Energy-reducing device for high-energy particles and its preparation method

A high-energy particle and energy-reducing technology, which is applied in radiation/particle treatment, ion implantation plating, nuclear engineering, etc., can solve the problems of toxicity, difficulty in popularization and application, and high price, and achieve good stability, convenient use, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The concrete steps of preparation are:

[0036] Step 1, first place the graphite substrate in a vacuum chamber. Then, according to the volume ratio of ammonia gas, boron chloride gas and nitrogen gas at a ratio of 0.8:1.2:40, the three gases are mixed to obtain a mixed gas.

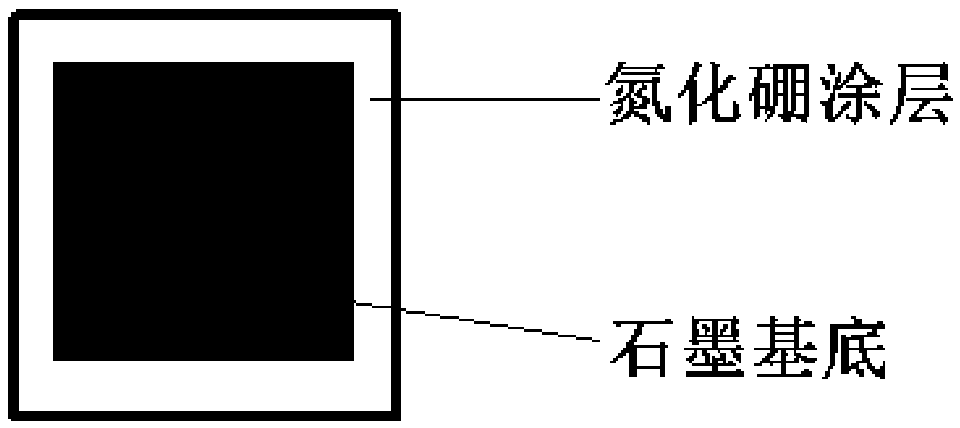

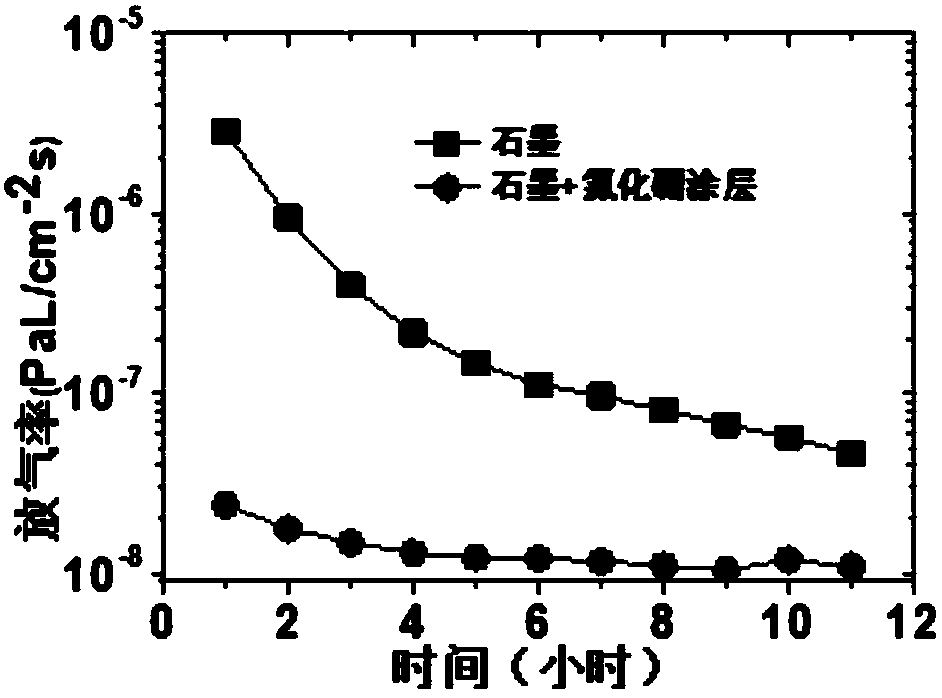

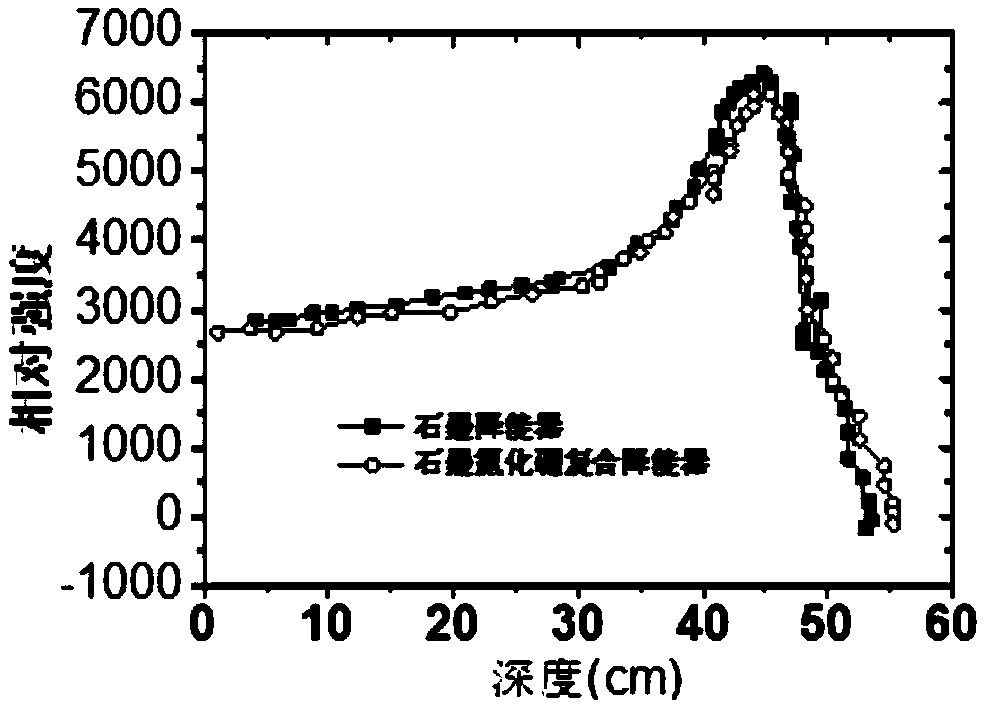

[0037] Step 2, firstly raise the temperature in the vacuum chamber to 500°C. Feed flow into the vacuum chamber again and be the mixed gas 36h of 10sccm, make such as figure 1 shown, and as figure 2 and image 3 The high-energy particle de-energy device shown in the curve in .

Embodiment 2

[0039] The concrete steps of preparation are:

[0040] Step 1, first place the graphite substrate in a vacuum chamber. Then, according to the volume ratio of ammonia gas, boron chloride gas and nitrogen gas at a ratio of 0.9:1.1:45, the three gases are mixed to obtain a mixed gas.

[0041] Step 2, first raise the temperature in the vacuum chamber to 875°C. Feed flow into the vacuum chamber again and be the mixed gas 30h of 32.5sccm, make such as figure 1 shown, and as figure 2 and image 3 The high-energy particle de-energy device shown in the curve in .

Embodiment 3

[0043] The concrete steps of preparation are:

[0044] Step 1, first place the graphite substrate in a vacuum chamber. Then, according to the volume ratio of ammonia gas, boron chloride gas and nitrogen gas at a ratio of 1:1:50, the three gases are mixed to obtain a mixed gas.

[0045] Step 2, first raise the temperature in the vacuum chamber to 1250°C. Pass into the vacuum chamber again and flow is the mixed gas 24h of 55sccm, makes such as figure 1 shown, and as figure 2 and image 3 The high-energy particle de-energy device shown in the curve in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com