High-temperature and high-pressure visual oil-water metering device and method

A high-temperature and high-pressure water, high-temperature and high-pressure technology, used in measuring devices, suspension and porous material analysis, instruments, etc., can solve the problems of time-consuming and laborious, inaccurate measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

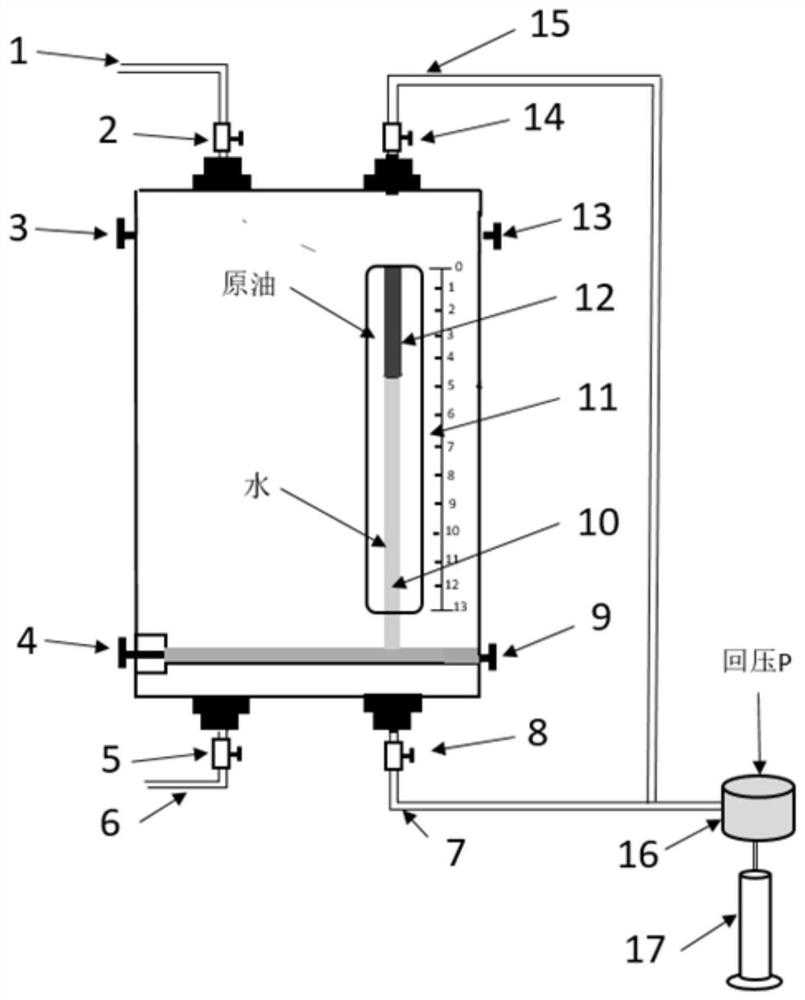

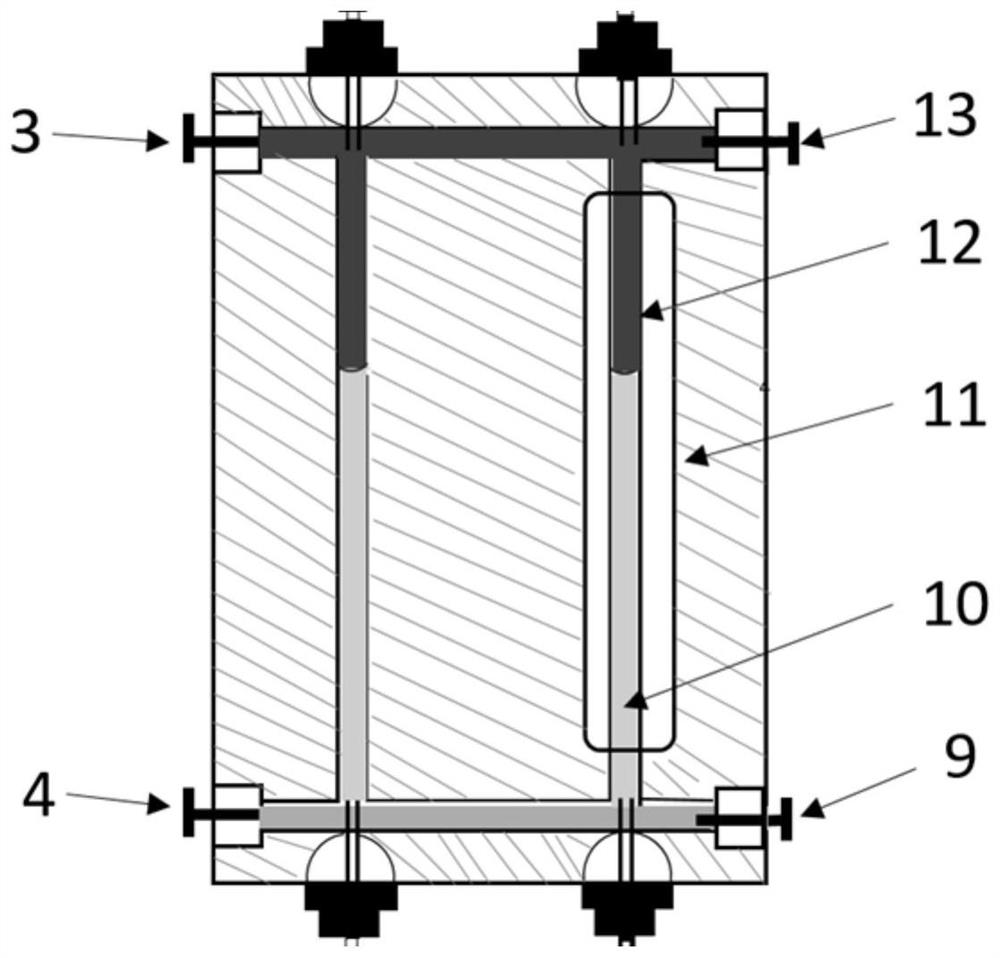

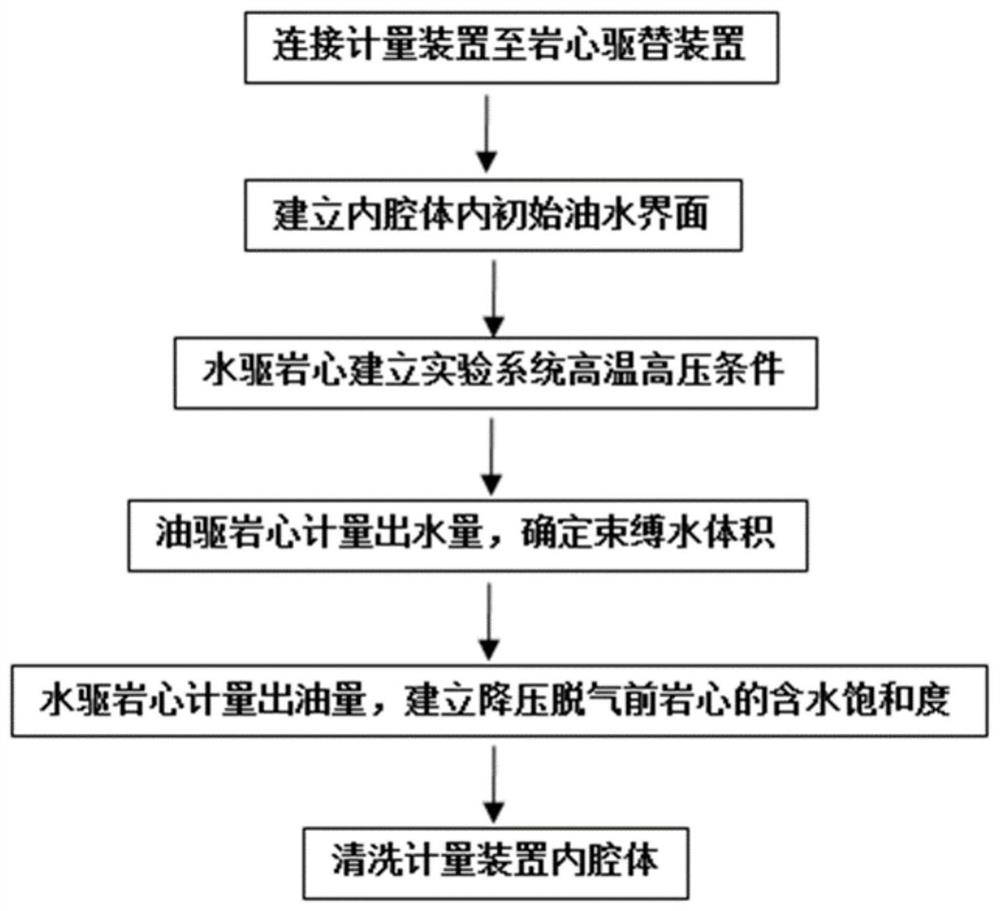

[0041] see Figure 1 to Figure 3 , the present invention provides a technical solution:

[0042] A high-temperature and high-pressure visualized oil-water metering device, comprising a metering body, the metering body is provided with a metering chamber, and the metering chamber is a well-shaped channel inner cavity that communicates with each other, that is, the inner well-shaped channel includes an upper horizontal metering channel and a lower horizontal metering channel. channel, left vertical metering channel, right vertical metering channel.

[0043] Further, the left and right ports of the upper horizontal metering channel are equipped with blocking parts, namely dead blocks 3 and 13, and the left and right ports of the lower horizontal metering channel are also equipped with blocking parts, namely dead blocks 4 and 9; The upper port of the metering channel is connected to the high-temperature and high-pressure gas-containing crude oil inlet pipe 1 through a joint, the ...

Embodiment 2

[0078] see Figure 1 to Figure 3 , the present invention provides a technical solution:

[0079] A high-temperature and high-pressure visualized oil-water metering device, comprising a metering body, the metering body is provided with a metering chamber, and the metering chamber is a well-shaped channel inner cavity that communicates with each other, that is, the inner well-shaped channel includes an upper horizontal metering channel and a lower horizontal metering channel. channel, left vertical metering channel, right vertical metering channel.

[0080] Further, the left and right ports of the upper horizontal metering channel are equipped with blocking parts, namely dead blocks 3 and 13, and the left and right ports of the lower horizontal metering channel are also equipped with blocking parts, namely dead blocks 4 and 9; The upper port of the metering channel is connected to the high-temperature and high-pressure gas-containing crude oil inlet pipe 1 through a joint, the ...

Embodiment 3

[0085] see Figure 1 to Figure 3 , the present invention provides a technical solution:

[0086] A high-temperature and high-pressure visualized oil-water metering device, comprising a metering body, the metering body is provided with a metering chamber, and the metering chamber is a well-shaped channel inner cavity that communicates with each other, that is, the inner well-shaped channel includes an upper horizontal metering channel and a lower horizontal metering channel. channel, left vertical metering channel, right vertical metering channel.

[0087] Further, the left and right ports of the upper horizontal metering channel are equipped with blocking parts, namely dead blocks 3 and 13, and the left and right ports of the lower horizontal metering channel are also equipped with blocking parts, namely dead blocks 4 and 9; The upper port of the metering channel is connected to the high-temperature and high-pressure gas-containing crude oil inlet pipe 1 through a joint, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com