Horizontal continuous magnetron sputtering coating machine online panel constant temperature heating device

A technology of constant temperature heating and magnetron sputtering, applied in the field of machinery, can solve the problems of low quality and low production capacity of anti-reflection conductive film coating, and achieve the effects of low cost, fast response speed and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

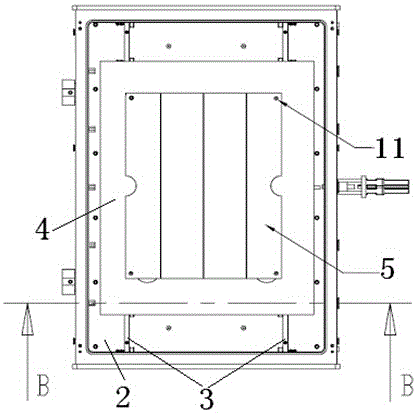

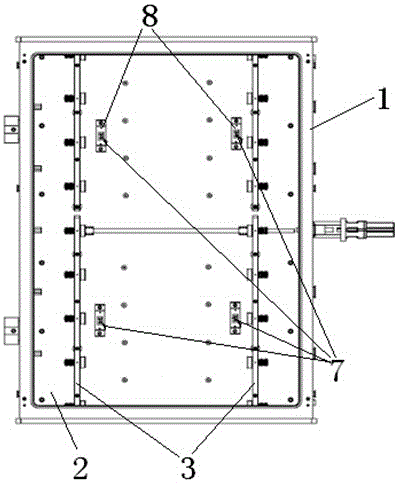

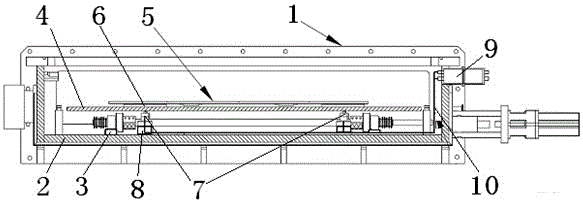

[0020] Such as figure 1 As shown, it is an online panel constant temperature heating device of a horizontal continuous magnetron sputtering coating machine, including a vacuum chamber 1, a working platform 2, a transmission guide rail 3, a transmission substrate 4, a copper conductive plate 5 and a copper disk electrode 6, and the working The platform 2 is arranged inside the vacuum chamber 1, and a pair of transmission guide rails 3 are arranged in parallel on the working platform, and the transmission guide rails 3 are slidably connected and horizontally provided with a transmission substrate 4 for transmitting the panel to be plated; the transmission substrate 4 is horizontally provided with The copper conduction plate 5 is equipped with an embedded thermocouple temperature measuring rod and a PTC constant temperature low-voltage heating element, and the power lead ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com