Limiting block sealing device and vacuumizing tire mold

A technology of sealing device and limit block, which is applied in the field of tire production, can solve the problems of poor sealing effect of equipment and failure to achieve sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

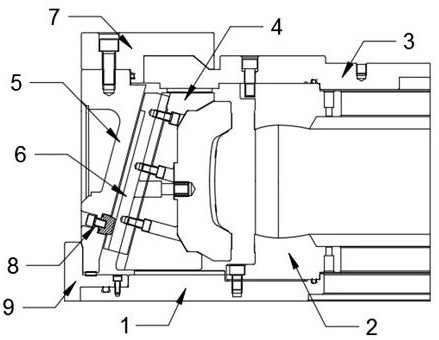

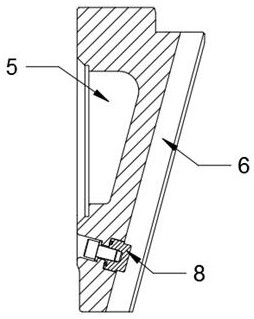

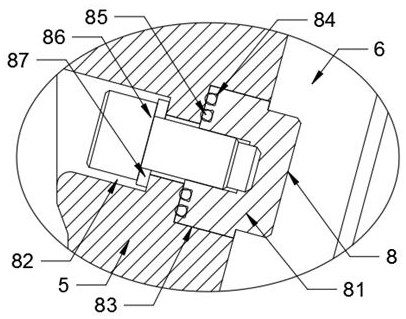

[0026] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 ,in, figure 1 A schematic diagram of the overall structure provided for the present invention; figure 2 Schematic diagram of the bonding structure of the guide ring and the inner template provided by the present invention; image 3 Schematic diagram of the seal structure provided by the present invention; Figure 4 A schematic diagram of the sealing structure at the bottom of the guide ring provided by the present invention; Figure 5 Schematic diagram of the pattern mold structure provided by the present invention; Figure 6 It is a schematic diagram of the fastening structure of the upper cover provided by the present invention. The limiting block sealing device and the vacuumized tire mold include: a bottom plate 1, a sidewall plate 2 and an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com