Prefabricated assembly type subway station platform and construction method thereof

A subway station, prefabricated assembly technology, applied to the processing of building materials, special buildings, small buildings, etc., can solve the problems that do not involve the subway station platform, etc., to reduce on-site cross operations, reduce mutual constraints, and reduce on-site pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

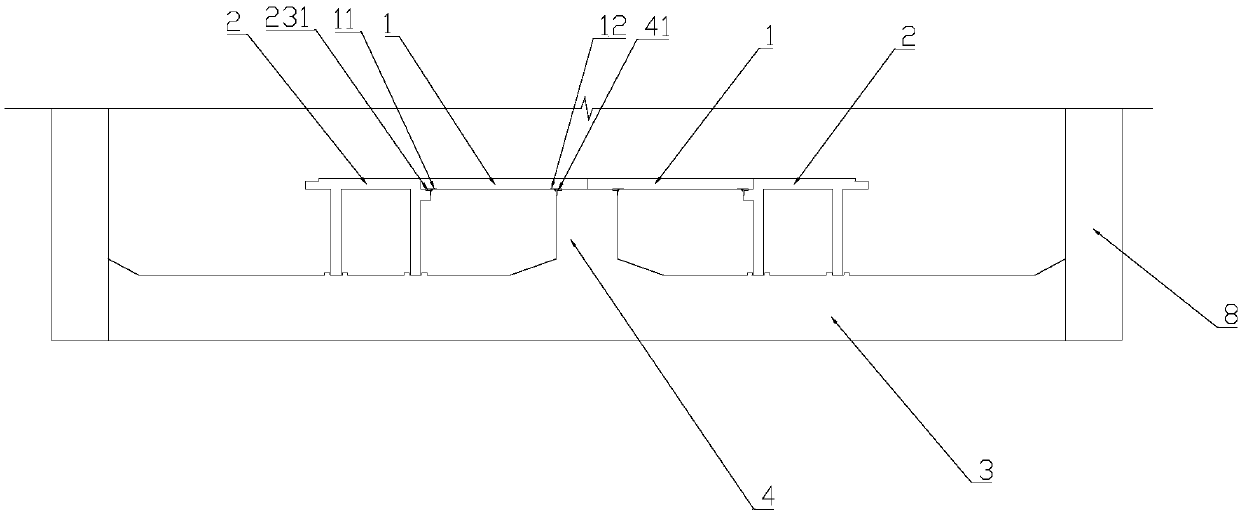

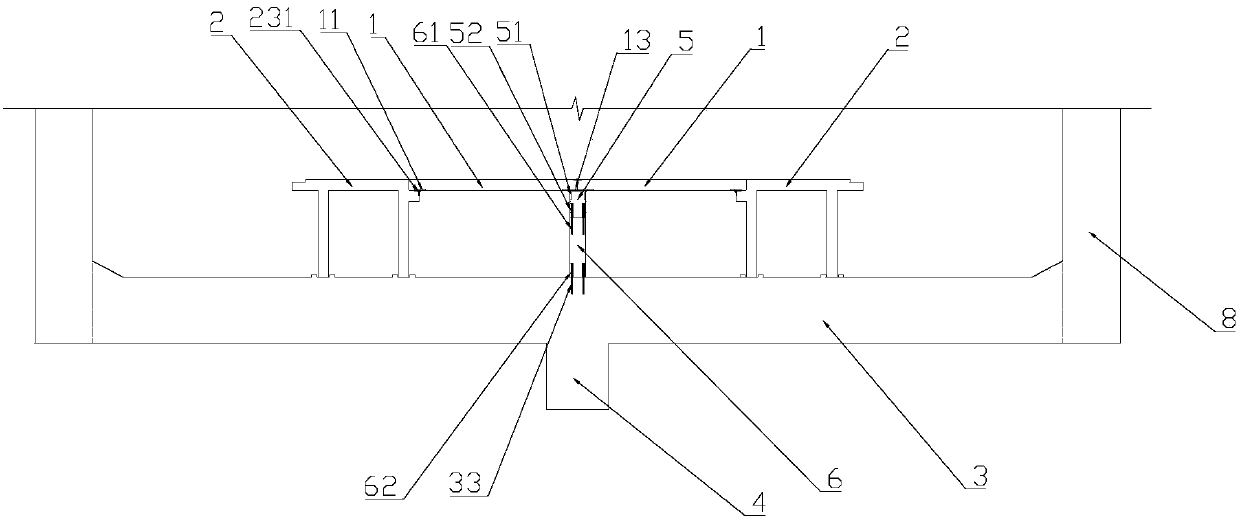

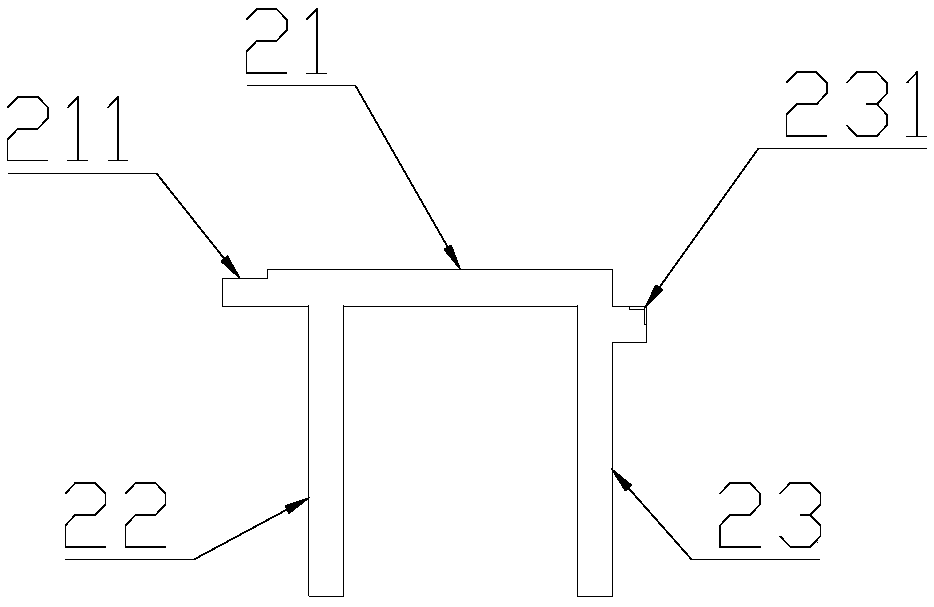

[0047] like Figure 1-2 As shown, a prefabricated assembled platform of a subway station includes a prefabricated platform slab 1, a prefabricated portal component 2 for supporting the prefabricated platform slab, and a supporting mechanism. The prefabricated portal component 2 and the supporting mechanism are fixed on the base plate 3 of the station. The supporting mechanism is a longitudinal beam 4 arranged on the station floor 3, and the longitudinal beam is turned up, and the longitudinal beam 4 and the station floor 3 are in an inverted T shape; and / or consists of prefabricated platform beams 5 and prefabricated platform columns 6 . When the supporting mechanism is the longitudinal beam 4, the prefabricated platform slab 1 is fixed on the prefabricated portal component 2 and the longitudinal beam 4. When the supporting mechanism is composed of prefabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com