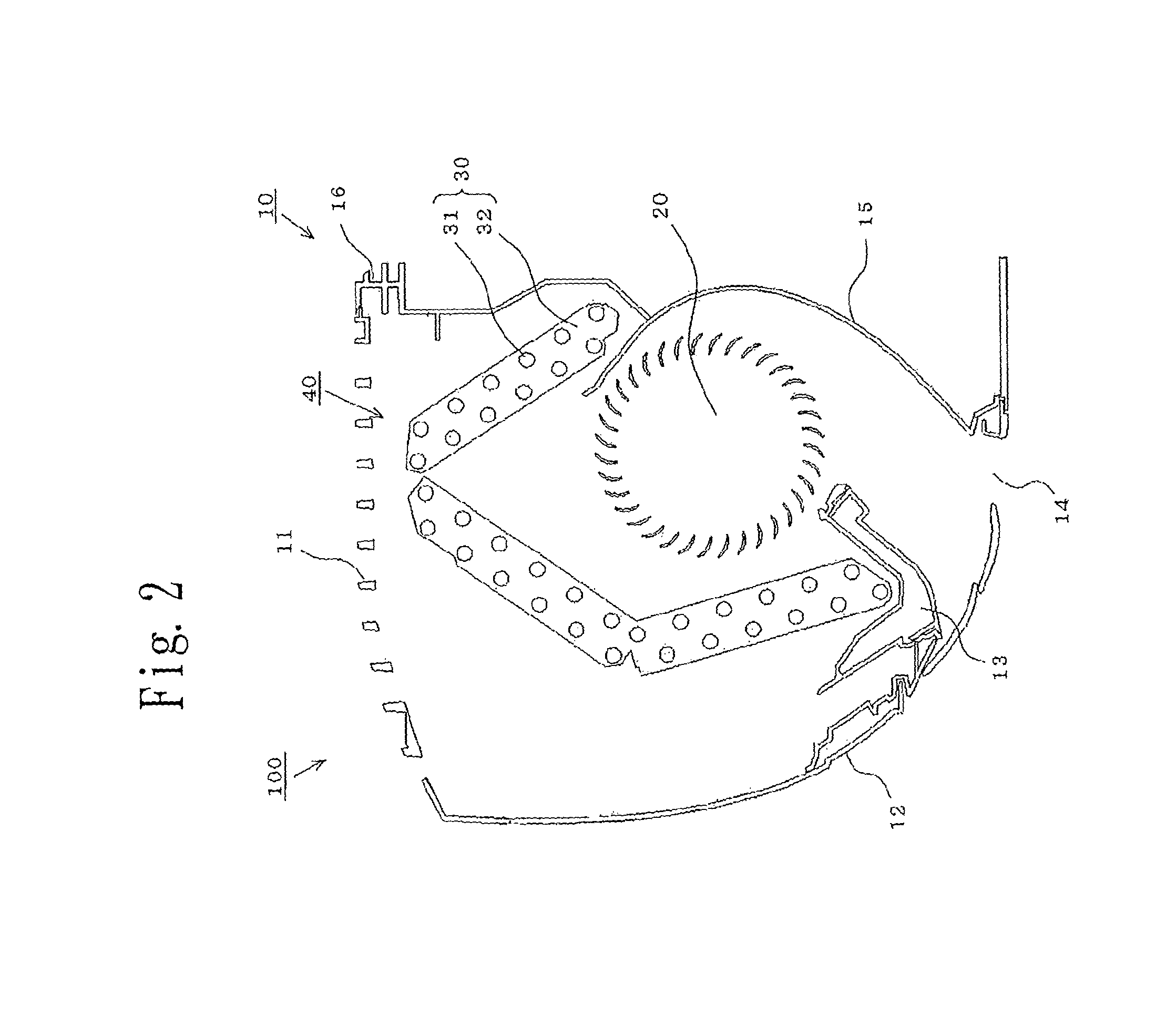

Adjustable bases for sighting devices

ActiveUS8240075B1Good long-term durabilityLarge range of motionSighting devicesButtsEngineeringTelescope

An adjustable base for attaching a sighting device such as a telescopic sight to a rifle or other ballistic projectile launcher, comprising upper and lower rails pivotally attached at the muzzle ends thereof, is disclosed. Adjustments are provided for altering the angle between the sight and the weapon's boreline or similar axis in elevation in increments of minutes of arc or fractions thereof.

Owner:COLD SHOT LLC

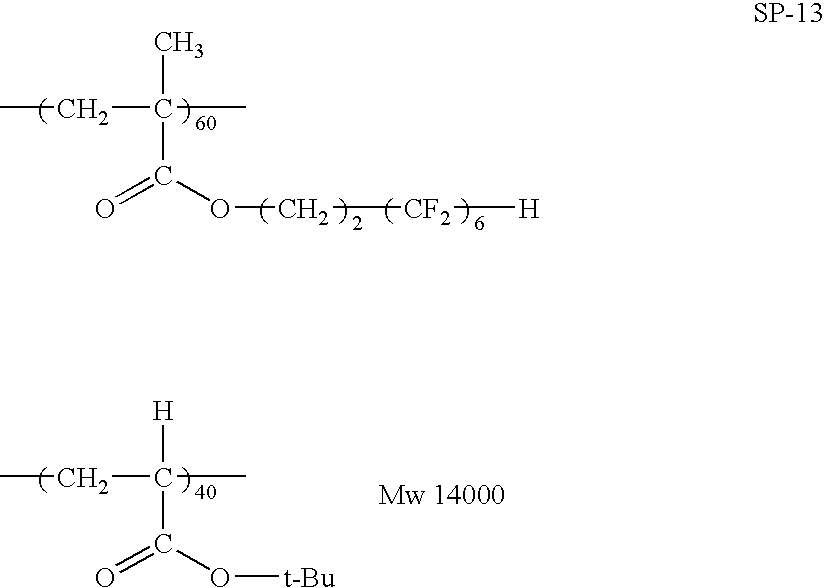

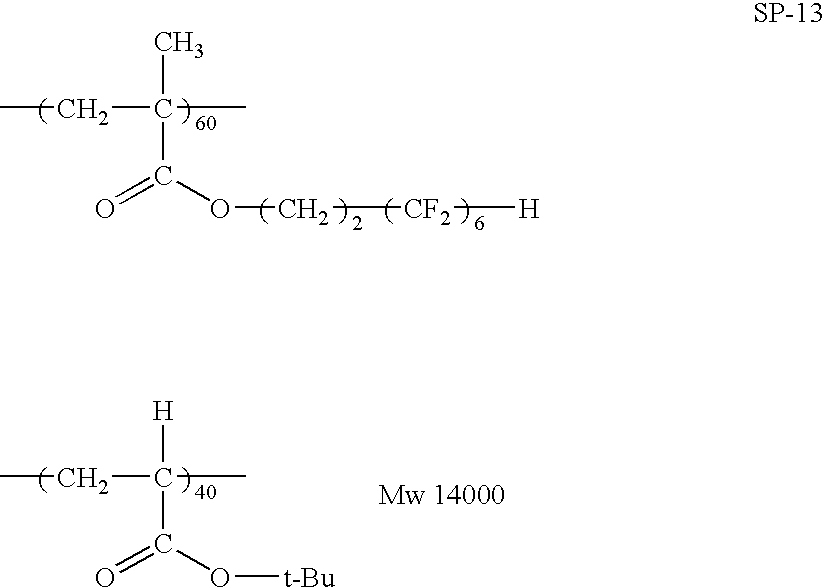

Thermoplastic polyester resin composition

InactiveUS6447913B1Excellent long-term durabilityGood long-term durabilityFilm/foil adhesivesFibre treatmentAnti stressChemistry

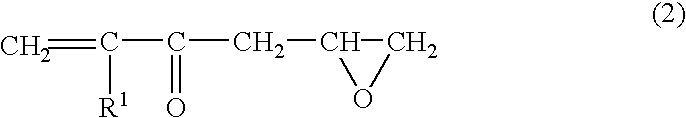

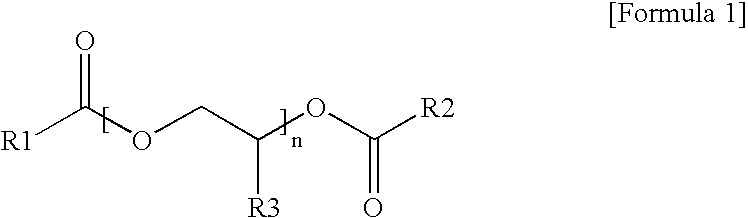

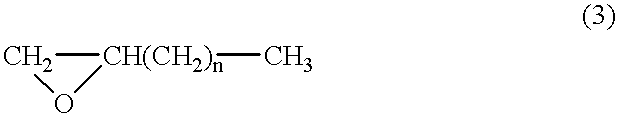

To provide a thermoplastic polyester resin composition which has a very good durability to alkaline solutions for a long period of time. That is, a thermoplastic polyester resin composition, wherein a thermoplastic polyester resin (A) is compounded with 1-25% by weight (in the total composition) of impact resistance rendering materials (B), 0.1-15% by weight (in the total composition) of a silicone compound and / or a fluorine compound (C), 1-50% by weight (in the total composition) of an inorganic filler (D), and 0.1-10% by weight of at least one polyfunctional compound (E) selected from the group consisting of an epoxy compound, an isocyanate compound and a carboxylic acid dianhydride. A molded article of the present invention has anti-stress properties even in a weld part thereof.

Owner:POLYPLASTICS CO LTD +1

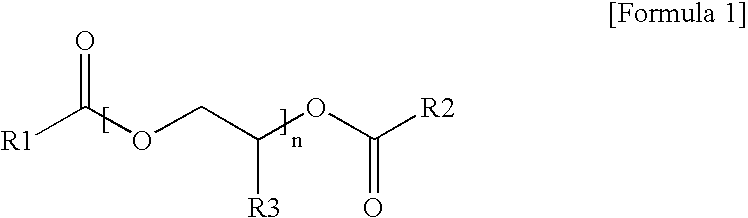

Acrylic pressure sensitive adhesive having antistatic property

ActiveUS20060045990A1Improve antistatic performanceGood compatibilityLiquid crystal compositionsFilm/foil adhesivesPolymer scienceLiquid-crystal display

The present invention relates to an acrylic pressure sensitive adhesive composition for the production of a polarizer, which has excellency in major characteristics including durability and antistatic property, more precisely, an acrylic pressure sensitive adhesive composition containing ester plasticizer having one or more ether bonds and alkali metallic salt, a polarizer applied with the pressure sensitive adhesive and liquid crystal display (LCD) device using the same. The acrylic pressure sensitive adhesive composition for the production of a polarizer of the present invention has excellent pressure sensitive adhesive functions and durability.

Owner:LG CHEM LTD

Polyester film and method for producing same, backsheet for solar cell, and solar cell module

InactiveUS20110306747A1Good long-term durabilityGood planar surface stateSynthetic resin layered productsCoatingsWeather resistancePolyester resin

A polyester film containing a polyester resin having an intrinsic viscosity IV of from 0.73 to 0.9 dL / g in which the polyester film has a specific heat change at 85° C. to 135° C. (ΔCp) of from 0.06 to 0.1 J / g, has an excellent weather resistance, a good planar surface state and a low thermal shrinkage.

Owner:FUJIFILM CORP

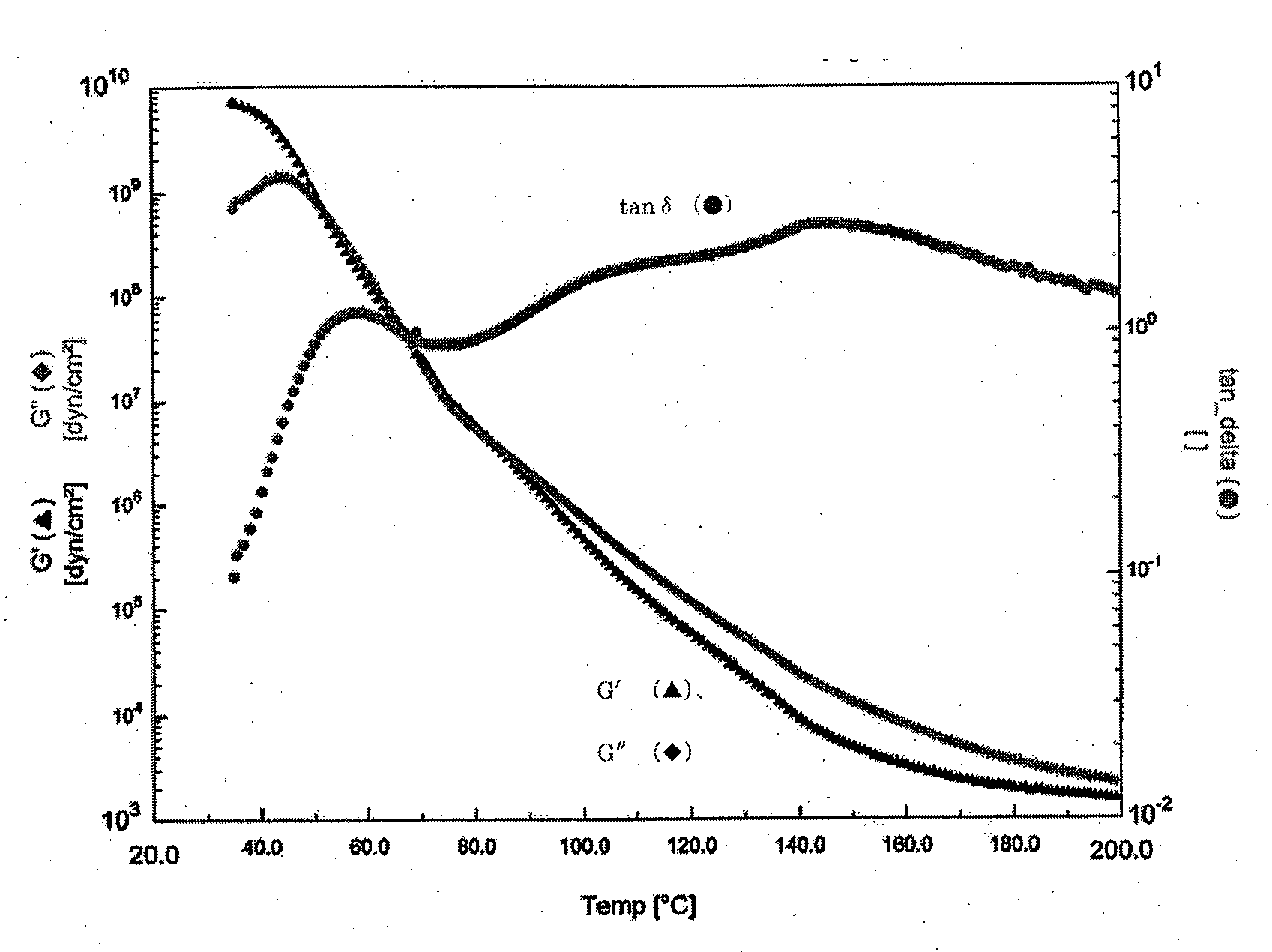

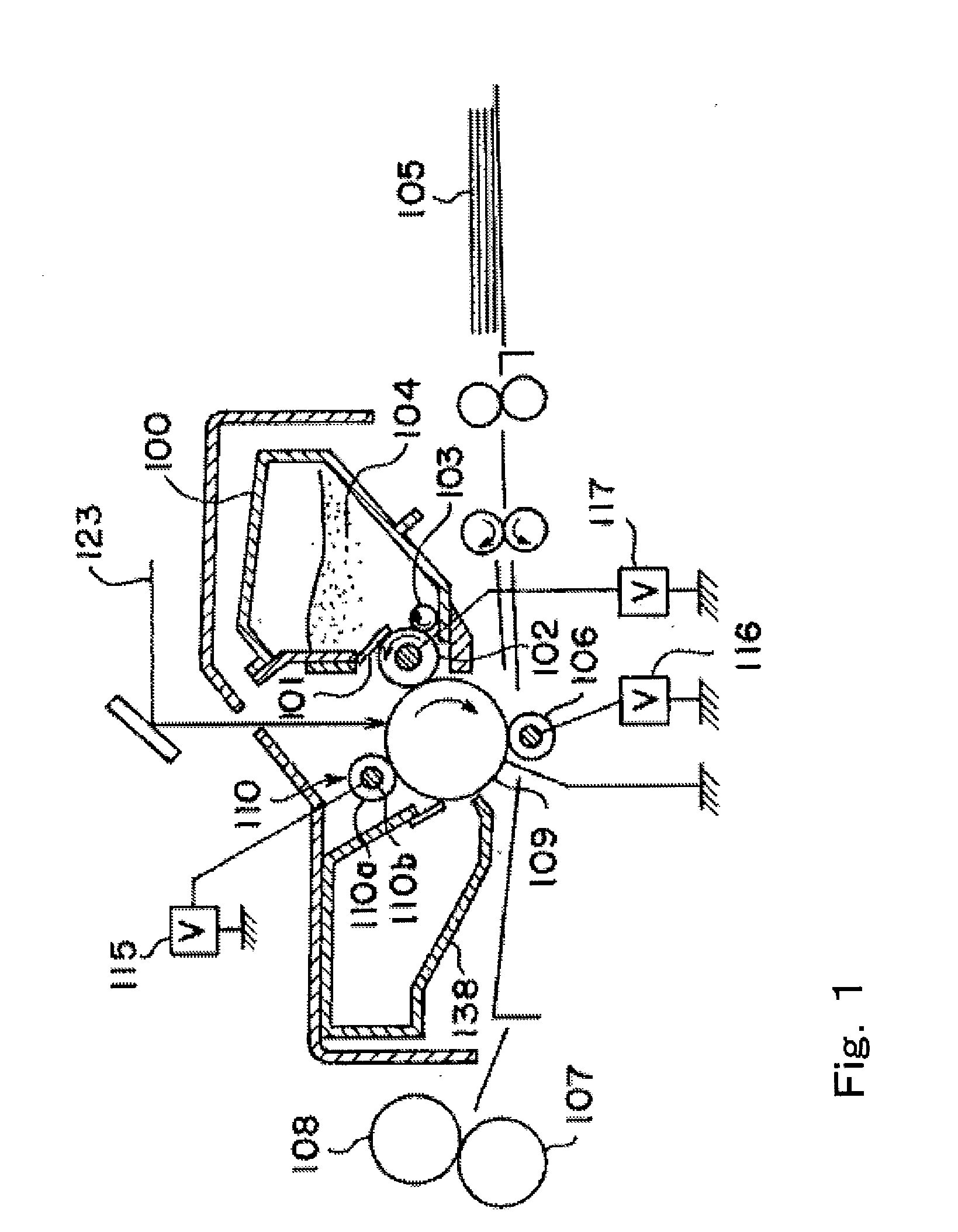

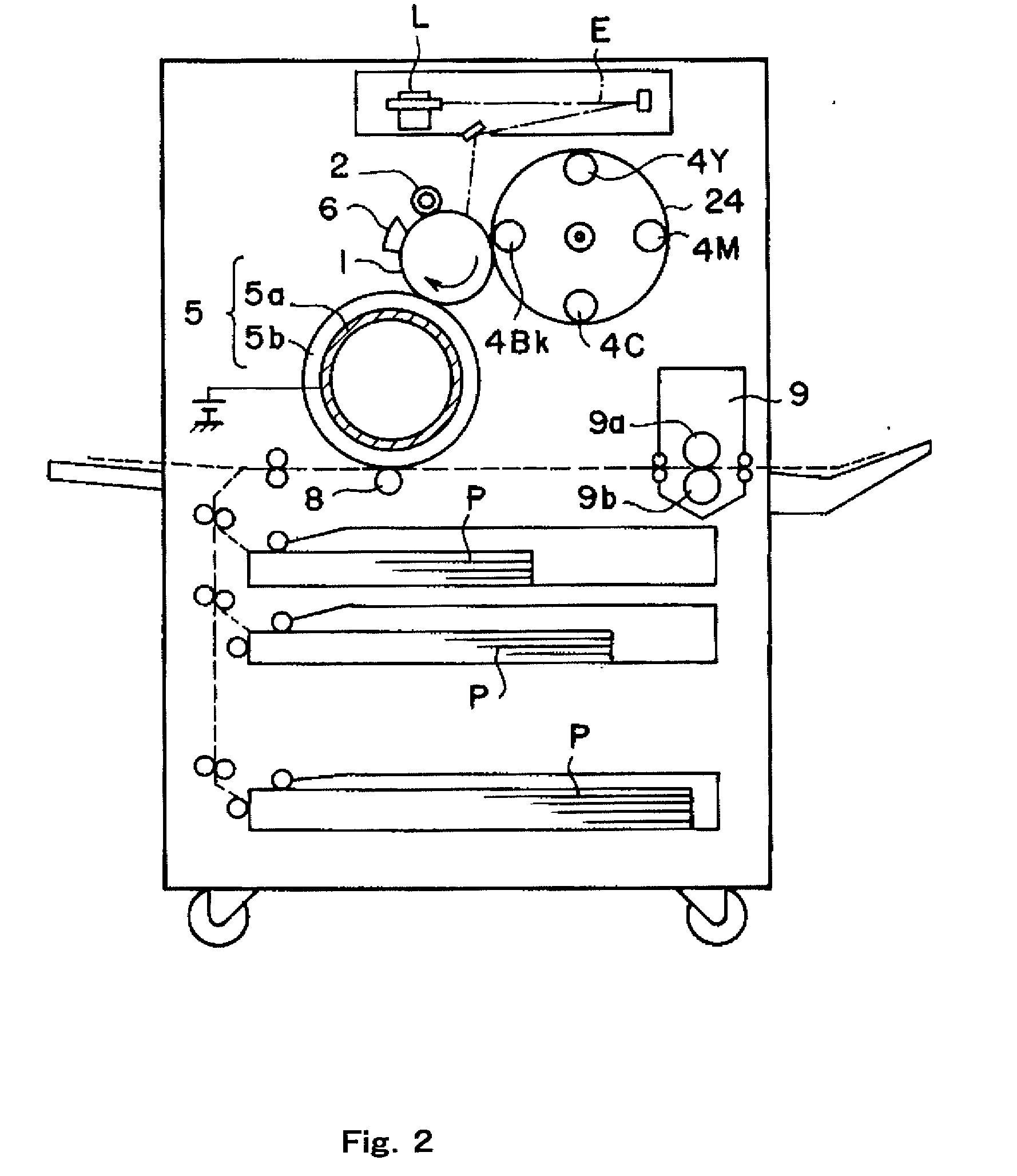

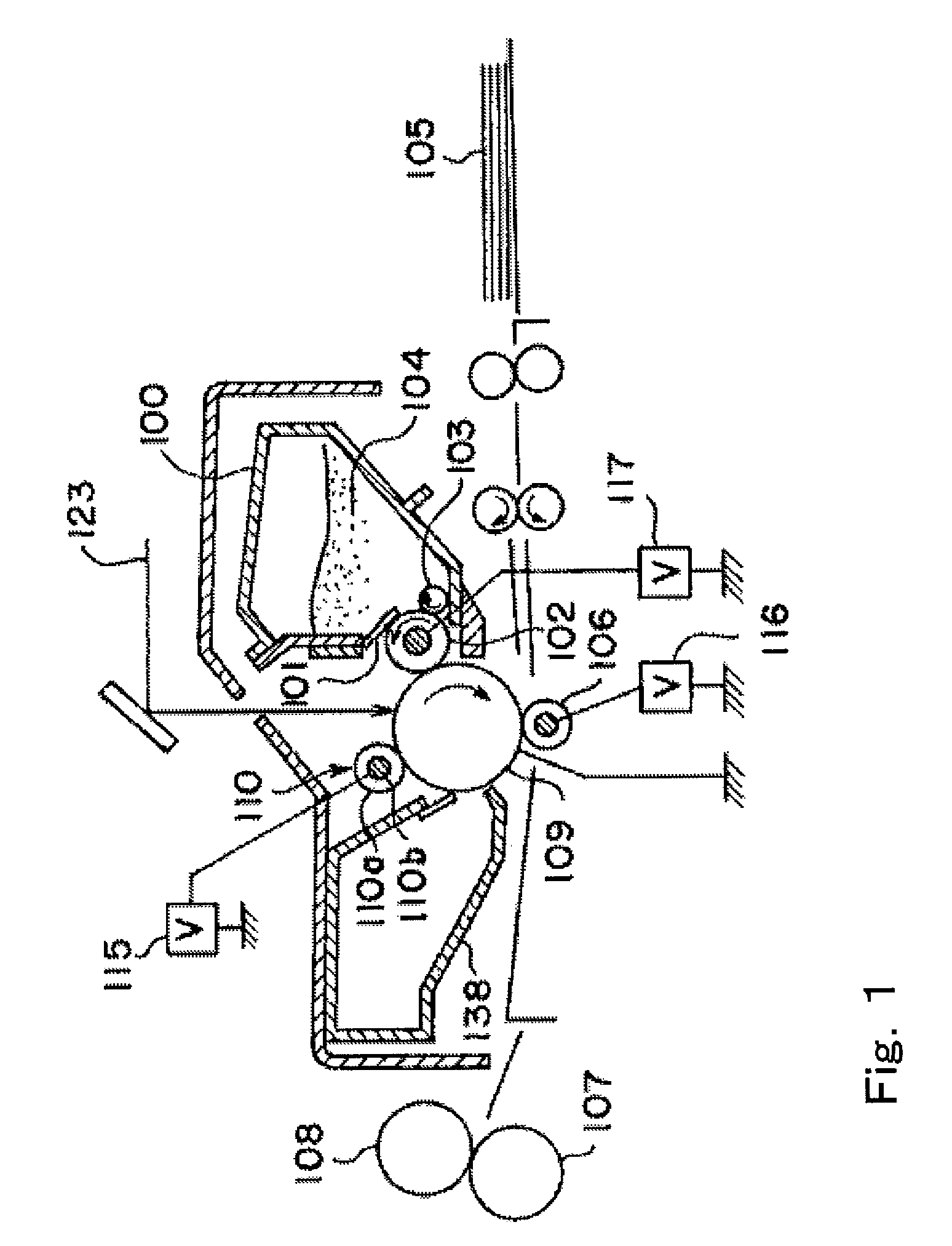

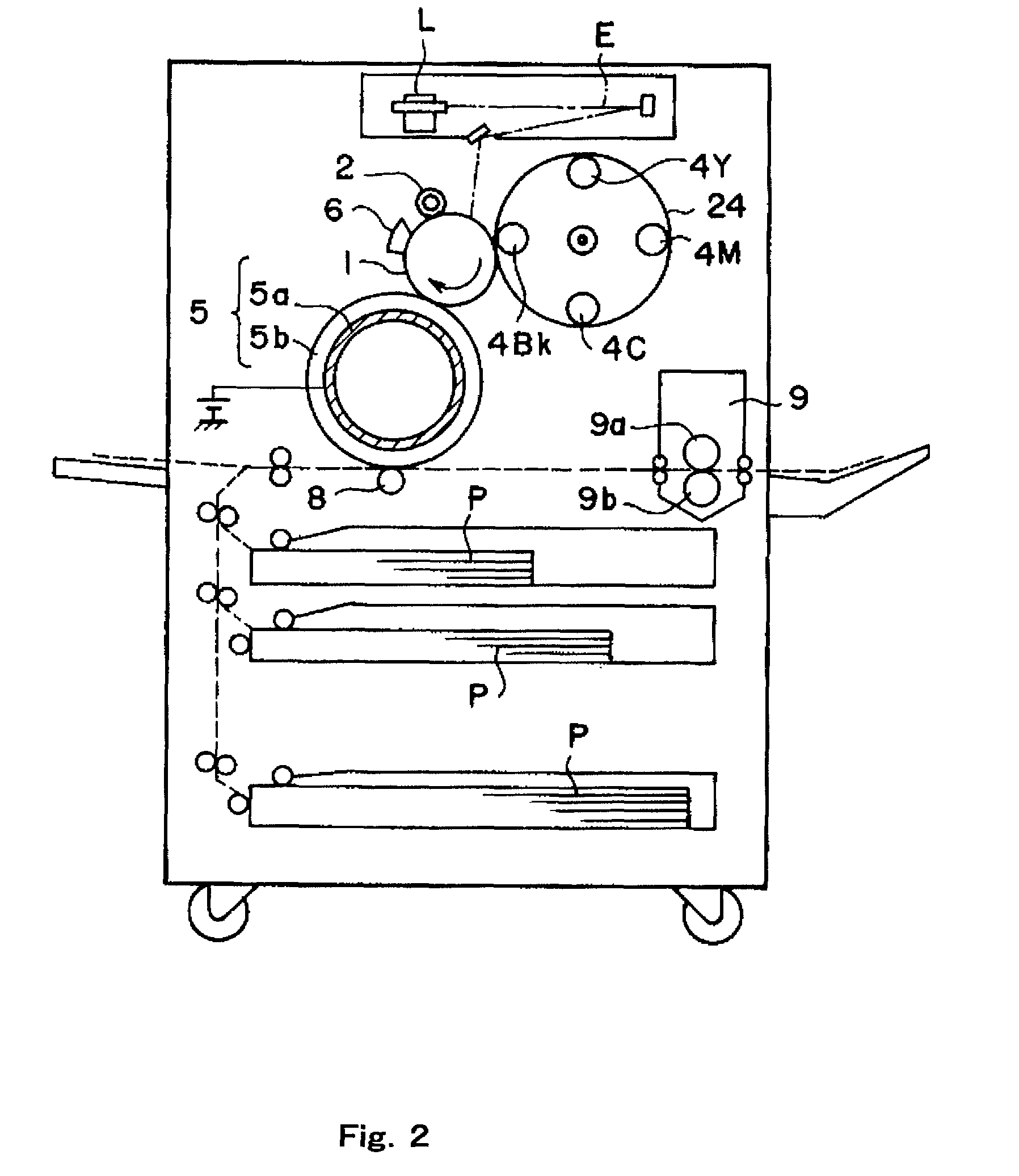

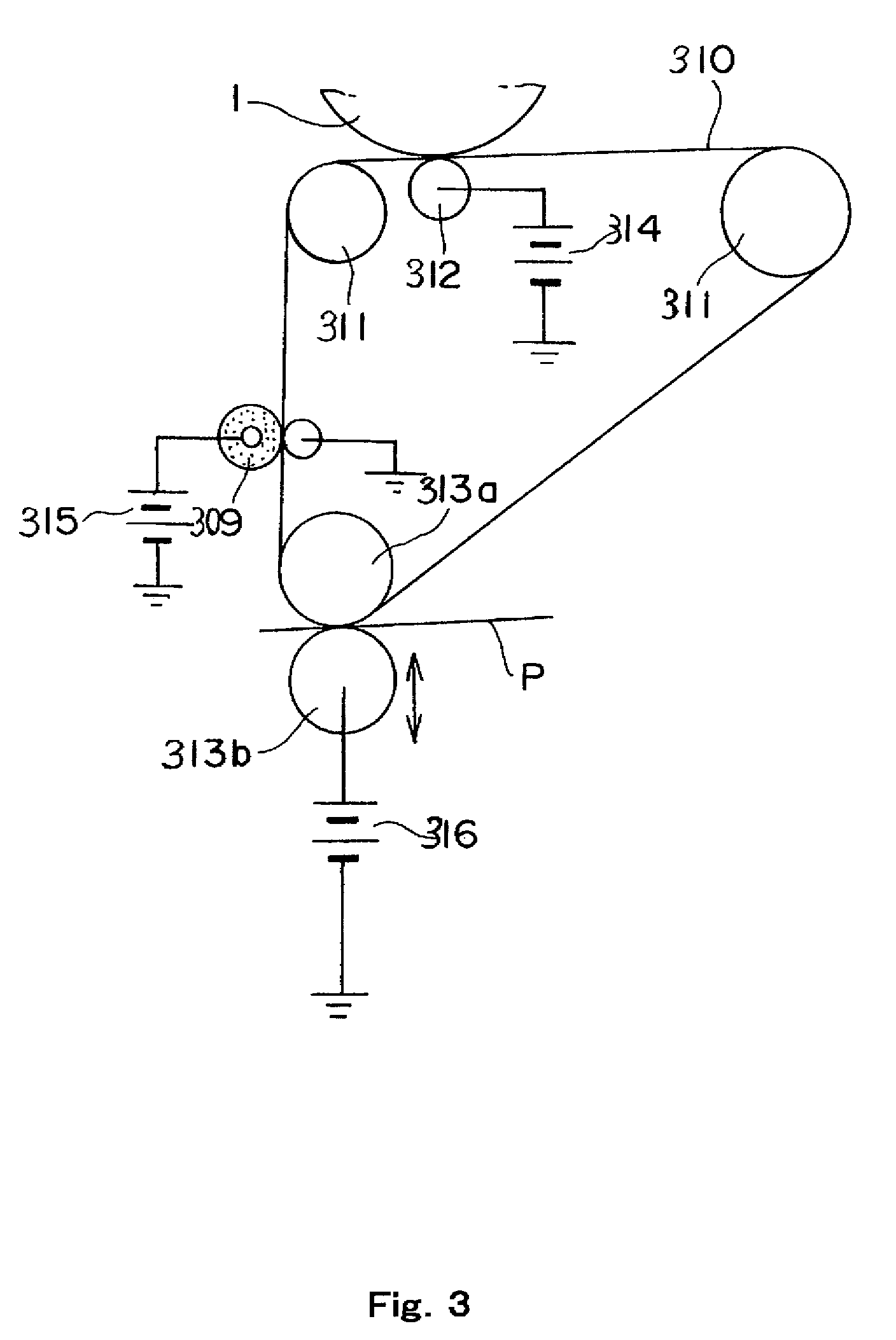

Non-magnetic toner

ActiveUS20090186290A1Excellent in transfer performanceLow-temperature fixabilityDevelopersWaxElastic modulus

Provided is anon-magnetic toner including toner particles each containing at least a binder resin, a colorant, and a wax component, and an inorganic fine powder, in which: (1) when a temperature in a temperature range of 50 to 80° C. at which a loss tangent (tan δ) shows a maximum is represented by T1, a storage elastic modulus of the toner at the temperature T1 (G′(T1)) satisfies a relationship of 5.00×107≦G′(T1)≦1.00×109 (dN / m2); (2) a continuous temperature range with a width of 15° C. or more in which the loss tangent (tan δ) is 0.80 to 2.00 is present in the temperature range of 50 to 80° C.; and (3) the loss tangent (tan δ) is 1.00 or more in a temperature range of 120 to 160° C.

Owner:CANON KK

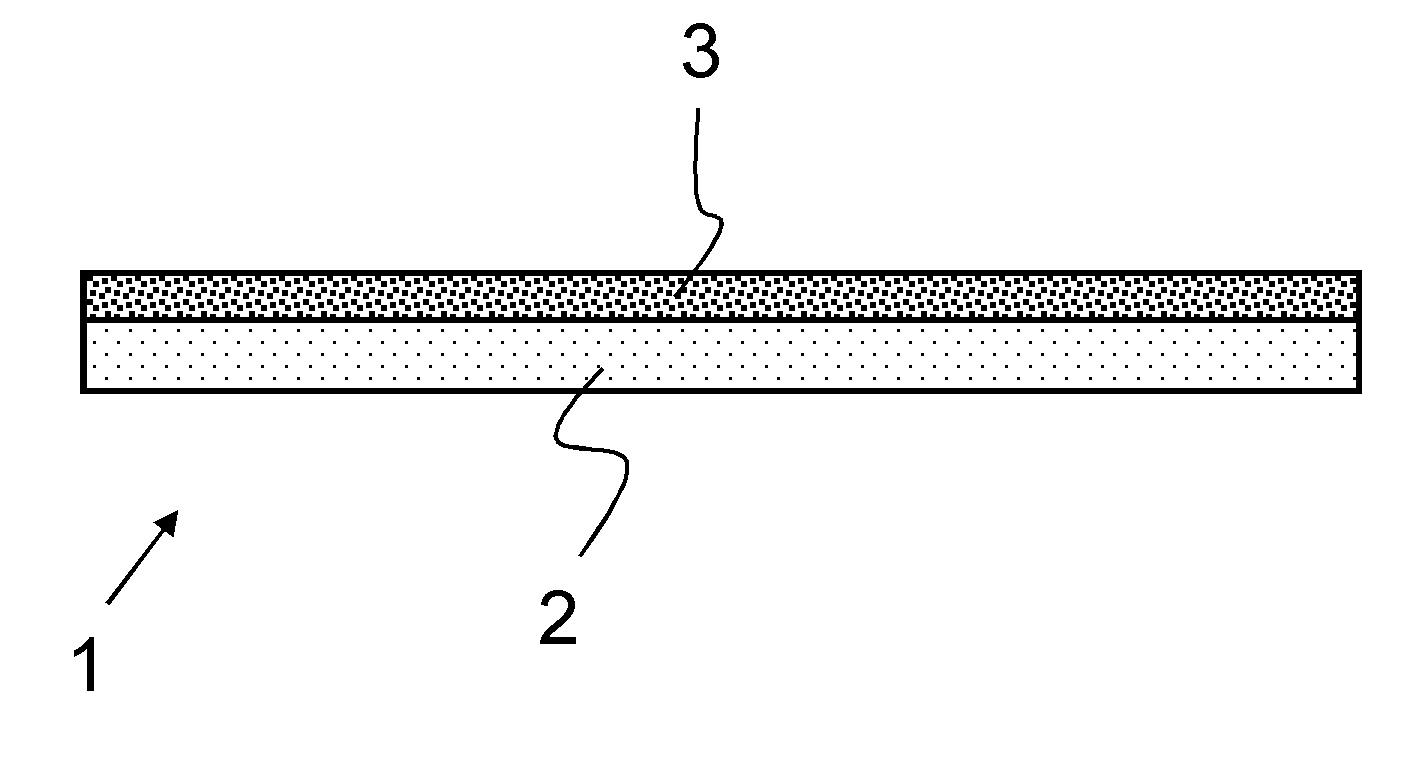

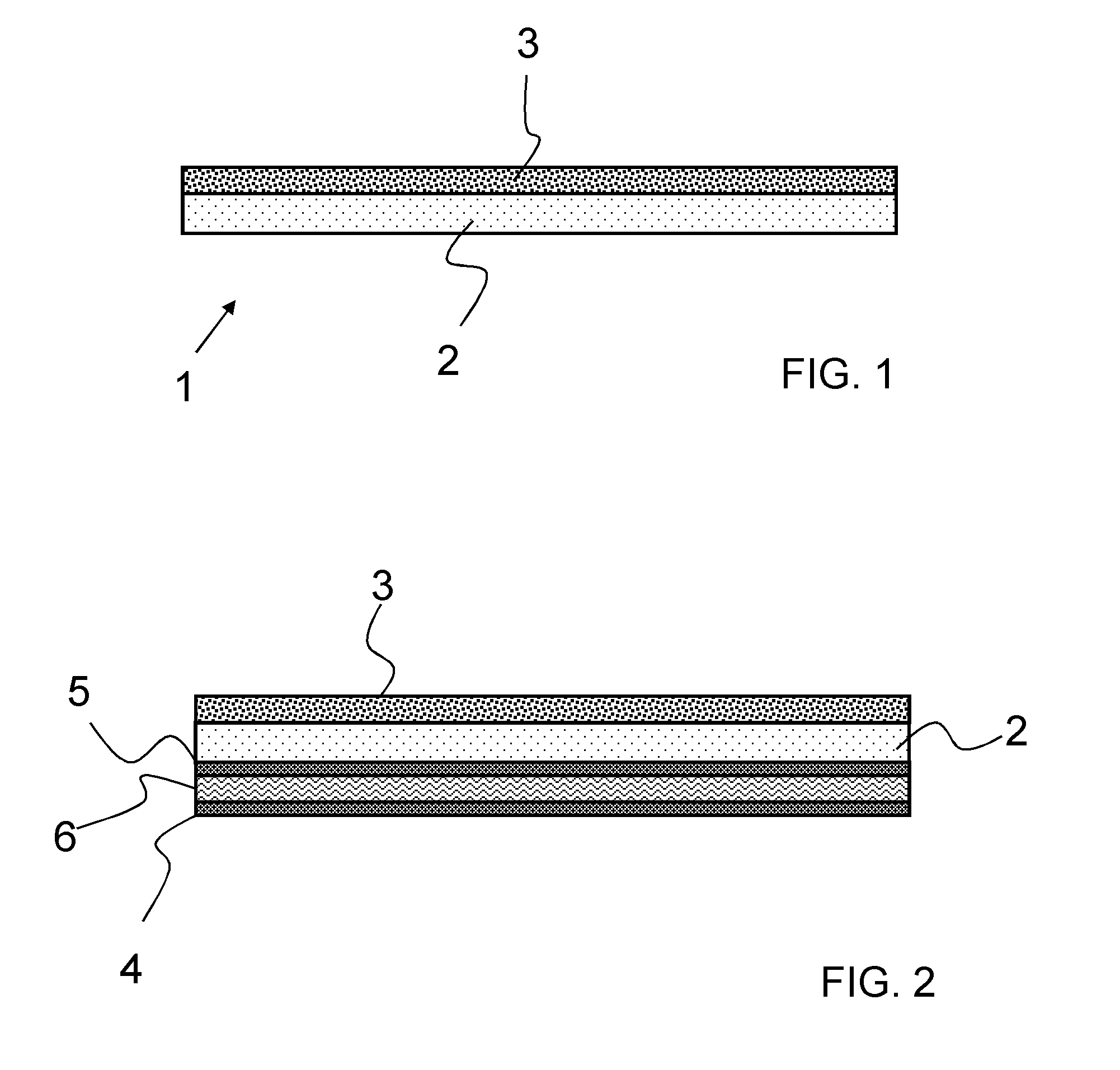

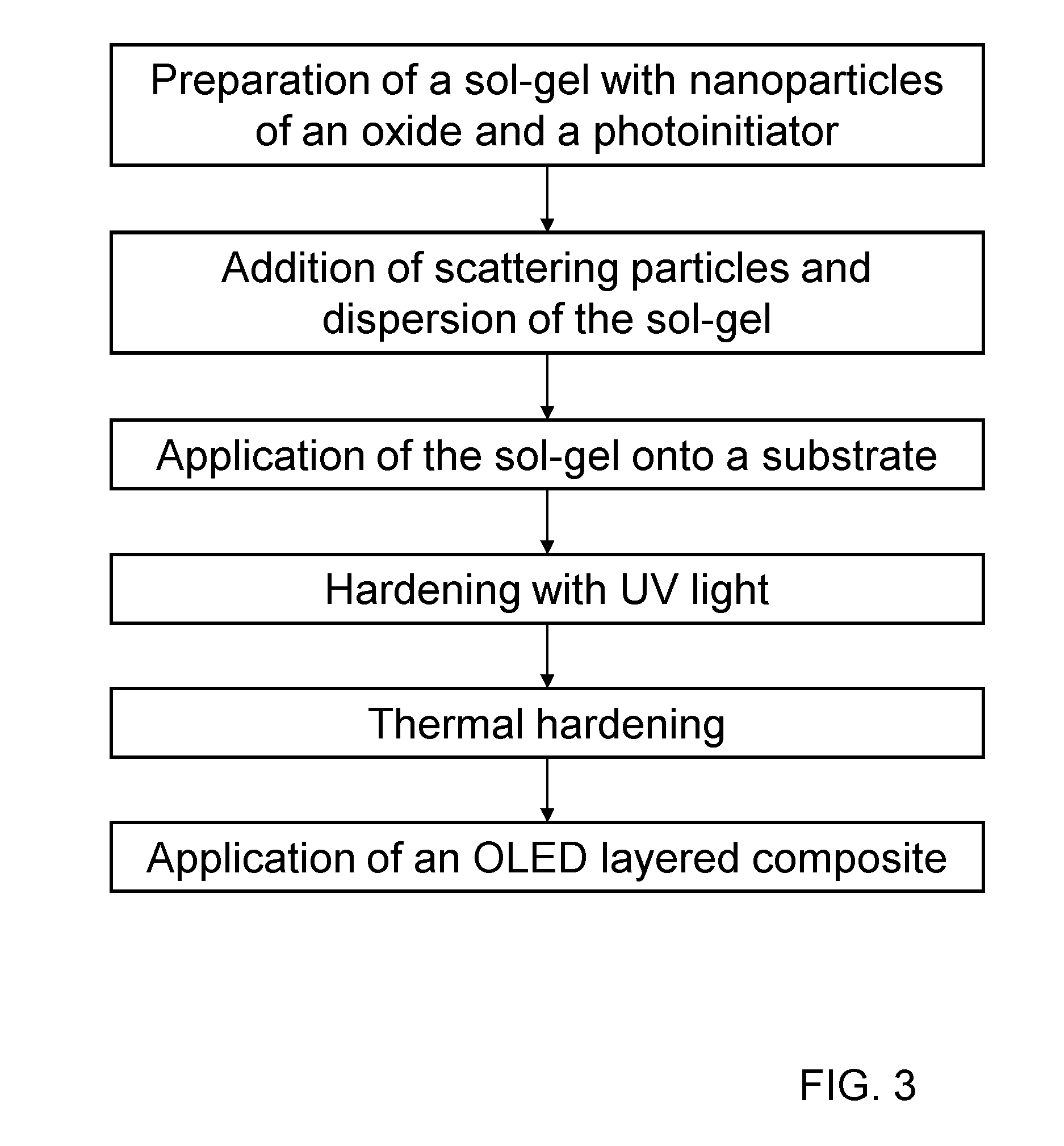

Substrate glass for leds with layer containing scattering particles and method for production thereof

InactiveUS20110045259A1Easy to produceReduce light lossMaterial nanotechnologyDiffusing elementsMetallurgyRefractive index

A composite material for LED's is provided. The composite material has a coating comprising scattering particles with an index of refraction greater than 1.6.

Owner:SCHOTT AG

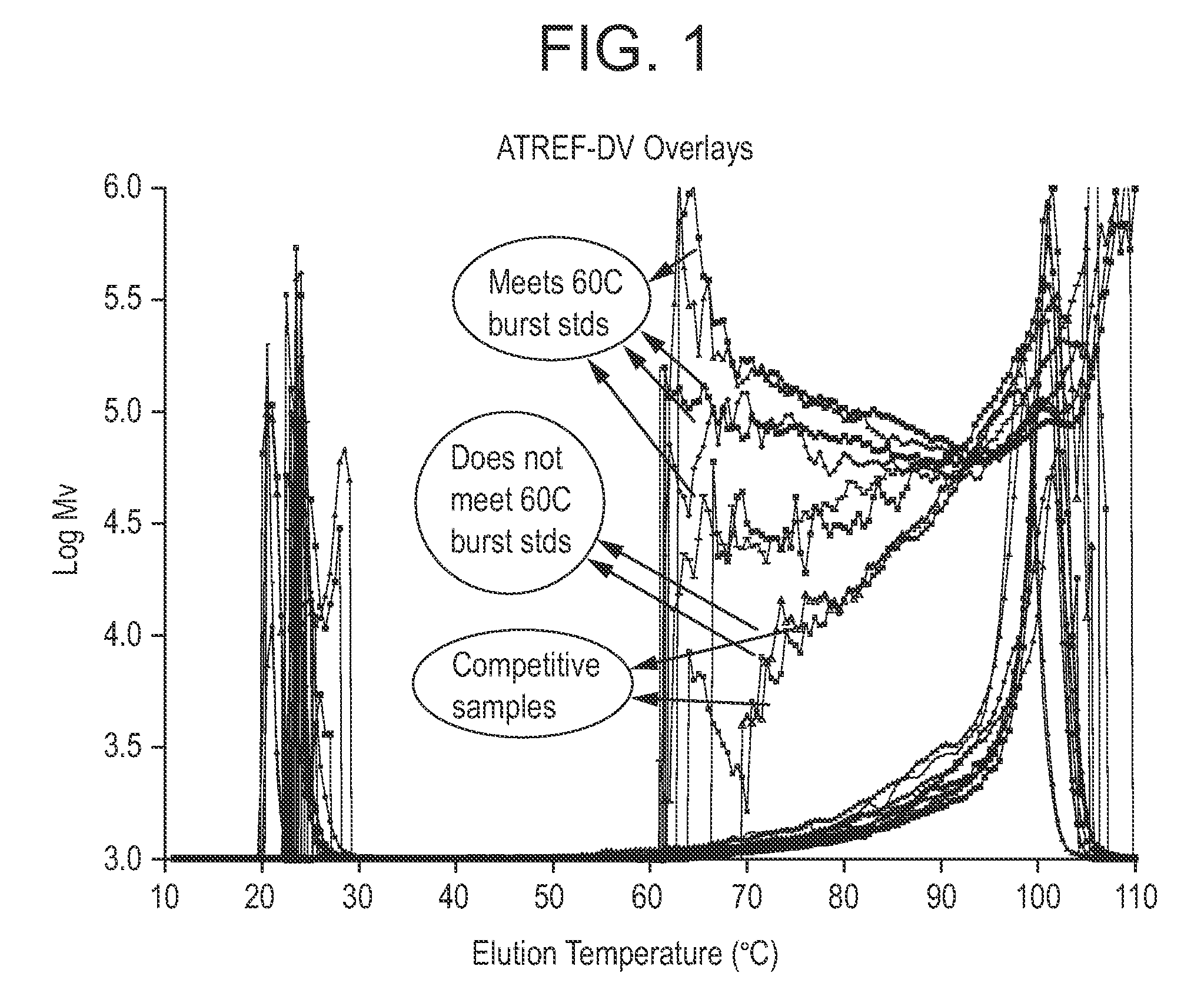

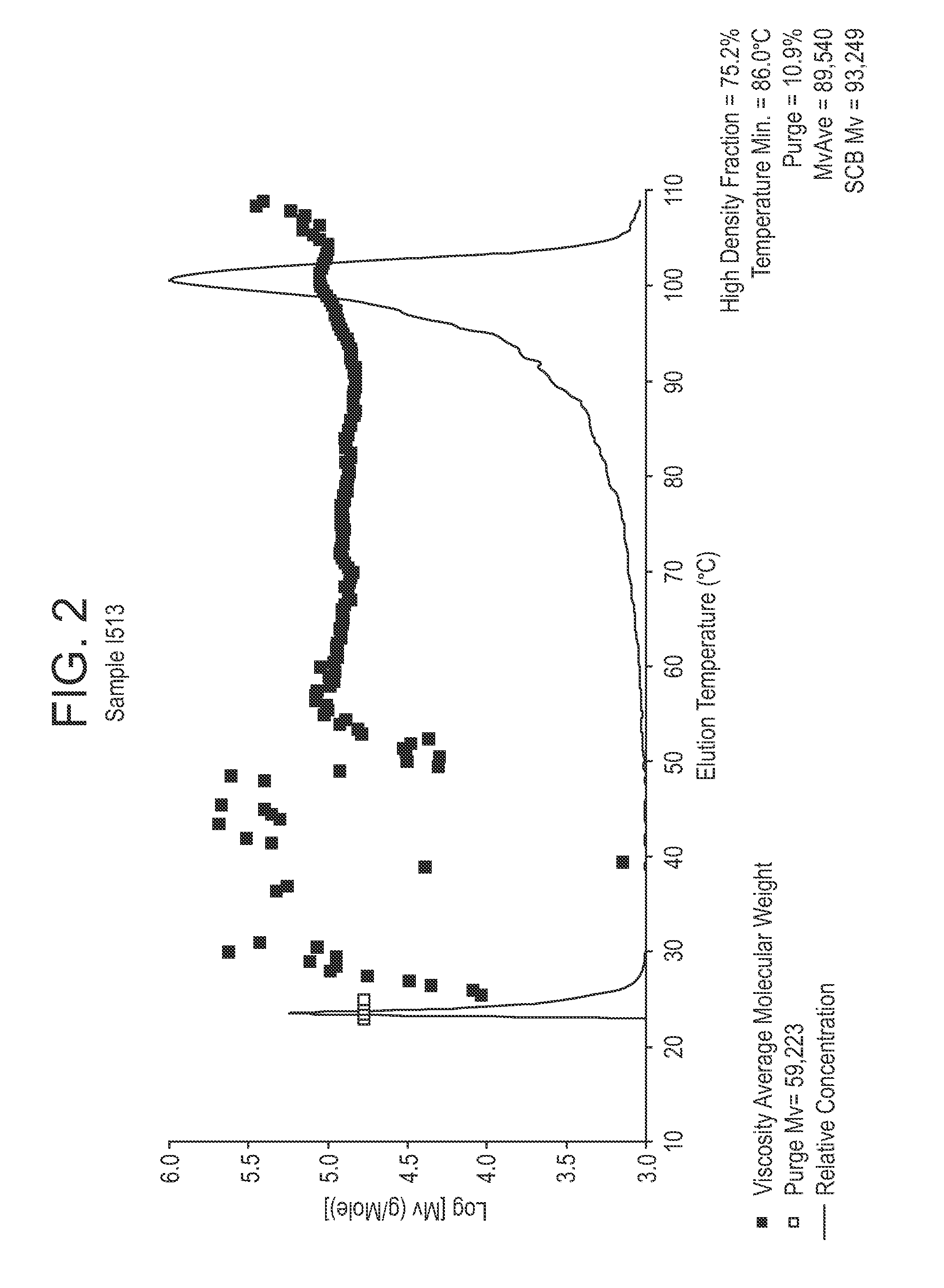

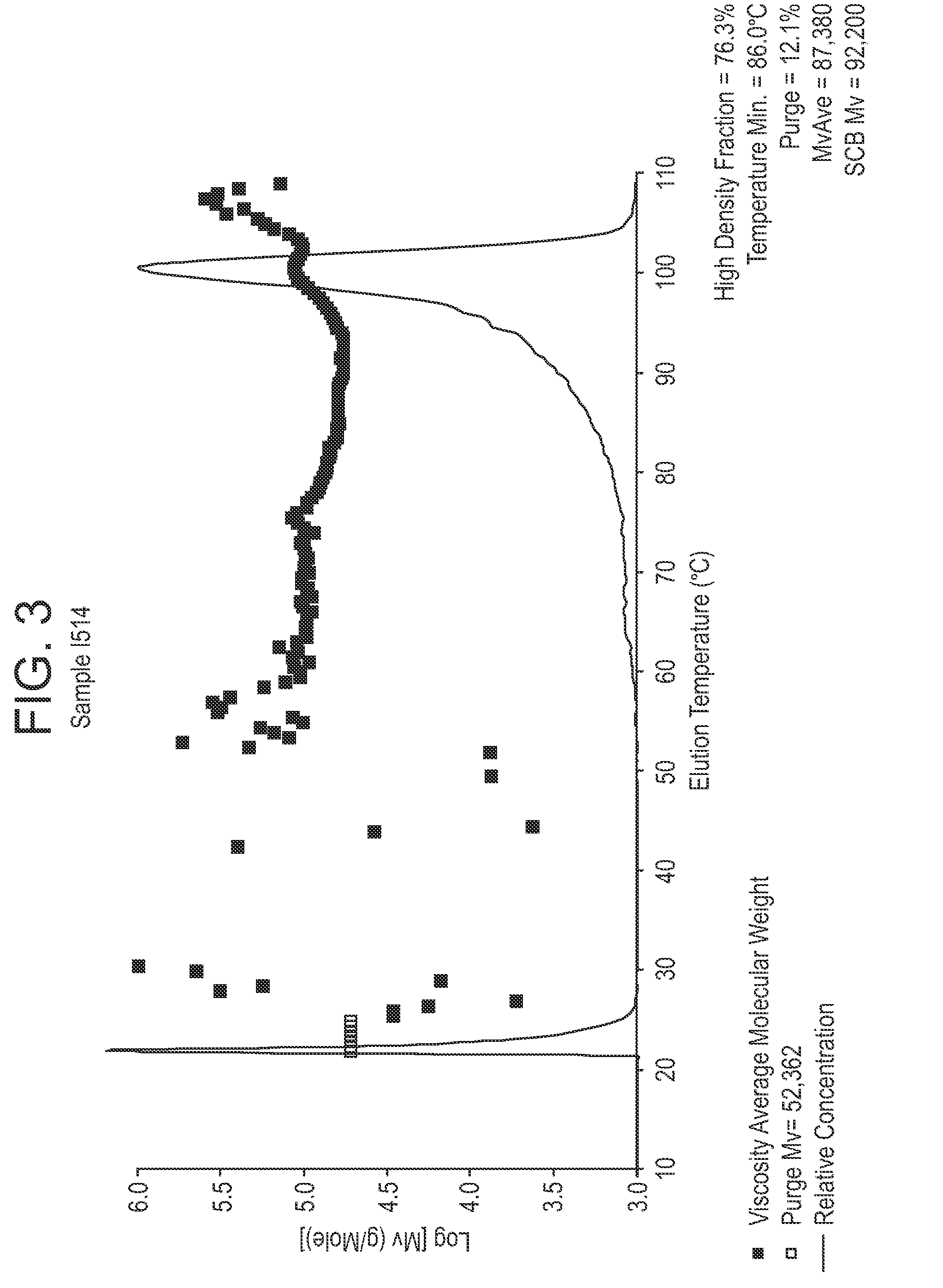

Polyethylene compositions, methods of making the same, and articles prepared therefrom

ActiveUS8344068B2Good long-term durabilityGood anti-sag performanceRigid pipesThin material handlingElutionViscosity

The invention is related to compositions suitable for the fabrication of pipes, and other articles, with excellent performance properties. The invention provides a composition, comprising a blend, wherein said blend comprises a high molecular weight ethylene-based interpolymer and a low molecular weight ethylene-based interpolymer, and the high molecular weight ethylene-based interpolymer is a heterogeneously branched linear or a homogeneously branched linear ethylene-based interpolymer, and has a density from 0.922 g / cc to 0.929 g / cc, and a high load melt index (I21) from 0.2 g / 10 min to 1.0 g / 10 min, and the low molecular weight ethylene-based interpolymer is heterogeneously branched linear or a homogeneously branched linear ethylene-based interpolymer, and has a density from 0.940 g / cc to 0.955 g / cc, and a melt index (I2) from 6 g / 10 min to 50 g / 10 min. The blend has a single peak in an ATREF profile eluting above 30° C., and has a coefficient of viscosity average molecular weight (CM?) less than −0.0032 in the log(calculated Mv) versus elution temperature, said CMv calculated in the range of elution temperatures from 70° C. to 90° C. The Mv is the viscosity average molecular weight.

Owner:DOW GLOBAL TECH LLC

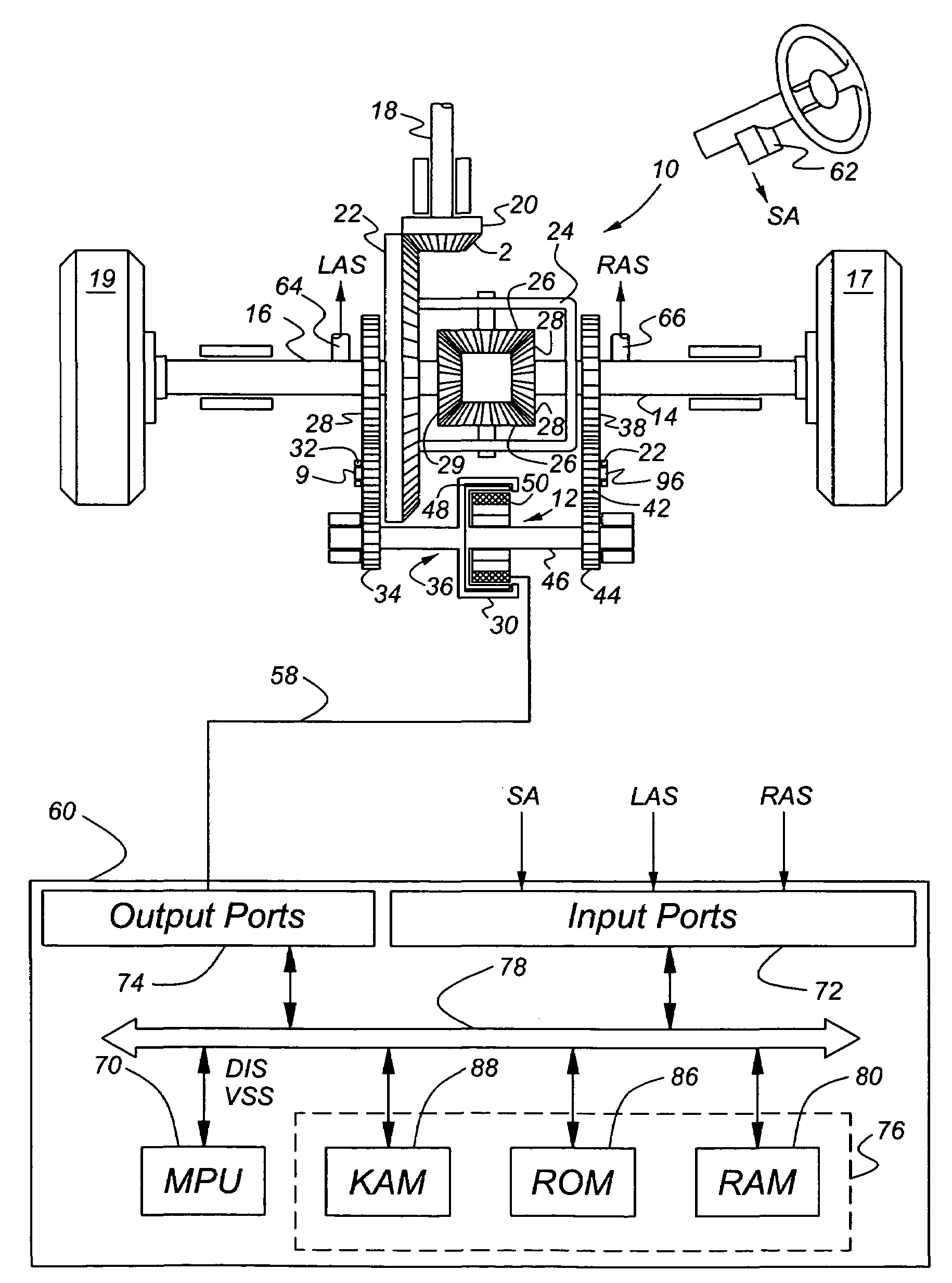

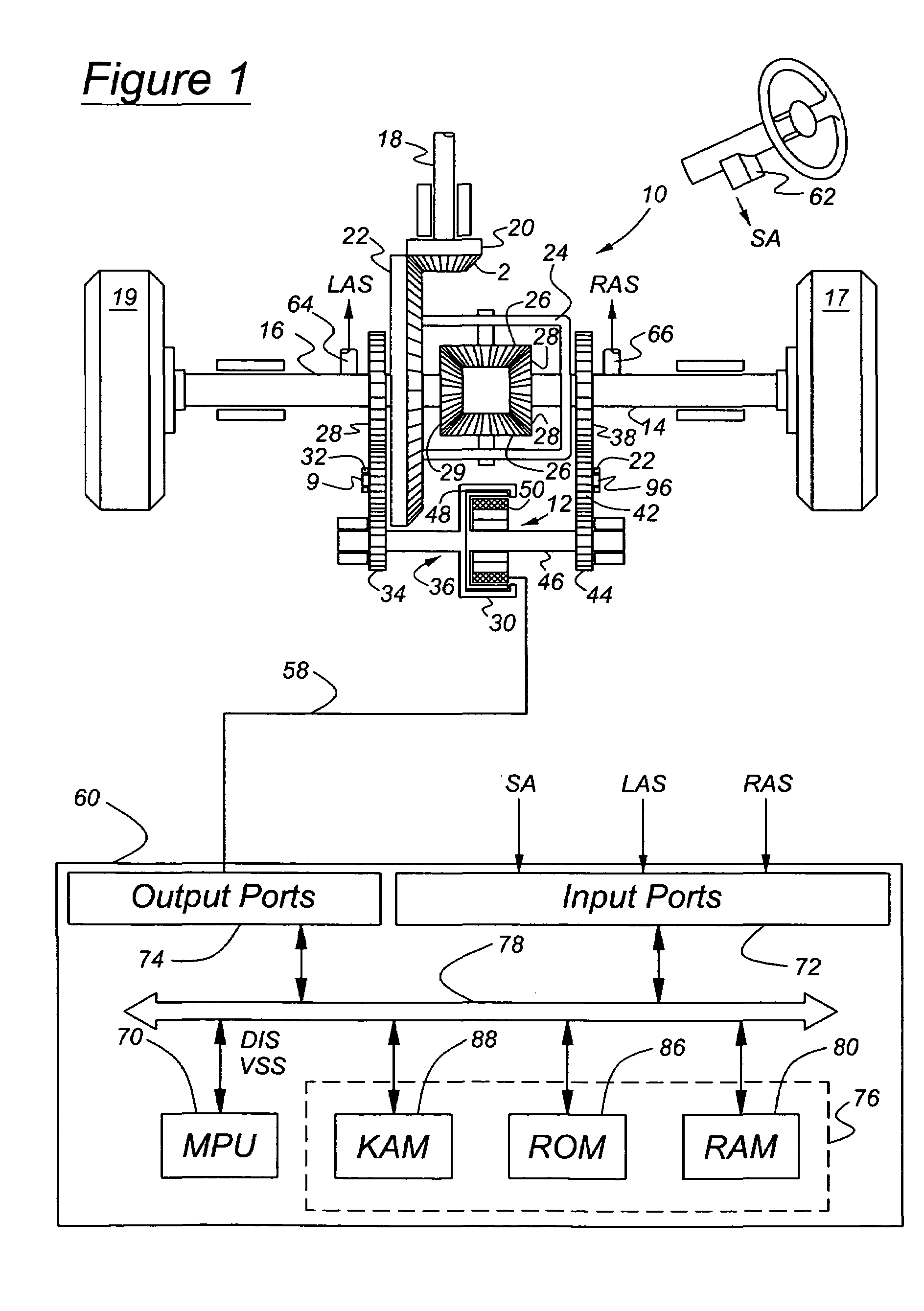

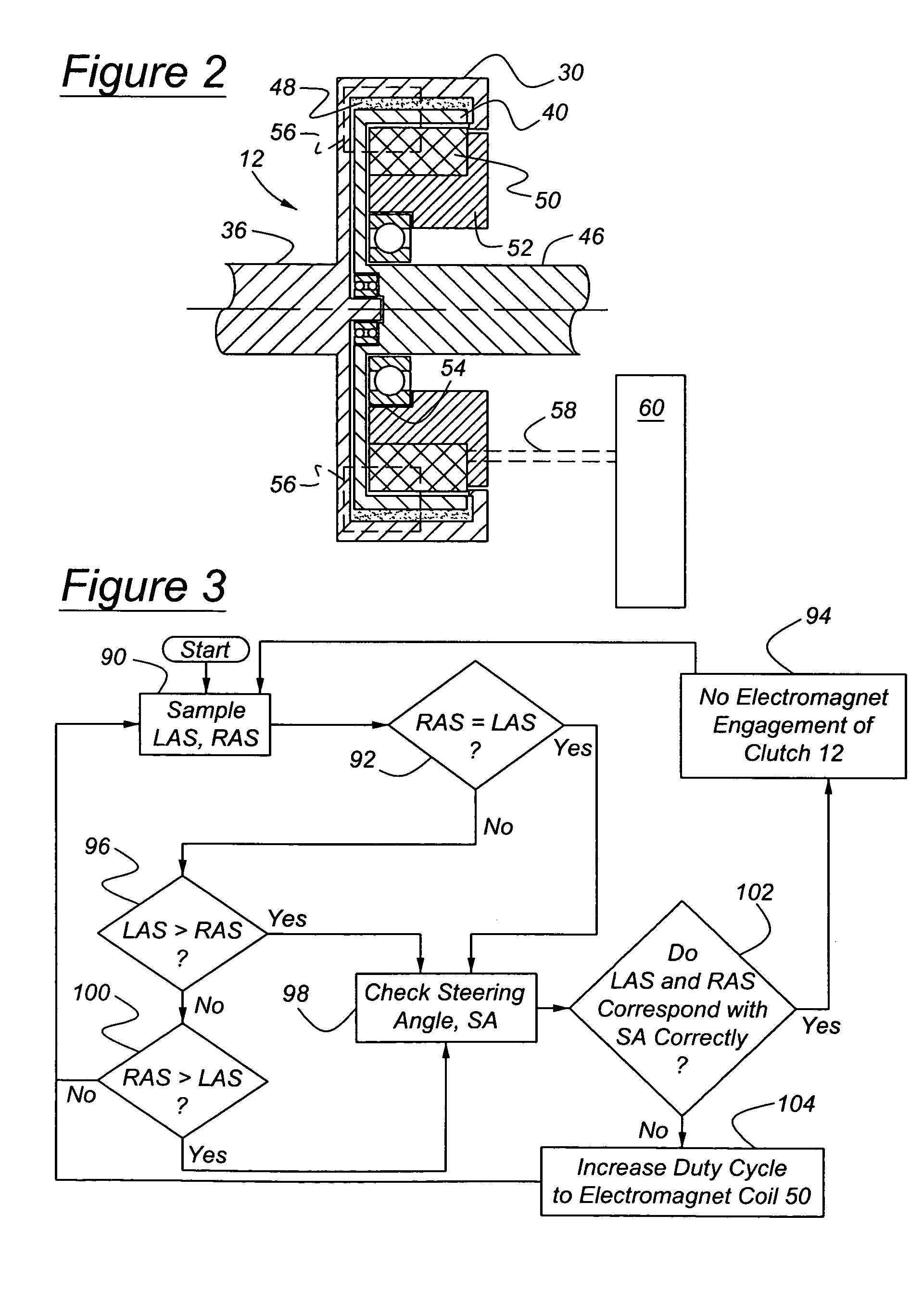

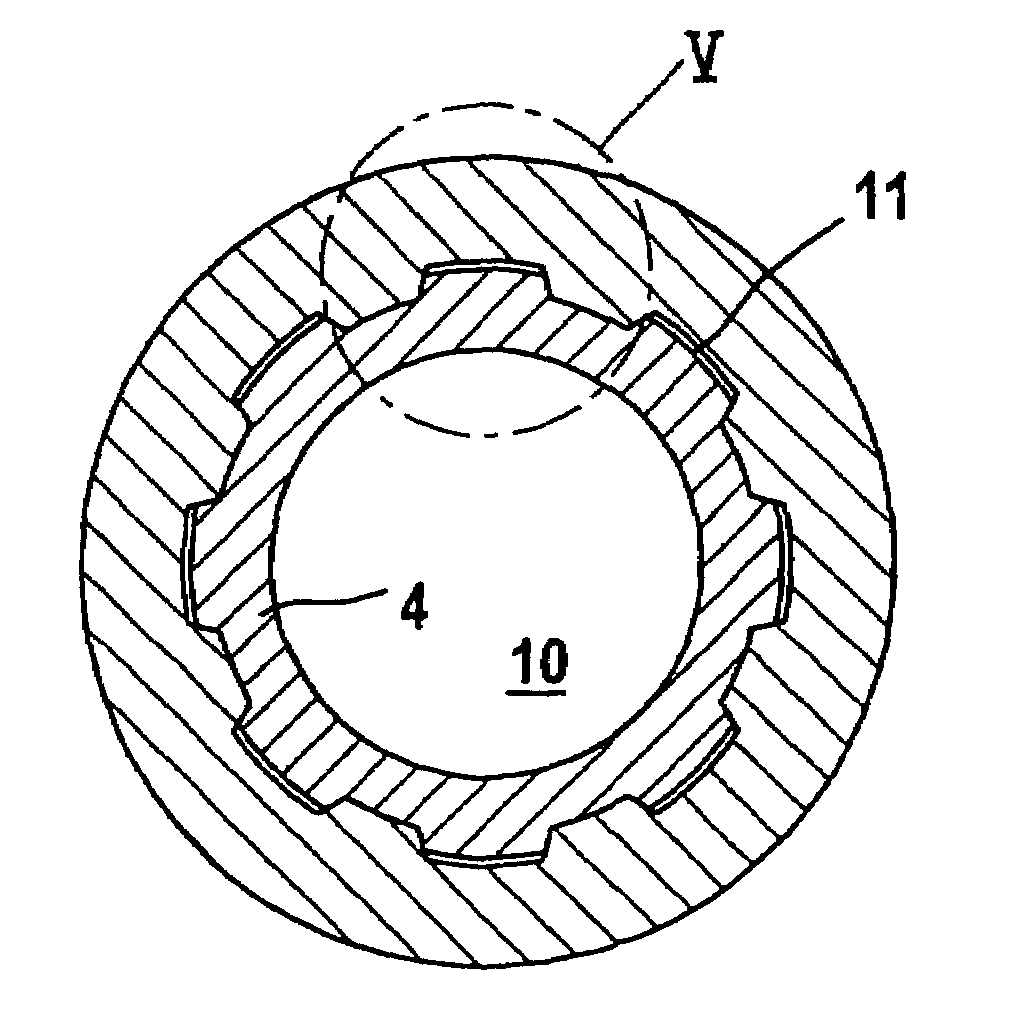

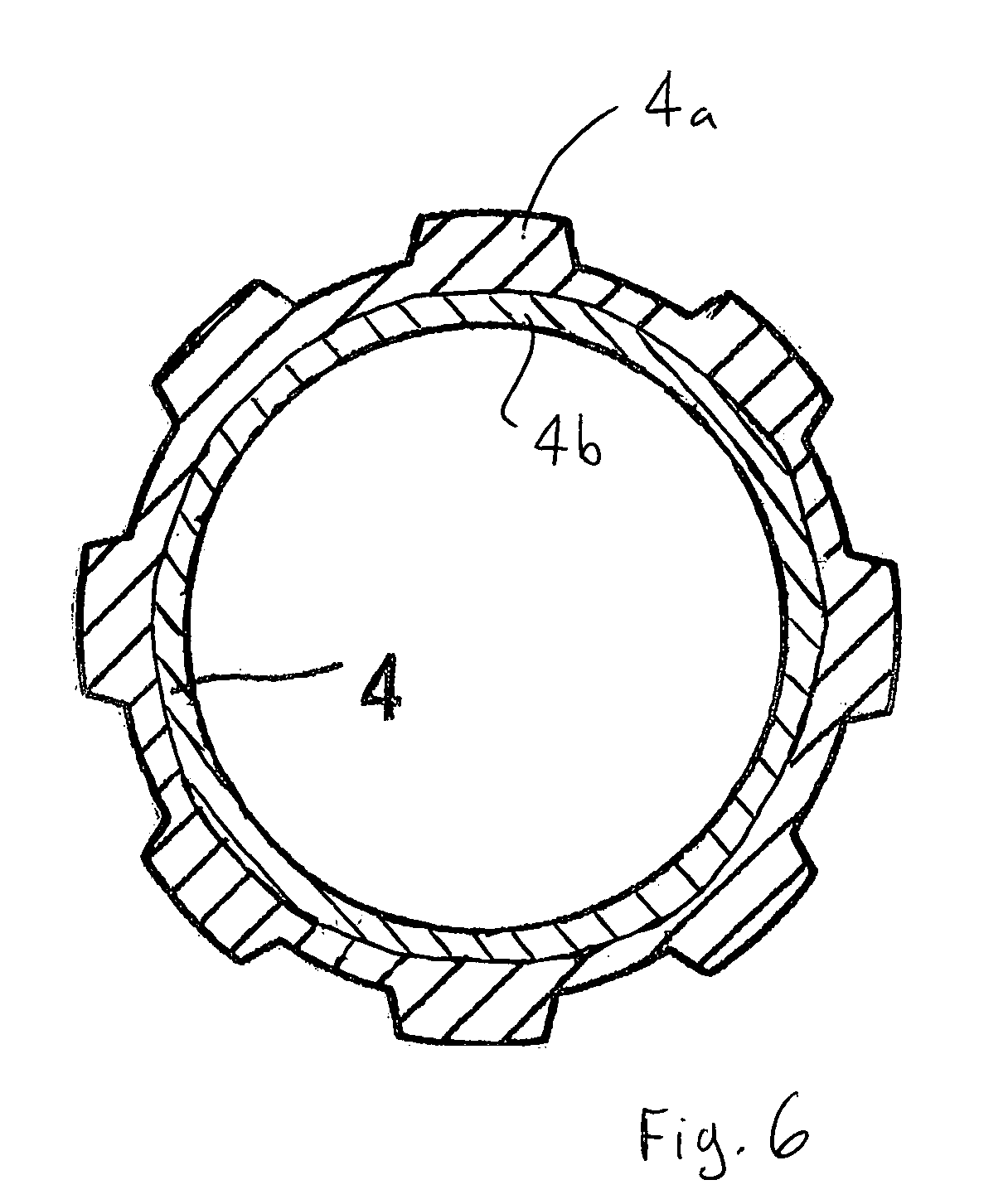

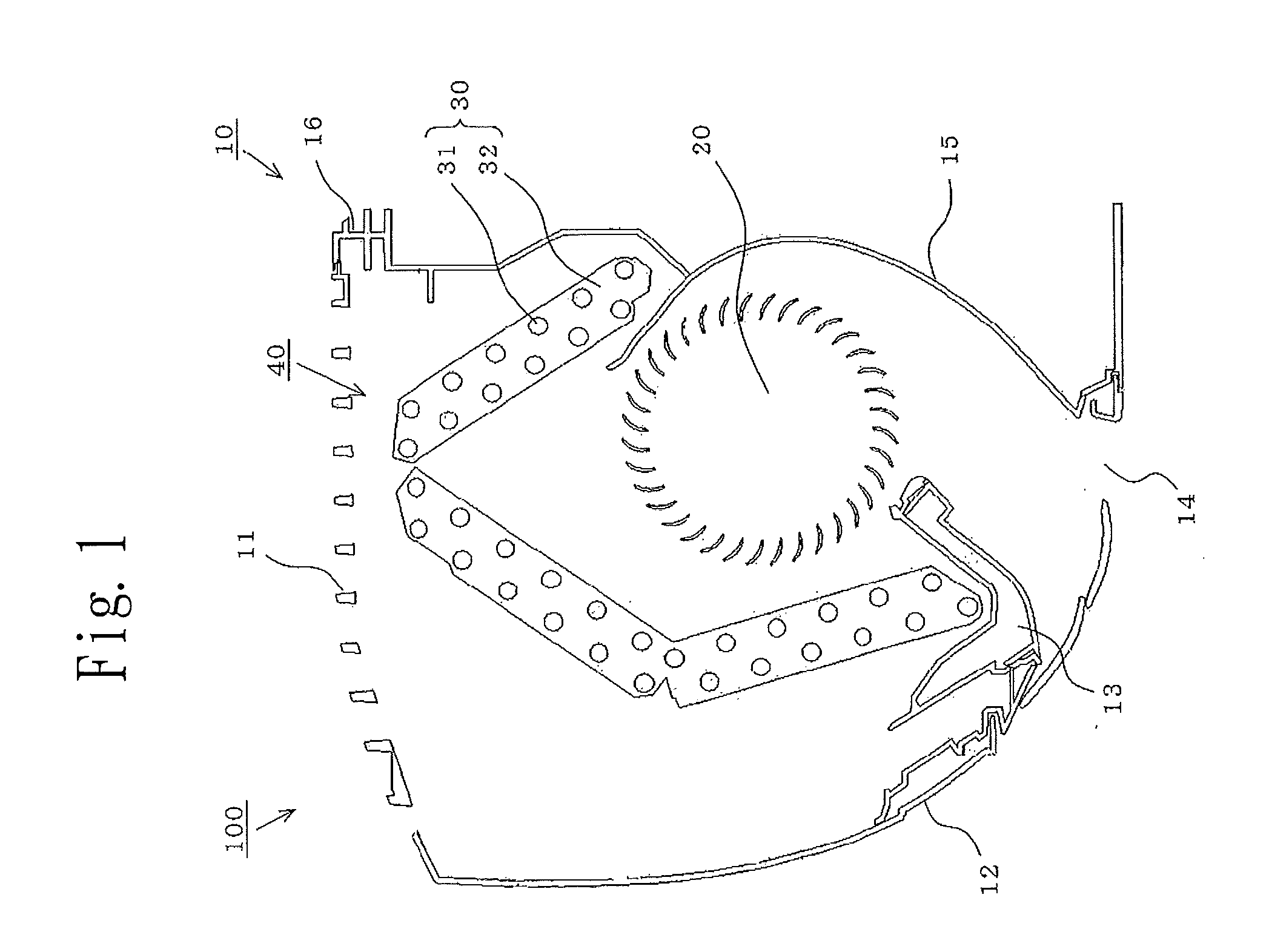

Magnetic powder torque transfer clutch for controlling slip across a differential mechanism

ActiveUS7016776B2Good long-term durabilityLittle wearClutchesDigital data processing detailsEngineeringVariable intensity

A control for a differential including magnetic powder torque transfer clutch for controlling slip across the differential mechanism. The clutch includes a first element driveably connected to a first control shaft, a second element driveably connected to the second output shaft, chamber bounded by the first and second elements, magnetic powder located in the chamber; and an elecromagnetic coil producing a magnetic field of variable strength passing through the chamber and magnetic powder and changing a capacity of the clutch to transmit torque between the first and second control shafts as the field strength changes.

Owner:FORD GLOBAL TECH LLC

Biaxially oriented polyester film for sealing back surface of photovoltaics

ActiveUS20120178897A1Improve hydrolysis resistanceLow shrinkageDomestic articlesPhotovoltaic energy generationPolyesterPolymer science

The present invention provides a biaxially oriented polyester film for a backsheet of photovoltaics which exhibits an excellent hydrolysis resistance and a low shrinkage rate. The present invention relates to a biaxially oriented polyester film for a backsheet of photovoltaics, comprising a polyester having an intrinsic viscosity of 0.65 to 0.90 dL / g as measured in a mixed solvent comprising phenol and tetrachloroethane at a mass ratio of 50 / 50 at 23° C., a carboxyl end group content of 0 to 26 equivalents / t, and a phosphorus element content of 0 to 170 ppm, which biaxially oriented polyester film has a shrinkage rate of not more than 0.8% as measured in a longitudinal direction thereof after subjected to heat treatment at 150° C. for 30 min.

Owner:MITSUBISHI CHEM CORP

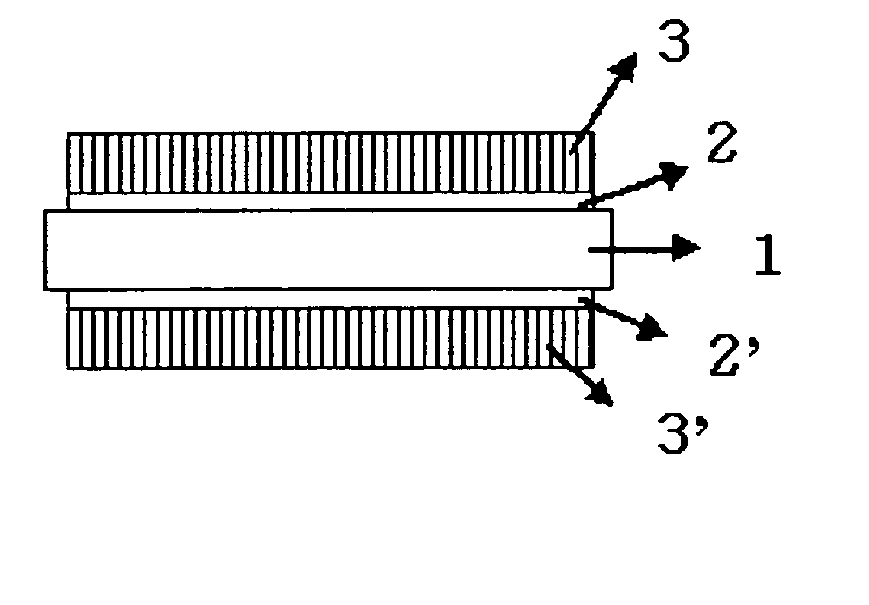

Acrylic pressure sensitive adhesive

InactiveUS7309737B2Low initial peel strengthHigh peel strengthSilicon organic compoundsPolyureas/polyurethane adhesivesCarbamateHigh humidity

The present invention relates to an acrylic pressure sensitive adhesive composition containing organic functional groups of urethane and pyridine, more precisely an acrylic pressure sensitive adhesive composition which has excellent removability owing to its low initial peel strength on glass and excellent long-term durability since the peel strength of the pressure sensitive adhesive composition onto glass is being increased under high temperature and high humidity. The present invention also relates to an acrylic pressure sensitive adhesive composition for a polarizer having excellent adhesive functions and durability, a polarizer and a LCD containing the same.

Owner:LG CHEM LTD

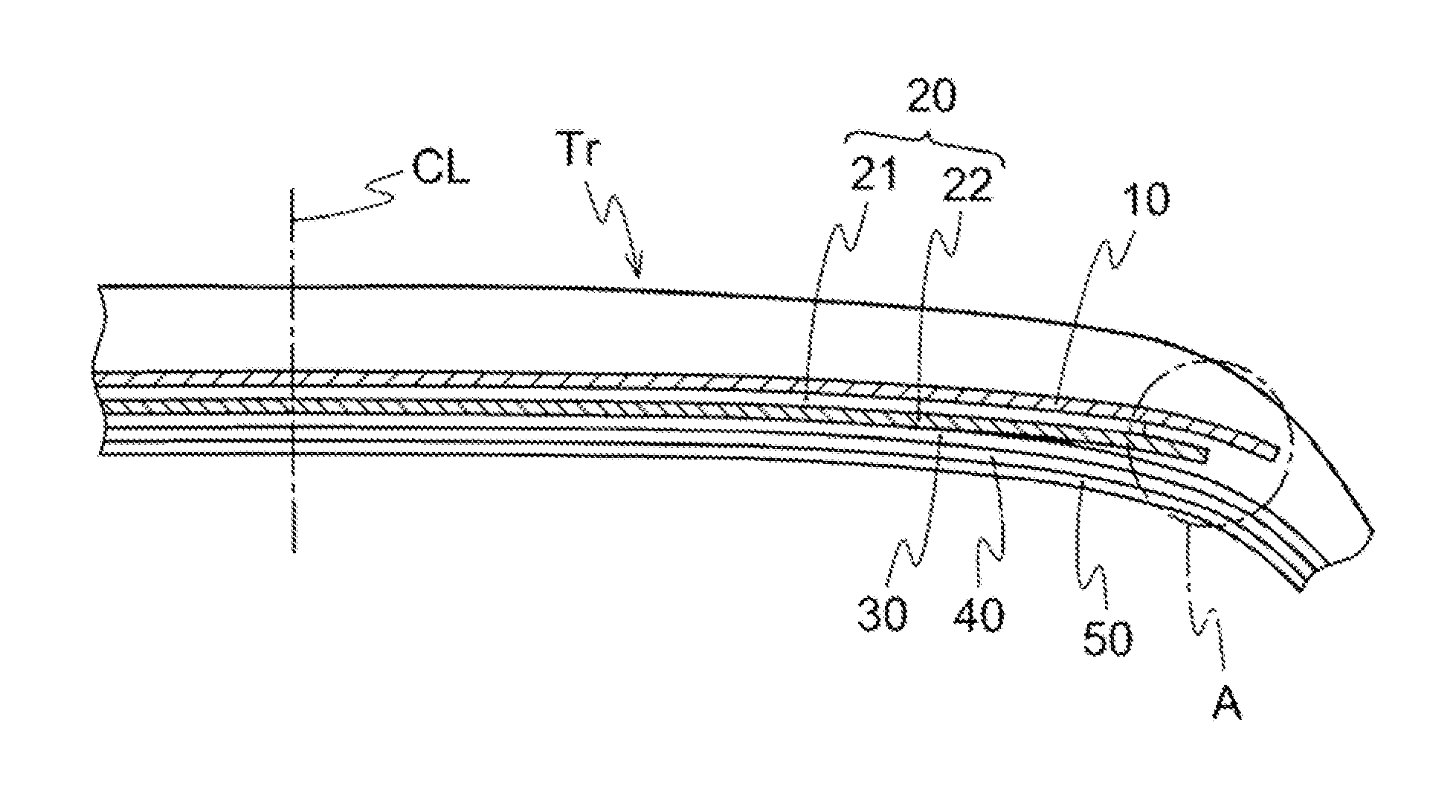

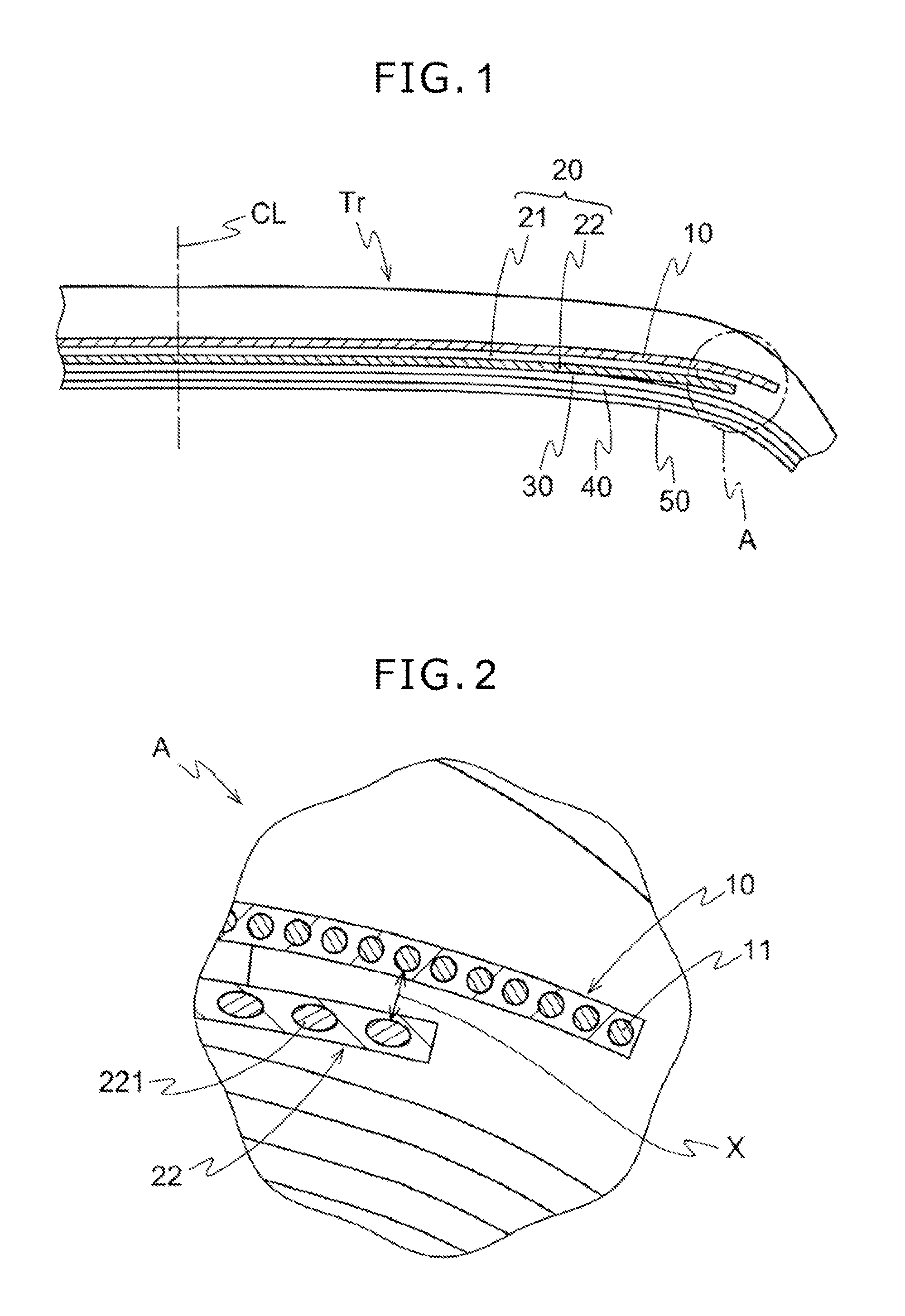

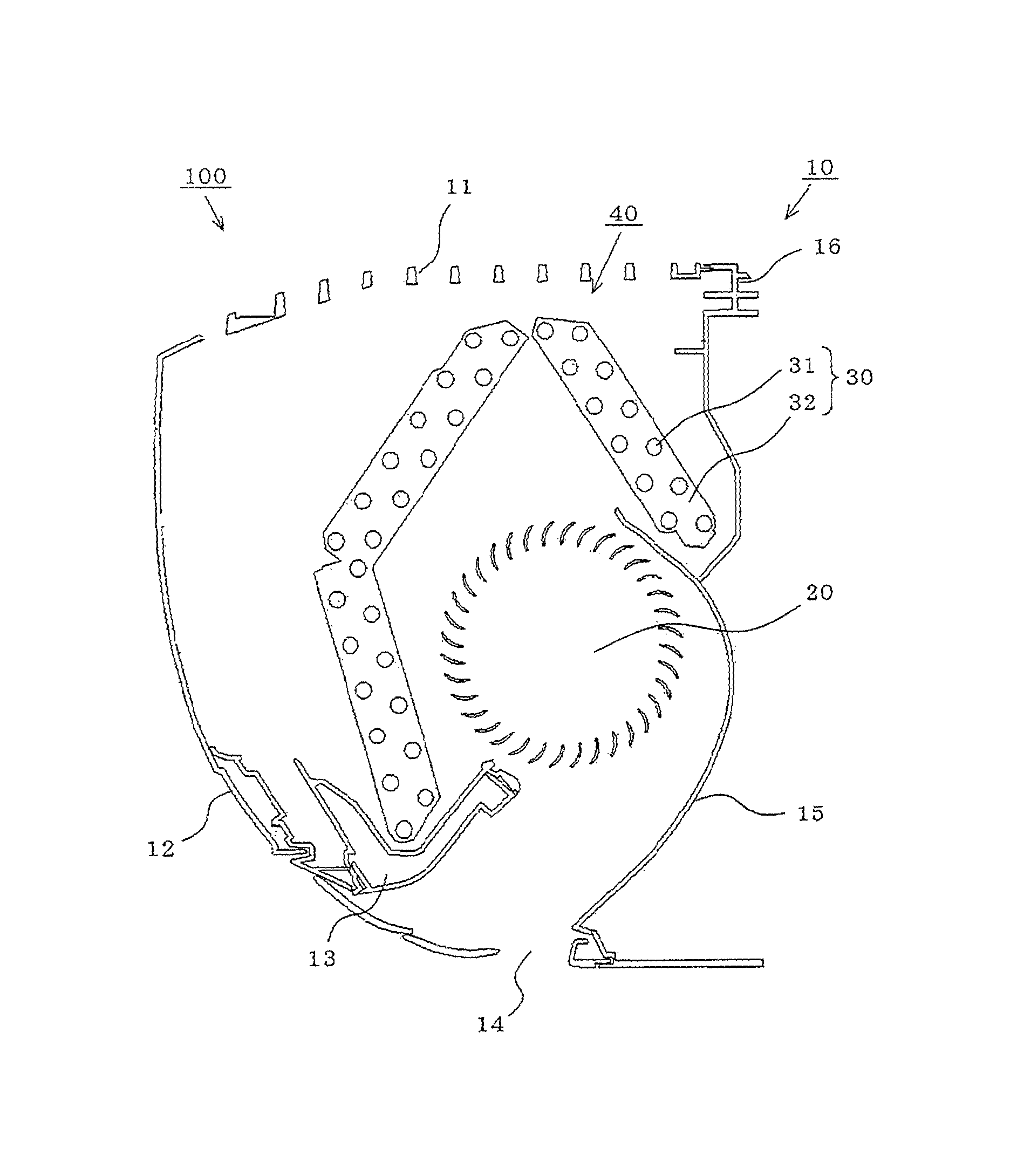

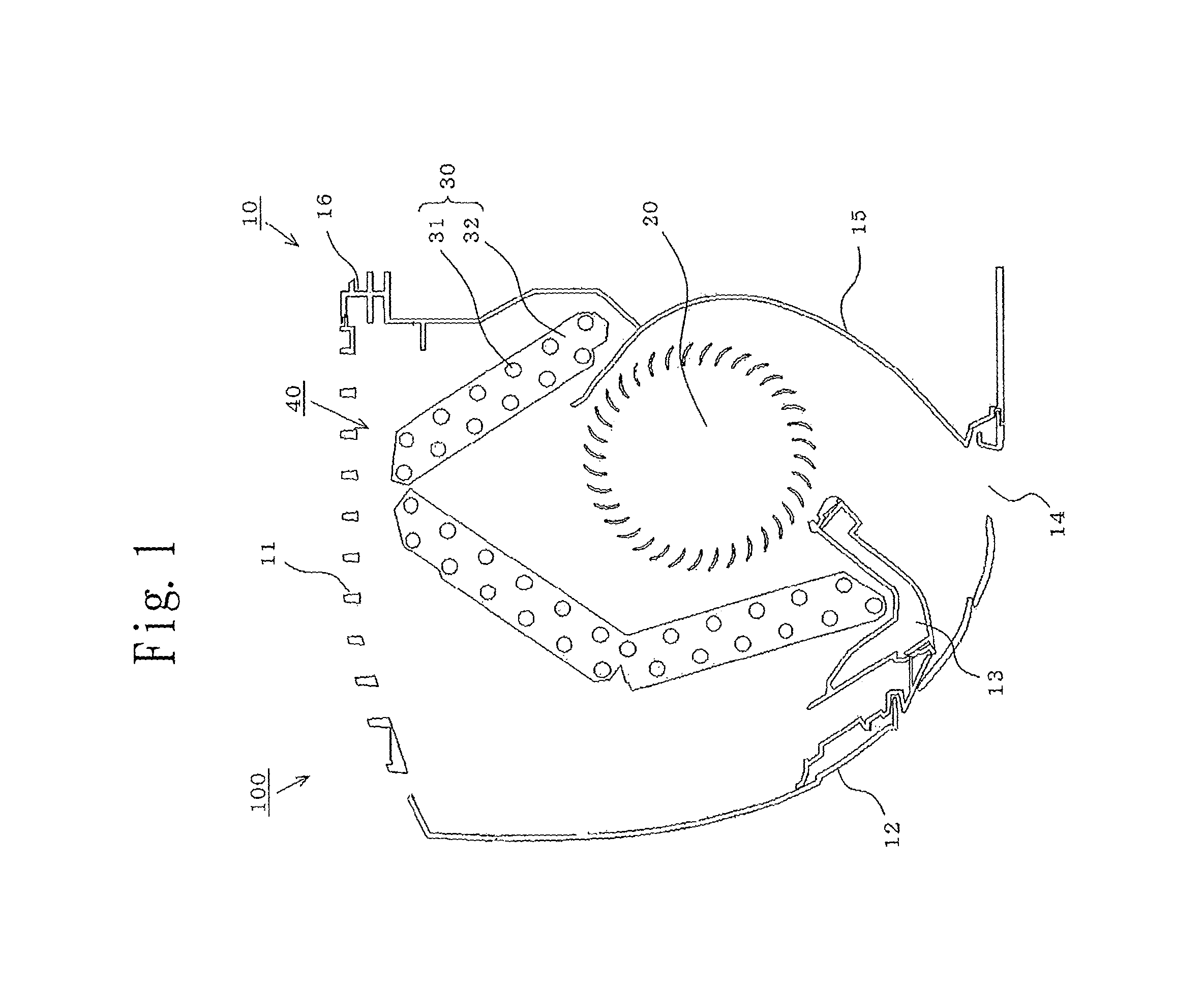

Pneumatic tire

InactiveUS20130139940A1Good long-term durabilityIncreased durabilitySpecial tyresPneumatic tyre reinforcementsBreaking strengthCresol

The present invention provides a pneumatic tire having a jointless band obtained by covering a cord having a cord breaking strength of 200 to 600 N and a degree of elongation at a tension of 66 N of 1.0 to 3.5% with a rubber composition for band cord topping comprising a given amount of sulfur, a given amount of a predetermined carbon black, a given amount of at least one compound selected by the group consisting of resorcinol resin, modified resorcinol resin, cresol resin, modified cresol resin, phenol resin and modified phenol resin, and a given amount of at least one compound selected from the group consisting of a partial condensate of hexamethoxymethylolmelamine and a partial condensate of hexamethylolmelaminepentamethylether based on a given amount of a rubber component.

Owner:SUMITOMO RUBBER IND LTD

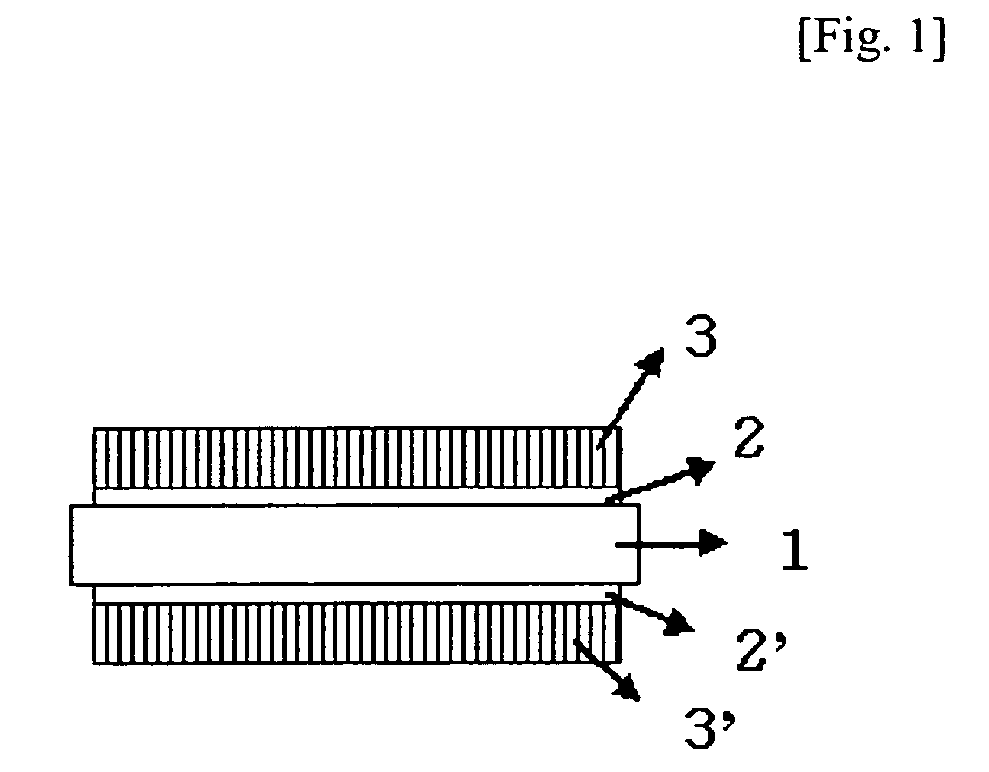

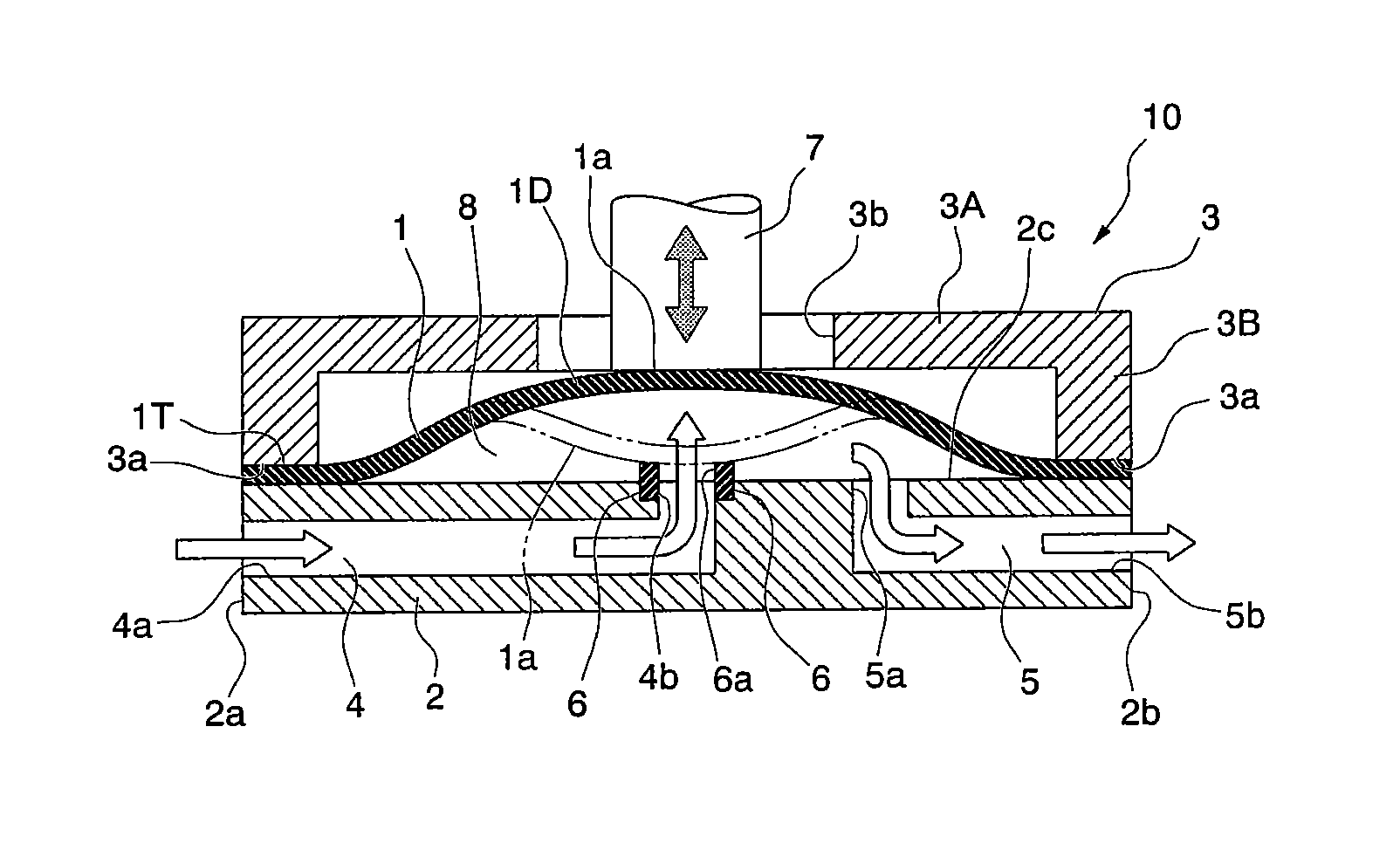

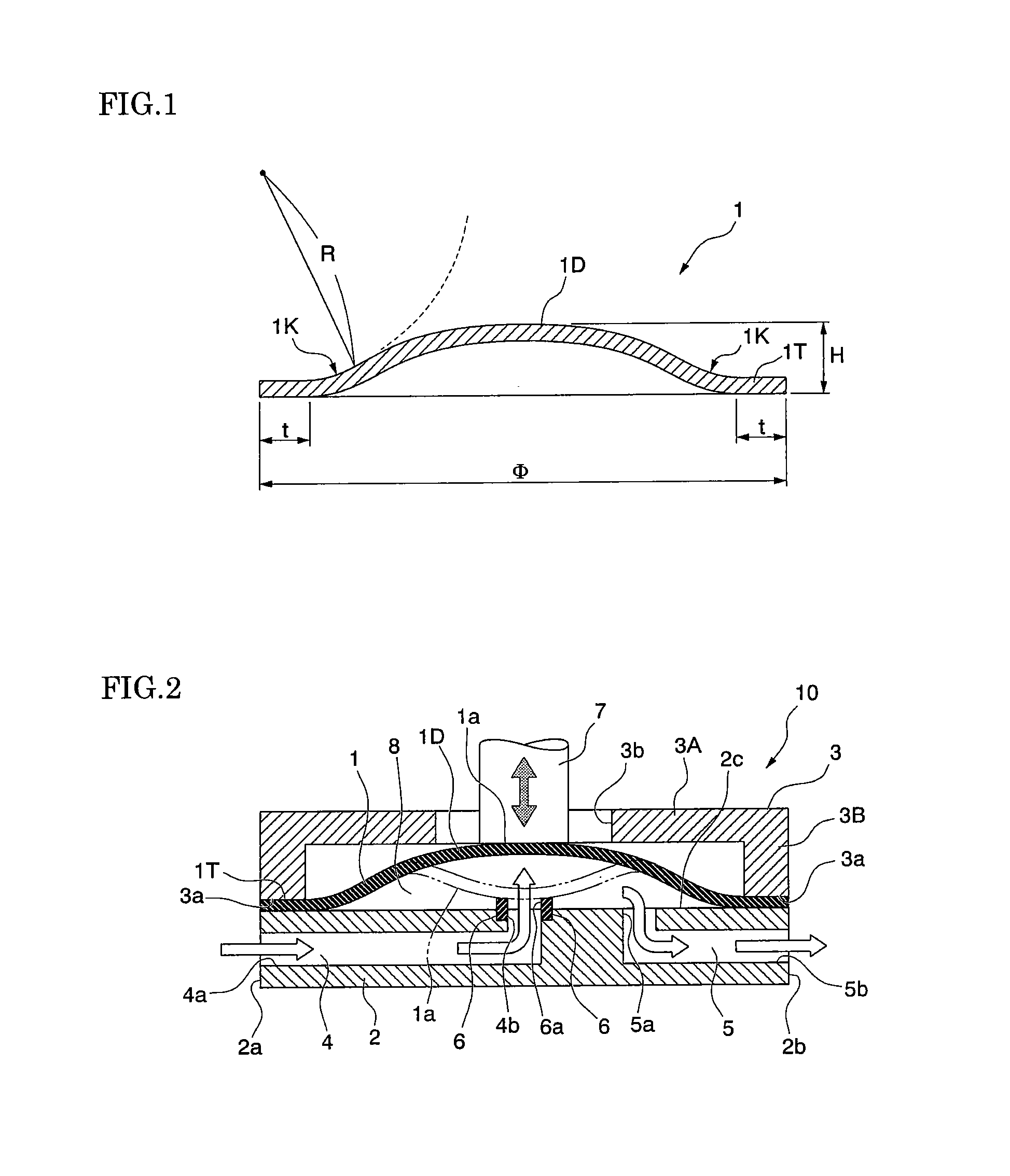

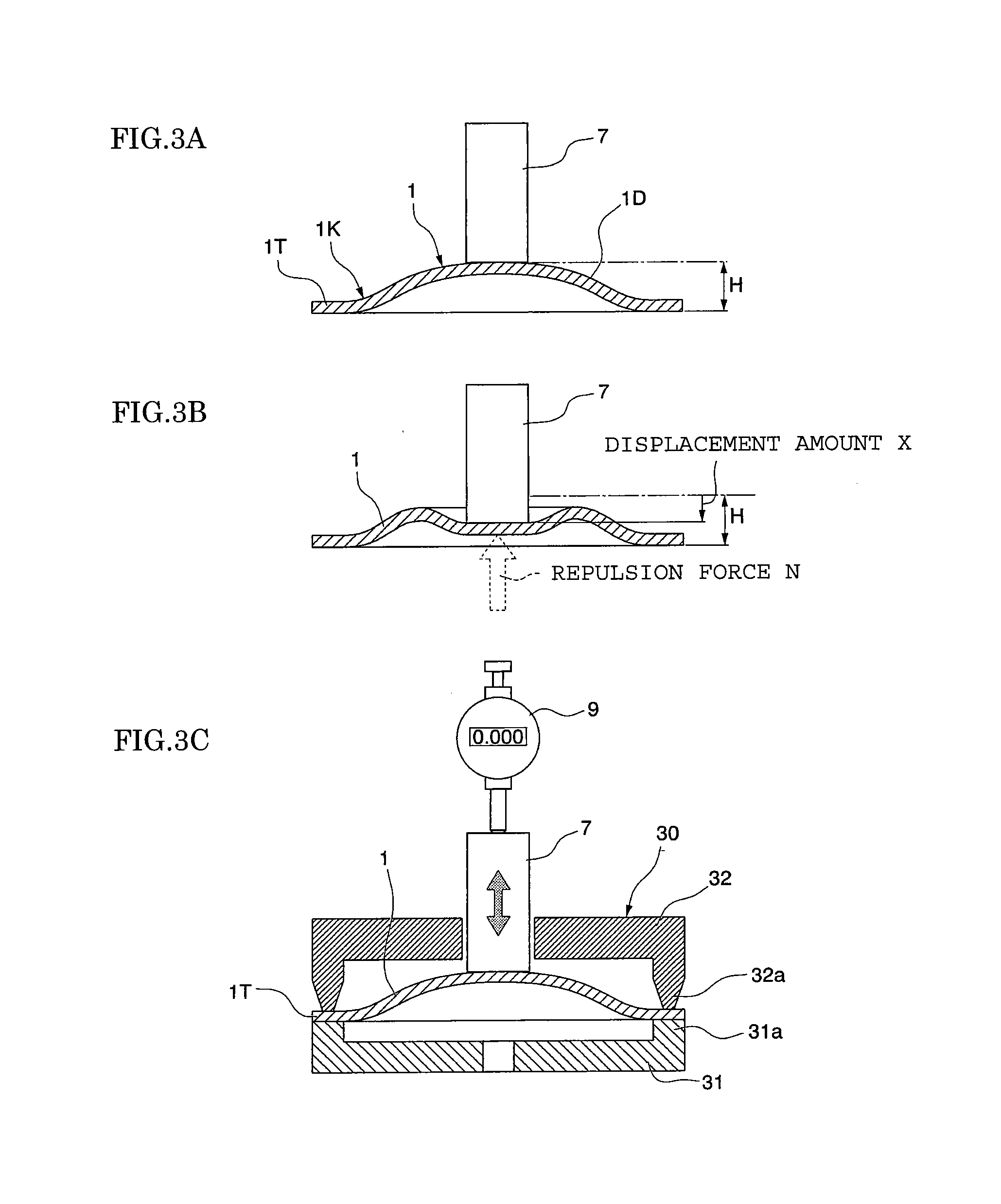

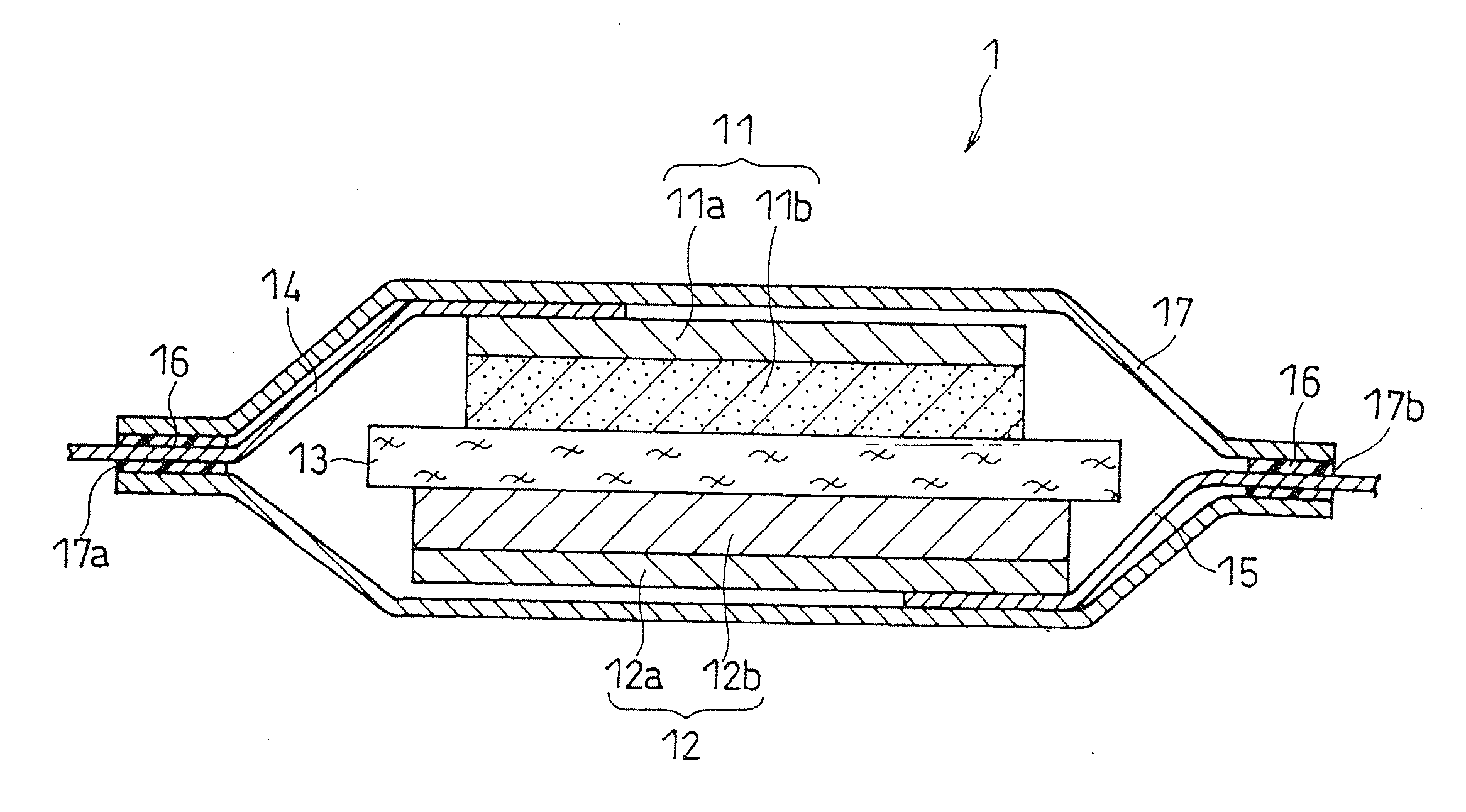

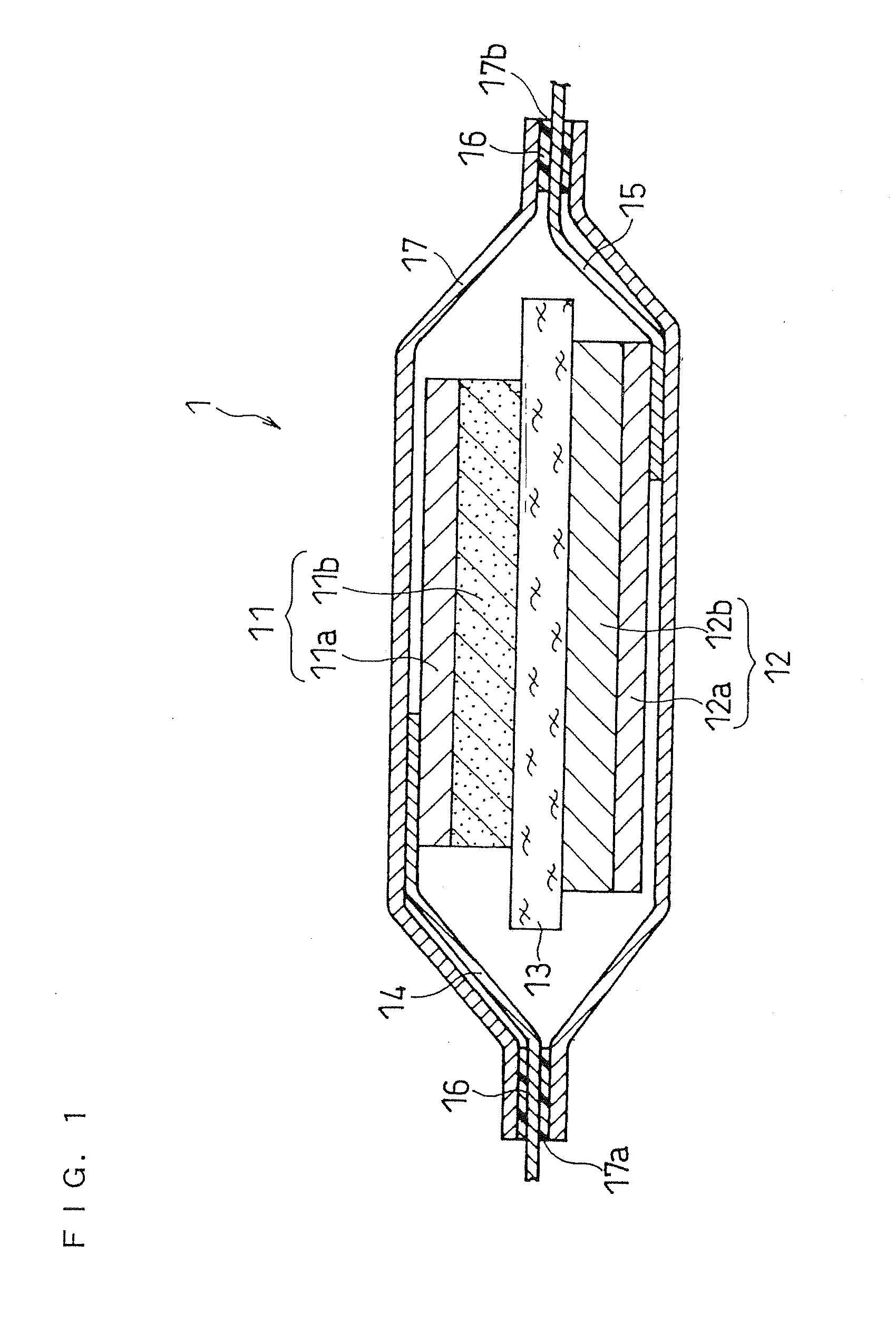

Diaphragm, diaphragm valve, and method of manufacturing diaphragm

ActiveUS20110233443A1Reducing stress appliedGood long-term durabilityDiaphragm valvesOperating means/releasing devices for valvesLong term durabilityConvex side

Provided are a diaphragm, a diaphragm valve, and a method of manufacturing a diaphragm capable of increasing a flow rate (Cv value) of gas without degrading long-term durability even when a displacement amount is increased. A diaphragm (1) has an outer diameter Φ of 10 to 35 mm and includes a dome portion (1D) in a dome shape and a flange portion (1T) formed continuously at a peripheral edge of the dome portion (1D) via a boundary portion (1K), the boundary portion (1K) has a radius of curvature R of 0.6 mm or more on a convex side of the dome portion (1D), and the diaphragm is formed of a cobalt-based super-alloy.

Owner:SEIKO INSTR INC

Acrylic pressure sensitive adhesive

InactiveUS20060035076A1Improve removabilityLow initial peel strengthSilicon organic compoundsPolyureas/polyurethane adhesivesCarbamateHigh humidity

The present invention relates to an acrylic pressure sensitive adhesive composition containing organic functional groups of urethane and pyridine, more precisely an acrylic pressure sensitive adhesive composition which has excellent removability owing to its low initial peel strength on glass and excellent long-term durability since the peel strength of the pressure sensitive adhesive composition onto glass is being increased under high temperature and high humidity. The present invention also relates to an acrylic pressure sensitive adhesive composition for a polarizer having excellent adhesive functions and durability, a polarizer and a LCD containing the same.

Owner:LG CHEM LTD

Separator for non-aqueous electrolyte battery and non-aqueous electrolyte battery

InactiveUS20080057400A1Excellent in resistance to oxidationHigh mechanical strengthLi-accumulatorsCell component detailsOrganic compoundCopolymer

A separator is made by using a copolymer for the separator including a monomer component derived from an olefin compound containing a fluorine atom and a monomer component derived from a polymerizable organic compound containing an oxygen atom in its molecule. This separator is excellent in resistance to oxidation and wettability to electrolytes. Therefore, by making a non-aqueous electrolyte battery using this separator, charge and discharge cycle life and storage characteristics of the battery improve. Further, similar effects can be obtained by using this separator, even in the case of a non-aqueous electrolyte battery using a high-potential positive electrode active material.

Owner:PANASONIC CORP

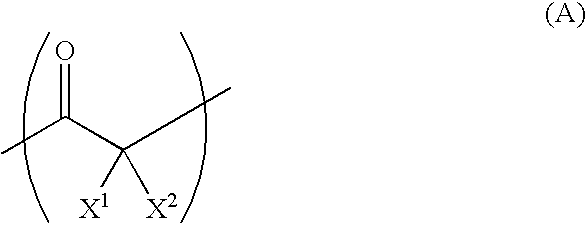

Curable composition

InactiveUS20020002263A1Maintain good propertiesHigh strengthOther chemical processesParaffin waxAnti ageing

A curable composition comprising 100 parts by weight of saturated hydrocarbon polymer having at least one silicon-containing group which has at least one hydroxyl or hydrolyzable group bonded to a silicon atom and is crosslinkable through the formation of a siloxane bond, 1-100 parts by weight of a compound which has at least one epoxy group at its end, and 1-100 parts by weight of mica. If necessary, paraffin hydrocarbon oil is mixed into said curable composition. Further, usual additives for a sealing material such as an anti-aging agent and a filler may be mixed into the curable composition.

Owner:BRIDGESTONE CORP

Macromolecular electrolyte membrane for a fuel cell, and a membrane electrode binder material and a fuel cell comprising the same

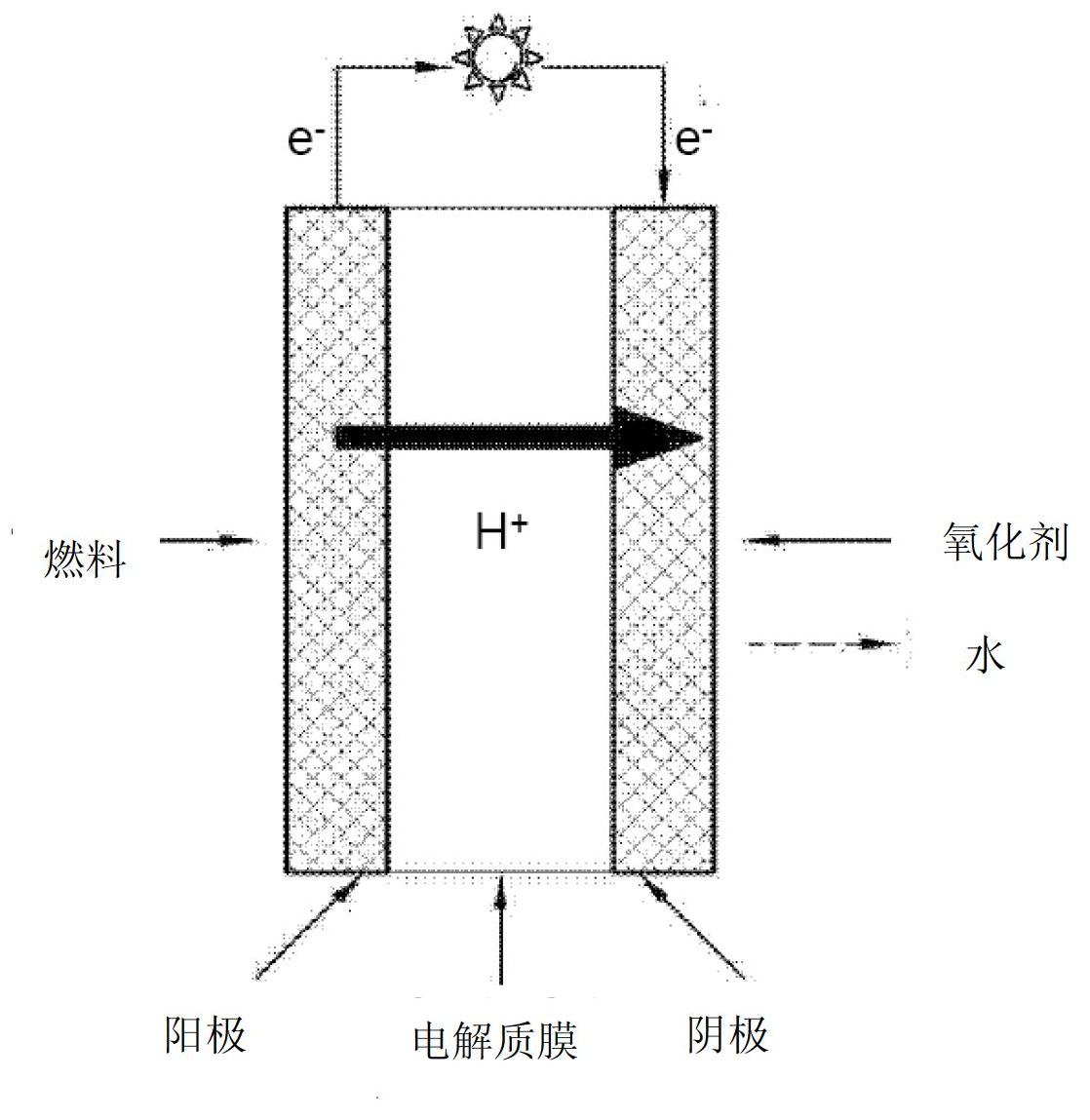

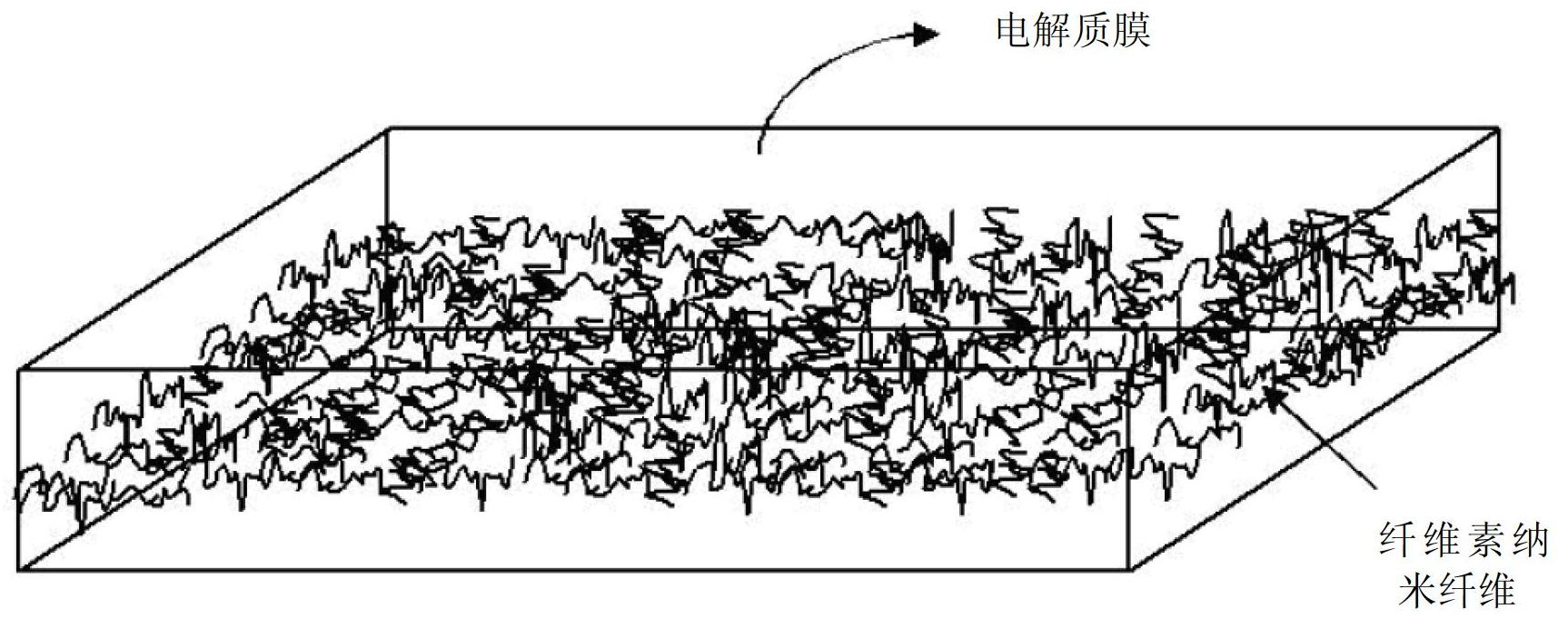

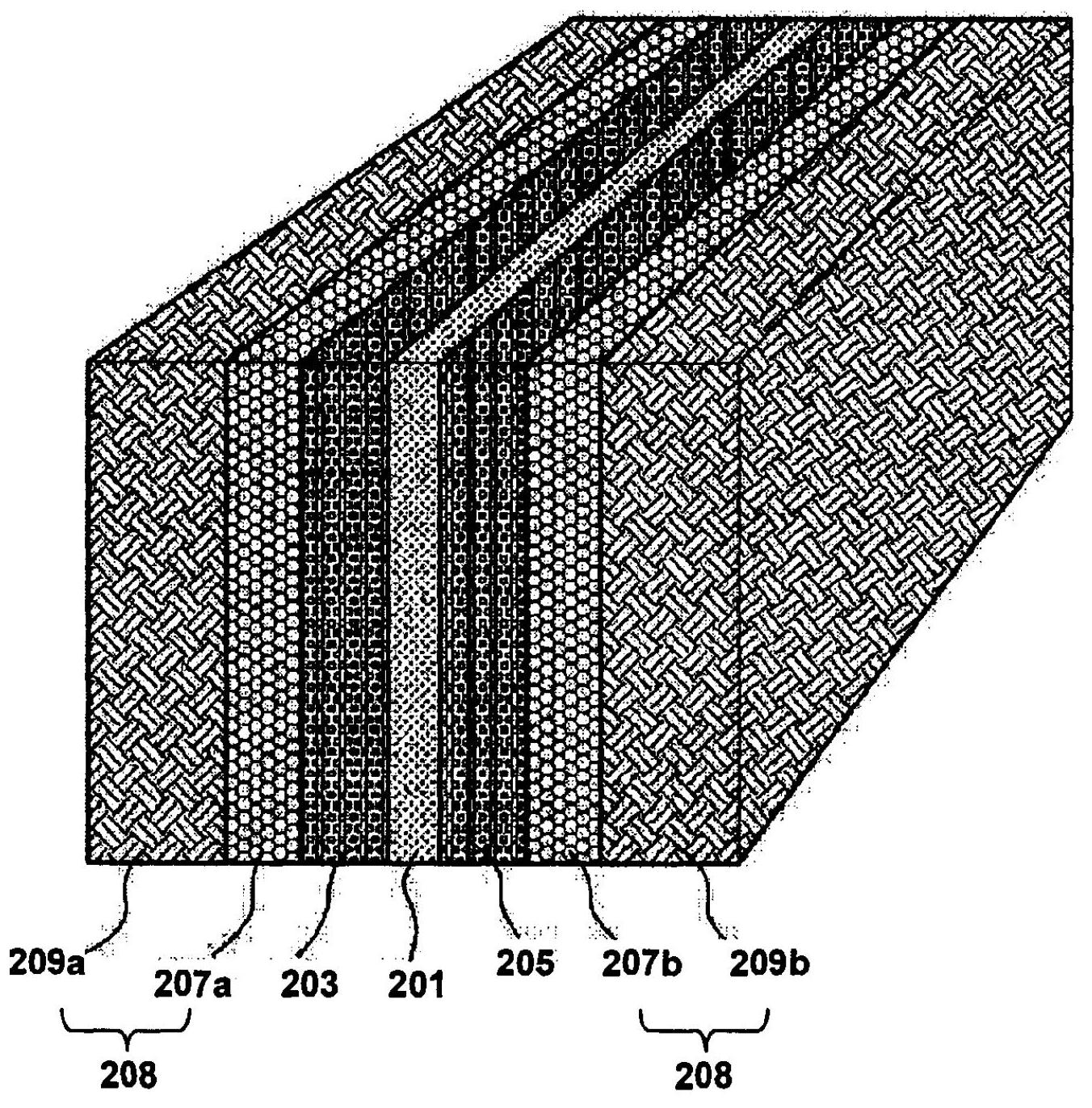

ActiveCN102668207AIncrease surface areaReduce manufacturing costSolid electrolytesNanostructure manufactureFiberLong term durability

The present invention relates to a macromolecular electrolyte membrane for a fuel cell, and to a membrane electrode binder material and a fuel cell comprising the same, and provides a macromolecular electrolyte membrane for a fuel cell comprising a cation exchange resin based on a hydrogen-ion-conducting hydrocarbon and comprising fibrous nanoparticles having a hydrophilic group. By using fibrous nanoparticles having a hydrophilic group in a mixture with a cation exchange resin based on a hydrogen-ion-conducting hydrocarbon, the present invention can provide a macromolecular electrolyte membrane having improved gas-screening properties and long-term durability without reducing the performance of the fuel cell, and can provide a fuel cell which comprises the macromolecular electrolyte membrane.

Owner:LG CHEM LTD

Non-magnetic toner

Provided is anon-magnetic toner including toner particles each containing at least a binder resin, a colorant, and a wax component, and an inorganic fine powder, in which: (1) when a temperature in a temperature range of 50 to 80° C. at which a loss tangent (tan δ) shows a maximum is represented by T1, a storage elastic modulus of the toner at the temperature T1 (G′(T1)) satisfies a relationship of 5.00×107≦G′(T1)≦1.00×109 (dN / m2); (2) a continuous temperature range with a width of 15° C. or more in which the loss tangent (tan δ) is 0.80 to 2.00 is present in the temperature range of 50 to 80° C.; and (3) the loss tangent (tan δ) is 1.00 or more in a temperature range of 120 to 160° C.

Owner:CANON KK

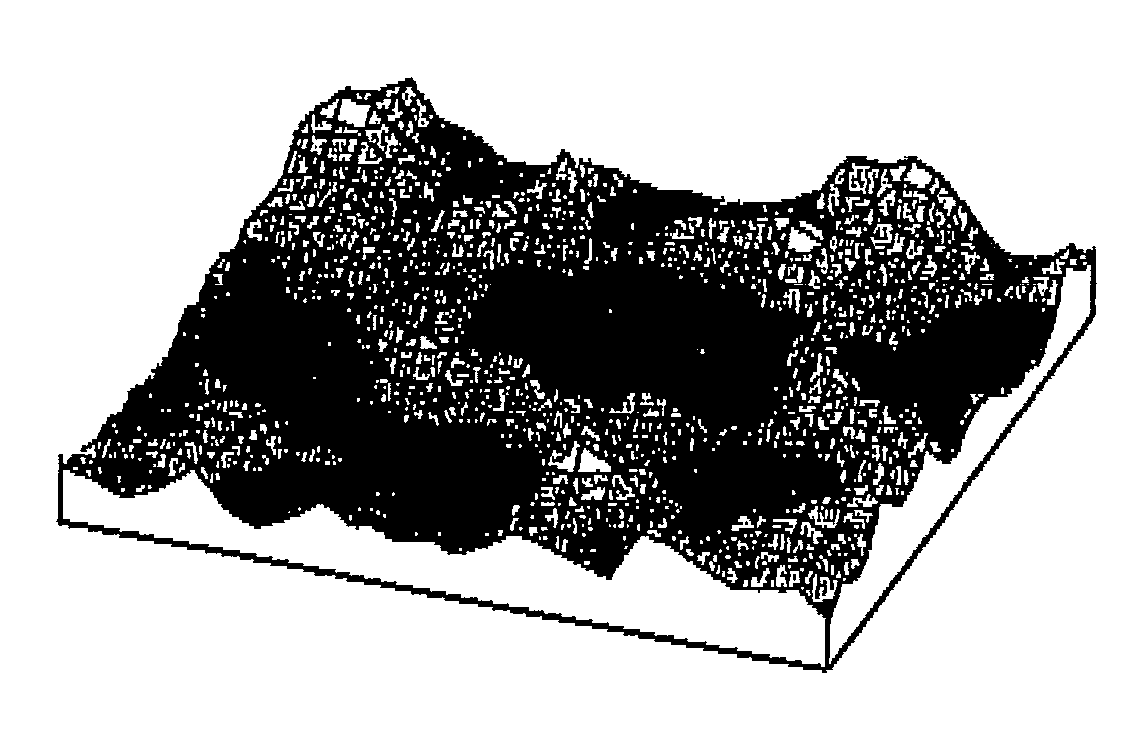

Antireflection film, polarizing plate and image display device

ActiveUS8318301B2Increase production capacityGood long-term durabilityDiffusing elementsSynthetic resin layered productsMeth-Display device

Provided is an antireflection film including, in the following order: a transparent support; at least one antiglare layer or diffusive layer containing a transparent resin and light-transmissive resin particles; and a low-refractivity layer having a refractive index lower than that of any of the transparent support and the antiglare layer or diffusive layer, wherein the transparent resin is formed by curing a mixture containing (A) a polyfunctional (meth)acrylate having at least two (meth)acryloyl groups, and (B) a modified polyfunctional (meth)acrylate modified through addition of any of ethylene oxide, propylene oxide or caprolactone, and the light-transmissive resin particles contain (C) high-crosslinking light-transmissive particles which are so high-crosslinking as to have a residual monomer content of at most 2.0% and which have a compression strength of from 39 to 98 N / mm2.

Owner:FUJIFILM CORP

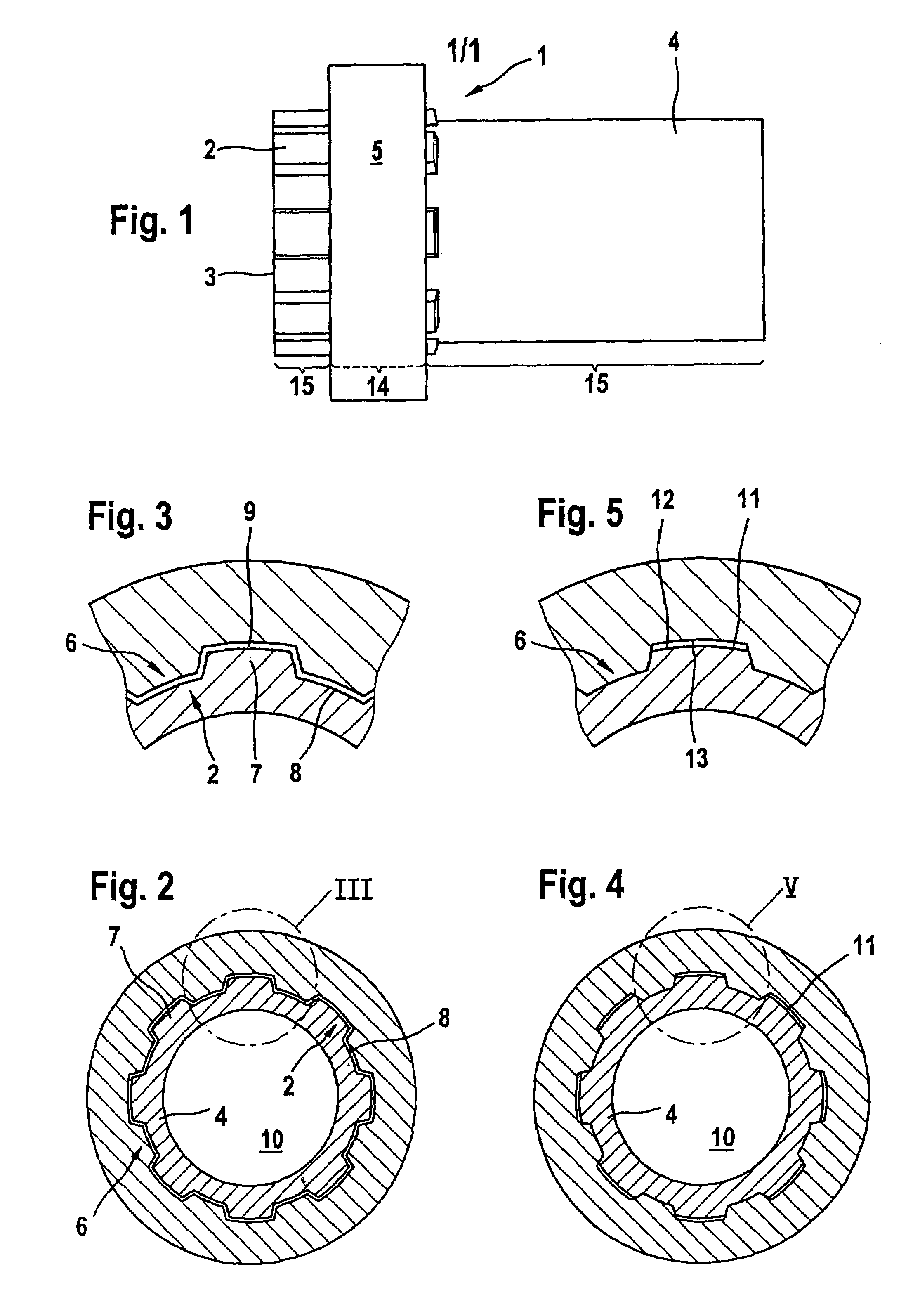

Method for the production of a shaft-hub connection

InactiveUS7076854B2Good long-term durabilityAvoid damageJoints with sealing surfacesToothed gearingsEngineeringMechanical engineering

Owner:DAIMLER AG

Antireflection film, polarizing plate and image display device

ActiveUS20090246490A1Increase production capacityGood long-term durabilityDiffusing elementsSynthetic resin layered productsMethacrylateMeth-

Provided is an antireflection film including, in the following order: a transparent support; at least one antiglare layer or diffusive layer containing a transparent resin and light-transmissive resin particles; and a low-refractivity layer having a refractive index lower than that of any of the transparent support and the antiglare layer or diffusive layer, wherein the transparent resin is formed by curing a mixture containing (A) a polyfunctional (meth)acrylate having at least two (meth)acryloyl groups, and (B) a modified polyfunctional (meth)acrylate modified through addition of any of ethylene oxide, propylene oxide or caprolactone, and the light-transmissive resin particles contain (C) high-crosslinking light-transmissive particles which are so high-crosslinking as to have a residual monomer content of at most 2.0% and which have a compression strength of from 39 to 98 N / mm2.

Owner:FUJIFILM CORP

Heat-radiation coating material for ceramic kiln

The invention discloses a heat-radiation coating material for a ceramic kiln. The heat-radiation coating material contains base materials, additives, a binder, a plasticizer and a solvent, wherein the base materials and the additives are selected from five kinds or all of gahnite powder, manganese-aluminum spinel powder, ilmenite powder, boron carbide, ferric oxide and desilicated zirconium powder; the binder is prepared from liquid aluminum dihydrogen phosphate and liquid magnesium dihydrogen phosphate; the weight percent of the base materials and the additives is 6-75%, the weight percent of the binder is 5-29%, the weight percent of the plasticizer is 0.5-3%, and the balance is the solvent. The coating material has the advantages that the operating temperature range is large, the coating material can be used at the temperature above 1,400 DEG C, and the maximum operating temperature can reach about 2,000 DEG C; the coating material is applicable to various substrates, has strong adhesive power to the substrates and is applicable to acid / base multiple atmospheres, the long-term durability is good, the thermal-shock resistance is strong, the energy source utilization ratio and heat efficiency are increased, the temperature of the substrates covered by the coating material is lowered, the wear resistance and corrosion resistance are good, the environmental impact is little, and the use is convenient.

Owner:启东市三江建筑机械有限公司

Thermal radiation coating for black body

The invention discloses a thermal radiation coating for a black body, the thermal radiation coating includes a base material, an additive, a binder, a plasticizer and a solvent, the base material and the additive are selected from five or all of zinc aluminum spinel powder, chrome aluminum spinel powder, titanium iron ore powder, boron carbide, iron oxide and silicon micropowder, the binder comprises liquid aluminum dihydrogen phosphate and liquid magnesium hydrogen phosphate, the weight percentages of the base material and the additive are 6% - 75%, the weight percentage of the binder is 5% - 29%, the weight percentage of the plasticizer is 0.5% - 3%, and the rest is the solvent. The thermal radiation coating has a wide working temperature range, can be used at more than 1400 DEG C with the highest use temperature up to about 1800 DEG C, is suitable for various matrixes, is strong in matrix adhesion, is suitable for acid-base multiple atmospheres, good in long-term durability and high in thermal shock resistance capability, improves energy utilization thermal efficiency, reduces the temperature of a matrix covered with the coating, is good in wear resistance and corrosion resistance, less in environmental impact and easy to use.

Owner:三明市梅列区众尚圭投资管理合伙企业(有限合伙)

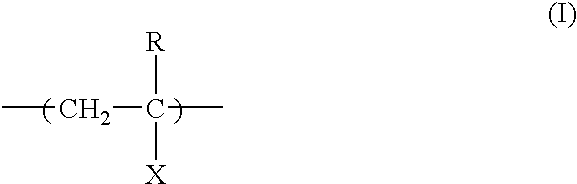

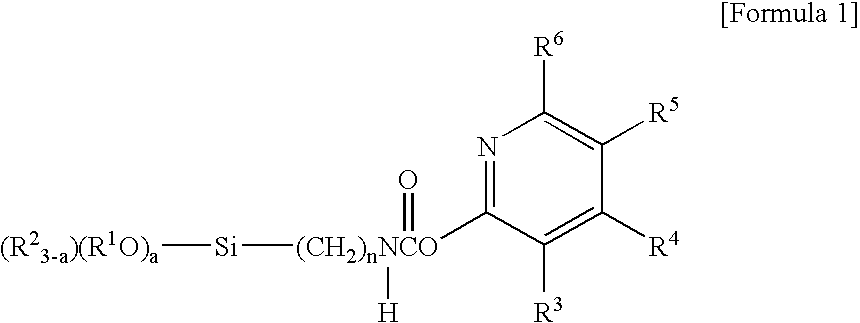

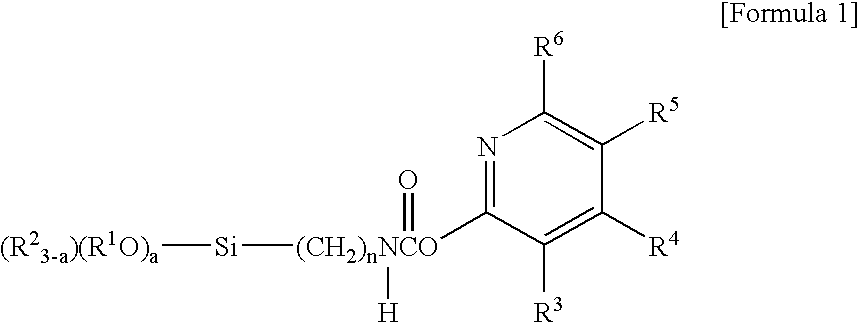

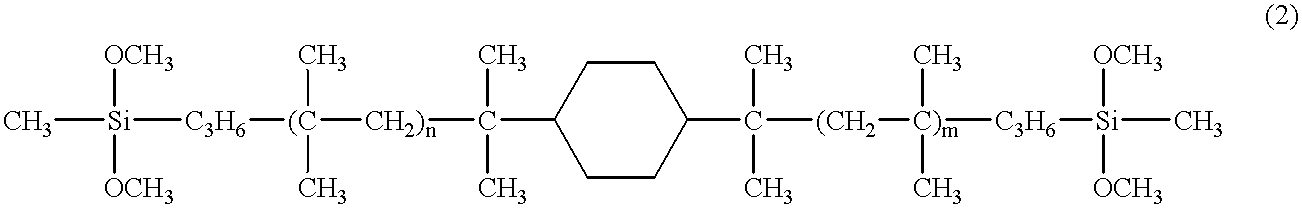

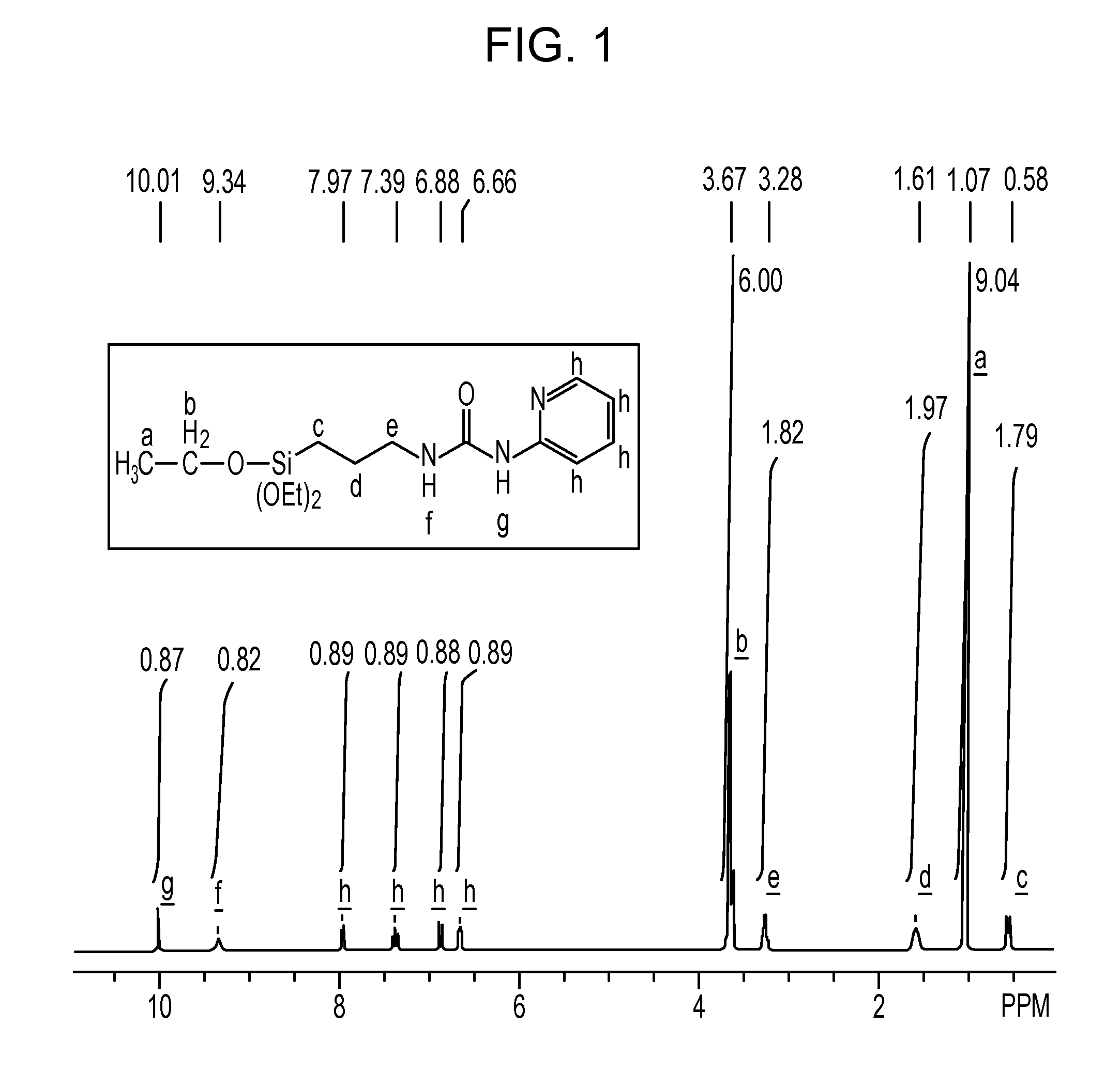

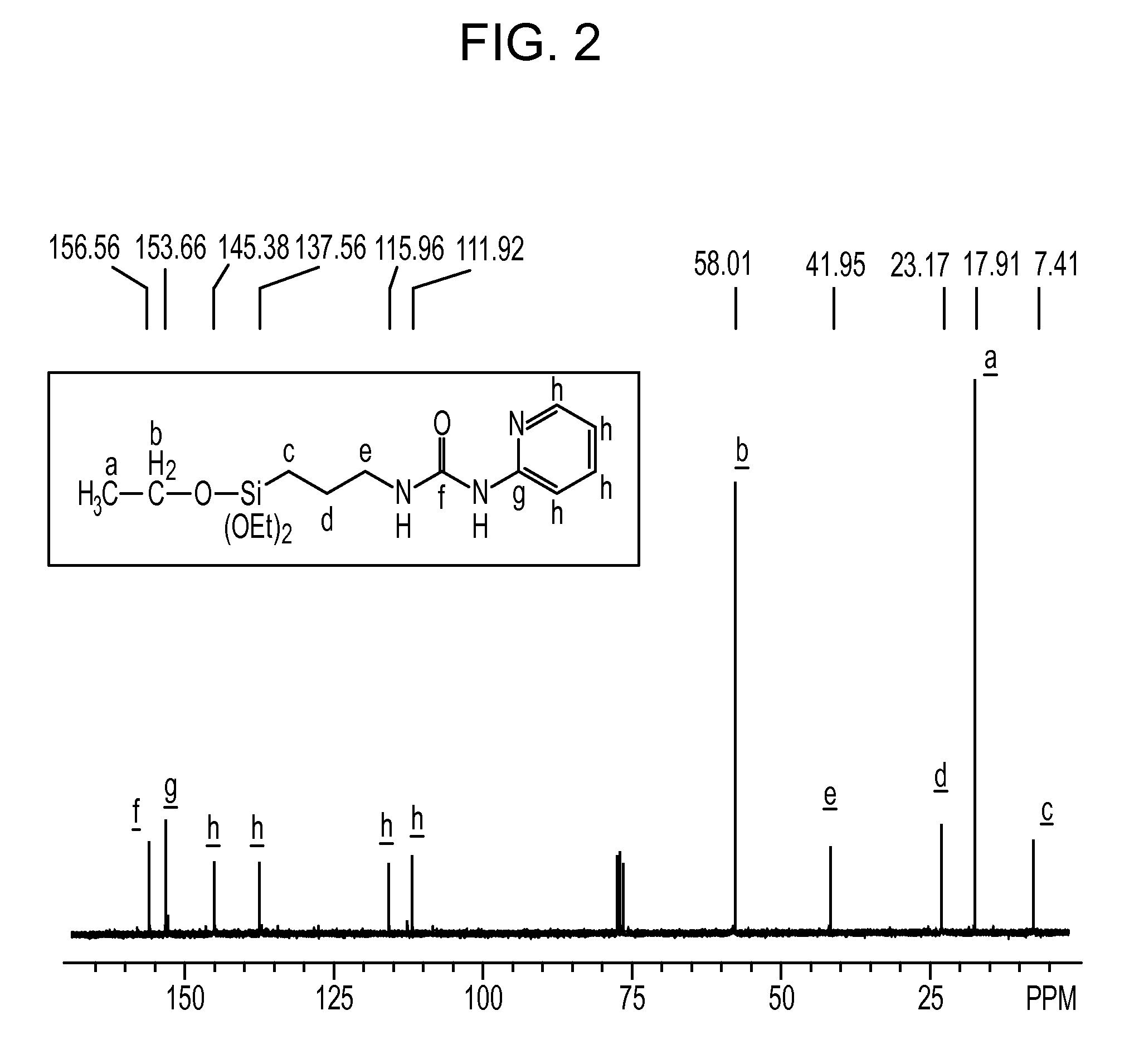

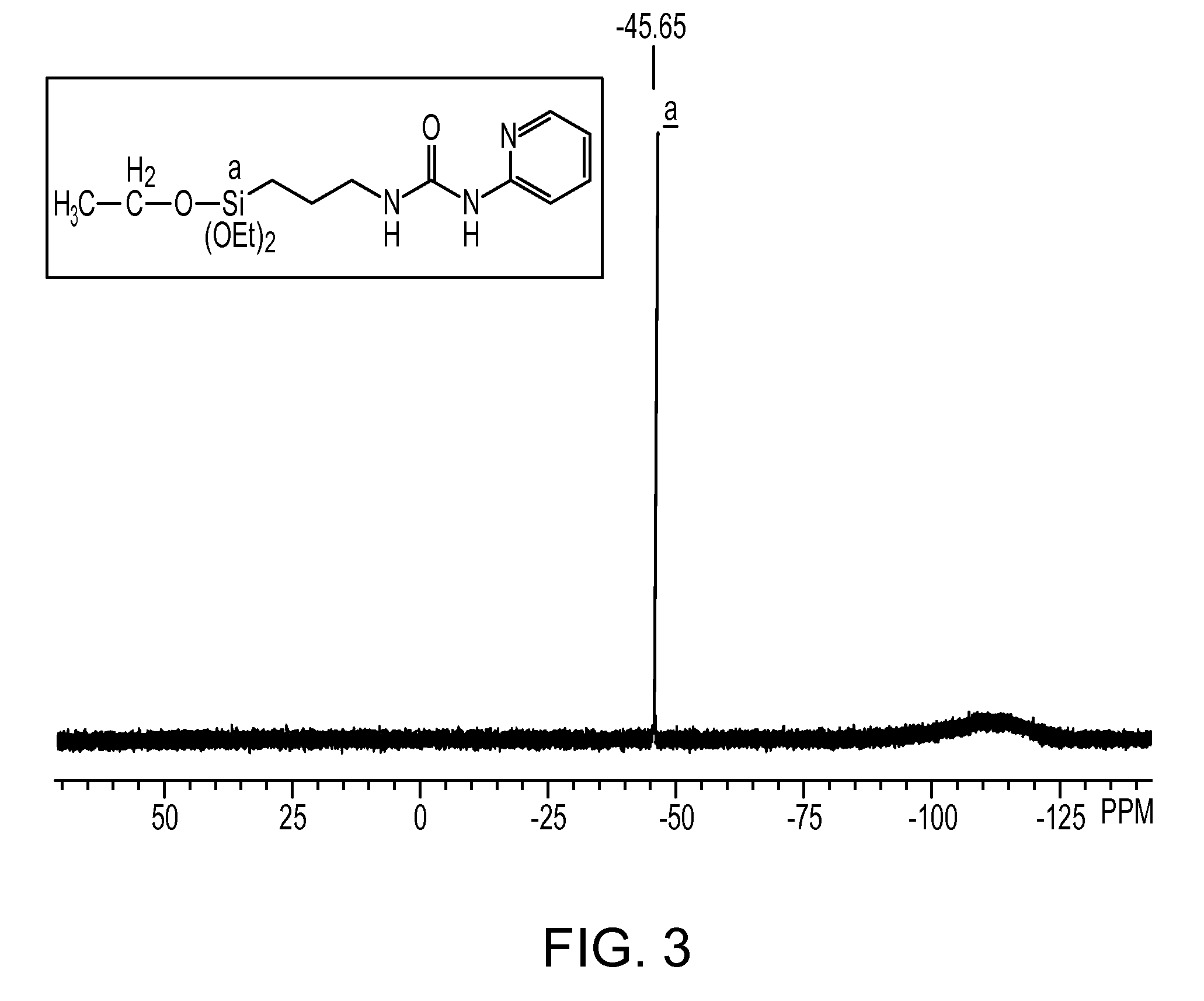

Organosilicon compounds, production processes thereof, pressure-sensitive adhesive compositions containing the organosilicon compounds, self-adhesive polarizers and liquid crystal displays

InactiveUS20100060829A1Improve coordinationGood long-term durabilitySilicon organic compoundsPolarising elementsPolymer scienceLiquid-crystal display

Organosilicon compounds are represented by the following formula:wherein R is a hydrolyzable group, R′ is an alkyl having 1 to 4 carbon atoms, A is an alkylene having 1 to 6 carbon atoms, X is O or S, Y is —NH— or S, L1 and L2 are C or N, Z and M are —NH—, O or S, R1 to R11 are H, alkyl having 1 to 6 carbon atoms, alkoxy or fluoroalkyl, or amino, m is 1 to 3, and n is 0 to 3. R1 and R2 or R2 and R3 may bonded together. R5 and R6 or R9 and R10 may directly bond together. R4 and R7 or R8 and R11 may form a ring skeleton. Their production processes, pressure-sensitive adhesive compositions, self-adhesive polarizers and LCDs are also disclosed.

Owner:SHIN ETSU CHEM IND CO LTD

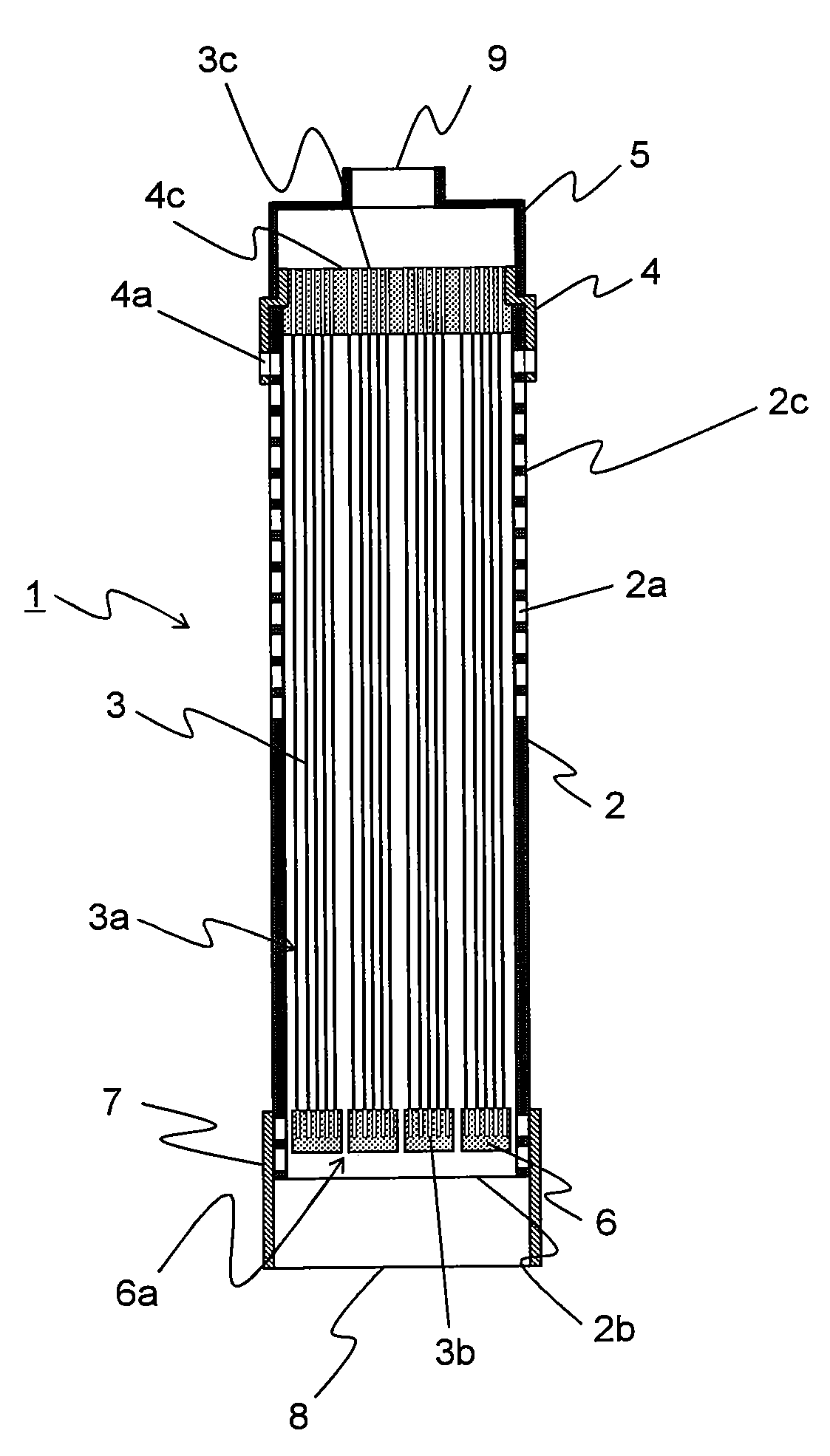

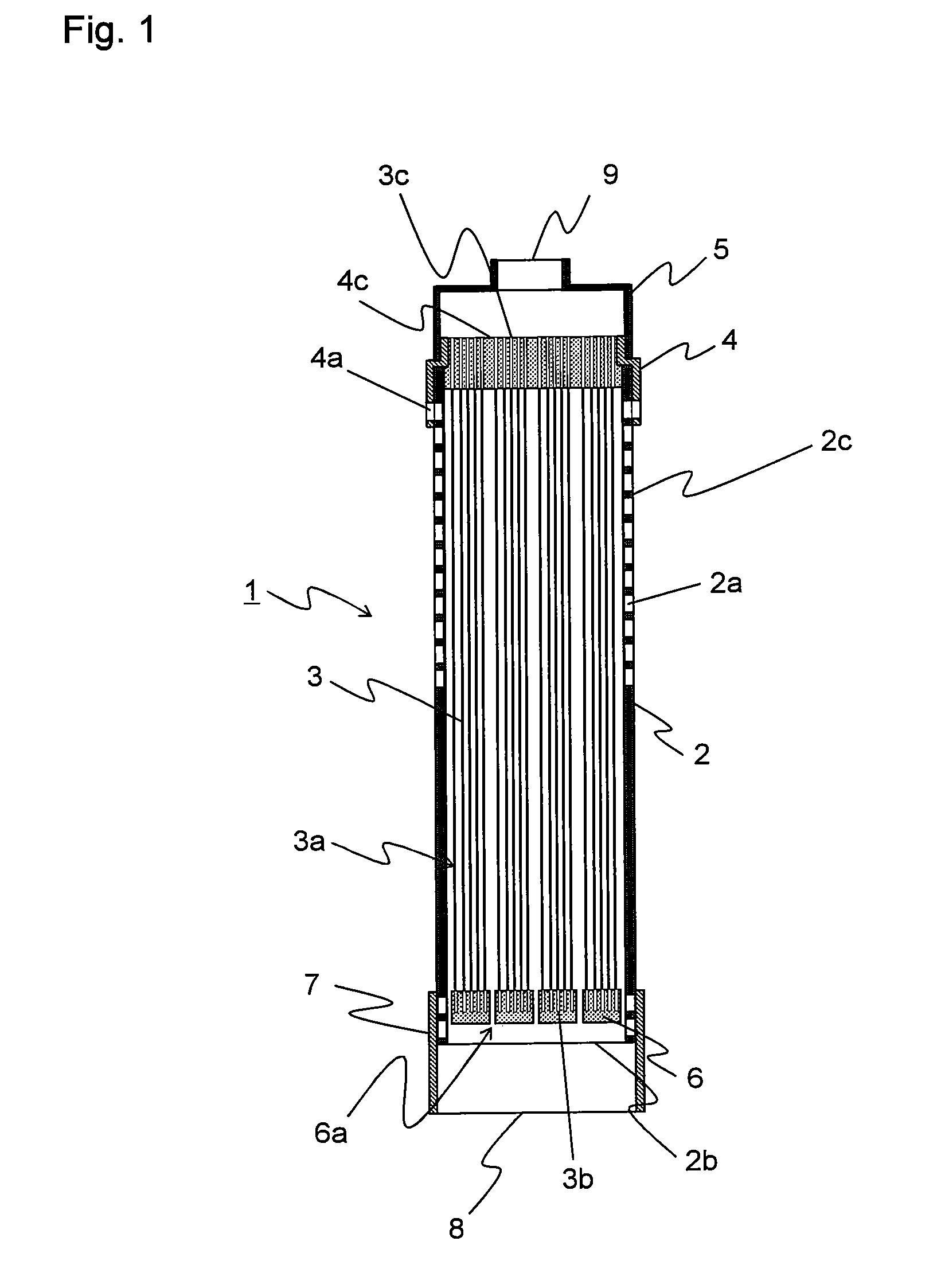

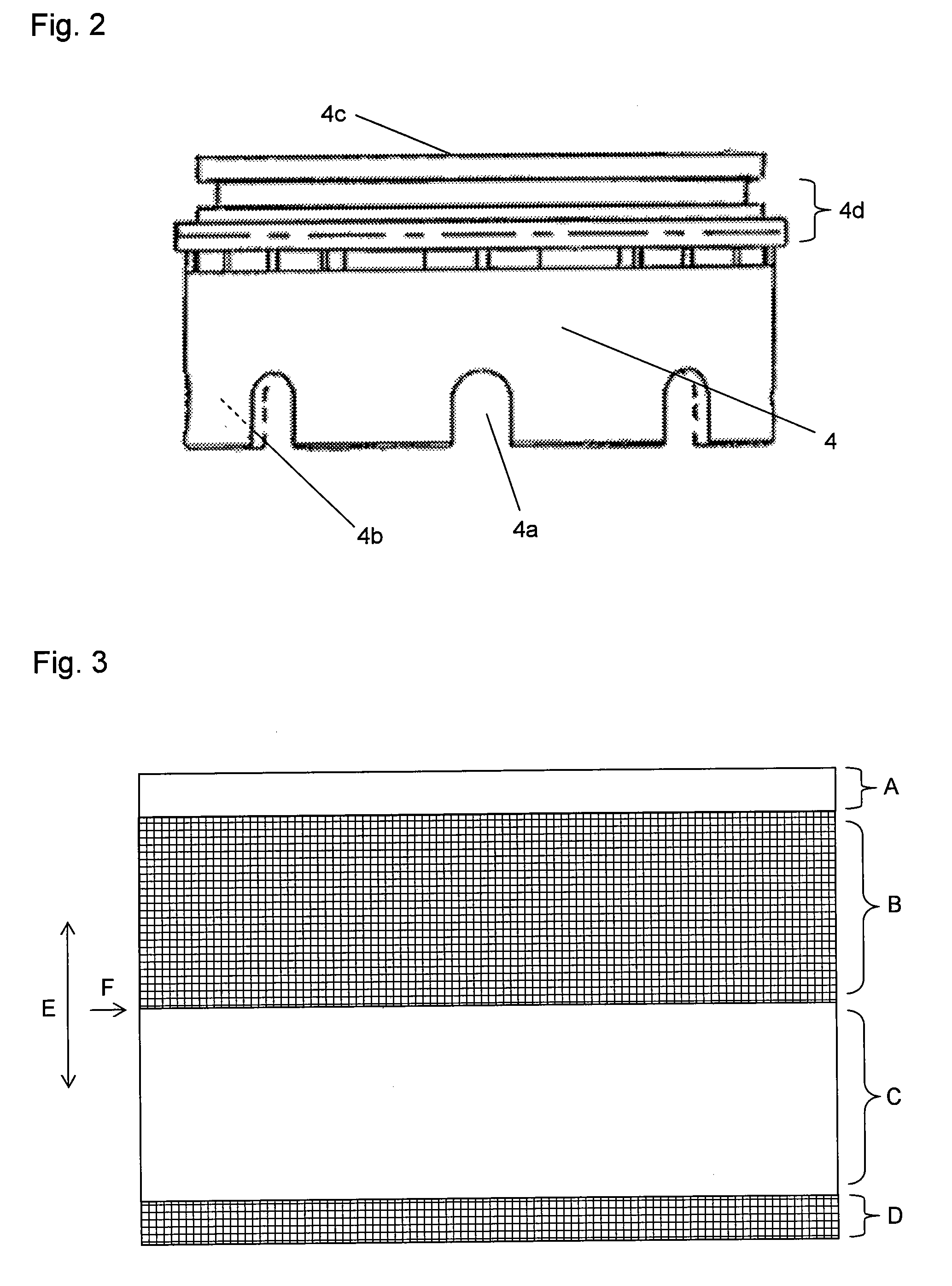

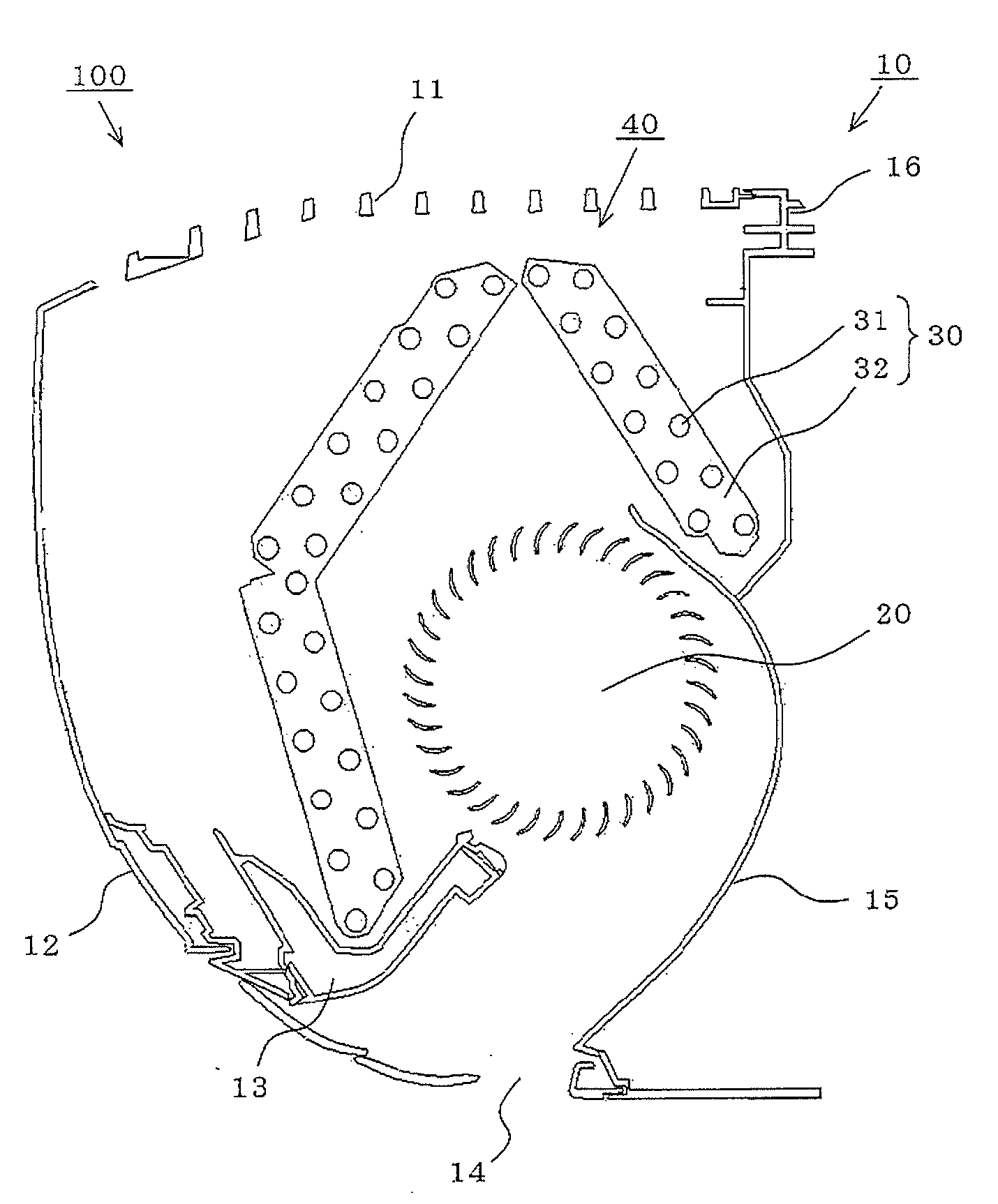

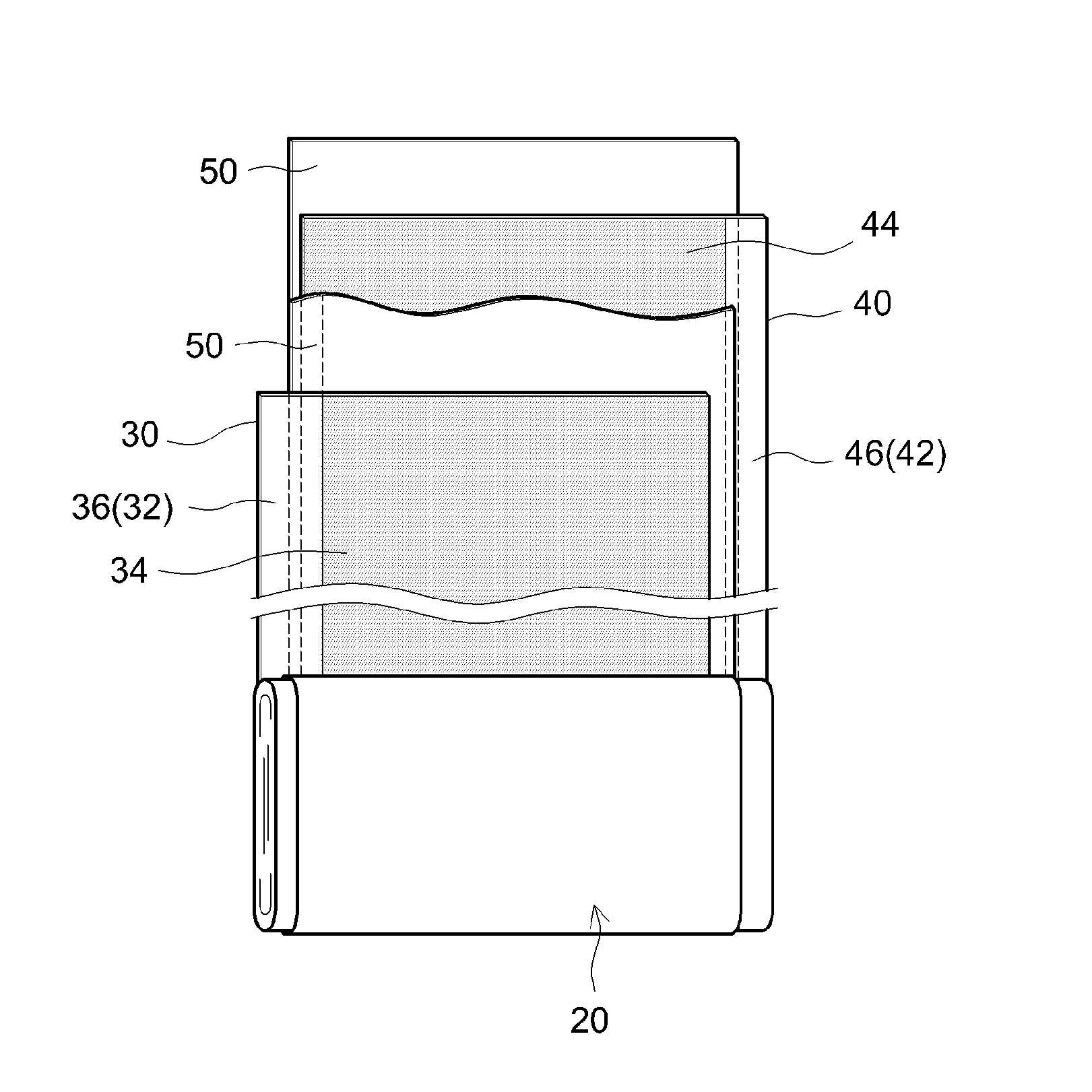

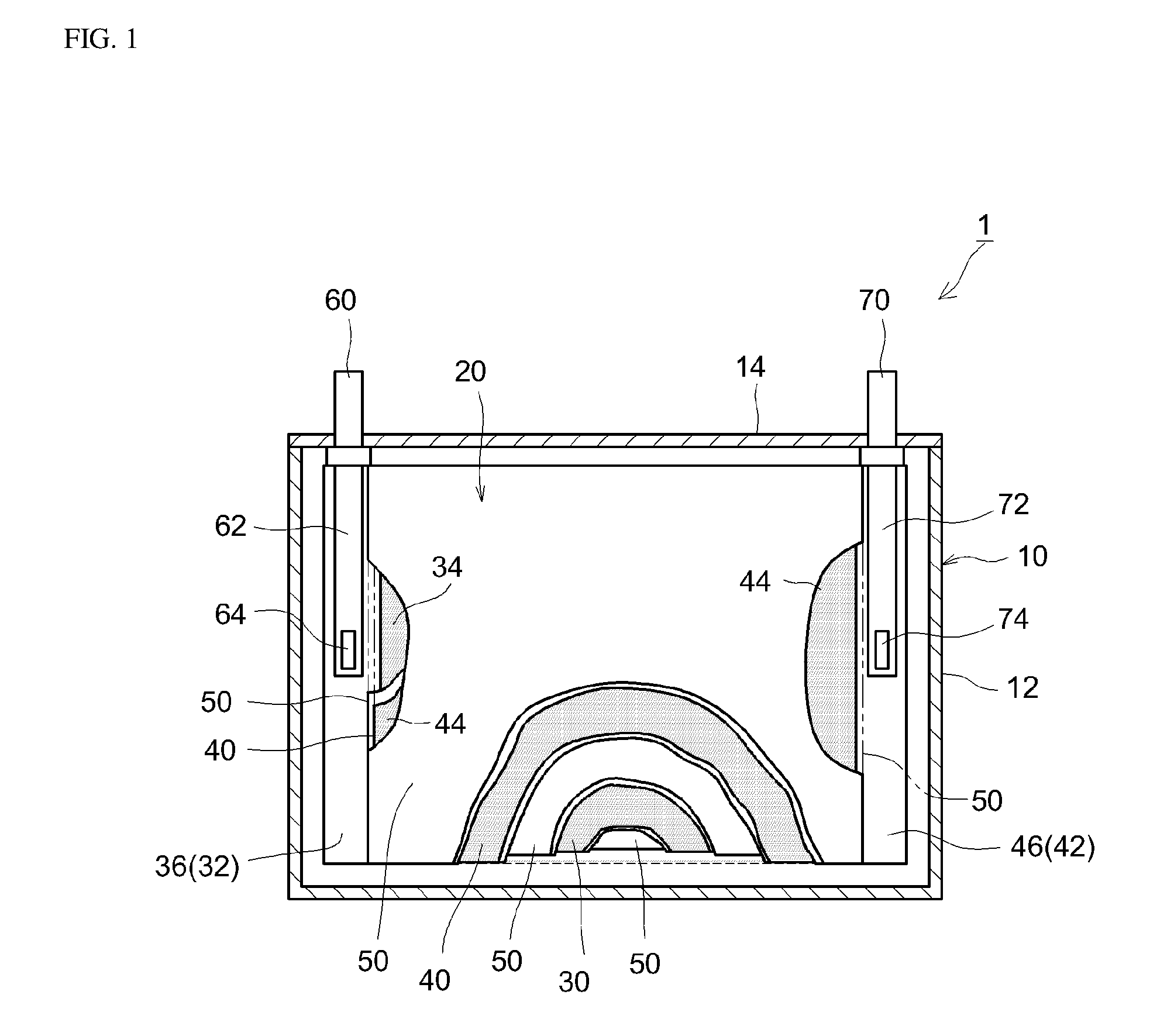

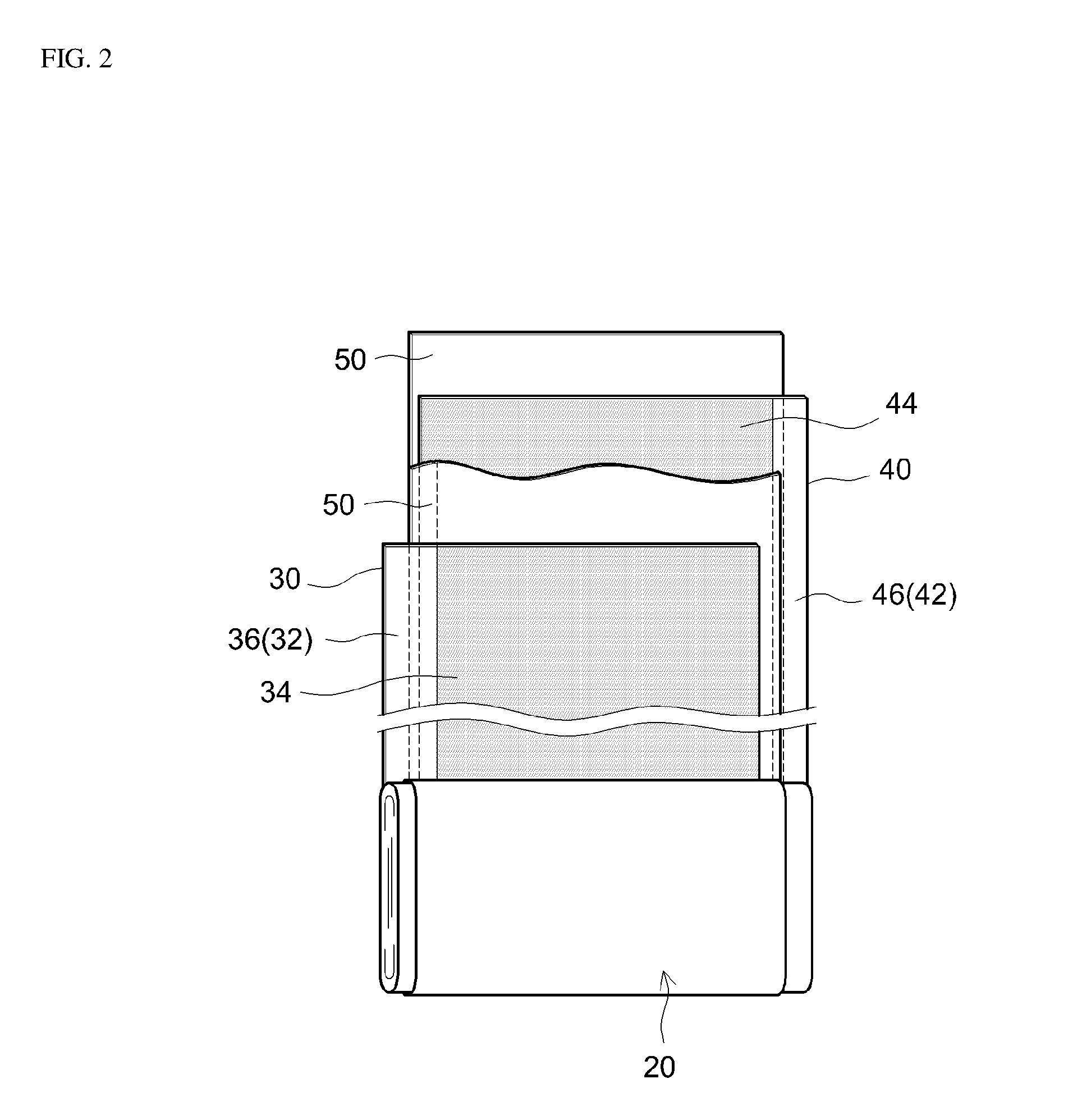

Submerged hollow fiber membrane module

InactiveUS20110114551A1Increase physical strengthEasy to peelMembranesUltrafiltrationHollow fibre membraneFiber

A submerged hollow fiber membrane module includes a cylindrical housing having openings at the upper and lower ends, in which at least a part of an upper half of an external exposed part of a peripheral wall is composed of a porous component and a lower half of the external exposed part of the peripheral wall is not opened, hollow fiber membrane bundles placed vertically in the cylindrical housing, a hollow fiber membrane bundle binding component fixes the hollow fiber membranes in a state where the hollow part of each hollow fiber membrane is opened and is adhesively fixed to the cylindrical housing, a water collecting cap connected to the hollow fiber membrane bundle binding component, a hollow fiber membrane sealing component seals the hollow part of each hollow fiber membrane, an air collecting cylinder, and a bonding part in the cylindrical housing is composed of a porous component.

Owner:TORAY IND INC

Novel high-temperature-resistant and anti-corrosion ceramic coating and preparation technology

InactiveCN105086803AReduce spraying costsIncrease working temperatureAnti-corrosive paintsPolyurea/polyurethane coatingsCeramic coatingStrong acids

The invention aims to provide a novel high-temperature-resistant and anti-corrosion ceramic coating which can resist strong-acid corrosion at the high temperature, has good wear-resisting property and heat conductivity, low spraying cost and long service life and can be firmly attached to walls of related equipment, and a preparation technology. The novel high-temperature-resistant and anti-corrosion ceramic coating comprises, in parts by weight, 45-50 parts of nano ceramic powder, 10-15 parts of powdery quartz, 10-15 parts of polyurethane resin, 5-8 parts of dodecylene alcohol ester, 3-4.5 parts of powdery calcium carbonate, 3-5 parts of cobalt powder, 2-3 parts of powdery purple clay, 1-2 parts of powdery silicon dioxide, 0.5-1 part of paraffin, 5-8 parts of ethyl acetate, 5-8 parts of n-butyl alcohol and 1-5 parts of powdery vermiculite.

Owner:中国大唐集团科学技术研究总院有限公司

Air conditioner and coating composition

ActiveUS20100095697A1Avoid condensationProvide performanceMechanical apparatusAntifouling/underwater paintsLong term durabilityEngineering

Disclosed is an air conditioner coated by the coating composition to the resin-made components where due formation occurs upon the cooling operation, provides the antifouling performance against various stains, restrains enlargement of droplet, and provides an excellent long-term durability (sticking property and peeling off property) all at the same time. The air conditioner of the present embodiment forms a coating film 103 to surfaces of resin-made components and resin-made components installed to a rear flow side of the heat exchanger, includes the silica ultrafine particles 101 and the fluororesin particles 102, and provides, within the coating film 103, a silica film 104 comprising the silica ultrafine particles and the fluororesin particles 102 partially exposed from a surface of the silica film 104 in dots, and an exposed area of the silica film 104 is greater than an exposed area of the fluororesin particles 102.

Owner:MITSUBISHI ELECTRIC CORP

Non-aqueous electrolyte secondary battery

ActiveUS20160336568A1Good long-term durabilityVariation in of solution can be suppressedCell seperators/membranes/diaphragms/spacersFinal product manufactureHigh rateElectrical battery

Provided is a non-aqueous electrolyte secondary battery in which an increase in resistance is suppressed when high rate pulsed charging and discharging is repeatedly carried out. The non-aqueous electrolyte secondary battery provided by the present disclosure is provided with: a positive electrode; a negative electrode; a separator; and a non-aqueous electrolyte solution. The separator is provided with a separator base made of a non-woven fabric; a first resin layer provided on a surface of the separator base that faces the positive electrode; and a second resin layer provided on a surface of the separator base that faces the negative electrode. In addition, a resin matrix of the first resin layer is constituted from polytetrafluoroethylene or a copolymer containing polytetrafluoroethylene as a primary component, and a resin matrix of the second resin layer is constituted from poly(vinylidene fluoride) or a copolymer containing poly(vinylidene fluoride) as a primary component.

Owner:TOYOTA JIDOSHA KK

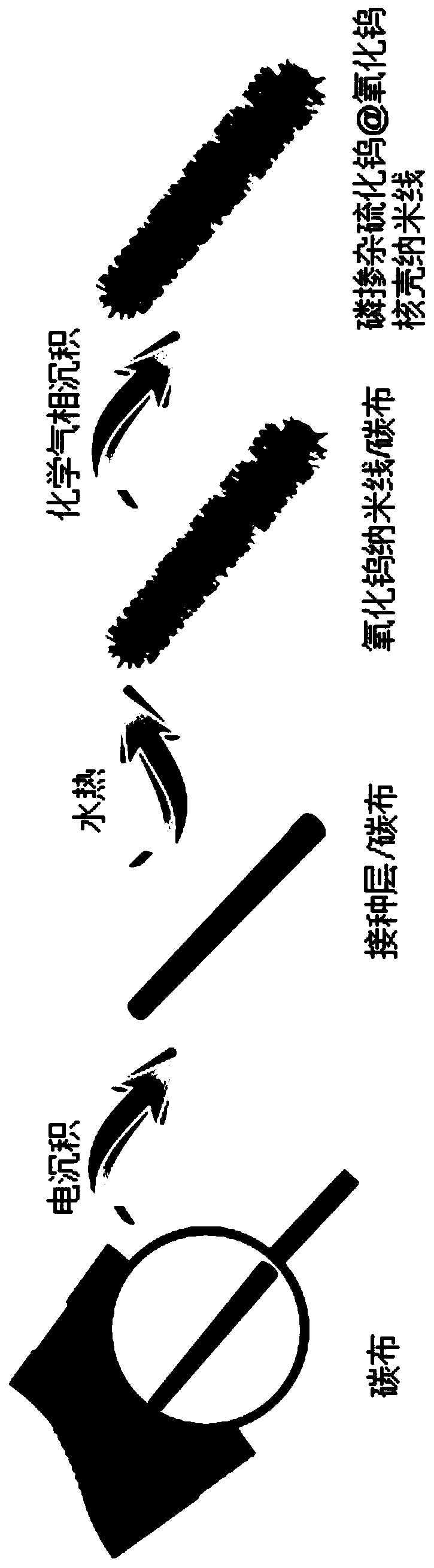

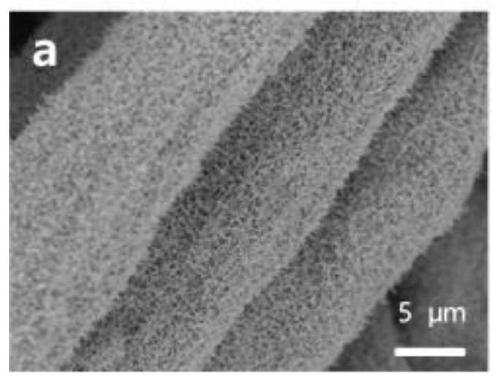

Phosphorus-doped tungsten sulfide@tungsten oxide porous core-shell nanowire flexible array electrode and preparation method thereof

ActiveCN110408953AActive active siteFacilitate mass transportElectrode shape/formsDissolutionHigh pressure

The invention discloses a phosphorus-doped tungsten sulfide@tungsten oxide porous core-shell nanowire flexible array electrode and a preparation method thereof, and belongs to the field of preparationmethods of electrocatalytic electrode materials. The method comprises the steps that after a carbon cloth with a tungsten oxide inoculation layer is prepared, sodium tungstate and acetic acid are dissolved in deionized water, concentrated nitric acid is added to a solution obtained after complete dissolution, and stirring continues until the solution is clarified; then ammonium sulfate is added,a tungsten oxide nanowire hydrothermal reaction solution is obtained after uniform stirring and placed in a high-pressure reaction kettle for a hydrothermal reaction, sodium hypophosphite and sulfur powder are uniformly mixed and then placed in the upstream portion of a double-temperature-zone tubular furnace, and a prepared tungsten oxide nanowire array is placed in the downstream portion of thedouble-temperature-zone tubular furnace; under the protection of argon gas, the upstream temperature of the tubular furnace is controlled to be 280-300 DEG C, the downstream temperature of the tubularfurnace is controlled to be 750-850 DEG C, and the phosphorus-doped tungsten sulfide@tungsten oxide porous core-shell nanowire flexible array electrode is obtained after a constant-temperature reaction is conducted for a certain period of time. The electrode has excellent electrochemical performance.

Owner:HARBIN UNIV OF SCI & TECH

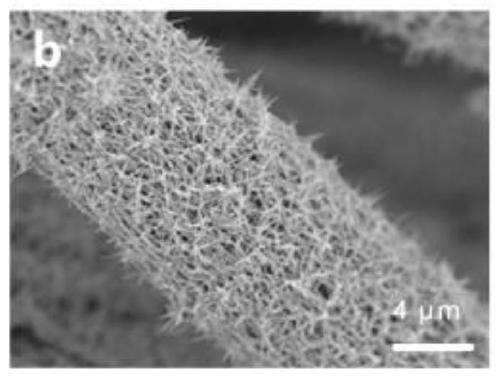

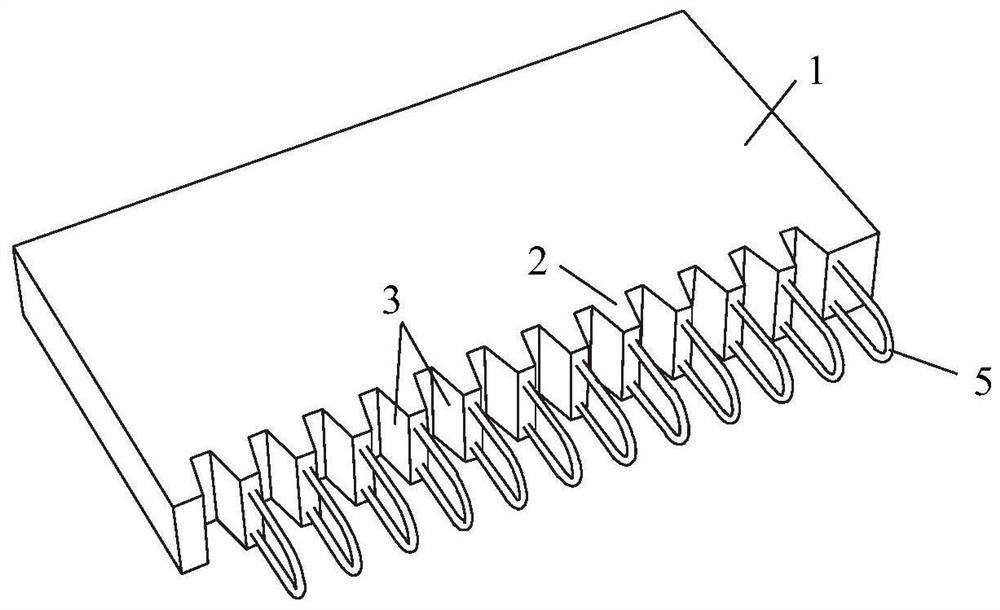

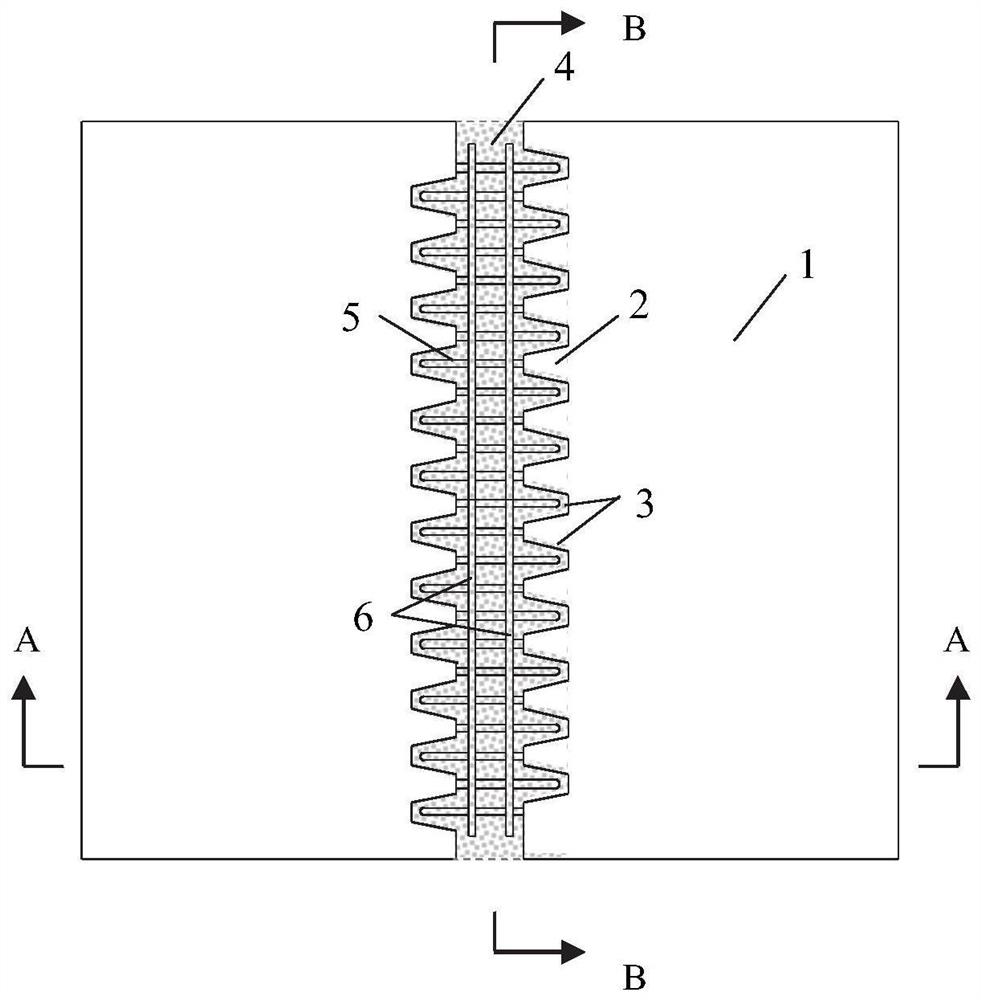

Prefabricated bridge deck slab wet joint connecting structure, prefabricated bridge and method

InactiveCN112127263AReduce on-site workloadImprove construction accuracyBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a prefabricated bridge deck wet joint connecting structure, a prefabricated bridge and a method thereof. The technical proposal is as follows: prefabricating concrete bridge deck, a plurality of conical tooth grooves are formed in one side of the prefabricated concrete bridge deck and there is an annular connecting joint steel bar extending out from the end face of the prefabricated concrete bridge deck; the annular connecting joint steel bars between the two prefabricated concrete bridge decks are overlapped and staggered; transverse penetrating steel bars are arrangedon the inner sides and the outer sides of the annular connecting joint steel bars; concrete is filled between the oppositely-arranged conical tooth grooves to form a wet joint. The conical tooth grooves are formed in the connecting interface of the prefabricated concrete bridge deck slabs, the bridge deck slabs are connected through the annular steel bars. The invention has the advantages of simple structure, reasonable stress, reliable force transmission, capable of meeting various requirements of the concrete bridge deck slabs in the normal use and bearing capacity limit state; The on-sitepouring amount is small, and construction is convenient and fast.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST

Air conditioner and coating composition

ActiveUS8171750B2Provide performanceGood long-term durabilityMechanical apparatusAntifouling/underwater paintsLong term durabilityEngineering

Disclosed is an air conditioner coated by the coating composition to the resin-made components where due formation occurs upon the cooling operation, provides the antifouling performance against various stains, restrains enlargement of droplet, and provides an excellent long-term durability (sticking property and peeling off property) all at the same time. The air conditioner of the present embodiment forms a coating film 103 to surfaces of resin-made components and resin-made components installed to a rear flow side of the heat exchanger, includes the silica ultrafine particles 101 and the fluororesin particles 102, and provides, within the coating film 103, a silica film 104 comprising the silica ultrafine particles and the fluororesin particles 102 partially exposed from a surface of the silica film 104 in dots, and an exposed area of the silica film 104 is greater than an exposed area of the fluororesin particles 102.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com