Phosphorus-doped tungsten sulfide@tungsten oxide porous core-shell nanowire flexible array electrode and preparation method thereof

A technology of tungsten oxide nanowires and flexible arrays, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve problems affecting intrinsic catalytic performance, electronic disturbance, etc., achieve excellent catalytic performance and long-term stability, and increase surface area , to promote the effect of mass transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

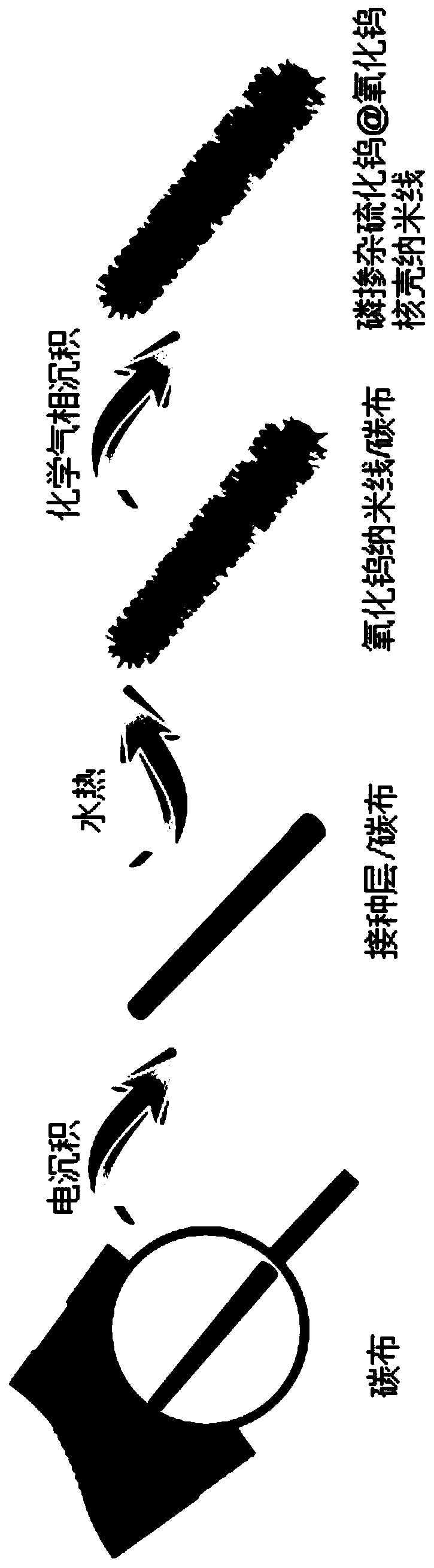

[0043] A method for preparing phosphorus-doped tungsten sulfide@tungsten oxide porous core-shell nanowire flexible array electrode, comprising the following steps:

[0044] Step 1, carbon cloth pretreatment: ultrasonically clean the carbon cloth with acetone, ethanol and deionized water for 1 to 2 times respectively, and set aside;

[0045] Step 2. Prepare carbon cloth with tungsten oxide seeding layer: Dissolve sodium tungstate and hydrogen peroxide solution in deionized water according to a certain ratio of material to liquid, adjust the pH of the solution to 1-1.2, and prepare the carbon cloth treated in step 1 Electrodeposit tungsten oxide in the solution, then after high temperature treatment, wash and dry to obtain carbon cloth with tungsten oxide seeding layer;

[0046] Step 3. Configure the tungsten oxide nanowire hydrothermal reaction solution: Dissolve sodium tungstate and acetic acid in deionized water according to a certain ratio of material to liquid, add a certai...

specific Embodiment approach 2

[0062] A phosphorus-doped tungsten sulfide@tungsten oxide porous core-shell nanowire flexible array electrode prepared according to the preparation method described in specific embodiment 1, with a current density of 10mAcm -2 When the overpotential is 89mV.

[0063] A phosphorus-doped tungsten sulfide@tungsten oxide porous core-shell nanowire flexible array electrode described in this embodiment is subjected to a linear sweep voltammetry test method, the voltage setting range is 0 to -1V, and the current setting is 5mV. The test results are as follows Figure 12 shown, from Figure 12 It can be seen from the above that the phosphorus-doped tungsten sulfide@tungsten oxide porous core-shell nanowire flexible array electrode has excellent electrochemical performance, and the current density is 10mAcm -2 When the overpotential is 89mV, the overpotential represents the difference between the electrode potential when the electrode reaction deviates from equilibrium and the equilib...

specific Embodiment approach 3

[0067] A method for preparing phosphorus-doped tungsten sulfide@tungsten oxide porous core-shell nanowire flexible array electrode, comprising the following steps:

[0068] Step 1, carbon cloth pretreatment: ultrasonically clean the carbon cloth with acetone, ethanol and deionized water for 1 to 2 times respectively, and set aside;

[0069] Step 2. Prepare carbon cloth with tungsten oxide seeding layer: Dissolve sodium tungstate and hydrogen peroxide solution in deionized water according to a certain ratio of material to liquid, adjust the pH of the solution to 1-1.2, and prepare the carbon cloth treated in step 1 Electrodeposit tungsten oxide in the solution, then after high temperature treatment, wash and dry to obtain carbon cloth with tungsten oxide seeding layer;

[0070] Step 3. Configure the tungsten oxide nanowire hydrothermal reaction solution: Dissolve sodium tungstate and acetic acid in deionized water according to a certain ratio of material to liquid, add a certai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com