A combination device of a new buffer excavator gear seat and bucket teeth

A combination device and a technology of machine tooth seat, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problem that the joint surface of the tooth seat and the blade plate cannot be completely fitted, the weld seam is easy to crack and extends to the entire blade plate, Reduce the strength of the tooth seat and other problems to achieve the effect of reducing the risk of weld cracking, eliminating impact, and enhancing the strength of the tooth seat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

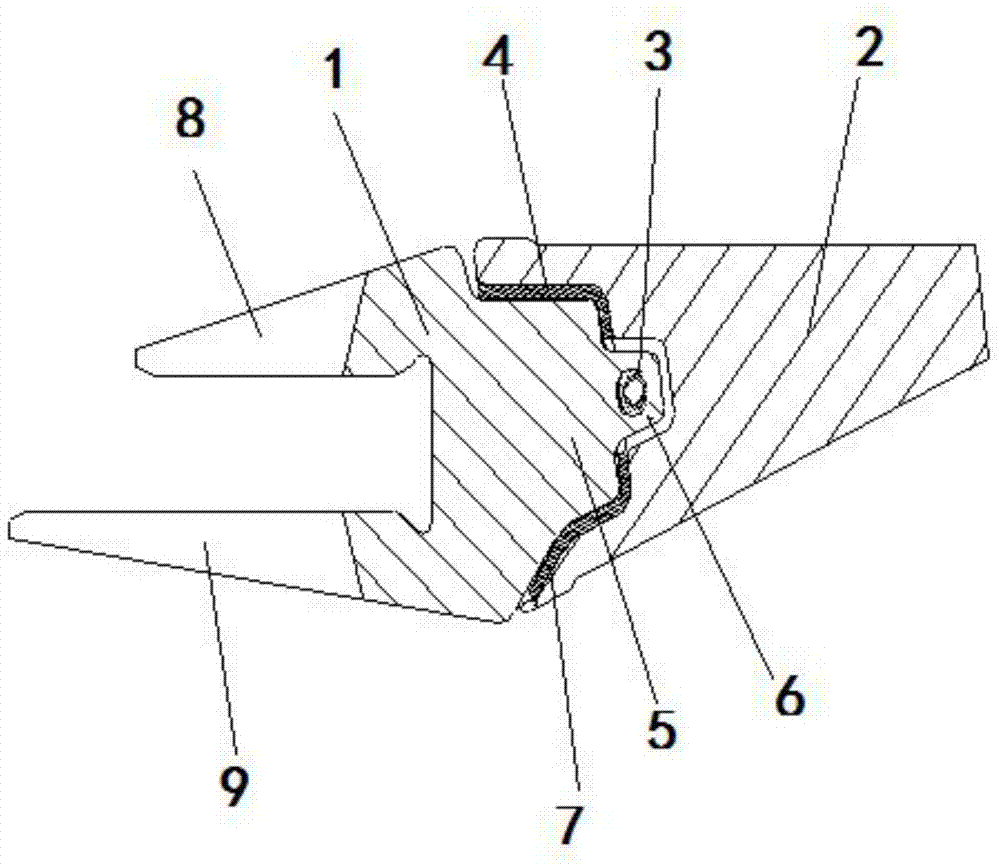

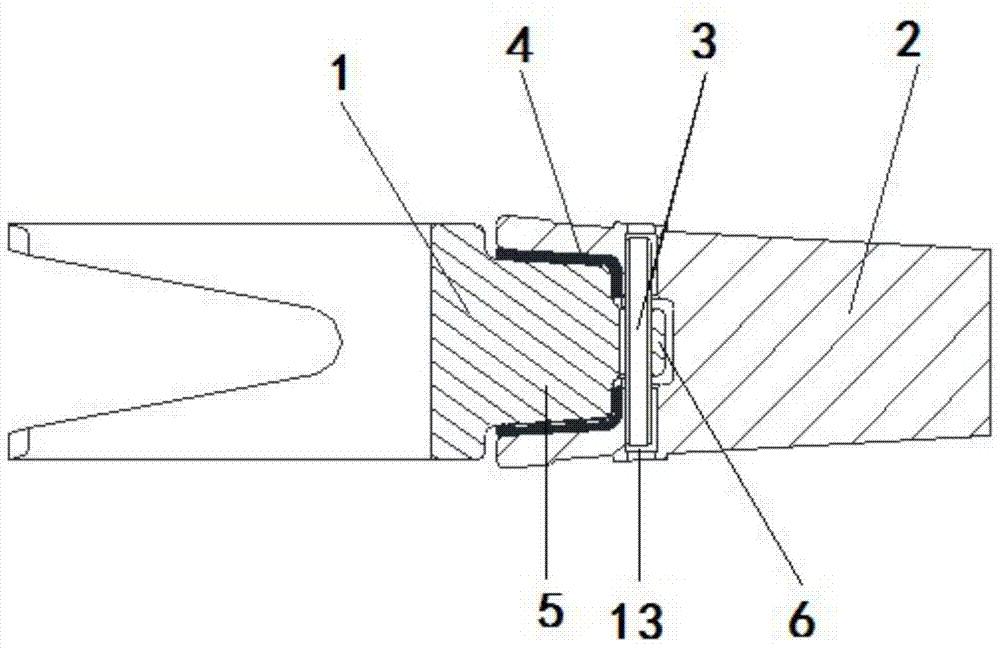

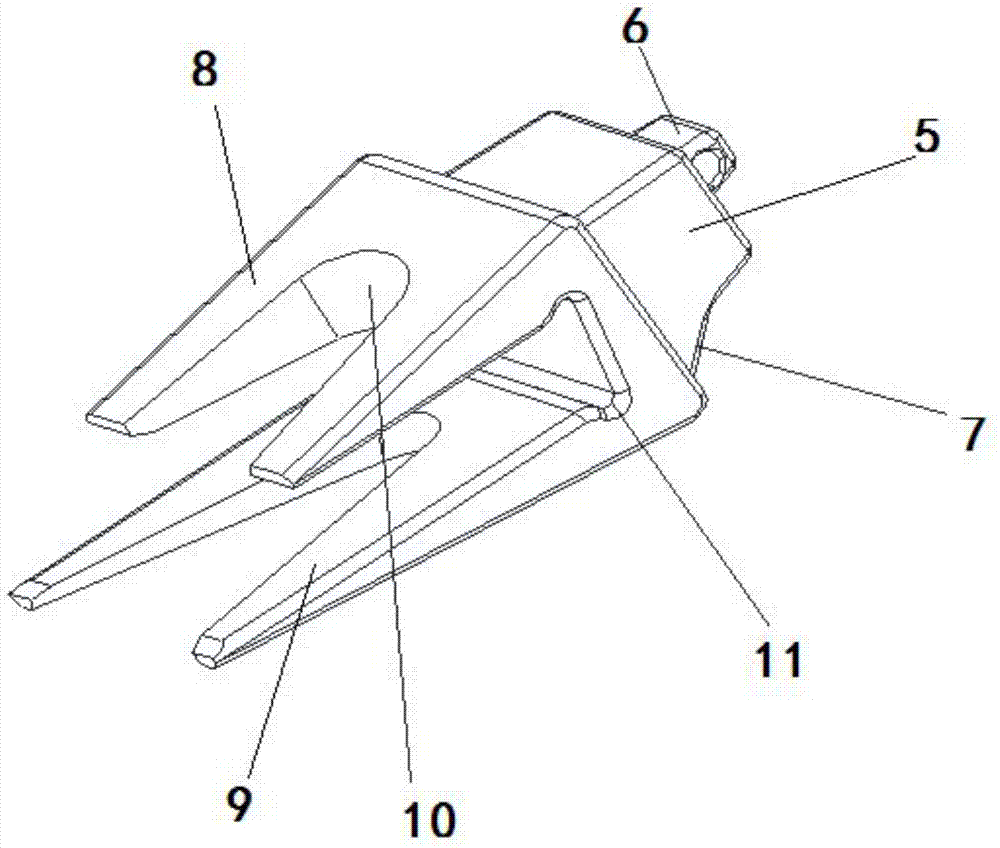

[0021] see Figure 1-4 , a combination device of a novel cushioning excavator tooth seat and bucket tooth, which includes a tooth seat 1, a bucket tooth 2, a bayonet pin 3 and a shock absorber 4, and the head of the tooth seat 1 and the bucket tooth 2 Assembled, the tail of the tooth holder 1 is assembled with the excavator blade, the tail of the tooth holder 1 includes an upper connecting plate 8 and a lower connecting plate 9 welded to the excavator blade, the tooth holder 1 Fitted with the bucket tooth 2 and fixed by the bayonet 3, the head of the tooth seat includes a boss 5, a bayonet positioning seat 6 and an excessive rib 7, and the boss 5, bayonet positioning seat 6 and The excessive reinforcement rib 7 is integrally formed, the bayonet positioning seat 6 is located at the end of the boss 5 away from the head of the tooth holder 1, the transition reinforcement rib 7 connects the boss 5 and the lower connecting plate 9, On the same side as the lower connecting plate 9,...

Embodiment 2

[0030] see Figure 1-4 , a combination device of a novel cushioning excavator tooth seat and bucket tooth, which includes a tooth seat 1, a bucket tooth 2, a bayonet pin 3 and a shock absorber 4, and the head of the tooth seat 1 and the bucket tooth 2 Assembled, the tail of the tooth holder 1 is assembled with the excavator blade, the tail of the tooth holder 1 includes an upper connecting plate 8 and a lower connecting plate 9 welded to the excavator blade, the tooth holder 1 Fitted with the bucket tooth 2 and fixed by the bayonet 3, the head of the tooth seat includes a boss 5, a bayonet positioning seat 6 and an excessive rib 7, and the boss 5, bayonet positioning seat 6 and The excessive reinforcement rib 7 is integrally formed, the bayonet positioning seat 6 is located at the end of the boss 5 away from the head of the tooth holder 1, the transition reinforcement rib 7 connects the boss 5 and the lower connecting plate 9, On the same side as the lower connecting plate 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com