Device for accurate measurement of micro deformation of composite rod for space

A composite material and precise measurement technology, which is applied in the field of aerospace, can solve the problems of low measurement accuracy and the inability to effectively measure the small deformation of composite material rods used in space, and achieve good repeatability and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

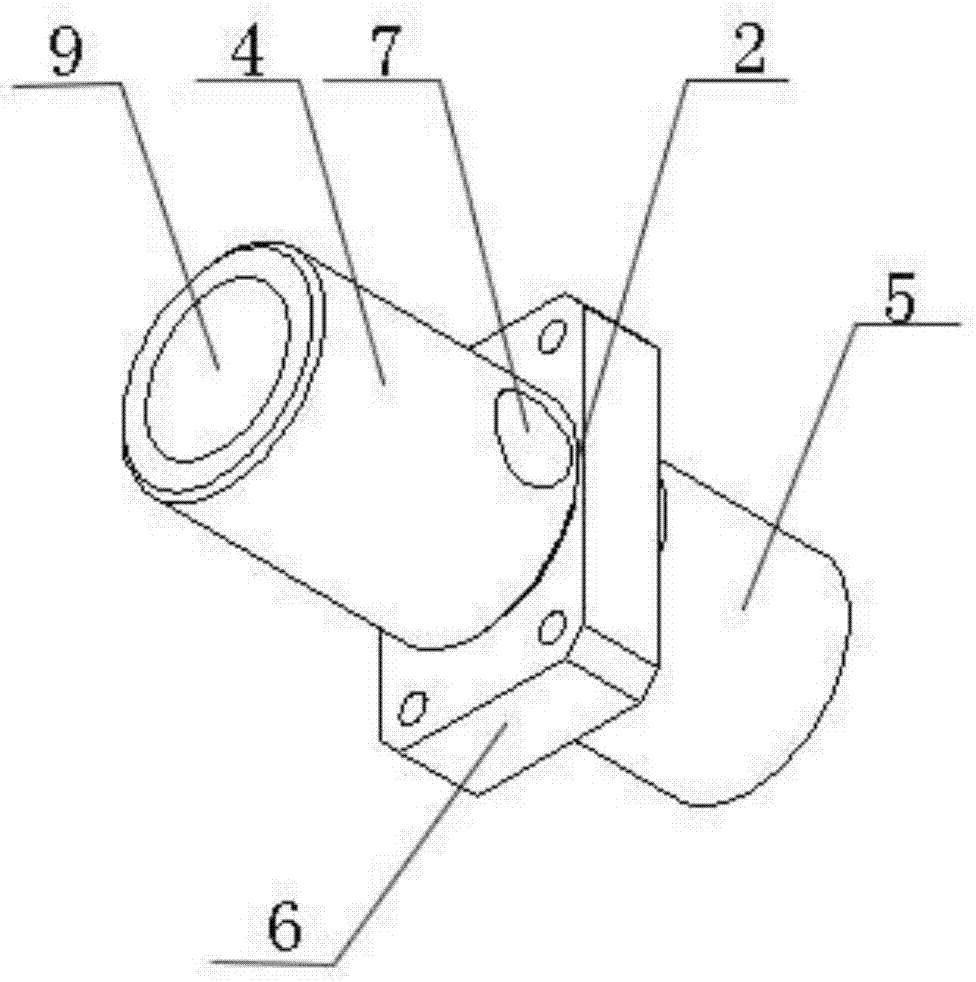

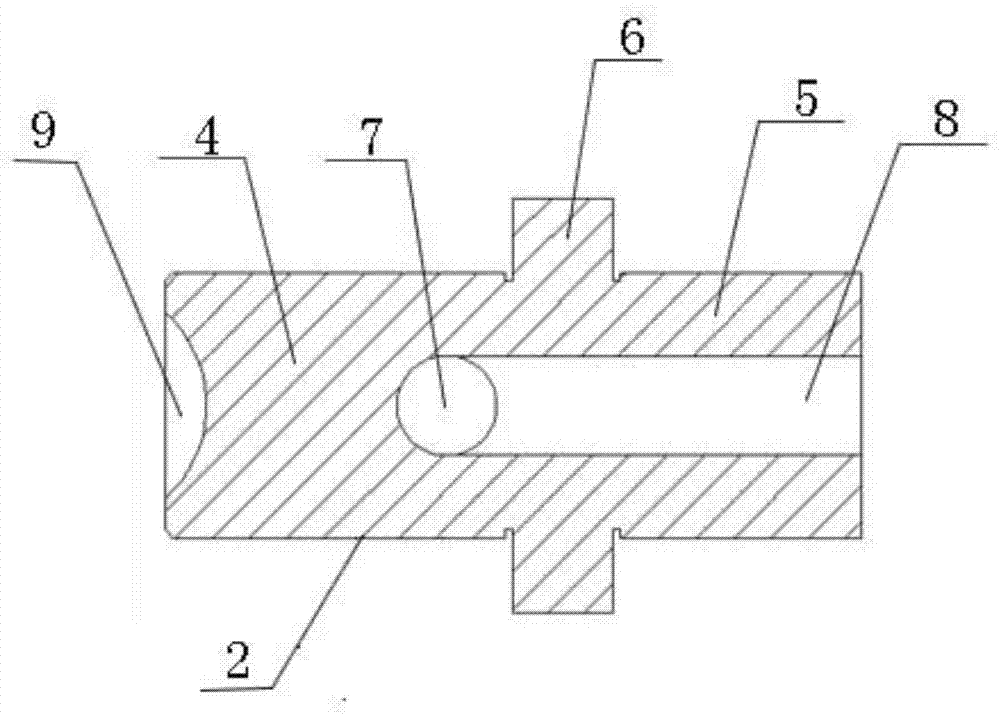

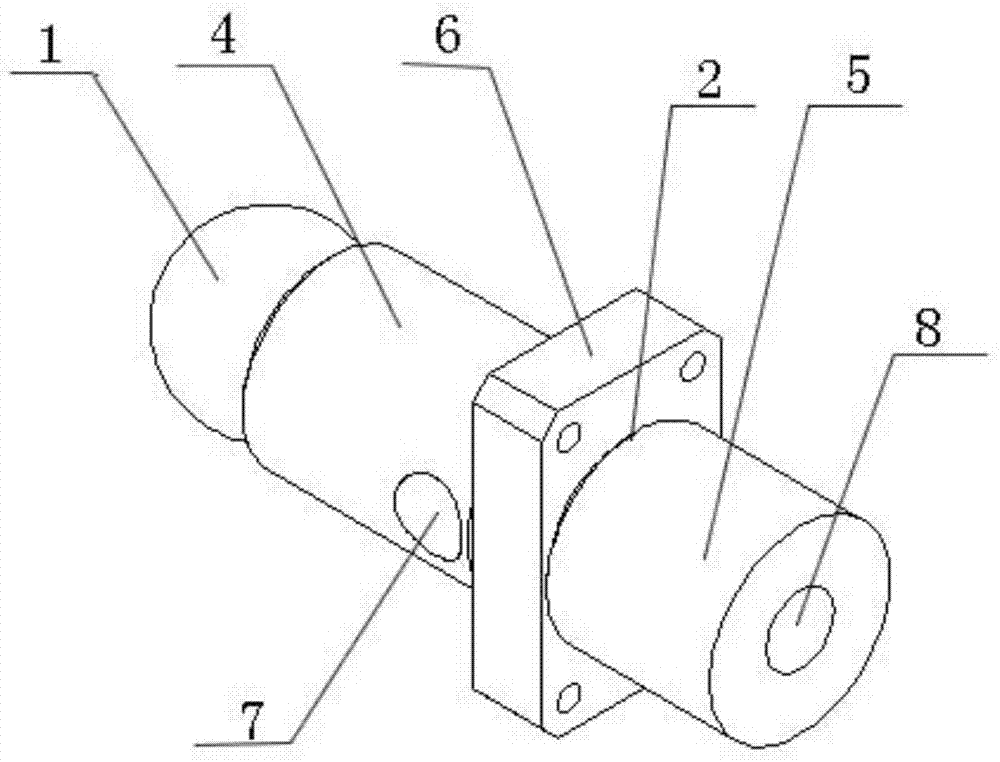

[0024] Such as image 3 As shown, the device for accurately measuring the micro-deformation of a space-use composite material bar according to the present invention consists of a steel ball 1 and a direct head 2 . The direct head 2 adopts a hollow structure design, and adopts mechanical integration processing and molding, such as figure 1 As shown, a first cylindrical structure 4 and a second cylindrical structure 5 are respectively arranged at both ends of the direct head 2, and a square structure 6 is arranged in the middle, the first cylindrical structure 4 cooperates with the steel ball 1, and the second cylindrical structure 5 cooperates with the composite material bar 3. Such as figure 2 As shown, a through hole 7 is provided on the first cylindrical structure 4 close to the radial direction of the square structure 6, and a spherical groove 9 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com