Prefabricated bridge deck slab wet joint connecting structure, prefabricated bridge and method

A bridge deck, wet joint technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as water leakage, poor fatigue performance, concrete cracking, etc., to enhance aggregate bite force, improve crack resistance, Low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

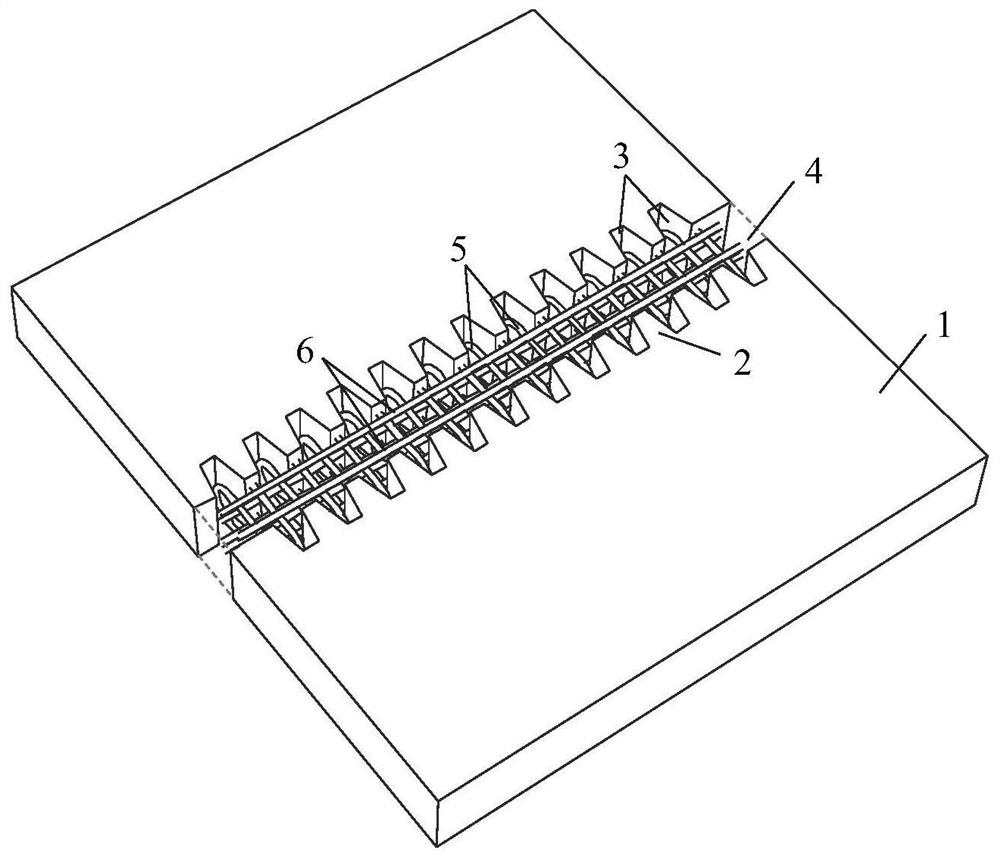

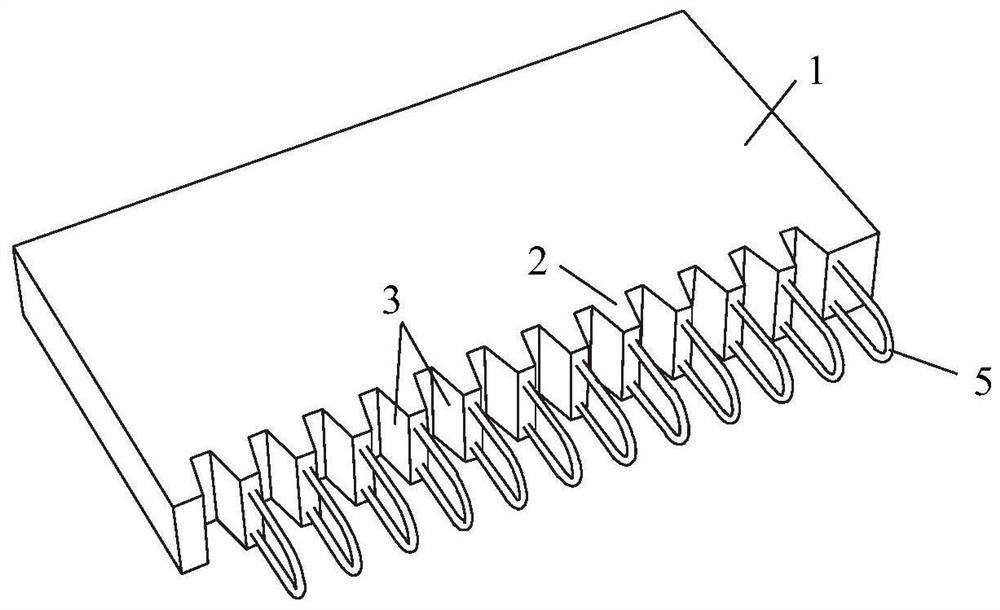

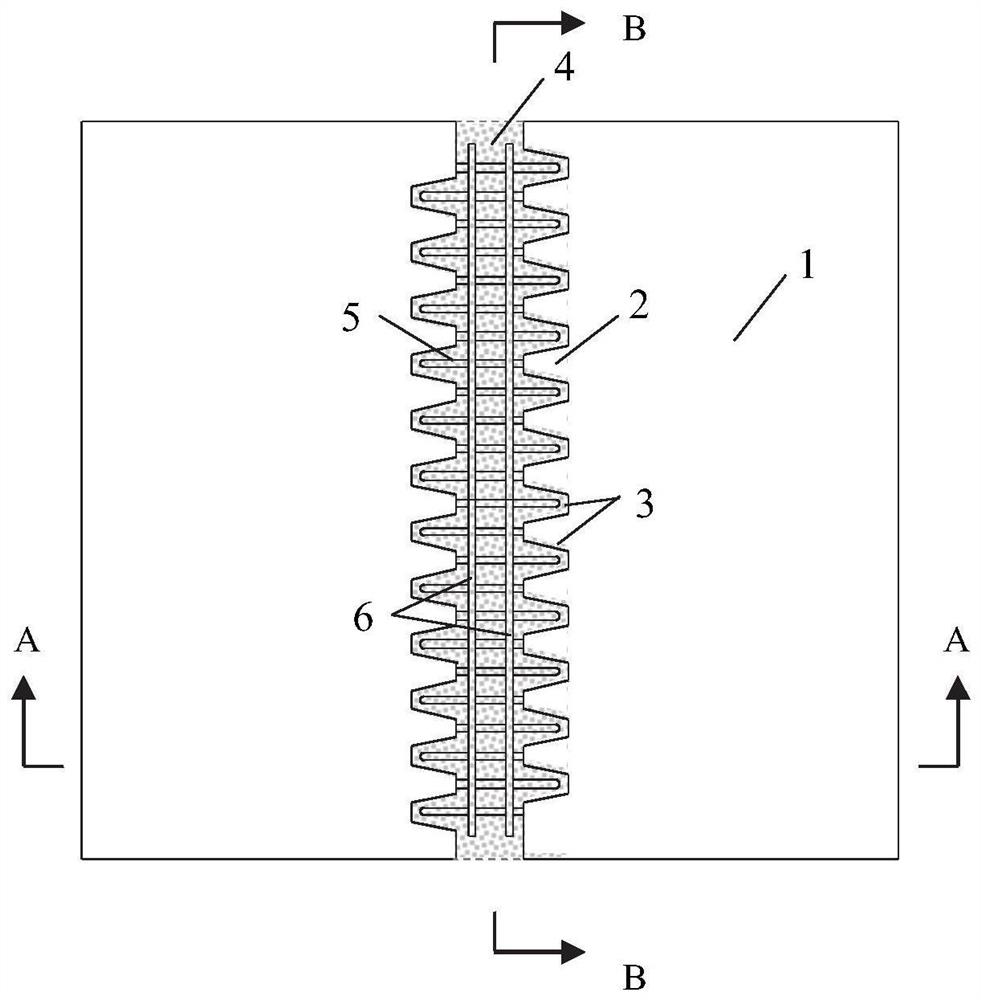

[0040] This embodiment provides a prefabricated bridge deck wet joint connection structure, which is applied to prefabricated concrete bridges or steel-concrete composite bridge structures; Figure 1-Figure 5 As shown, it includes prefabricated concrete bridge deck 1, concrete filler 4, transverse penetrating steel bars 6, longitudinal steel bars 7, and transversely distributed steel bars 8, and a number of tapered tooth grooves 2 are arranged on one side of precast concrete bridge deck 1.

[0041] The prefabricated concrete bridge deck 1 is an ordinary concrete slab or a fiber concrete slab mixed with fibers. There is a certain distance between two prefabricated concrete bridge decks 1 , and a wet joint is formed through cast-in-place concrete filler 4 . After vibrating and curing, the two prefabricated concrete bridge decks 1 can be connected into a whole after reaching the strength.

[0042]In this embodiment, the width of the wet joint is 420 mm, of course, in other embod...

Embodiment 2

[0053] This embodiment provides a prefabricated bridge, including the wet joint connection structure described in Embodiment 1.

Embodiment 3

[0055] This embodiment provides a construction method for the wet joint connection structure of the prefabricated bridge deck, including the following steps:

[0056] First, in the factory, the end of the longitudinal reinforcement 7 is bent at 180° to form a circular connection joint reinforcement 5, and then the longitudinal reinforcement 7 and the horizontal distribution reinforcement 8 are placed in the reinforcement formwork according to the designed spacing, and are bound by steel wires to form reinforcement cage.

[0057] Afterwards, the reinforcement cage is hoisted into the prefabricated formwork, and concrete is poured to form a prefabricated concrete bridge deck 1 with conical tooth grooves 2 . And carry out maintenance and storage according to the specification requirements; after reaching the corresponding age, the interface 3 between the bridge deck and the wet joint is chiseled to meet the specification standards.

[0058] During on-site construction, the preca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com