Steel box girder lifting structure and lifting method of large-span combined beam

A technology of steel box girders and combined beams, which is applied to bridges, bridge construction, trolley cranes, etc., can solve problems such as the difficulty of lifting large-span steel box girders, and achieve roadbed leveling costs, good economy, and flexible construction operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

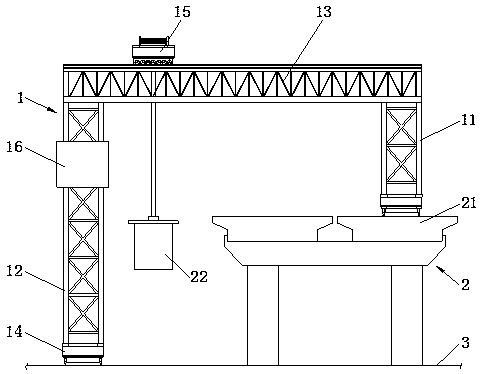

[0029] Such as figure 1 As shown, a steel box girder hoisting structure of a large-span combined beam in the present embodiment includes a gantry hoisting frame 1 and a reinforced concrete box girder 21, and the gantry hoisting frame 1 includes a crossbeam 13 and two supporting columns, and the two supporting The upper ends of the columns are flush and the lower ends have a height difference to form high support columns 11 and low support columns 12. The beams 13, high support columns 11 and low support columns 12 are all welded by square steel pipes and angle steels. The crossbeam 13 is provided with a lifting trolley 15, and the upper ends of the high support column 11 and the low support column 12 respectively support the two ends of the crossbeam 13 and the lower ends are provided with a walking trolley 14. The reinforced concrete box gi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com