Liquid injection method for hydraulic bushing for rail transit

A hydraulic bushing and rail transportation technology, which is applied in the field of rail transportation, can solve the problems of noise in fluid flow, large drill bit deflection, long axial liquid injection channel, etc., to achieve no noise in fluid flow, high injection efficiency, The effect of excellent dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

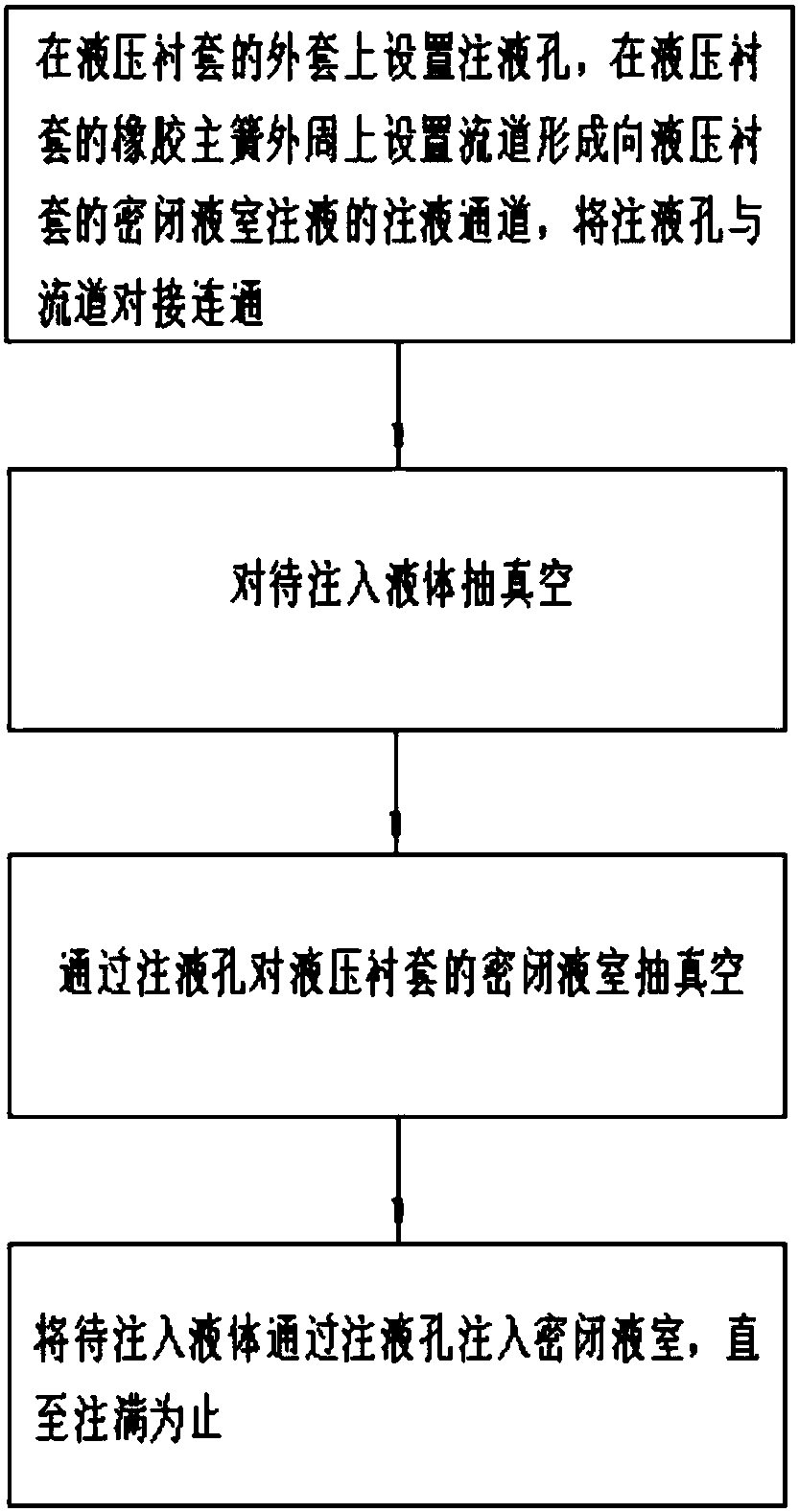

[0028] Such as figure 1 As shown, the liquid injection method of the rail transit hydraulic bushing of the present embodiment includes the following steps:

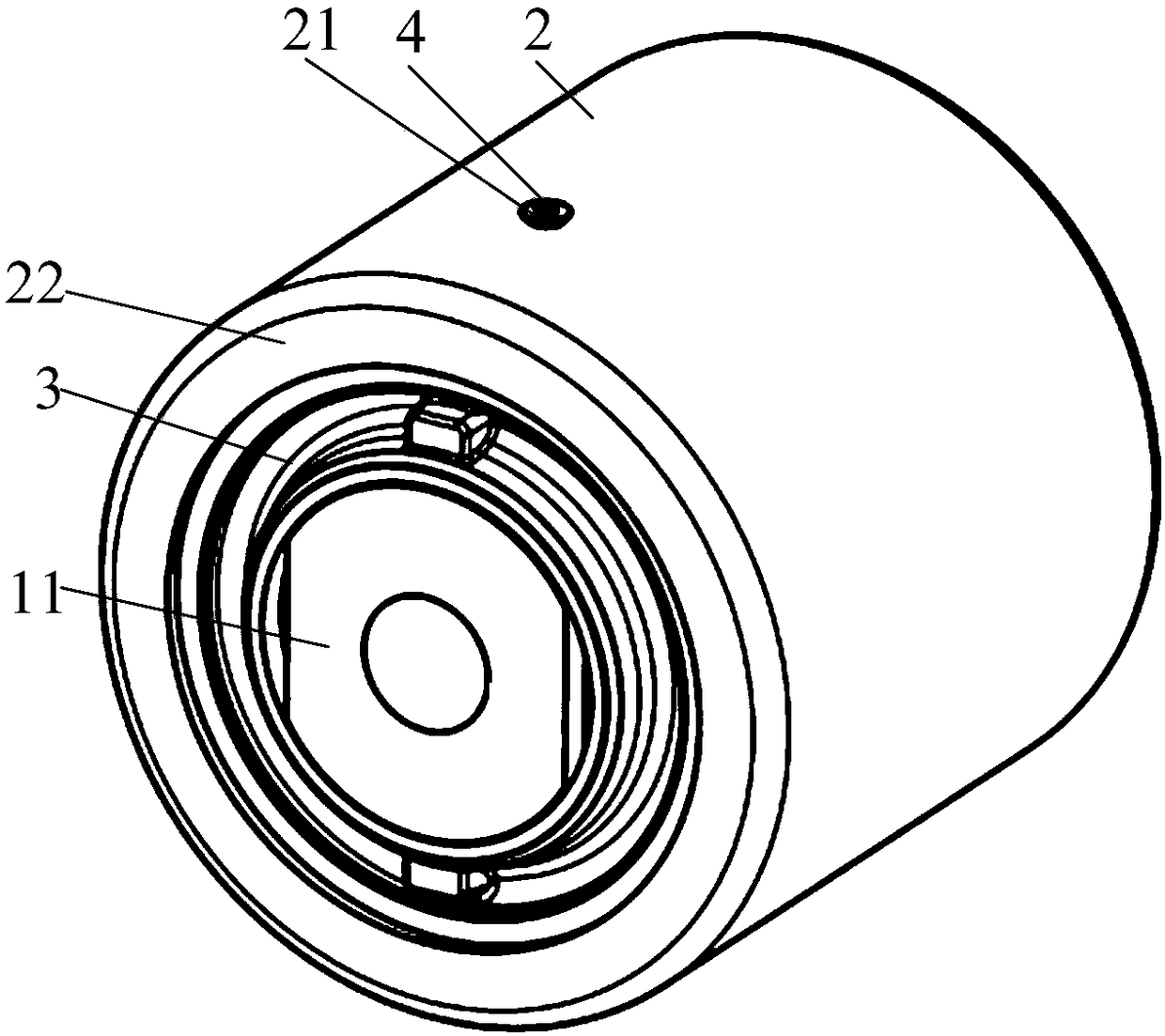

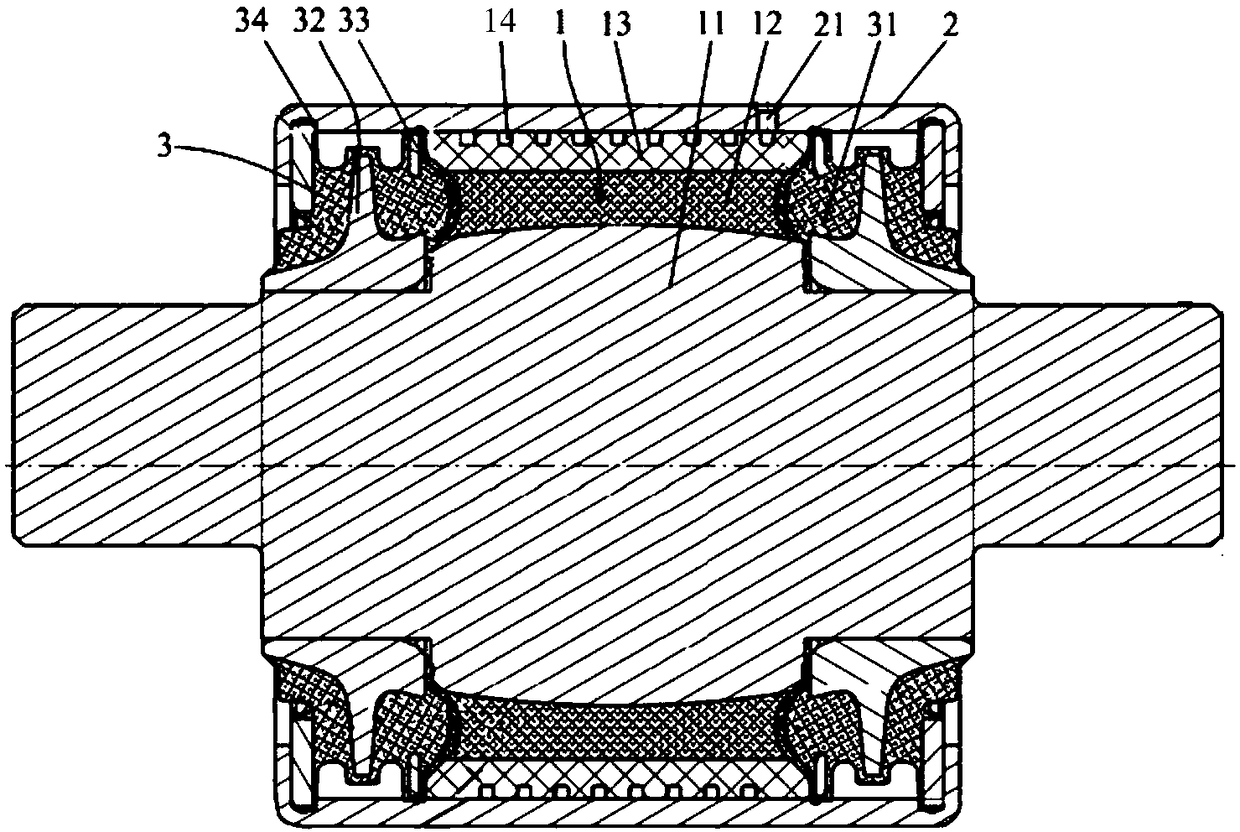

[0029] 1) A liquid injection hole 21 is provided on the bush jacket 2 of the hydraulic bush, and a flow channel 15 is provided on the outer periphery of the rubber main spring 1 of the hydraulic bush to form a liquid injection channel for injecting liquid into the closed liquid chamber of the hydraulic bush. The injection hole 21 is connected to the flow channel 15;

[0030] 2) Vacuumize the liquid to be injected;

[0031] 3) Vacuumize the sealed liquid chamber of the hydraulic bush through the liquid injection hole 21;

[0032] 4) The liquid to be injected is injected into the sealed liquid chamber thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com