Glass liner structure of vacuum electric heating vessel

A vacuum and container technology, which is applied in the field of the bladder structure of a vacuum electric heating container, can solve the problems of poor processing technology of the bladder, affecting the quality of the kettle body, and inconvenient welding of the inner bladder, so as to ensure the vacuum degree, ensure the welding quality, The effect of improving the manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

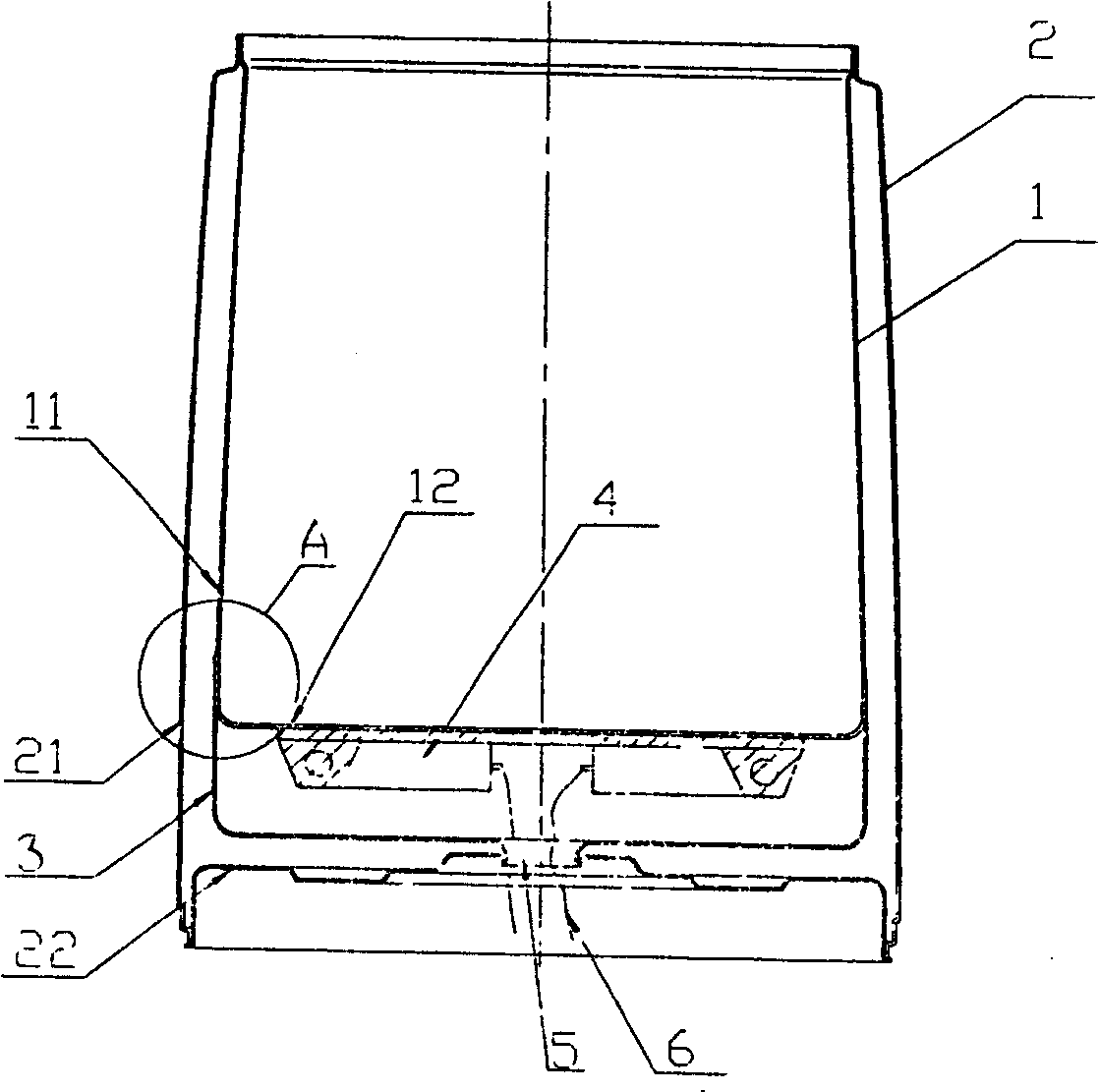

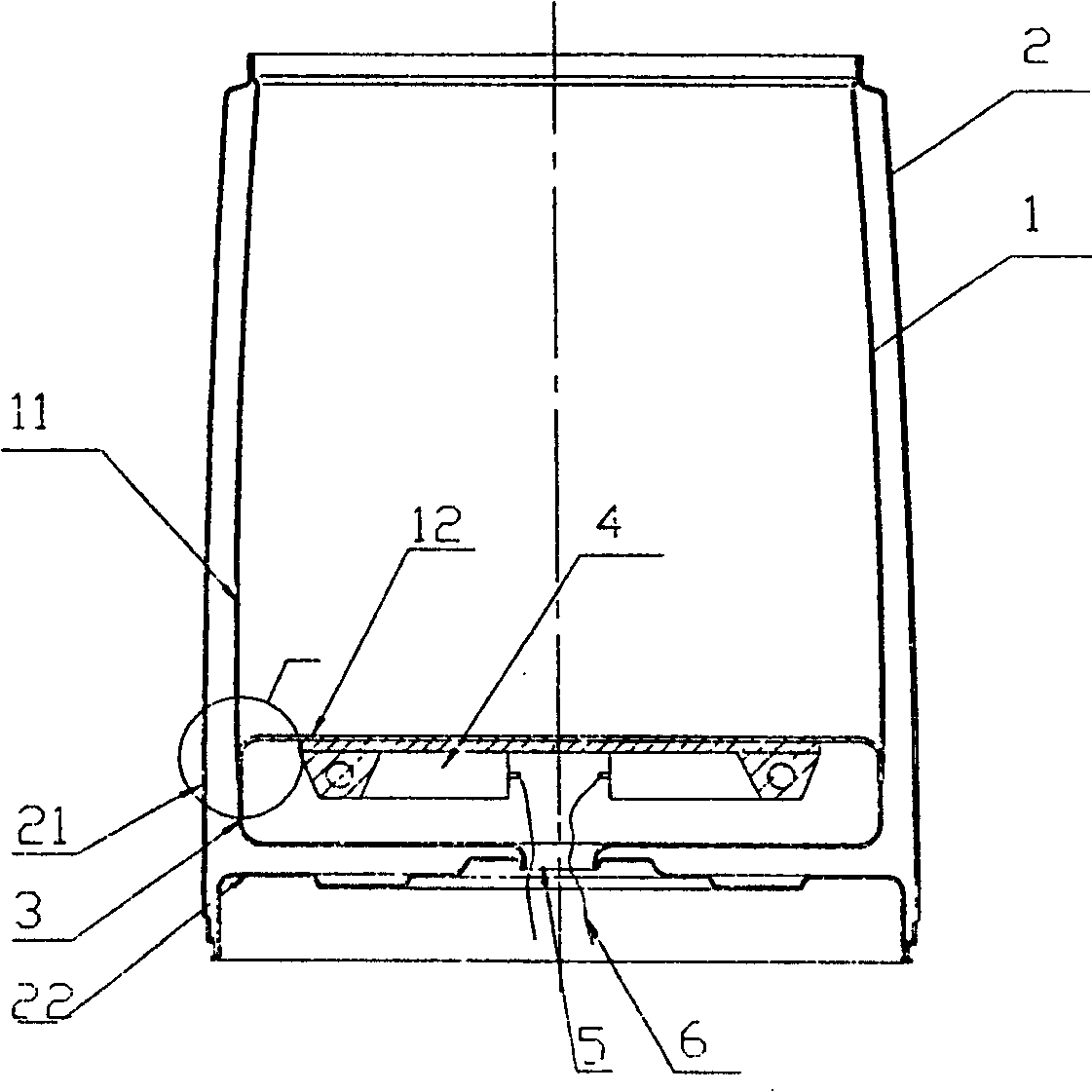

[0016] Embodiment 1: This embodiment includes an inner tank 1 , an outer tank 2 , a vacuum connection layer 3 and an electric heating device 4 . The inner tank is composed of an upper inner tank 11 and a lower inner tank 12; the electric heating device 4 is composed of an aluminum alloy heat dissipation material and an electric heating wire arranged in the aluminum alloy heat dissipation material, and is located between the inner tank 1 and the vacuum connection layer 3 , the aluminum alloy heat dissipation material is placed on the back of the bottom inner tank 12, and the bottom inner tank 12 is welded with the bottom. Boil-dry prevention device and temperature sensor can be provided at the back of bottom liner 12 . The outer bladder is composed of an upper outer bladder 21 and a bottom outer bladder 22, and the upper outer bladder 21 and the lower outer bladder 22 are sealed and welded together at the corners. The bottom back of the inner container in the space formed betw...

Embodiment 2

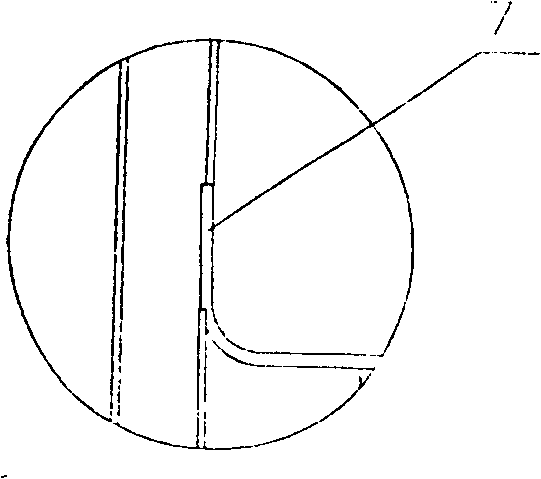

[0017] Embodiment 2: This embodiment includes an inner container 1 , an outer container 2 , a vacuum connection layer 3 and an electric heating device 4 . Its structure is basically the same as that of Embodiment 1, the difference is that the bottom liner 12 is provided with a downward folded edge 8 around the periphery, and the outer end of the vacuum connection layer 3 is sealed with the outer end of the bottom liner 12 lower folded edge 8 Welding, a sunken circular step is processed along the circumferential direction on the outer surface of the root of the lower flange of the bottom inner tank 12, and the lower end of the upper inner tank 11 is set on the sunken circular step at the root of the lower flange 8 of the bottom inner tank to seal against it Welding can fully guarantee the welding quality.

[0018] After the above structure is adopted in the present invention, the manufacturability of the tank structure of the vacuum electric heating container can be greatly imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com