A flat plate electrode fixing structure

A fixed structure, flat electrode technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problem of plasma inhomogeneity, achieve the effect of wide distribution range of uniformity, good uniformity effect, and maintain vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

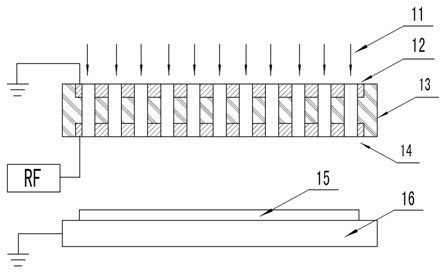

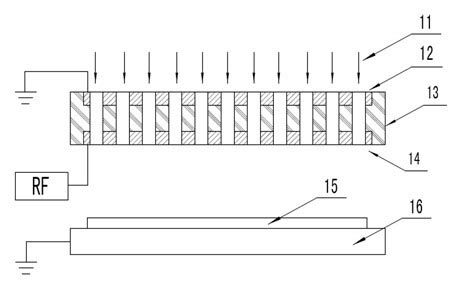

[0015] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

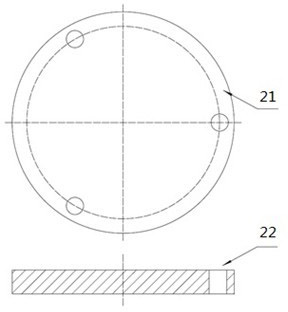

[0016] like figure 2 As shown, the embodiment of the present invention provides a plate electrode fixing structure, including an insulating support 13, a plurality of air inlet holes are arranged on the insulating support 13, and the upper electrode 12 and the lower electrode 14 are evenly distributed around the air inlet holes. The upper electrode 12 and the lower electrode 14 are metal electrodes, and the material of the metal electrodes may be, but not limited to, graphite, molybdenum, galvanized aluminum, stainless steel, aluminum alloy, or oxygen-free copper. The thickness of the insulating support 13 is 5 to 1000 mm. The insulating support 13 is made of insulating material, and the insulating material may be, but not limited to, ceramic, quartz, polytetrafluoroethylene or polycarbonate. The frequency of the radio freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com