Plate cutting device for constructional engineering

A cutting device and construction engineering technology, which is applied in the direction of manufacturing tools, wood processing equipment, special forming/shaping machines, etc., can solve the problems of personal injury, danger, and inability to cut and use large plates, and achieve flexible processing operations and improved The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

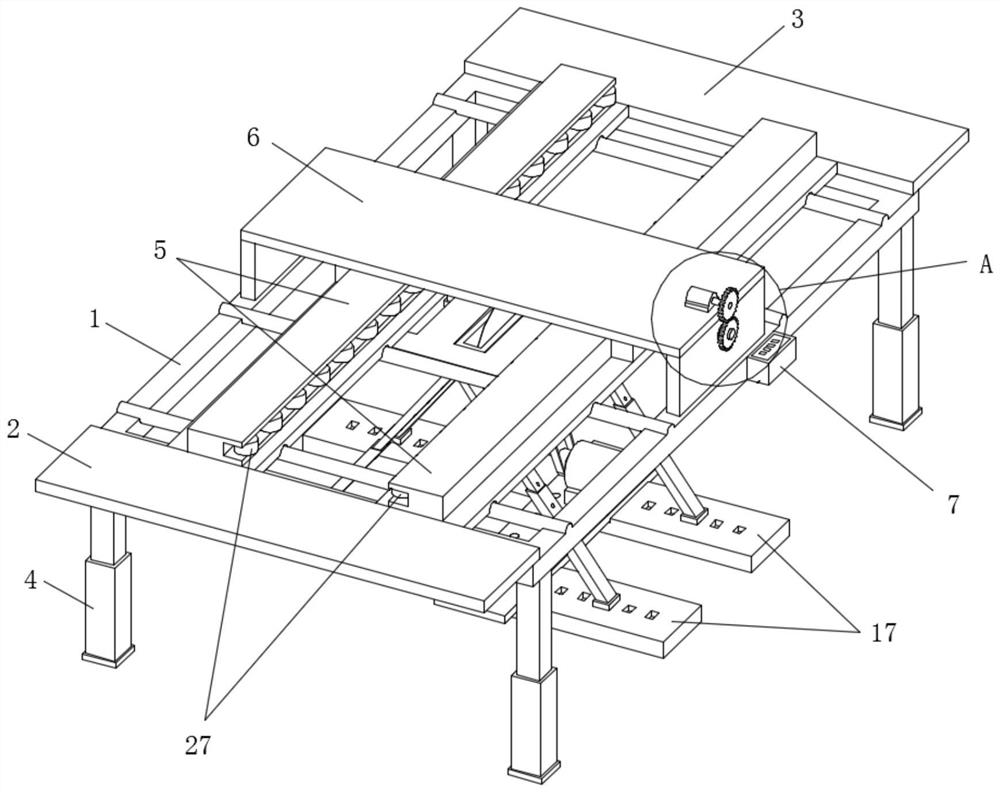

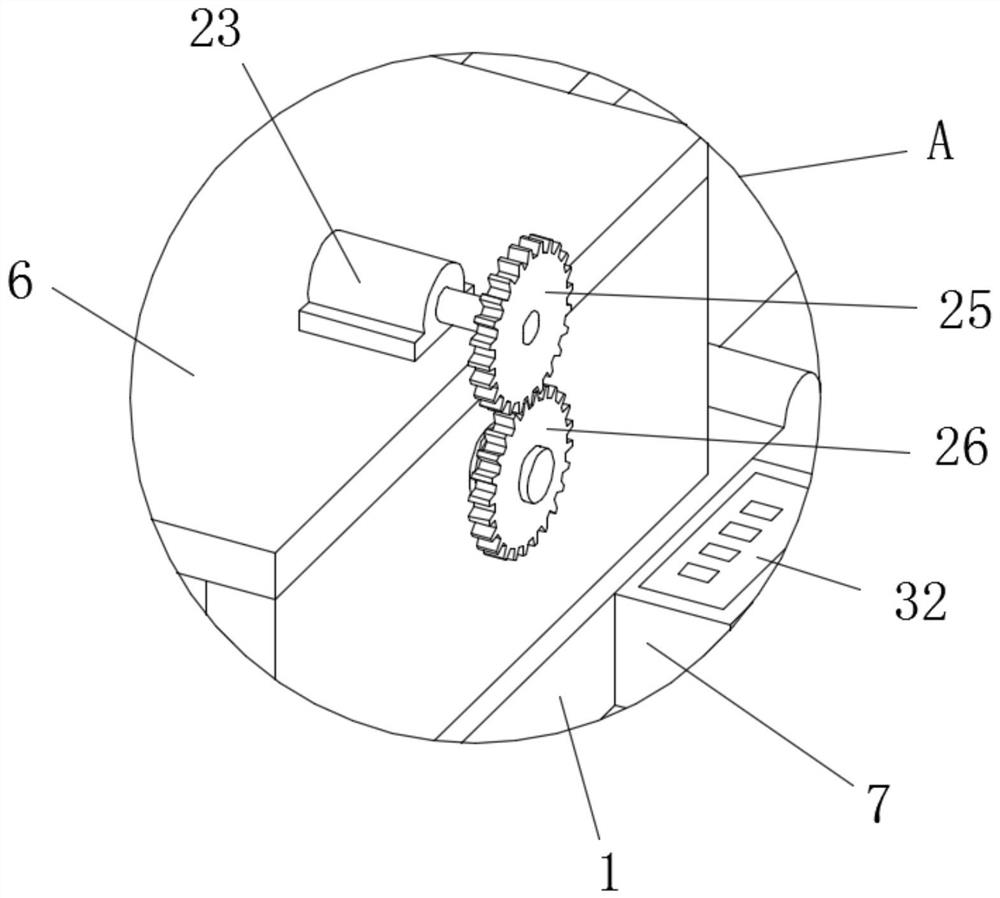

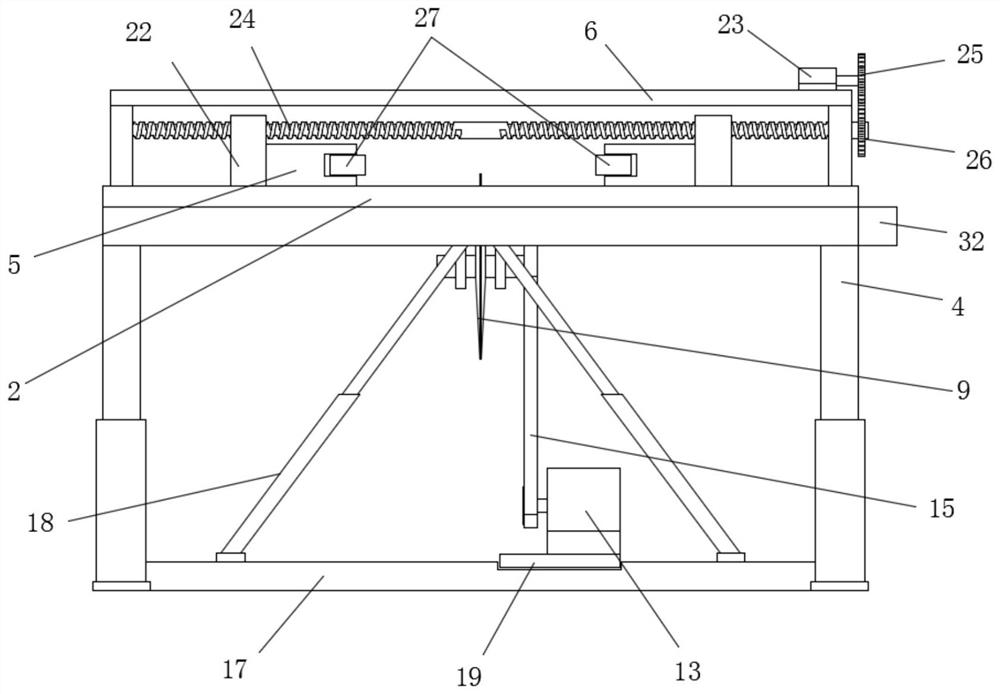

[0035] like Figure 1-Figure 10 Shown, a kind of plate cutting device for construction engineering, including

[0036] A cutting section, including a cutting mechanism, a driving mechanism for driving the cutting mechanism, and a supporting mechanism capable of supporting the cutting mechanism and the driving mechanism. The supporting mechanism is arranged as an adjustable supporting mechanism, which can adjust the positions of the cutting mechanism and the driving mechanism. During operation, the overall processing height can be adjusted according to the height of the workers and the needs of the processing site;

[0037] Specifically, the cutting mechanism includes a blade 9 capable of cutting plates, a knife seat 10 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com