Photohardening resin composition and application thereof

A technology of resin composition and photohardening, applied in the field of photohardenable resin composition, can solve the problems of small volume shrinkage, poor hardening rate, defectiveness, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

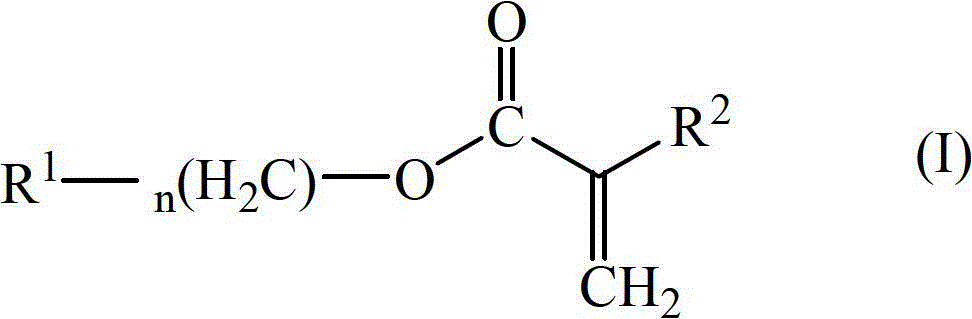

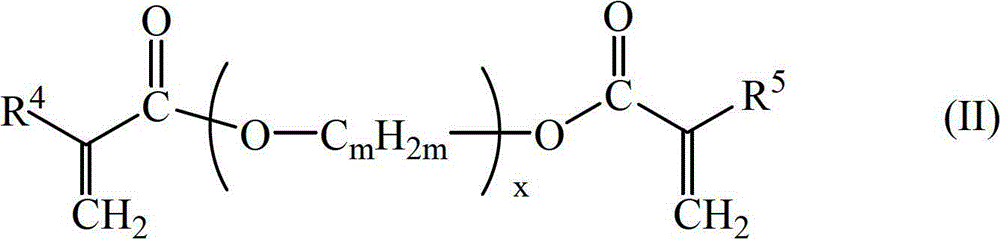

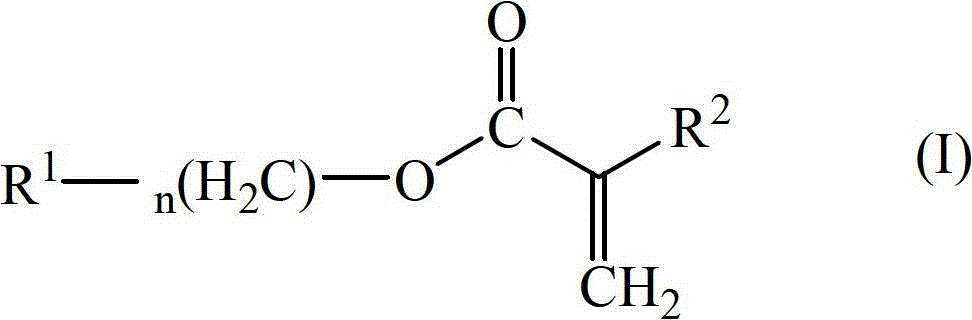

Method used

Image

Examples

Embodiment 1

[0059] Preparation of light-curing resin composition

[0060] The photocurable resin composition of Example 1 contains (A) 100 parts by weight of the oligomer UC203 containing an ethylenic bond, and (B) a monomer containing at least one acrylate group including dicyclopentadienyl ethoxyacrylate 22.2 Parts by weight and 12.3 parts by weight of methyltriethylene glycol acrylate, (C) photoinitiator includes 3.4 parts by weight of TPO and 6.8 parts by weight of I184, and (D) 196.6 parts by weight of softener polybutadiene. After the above-mentioned components are uniformly mixed, the photocurable resin composition is prepared.

[0061] Hardened programming

[0062] The photocurable resin composition was irradiated with a low-pressure mercury lamp contained in an exposure machine (purchased from USHIO, model USH-500BYI), where the ultraviolet band was 365nm and the exposure intensity was 30mW / cm 2 And the radiation dose is 5000mJ / cm 2 , Curing the resin composition.

[0063] Curing ratio ...

Embodiment 2~4 and comparative example 1~2

[0075] The preparation methods of the photocurable resin compositions of Examples 2 to 4 and Comparative Examples 1 to 2 are the same as those of Example 1, except that the examples and comparative examples select different compounds containing at least one acrylate group monomer Types, the chemicals used in Examples 2 to 4 and Comparative Examples 1 to 2 and their amounts are described in Table 1.

[0076] The photocurable resin compositions of Examples 2 to 4 and Comparative Examples 1 to 2 were analyzed for curing rate. The analysis and calculation methods are the same as those of Example 1. The calculation results are shown in Table 1.

[0077] Table 1

[0078]

[0079] As shown in Table 1, the compositional difference between Examples 1 to 4 and Comparative Examples 1 to 2 mainly lies in the types of monomers containing at least one acrylate group. From the test results, it can be clearly known that Examples 1 to 4 can obtain a curing rate higher than 90% and a forward bonding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com