Patents

Literature

76results about "Gasless spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

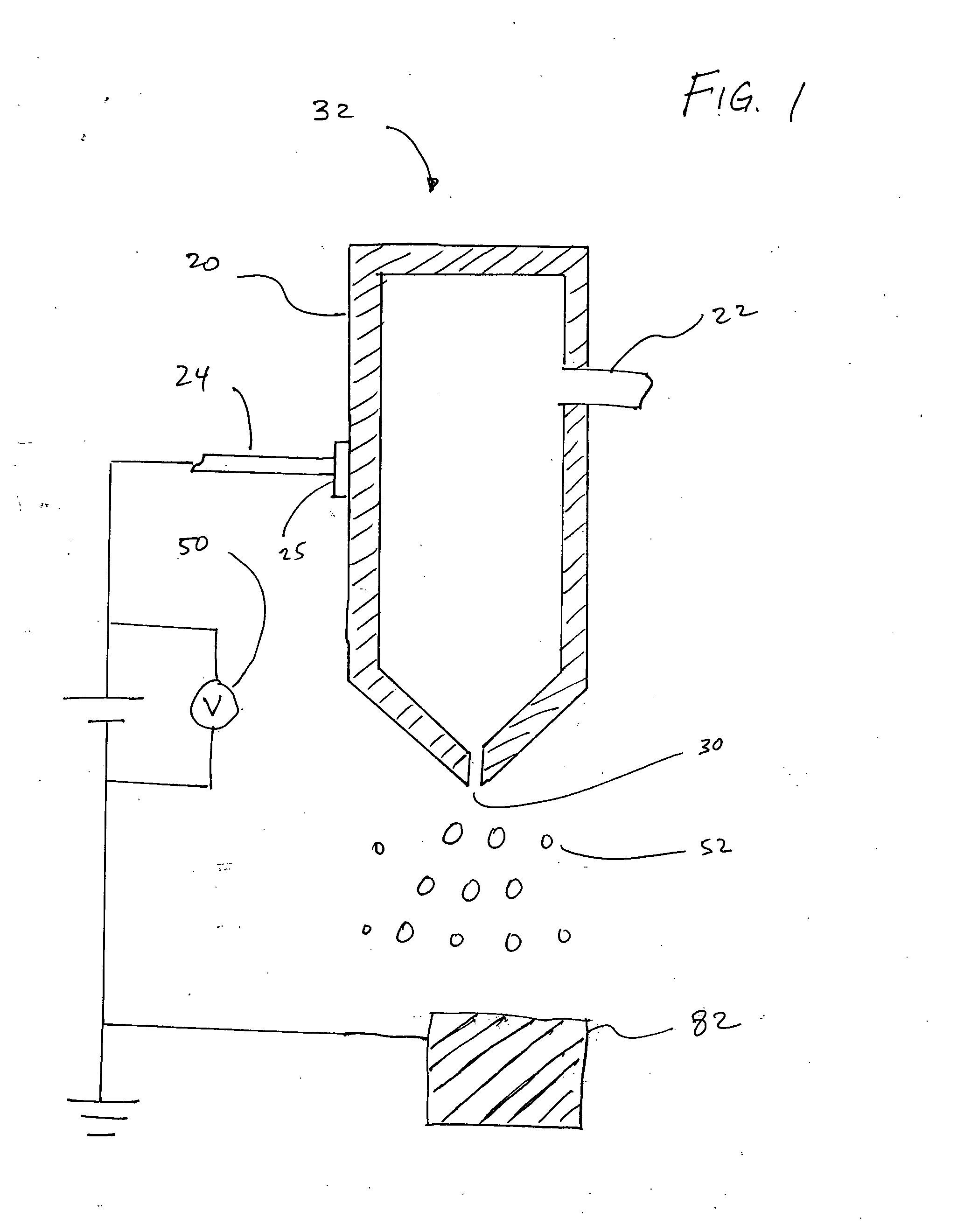

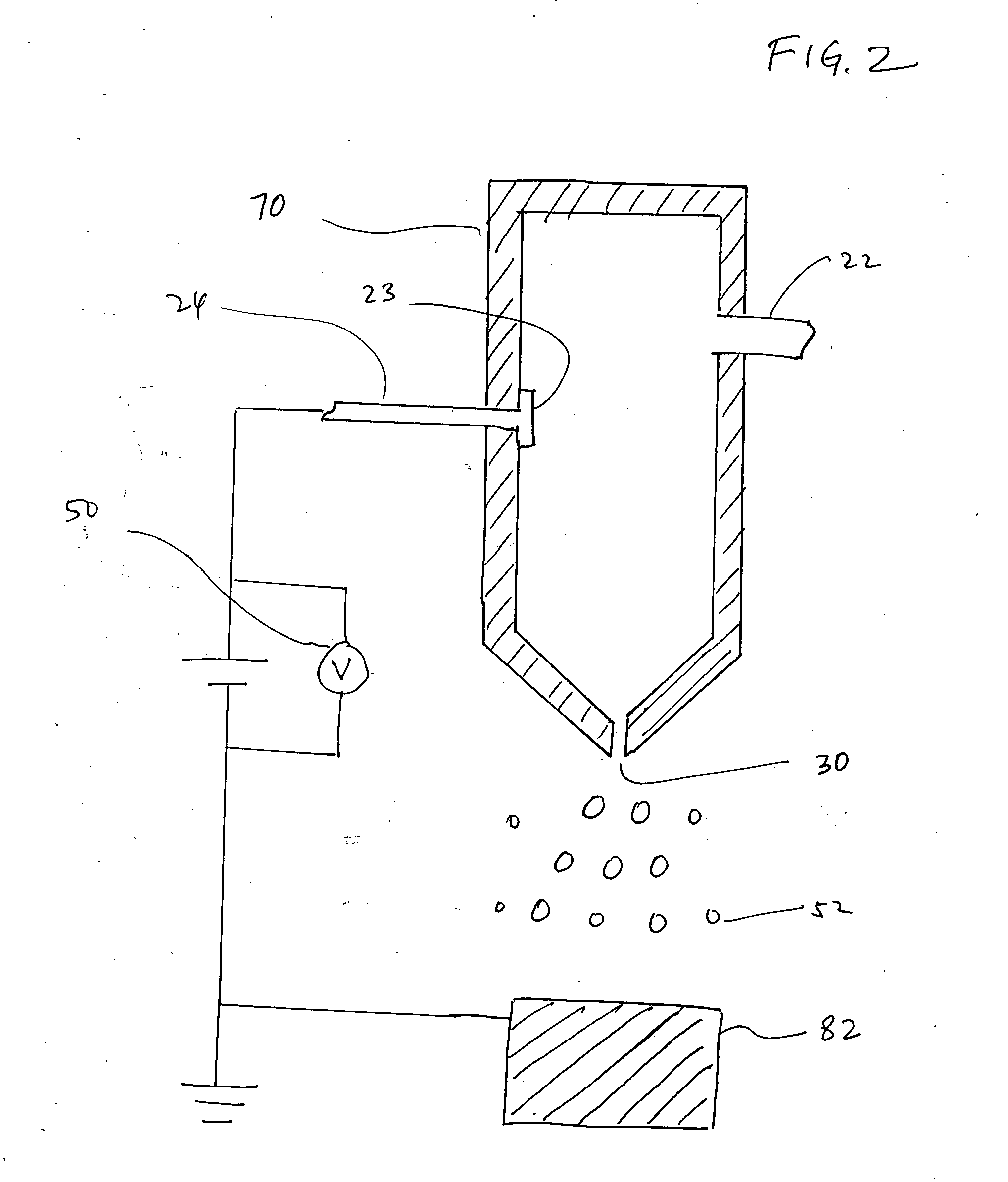

System and method for electrostatic-assisted spray coating of a medical device

A system and method for the electrostatic spray application of a coating material onto a medical device. The coating material is electrically charged and an atomizer is used to atomize the coating material, creating electrically charged droplets which coat the medical device. In alternate embodiments, a swirl atomizer, a pressure atomizer, an ultrasound atomizer, a rotary atomizer, and an effervescent atomizer are used to atomize the coating material.

Owner:BOSTON SCI SCIMED INC

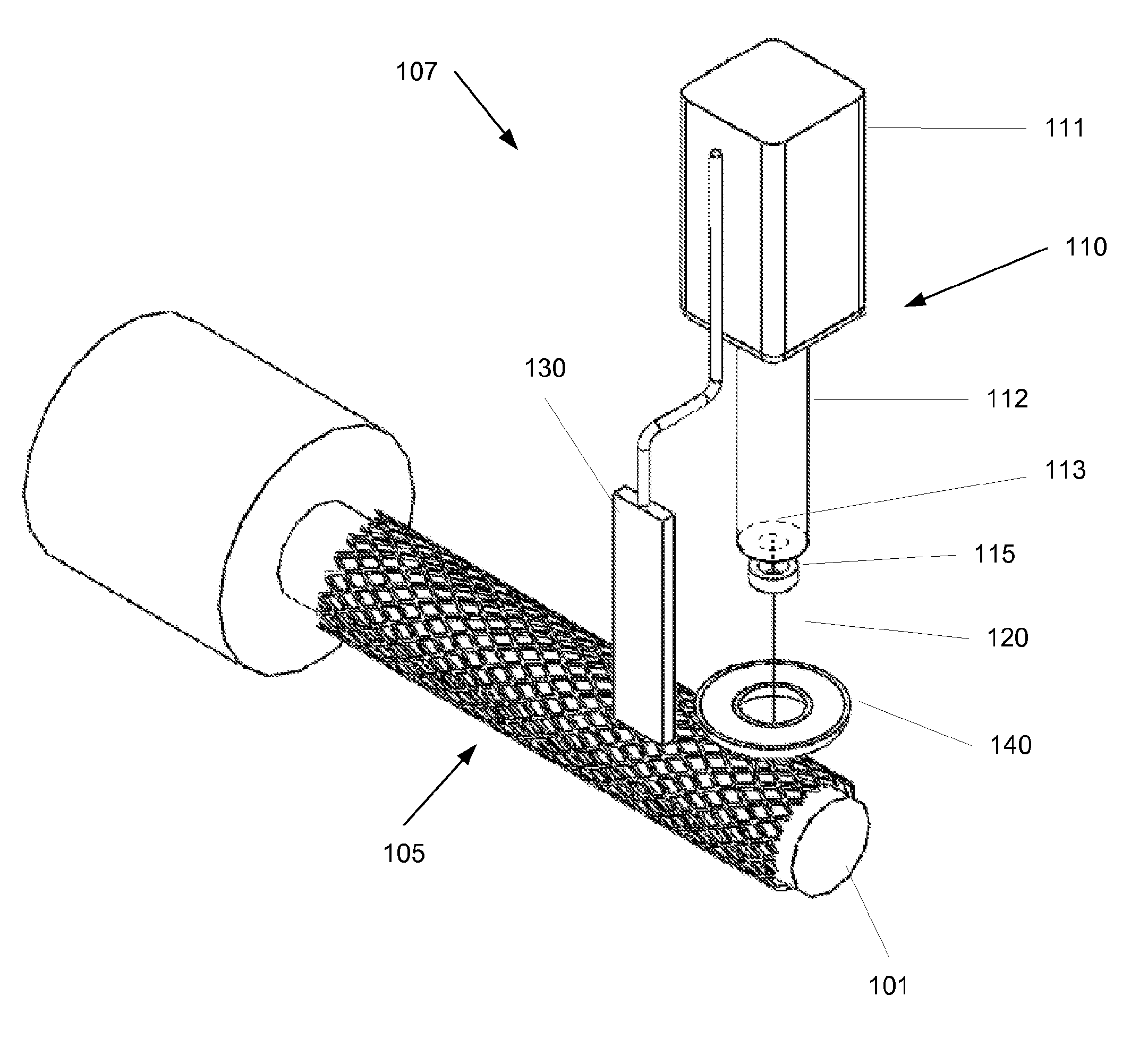

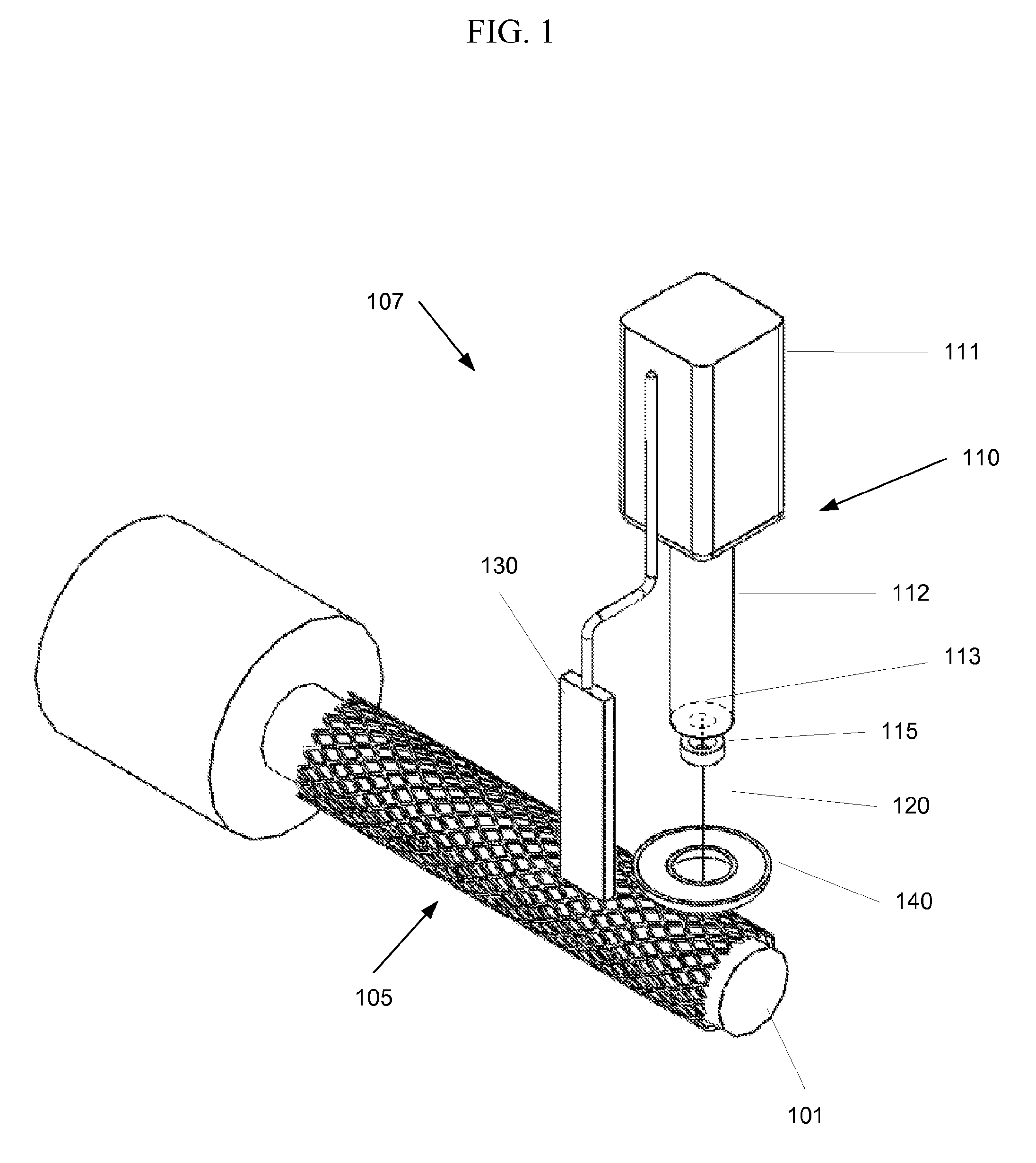

Method of producing particles utilizing a vibrating mesh nebulizer for coating a medical appliance, a system for producing particles, and a medical appliance

A method of coating a medical device is provided that includes contacting a solution with a first side of a mesh nebulizer and vibrating the mesh nebulizer. The solution including a material. The mesh nebulizer includes at least one aperture. The method also includes evaporating a solvent from the solution in a region of a second side of the mesh nebulizer that is opposite the first side. The evaporating operation forms the particle of the material. The method also include contacting the particle with the medical device. A medical appliance is provided having a coating applied by a method. A system for creating a plurality of particles is provided.

Owner:BOSTON SCI SCIMED INC

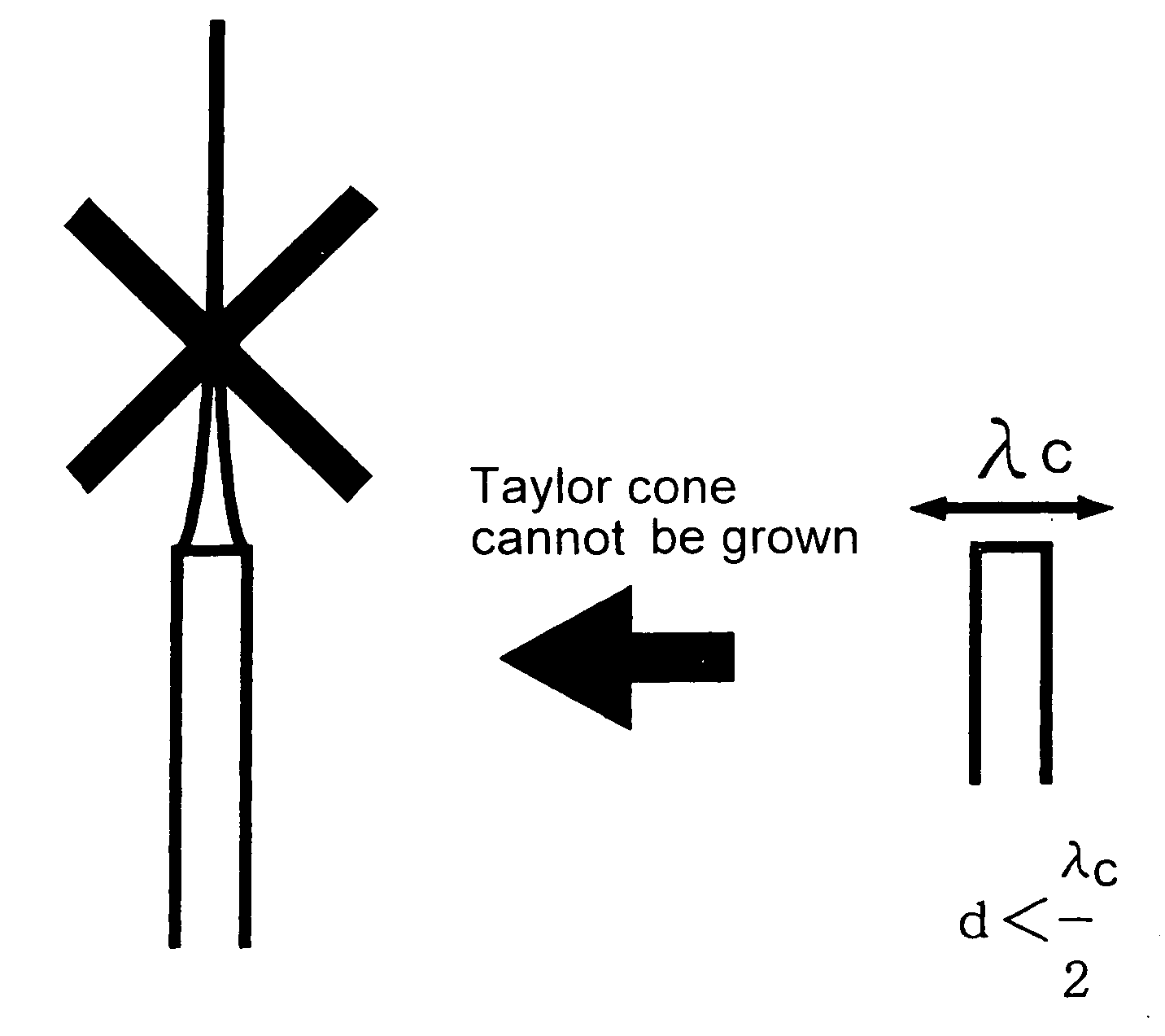

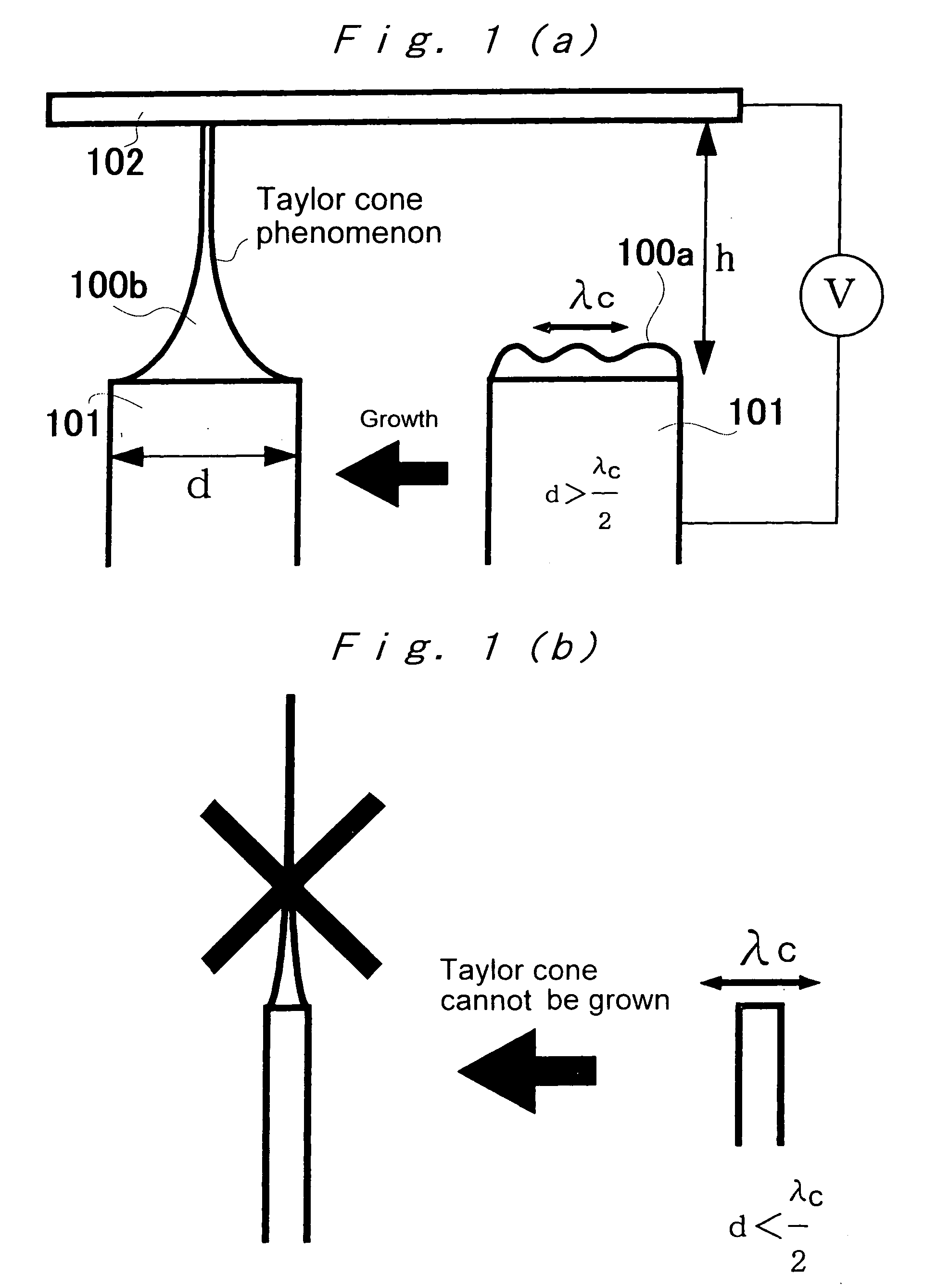

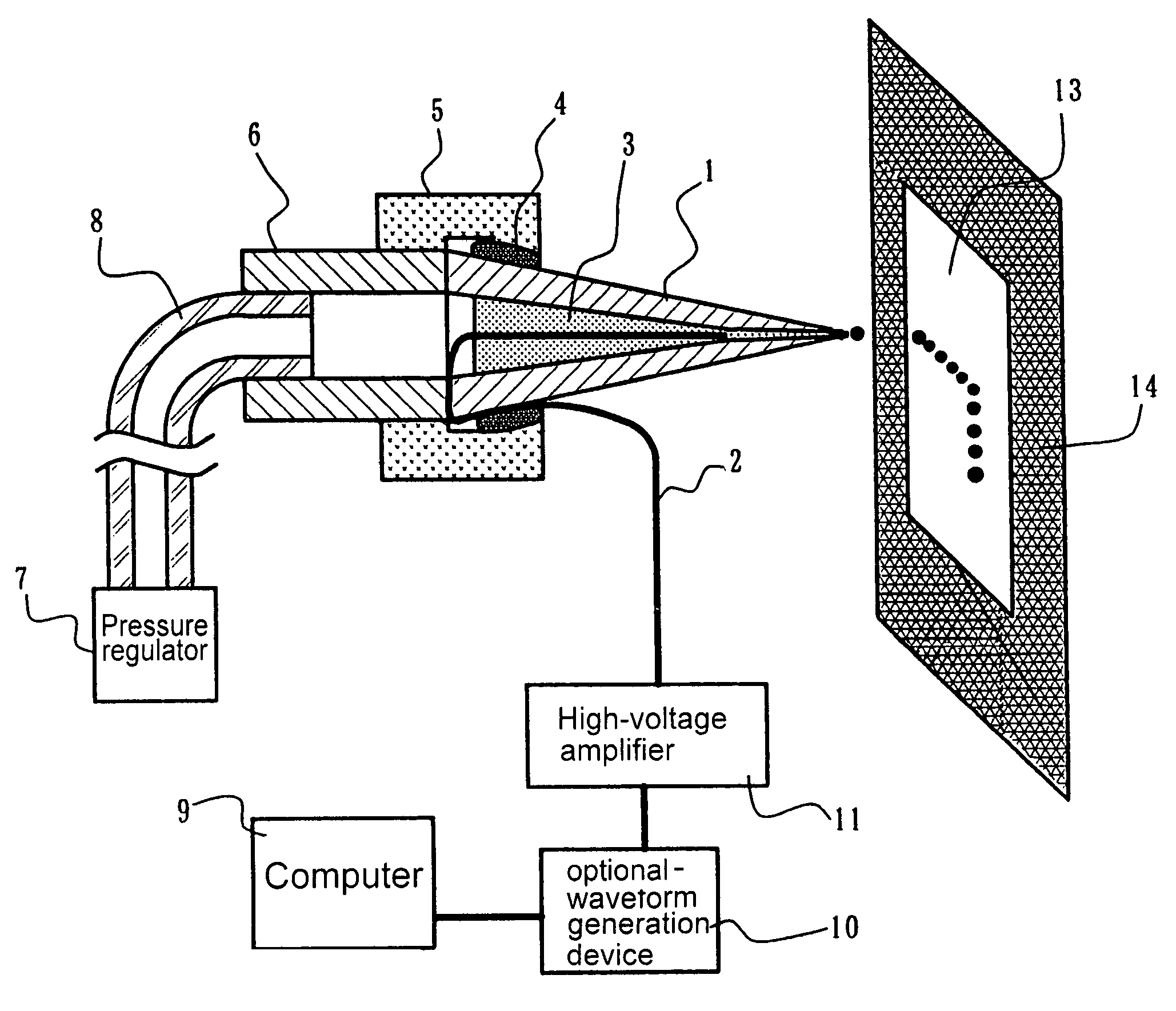

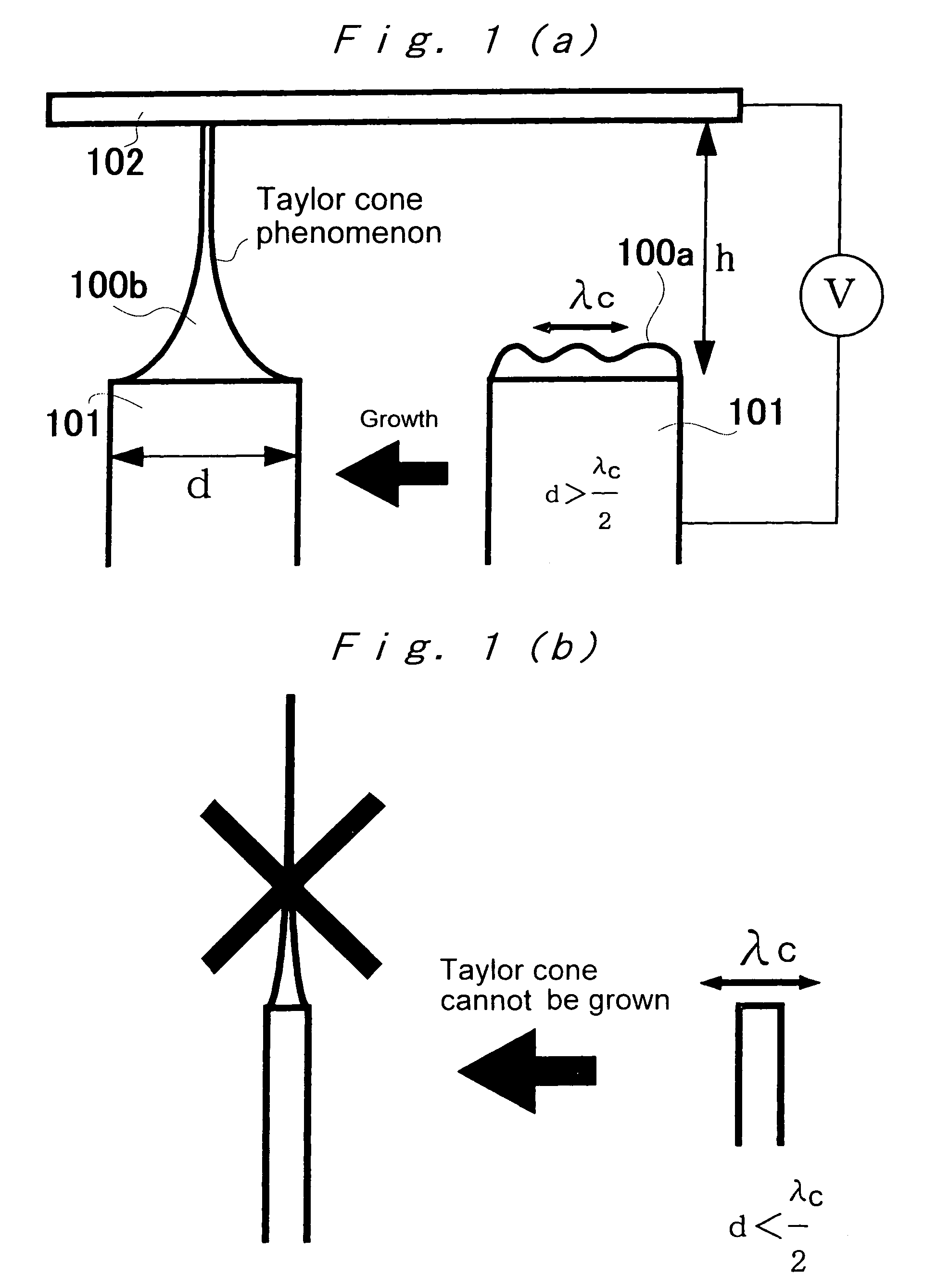

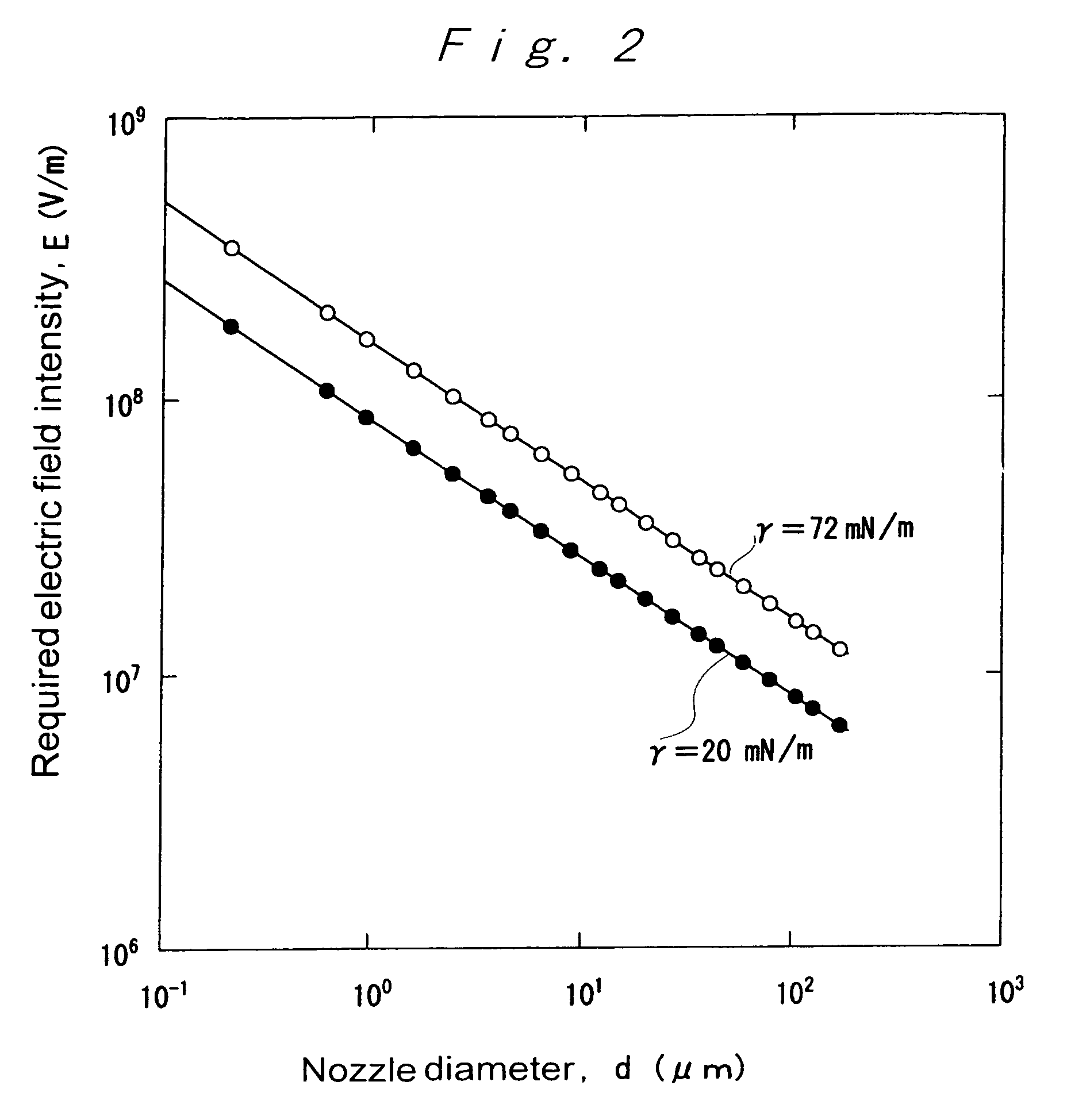

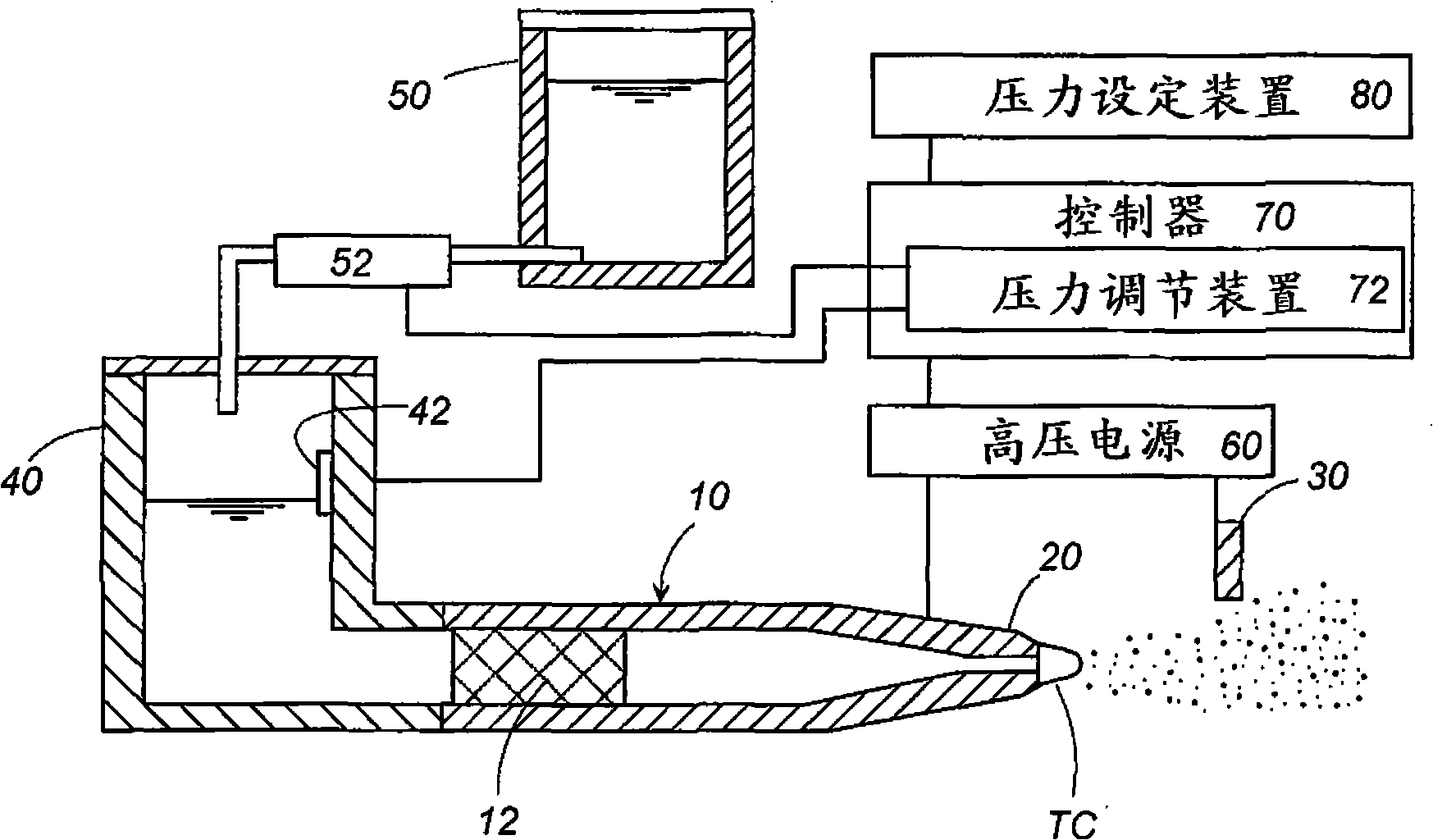

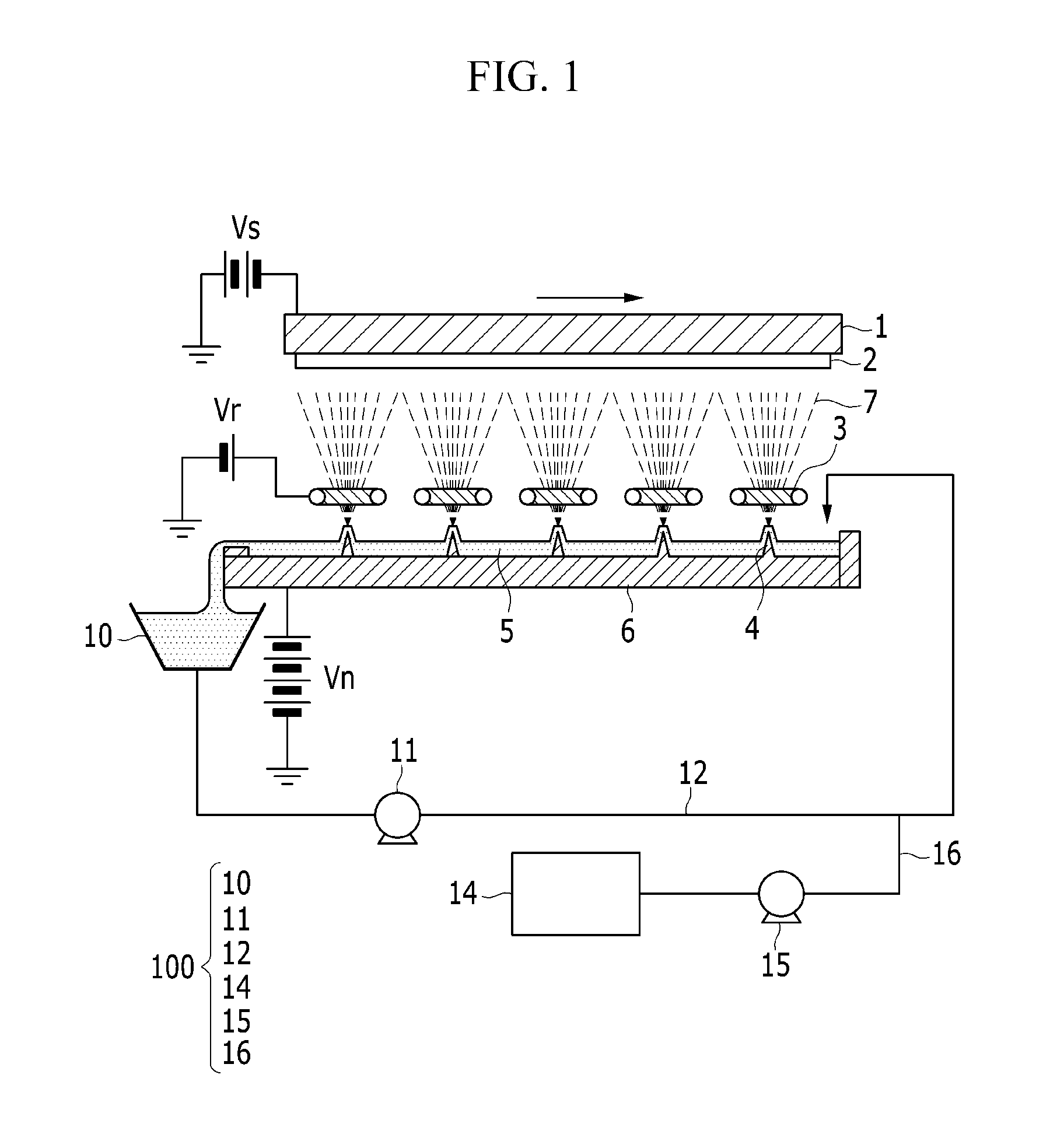

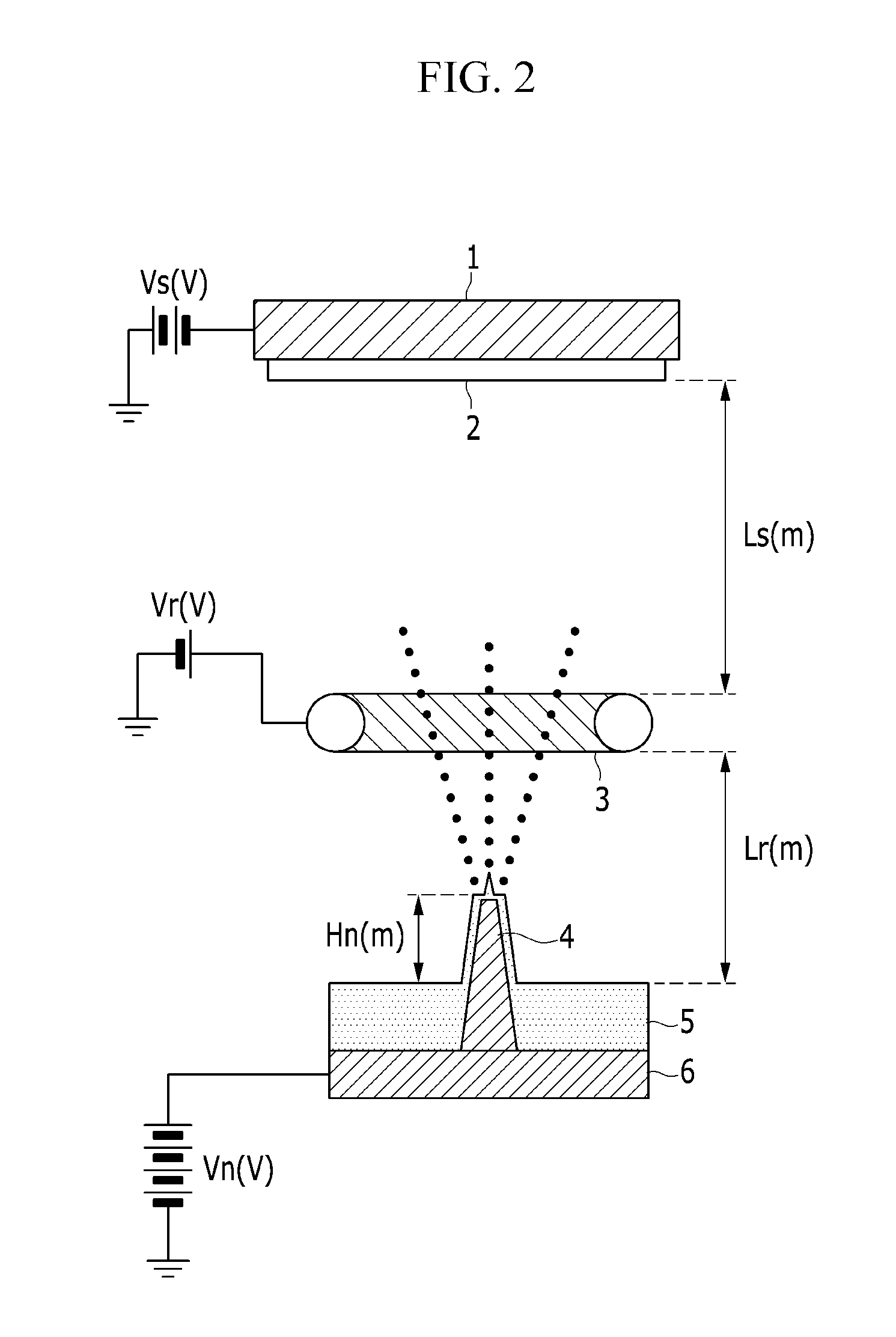

Ultrafine fluid jet apparatus

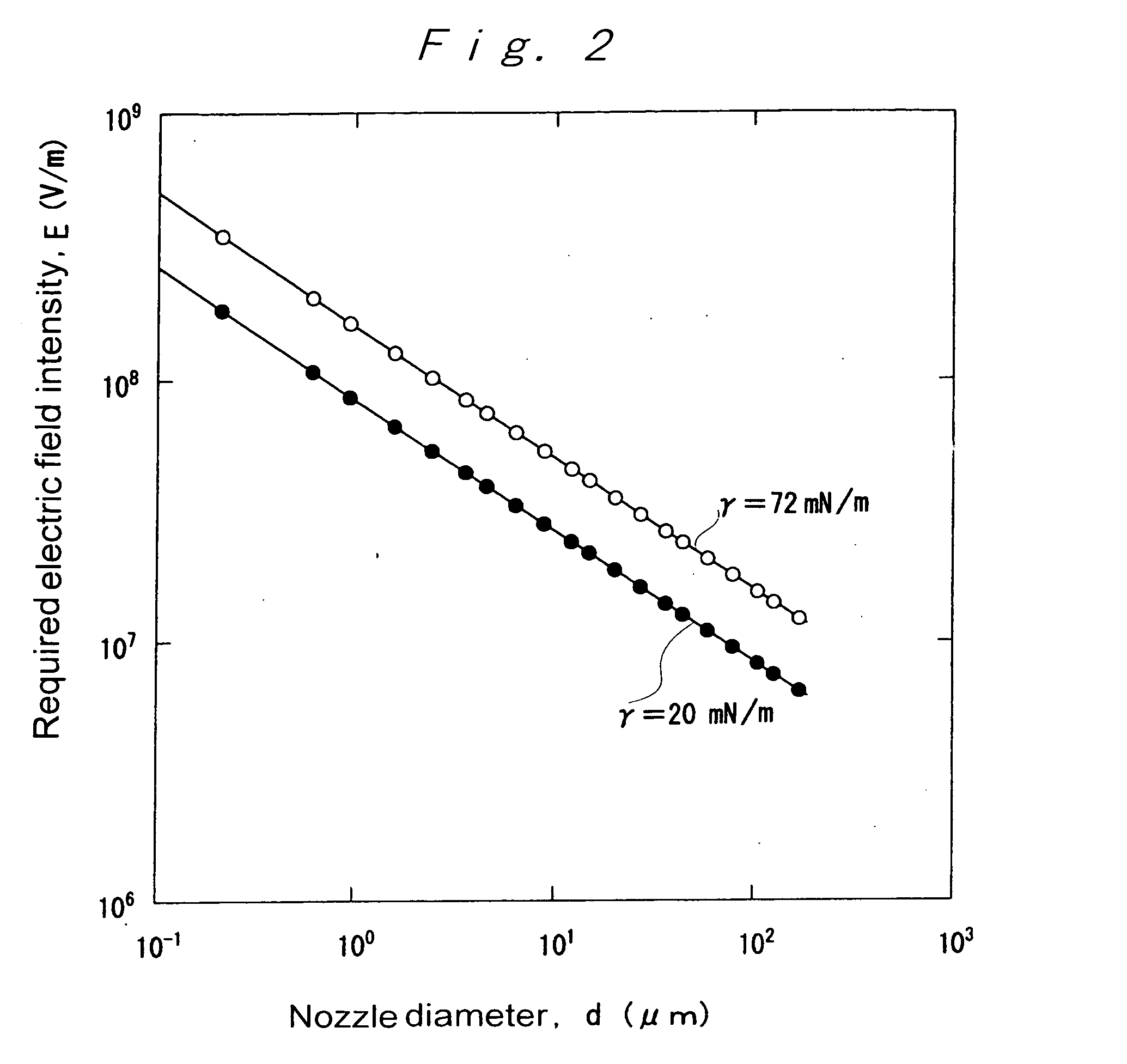

ActiveUS20050116069A1Improve the immunityReduce the overall diameterBurnersLiquid spraying plantsElectrical field strengthEvaporation

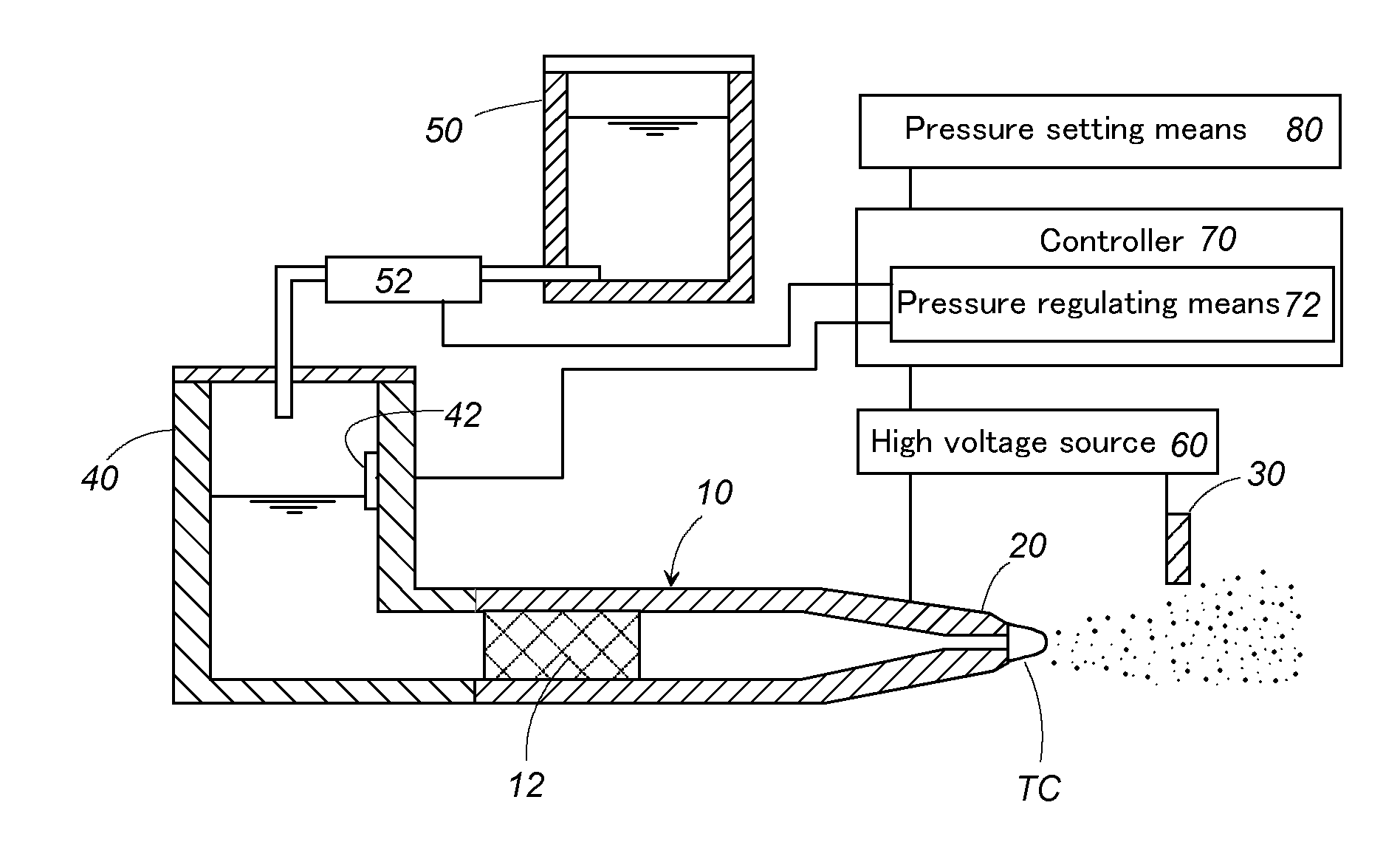

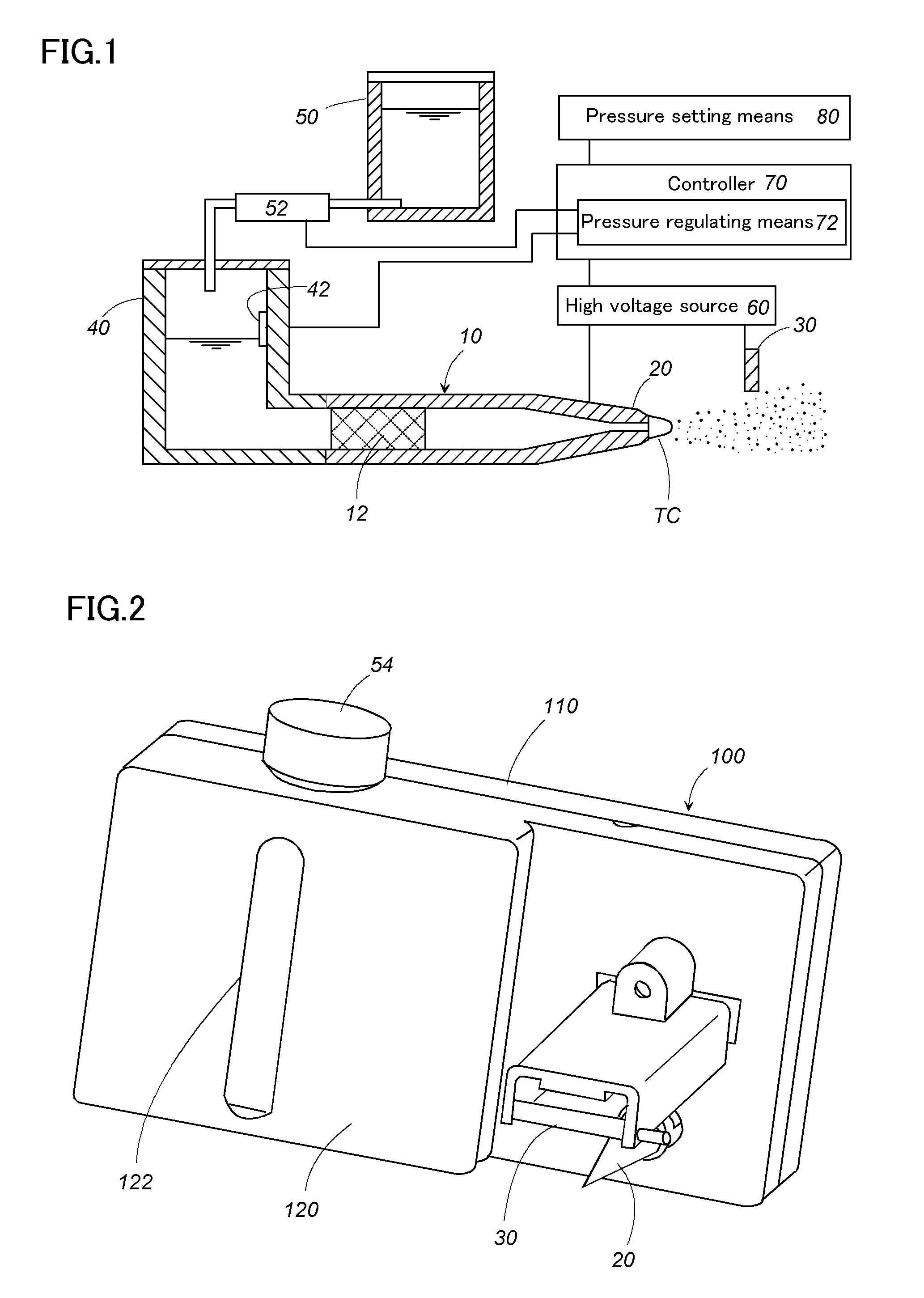

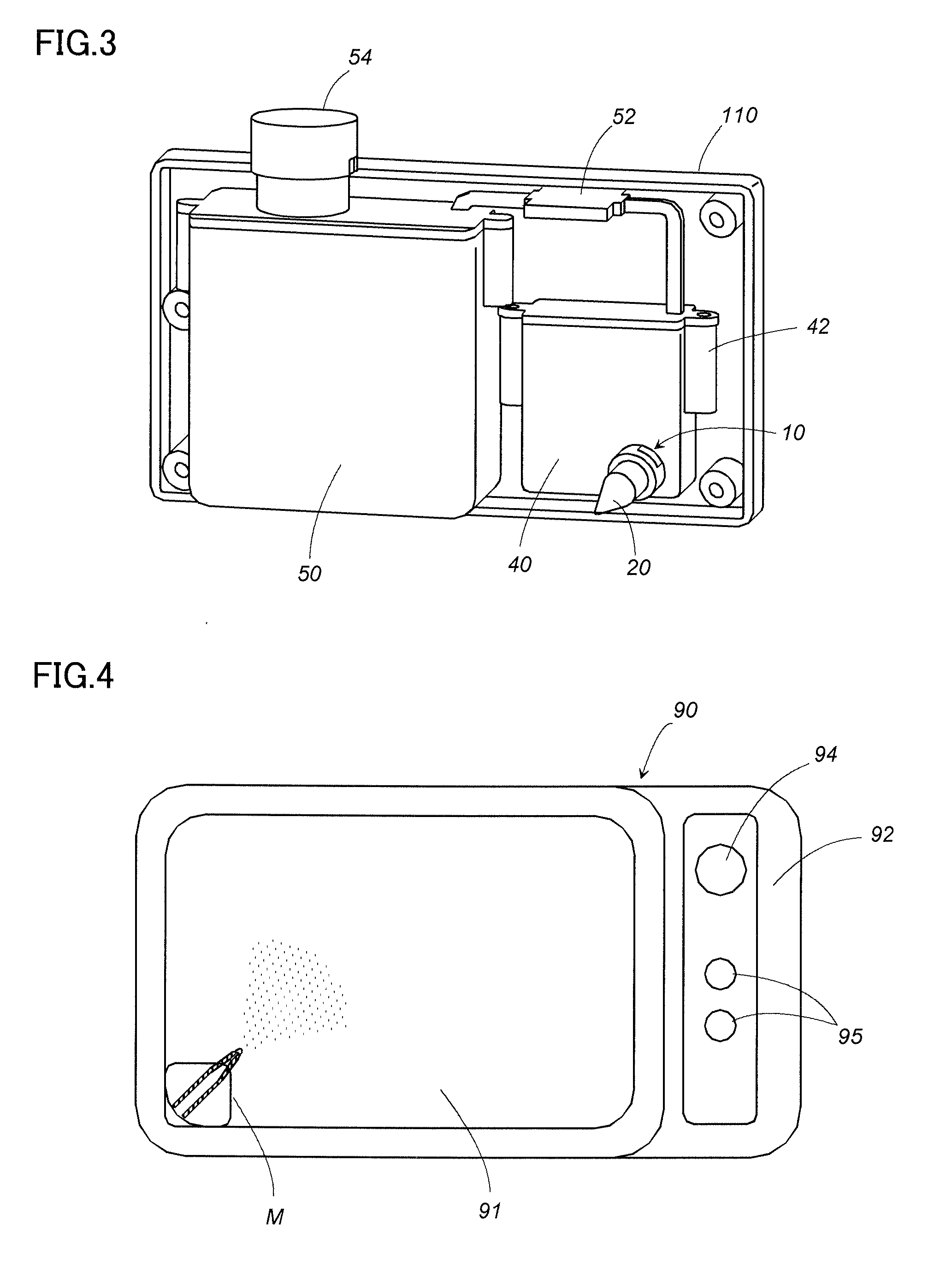

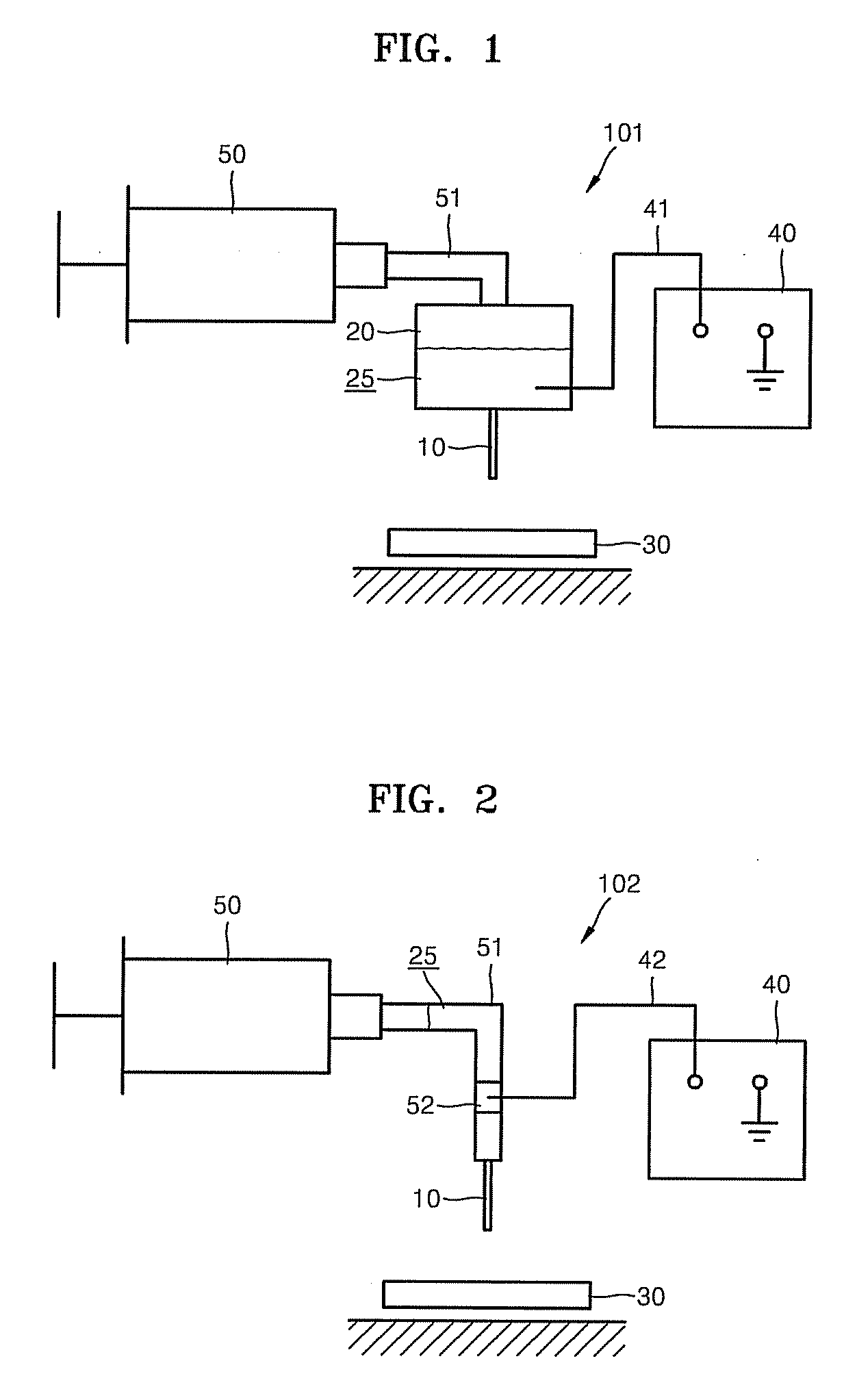

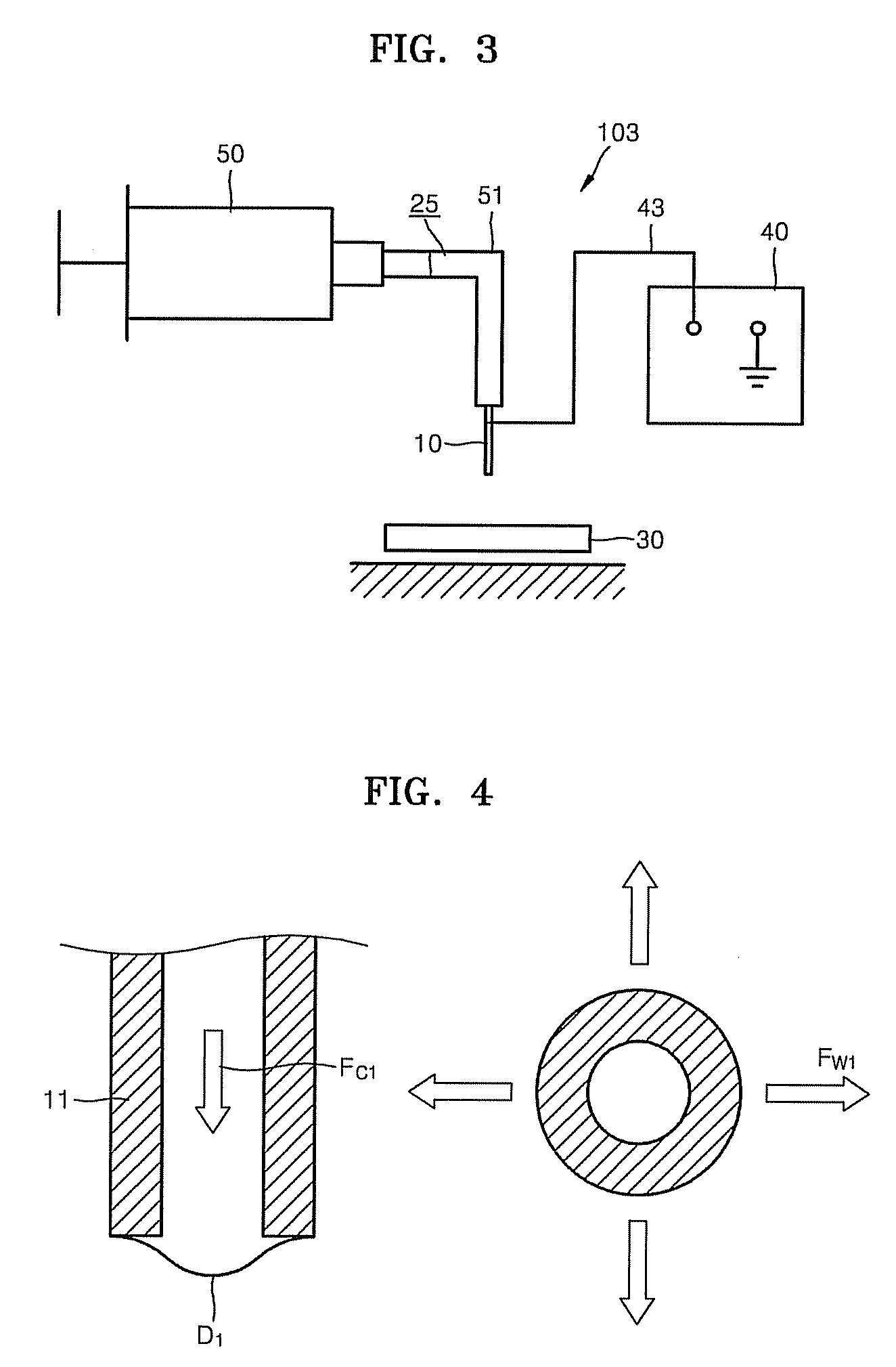

An ultrafine fluid jet apparatus comprising a substrate arranged near a distal end of an ultrafine-diameter nozzle to which a solution is supplied, and an optional-waveform voltage is applied to the solution in the nozzle to eject an ultrafine-diameter fluid droplet onto a surface of the substrate; wherein an electric field intensity near the distal end of the nozzle according to a diameter reduction of the nozzle is sufficiently larger than an electric field acting between the nozzle and the substrate; and wherein Maxwell stress and an electro-wetting effect being utilized, a conductance is decreased by a reduction in the nozzle diameter or the like, and controllability of an ejection rate by a voltage is improved; and wherein landing accuracy is exponentially improved by moderation of evaporation by a charged droplet and acceleration of the droplet by an electric field.

Owner:SIJTECH +1

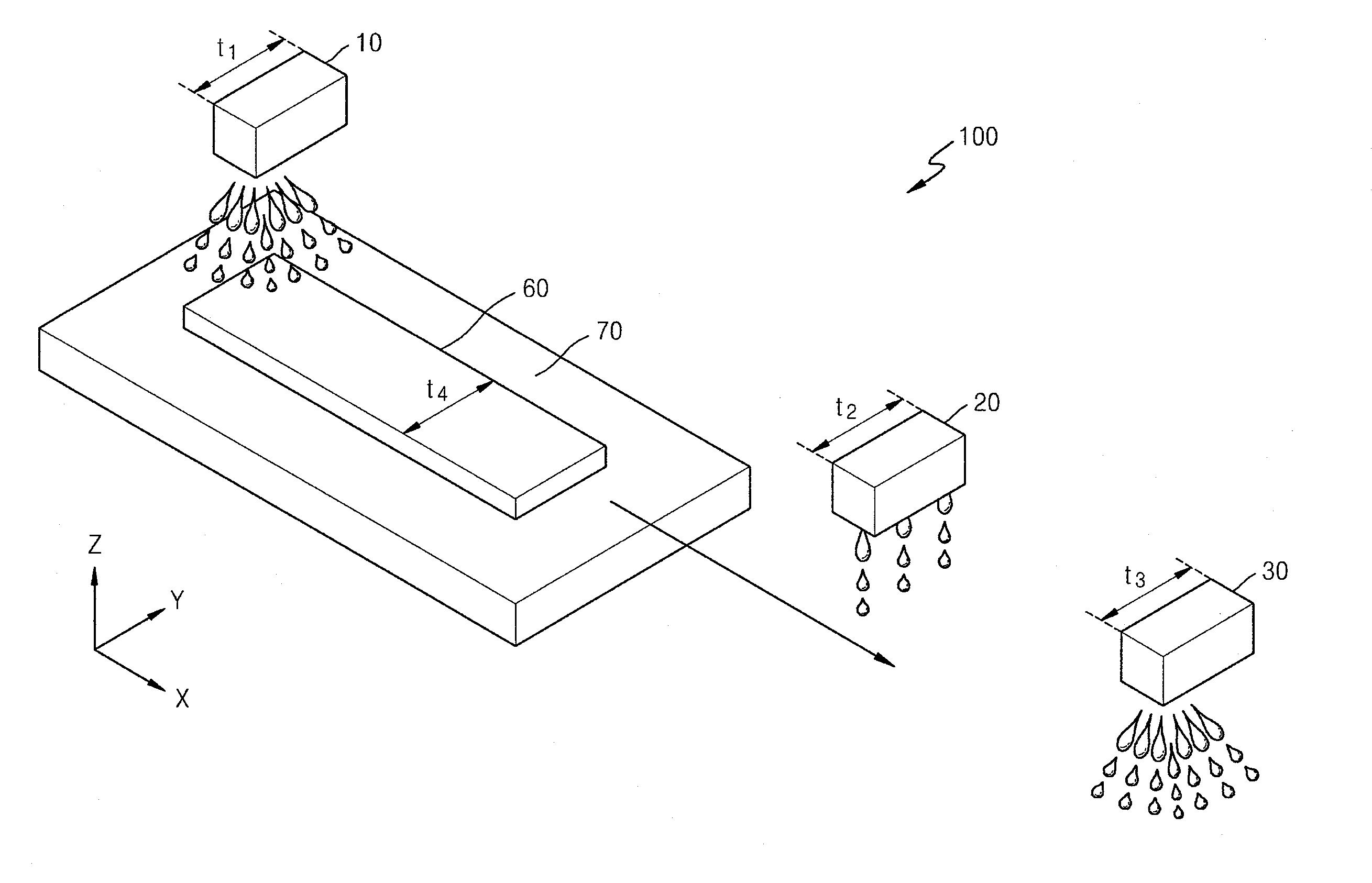

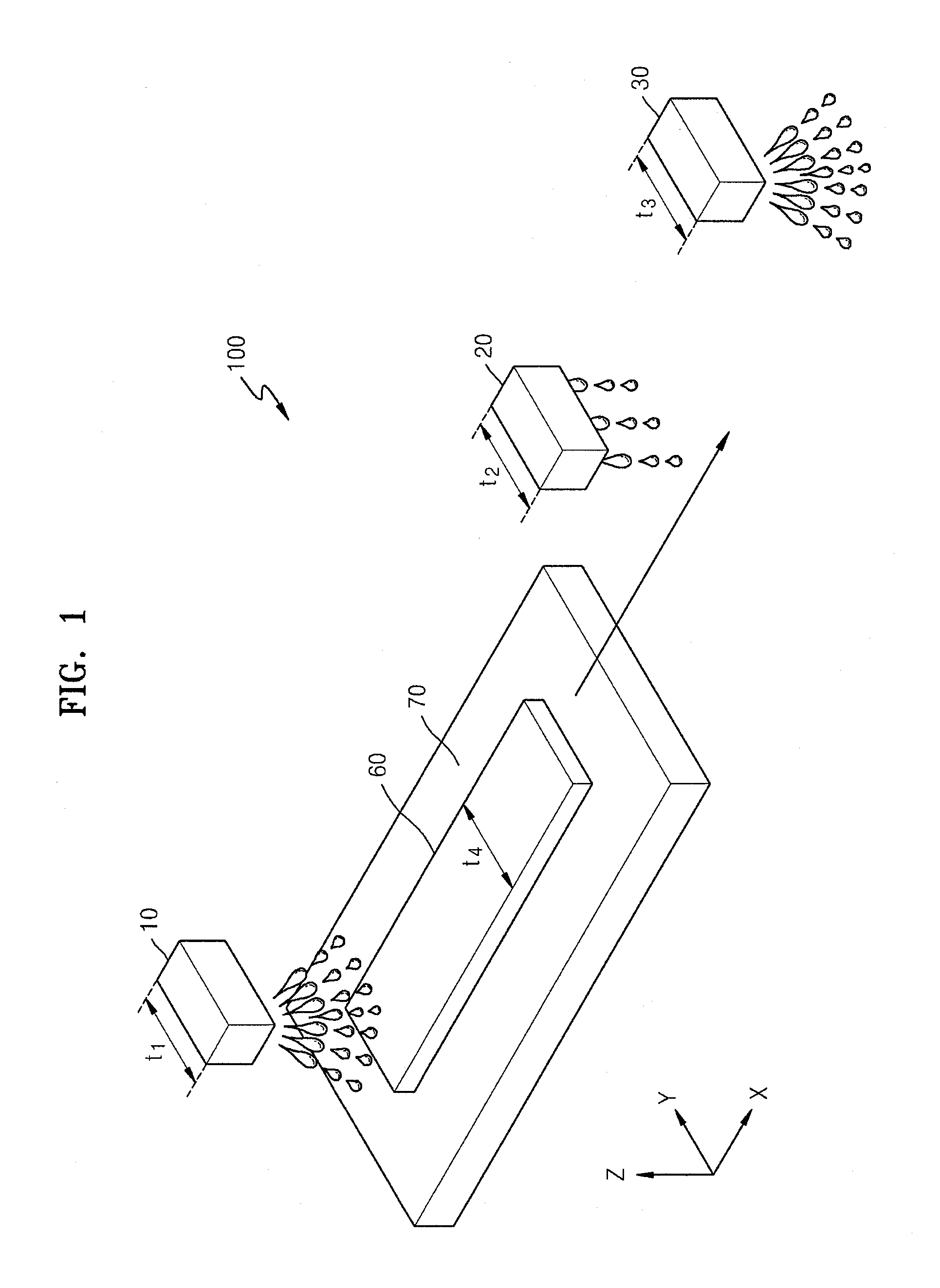

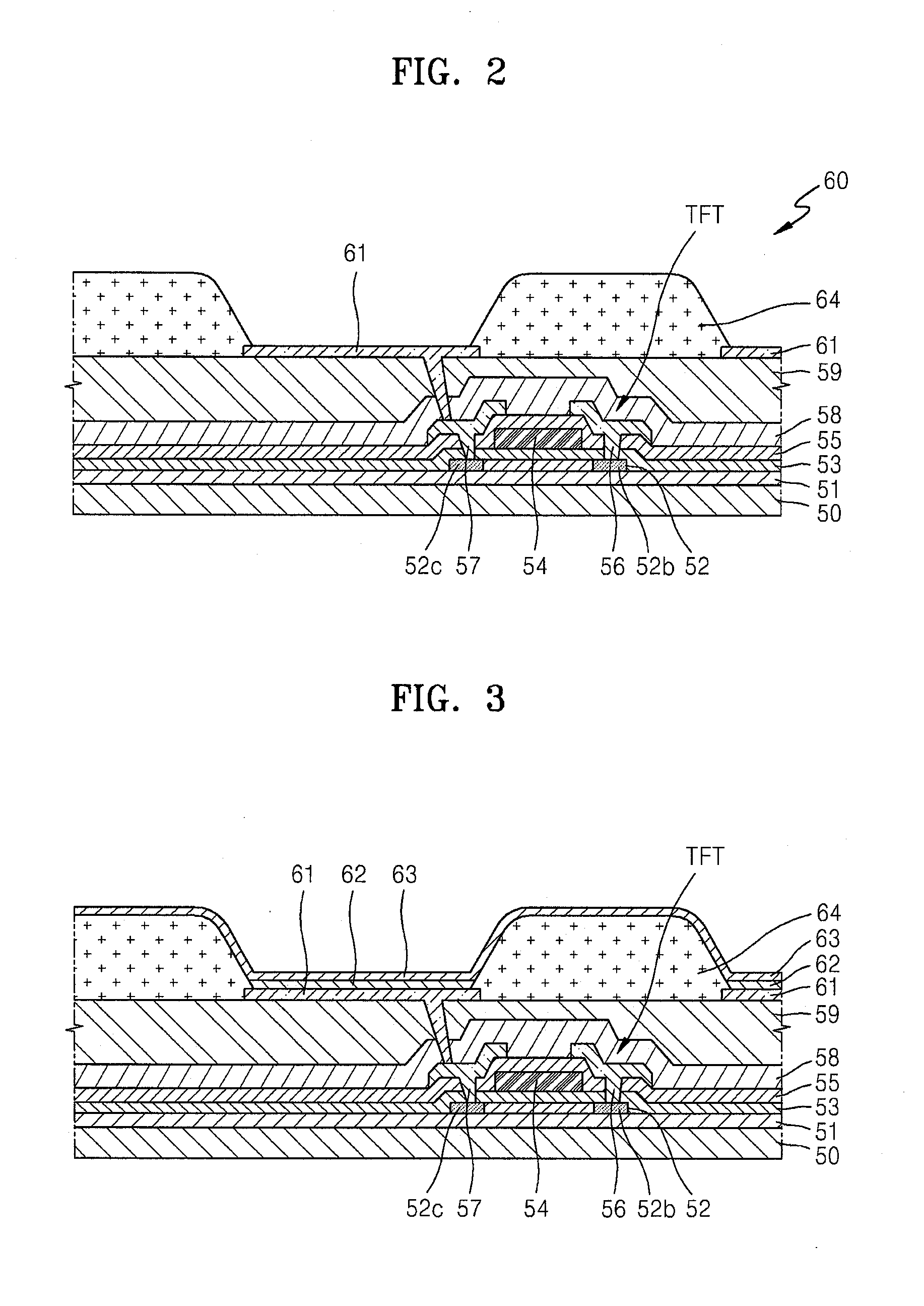

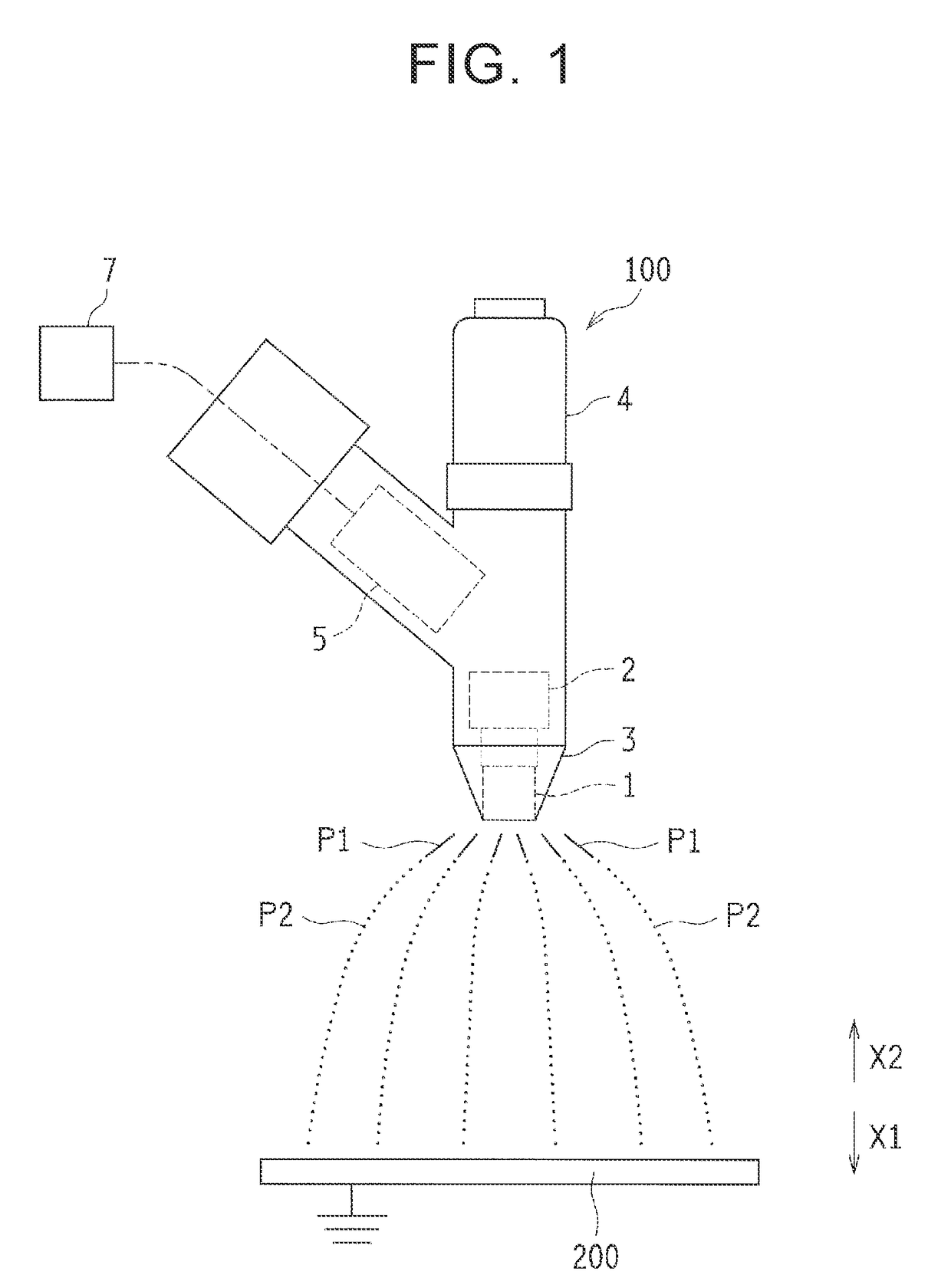

Apparatus for forming thin layer, method of manufacturing organic light-emitting display apparatus using the same and organic light-emitting display apparatus manufactured using the method

InactiveUS20120098416A1Improve manufacturing yieldLiquid surface applicatorsDischarge tube luminescnet screensThin layerEngineering

An apparatus for forming a thin layer on a large substrate, a method of manufacturing an organic light-emitting display apparatus by using the apparatus, and an organic light-emitting display apparatus manufactured using the method.

Owner:SAMSUNG DISPLAY CO LTD

Ultrafine fluid jet apparatus

ActiveUS7434912B2Improve the immunityReduce the overall diameterBurnersLiquid spraying plantsElectrical field strengthEngineering

An ultrafine fluid jet apparatus including a substrate arranged near a distal end of an ultrafine-diameter nozzle to which a solution is supplied, and an optional-waveform voltage is applied to the solution in the nozzle to eject an ultrafine-diameter fluid droplet onto a surface of the substrate; wherein an electric field intensity near the distal end of the nozzle according to a diameter reduction of the nozzle is sufficiently larger than an electric field acting between the nozzle and the substrate; and wherein Maxwell stress and an electro-wetting effect being utilized, a conductance is decreased by a reduction in the nozzle diameter or the like, and controllability of an ejection rate by a voltage is improved; and wherein landing accuracy is exponentially improved by moderation of evaporation by a charged droplet and acceleration of the droplet by an electric field.

Owner:SIJTECH +1

Electrostatic atomizer and food preserving cabinet with electrostatic atomizer

InactiveCN101346187AGuaranteed freshLiquid supply arrangementsFruit and vegetables preservationEngineeringMicroparticle

High voltage is applied to liquid supplied to a discharge electrode at the tip end of a liquid carrying body to charge the liquid, whereby nano-order charged microparticle mist is emitted from the discharge electrode. A pressurizing force applied to liquid supplied to the discharge electrode can emit micron-order charged micropaticle mist at the same time. Radicals contained in the nano-order charged microparticle mist sterilize, deodorize and decompose offensive or harmful matters in a space, and micron-order charged micropaticle mist emitted at the same time can efficiently humidify a space.

Owner:PANASONIC CORP

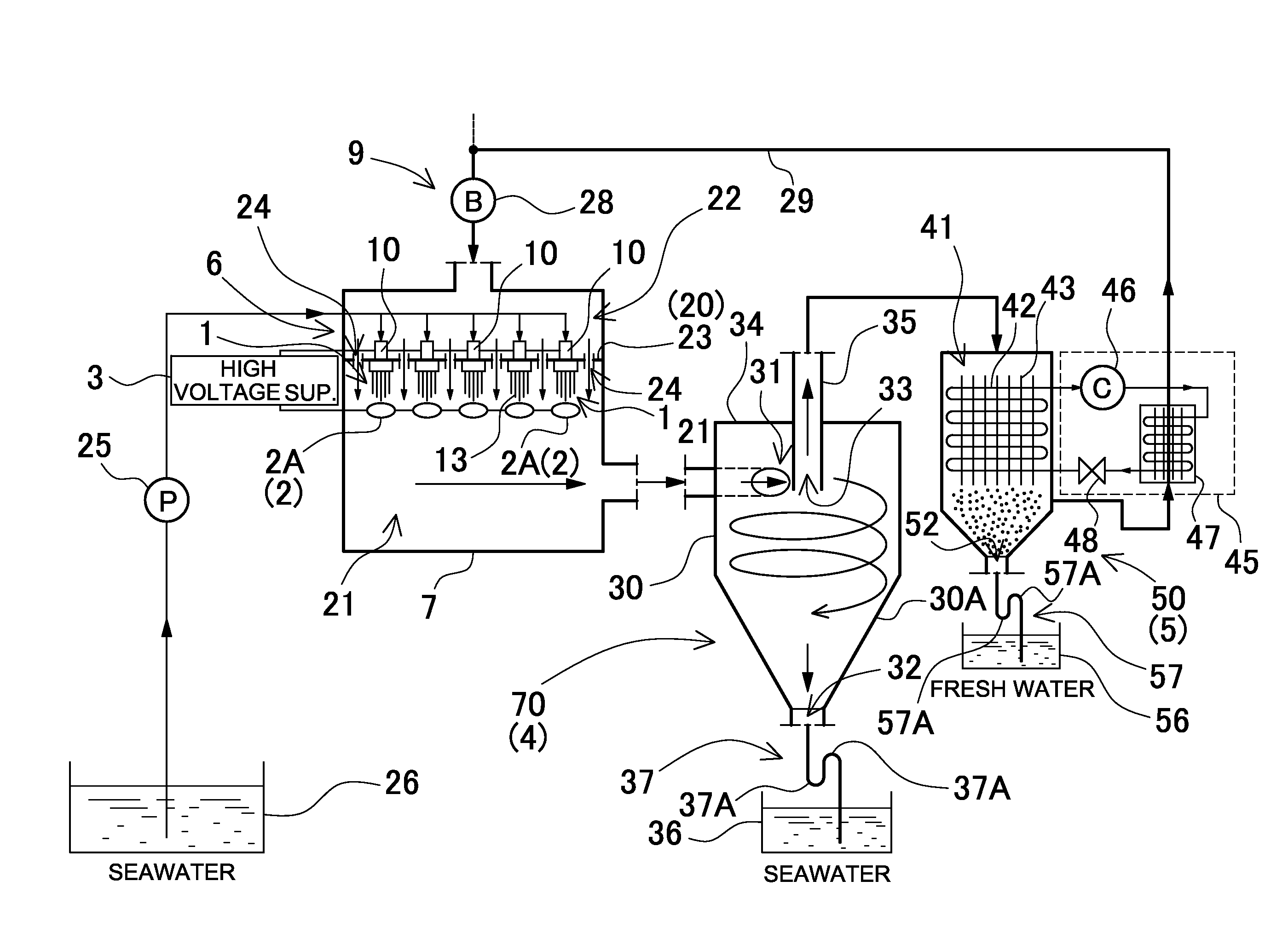

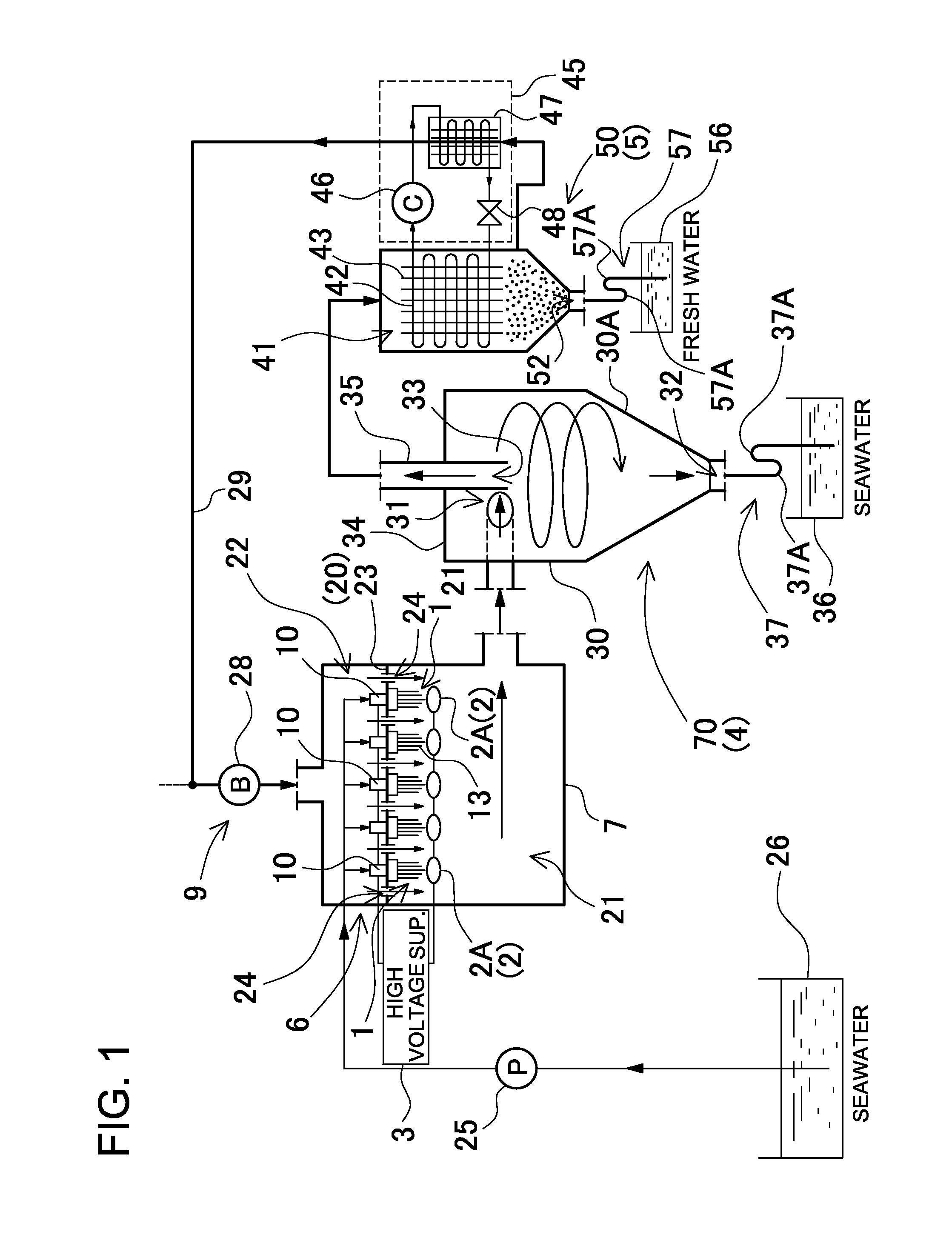

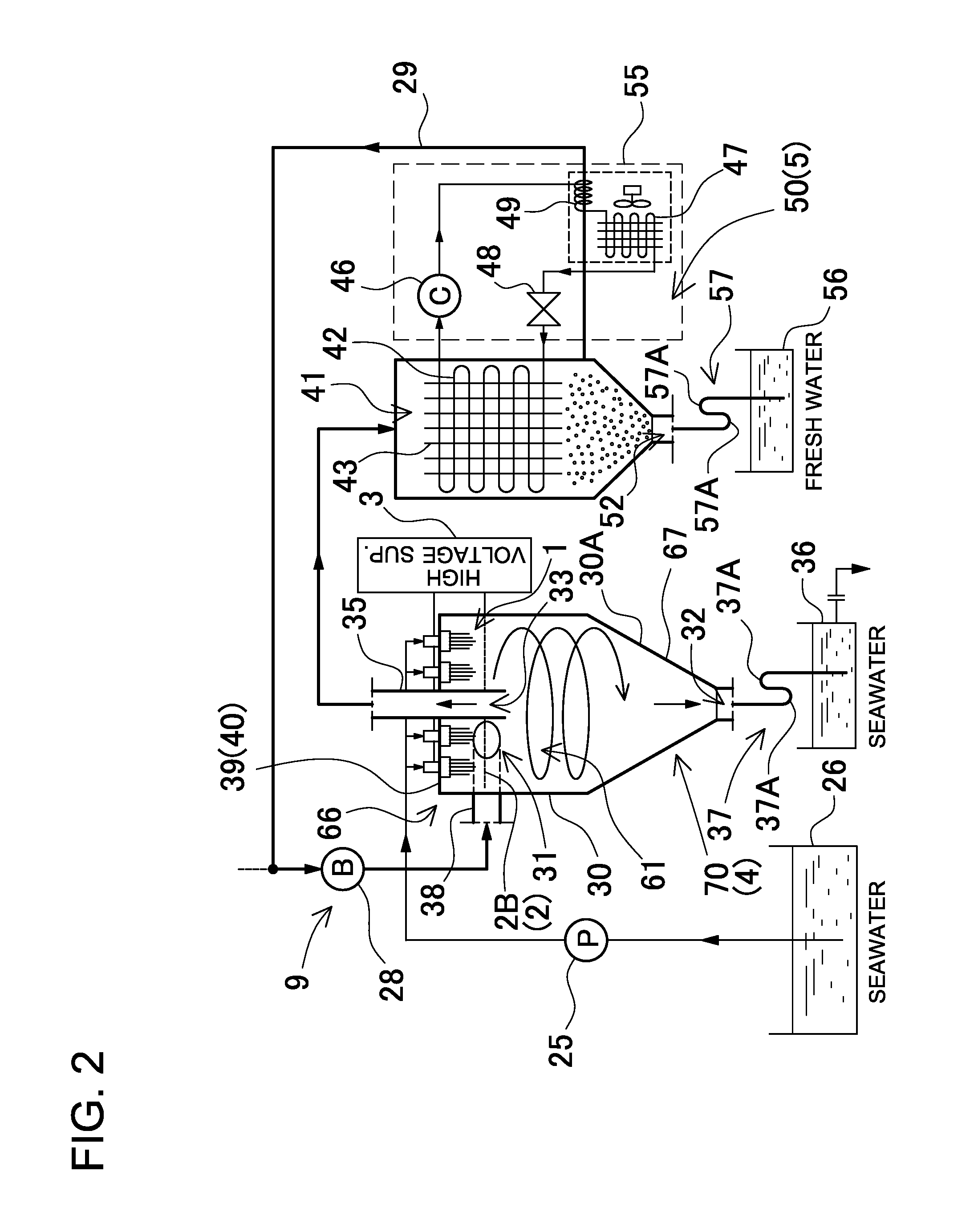

Seawater desalination apparatus

InactiveUS20140048467A1Reduce power consumptionEfficiently atomizedGeneral water supply conservationSeawater treatmentFresh waterSeawater

A seawater desalination apparatus includes a spray (1), a gas supplier (9), an atomizing electrode (2), a high voltage power supply (3), a mist classifier (4), and a mist collector (5). The spray includes apertures for producing a seawater mist. The supplier supplies gas for carrying the mist from the spray. The electrode electrostatically produces fine droplets from the mist from the spray. The power supply is connected to the electrode and the spray, and applies high voltage between the electrode and the spray for the production of fine droplets from the mist from the atomizer. The classifier separates the fine droplets in the mist from the electrode. The collector collects the mist discharged from the classifier thereby producing fresh water.

Owner:NANO MIST TECH

Thin film fabricating apparatus and manufacturing method of organic light emitting device using the same

ActiveUS20160096185A1Liquid spraying plantsLiquid surface applicatorsOrganic light emitting deviceOptoelectronics

Owner:SAMSUNG ELECTRONICS CO LTD

Electrostatically atomizing device and food container provided with the same

InactiveUS20090127357A1Keep freshStable particle size distributionBurnersFruit and vegetables preservationHazardous substanceEngineering

The liquid is supplied to an emitter electrode which is provided at a tip of a liquid carrier, receives a high voltage, is electrical-charged, and discharged as a mist of charged minute water particles of nanometer order from the emitter electrode. The emitter electrode discharges the mist of the charged minute water particles of micron order at the same time by a pressure which is applied to the liquid which is supplied to the tip of the emitter electrode. An electrostatically atomizing device supplies liquid to an emitter electrode of a tip of a liquid carrier, applies the high voltage to the liquid, electrically-charges the liquid, and causes the emitter electrode to discharge a mist of charged minute water particles of nanometer order. In addition, the electrostatically atomizing device applies a pressure to the emitter electrode and causes the emitter electrode to discharge a mist of the charged minute water particles of micron order. The electrostatically atomizing device is able to humidify a space by the mist of the charged minute water particles of micron order as well as is able to decompose harmful substances in the space, is able to sterilize and deodorize the substances in the space by radicals which is included by the mist of the charged minute water particles of nanometer order.

Owner:PANASONIC CORP

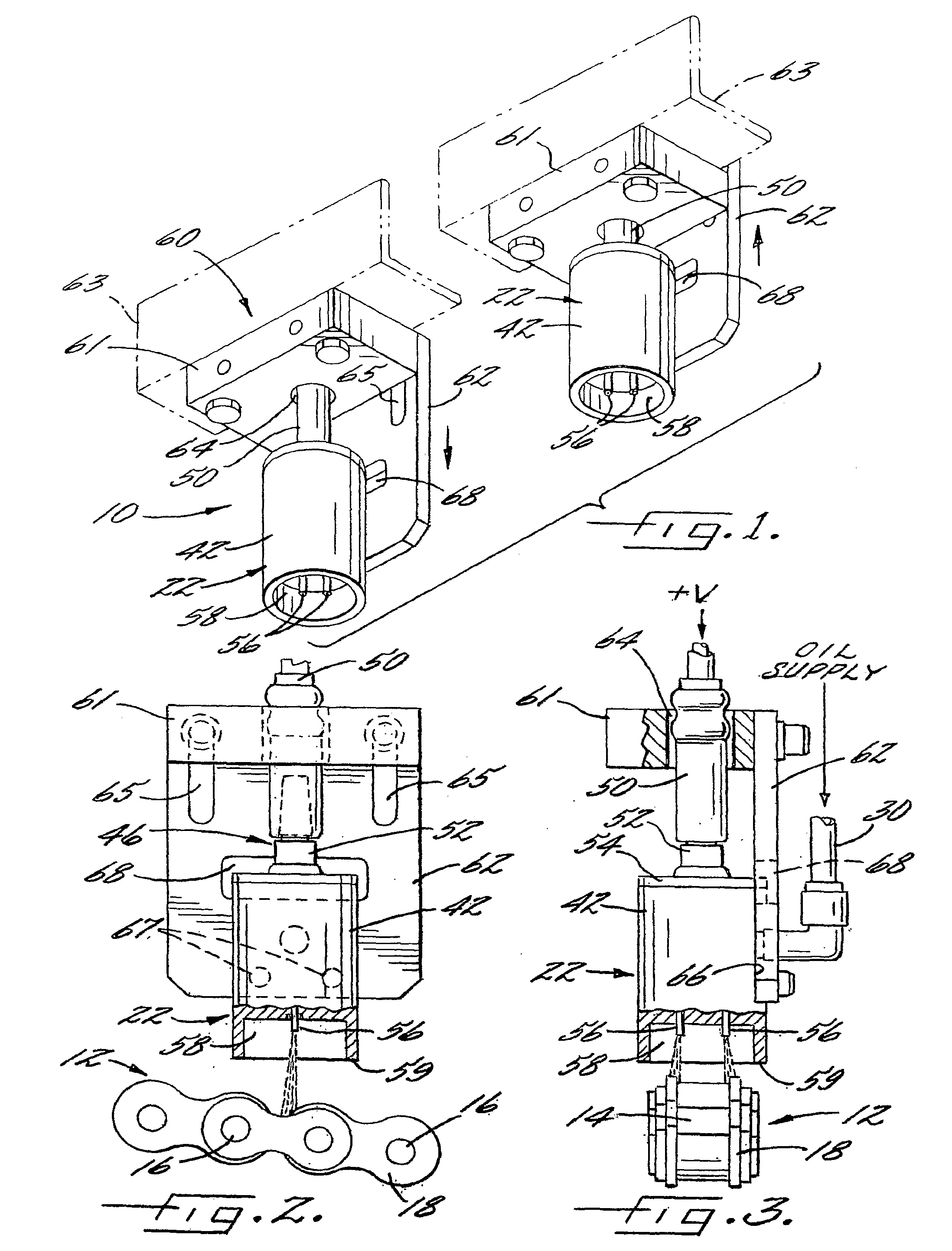

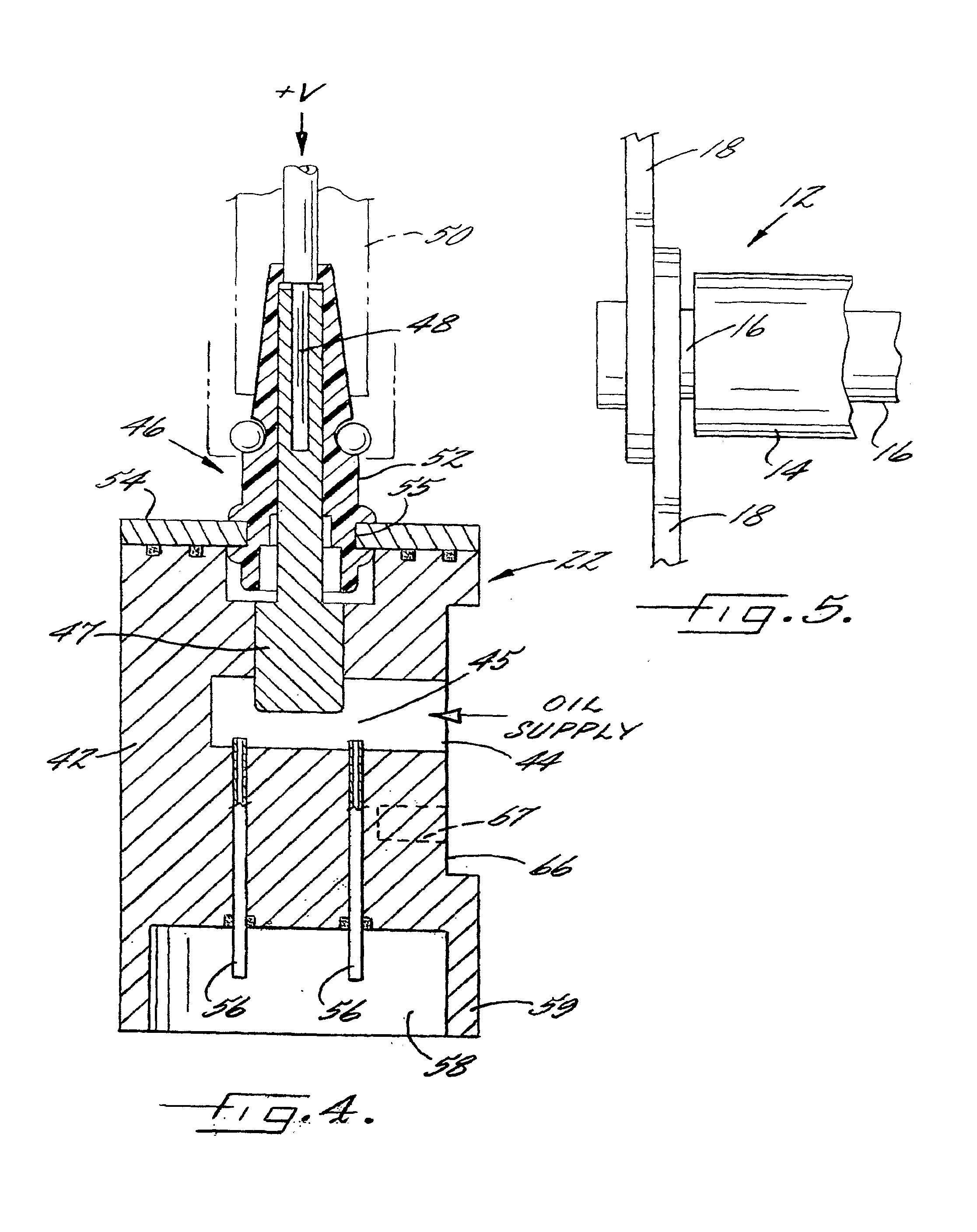

Electrostatic lubricant dispensing system

A lubricant dispensing system is provided. The dispensing system includes a lubricant supply, a lubricant dispensing nozzle and a control panel. The dispensing nozzle includes a nozzle body with a fluid passageway therein which is in fluid communication with the lubricant supply, an electrode assembly for electrostatically charging lubricant in the fluid passageway and at least one discharge orifice through which electrostatically charged lubricant can be discharged. The discharge orifice is defined by at least one spray needle having a first end in fluid communication with the fluid passageway and a second end that extends outward of the nozzle body. The control panel directs the flow of lubricant from the lubricant supply to the lubricant dispensing nozzle and controls the electric power supplied to the electrode assembly.

Owner:SPRAYING SYST

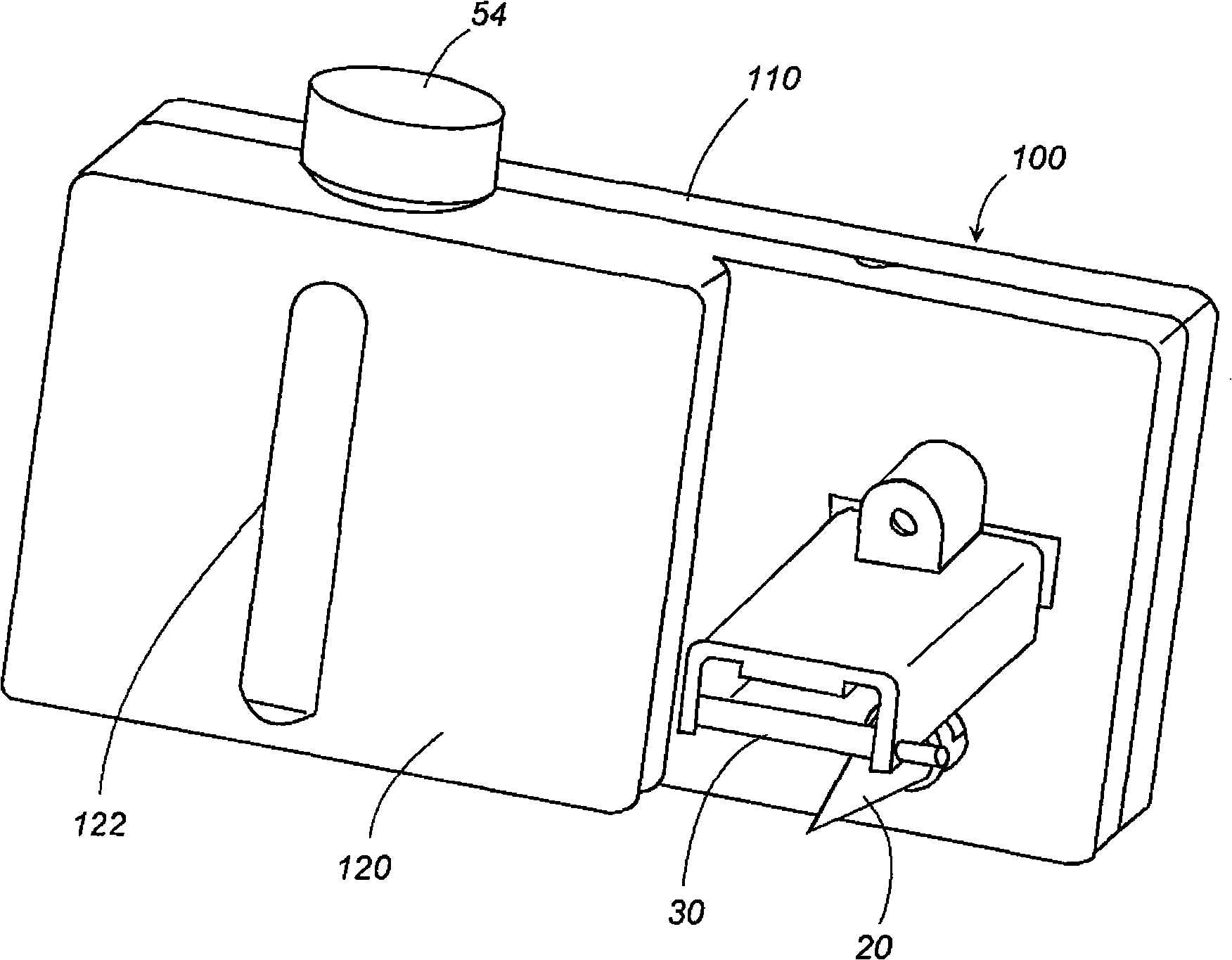

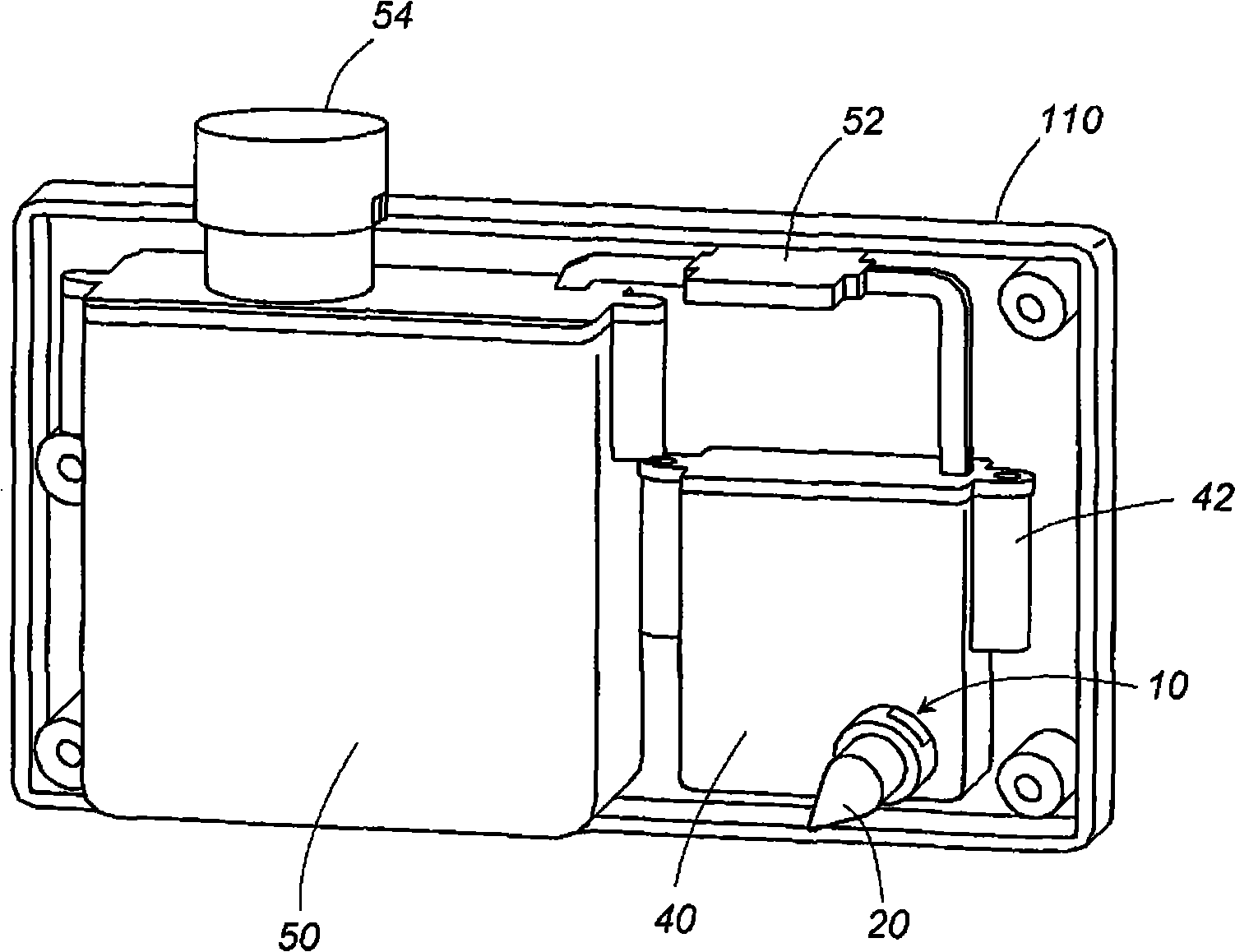

Coat-forming device

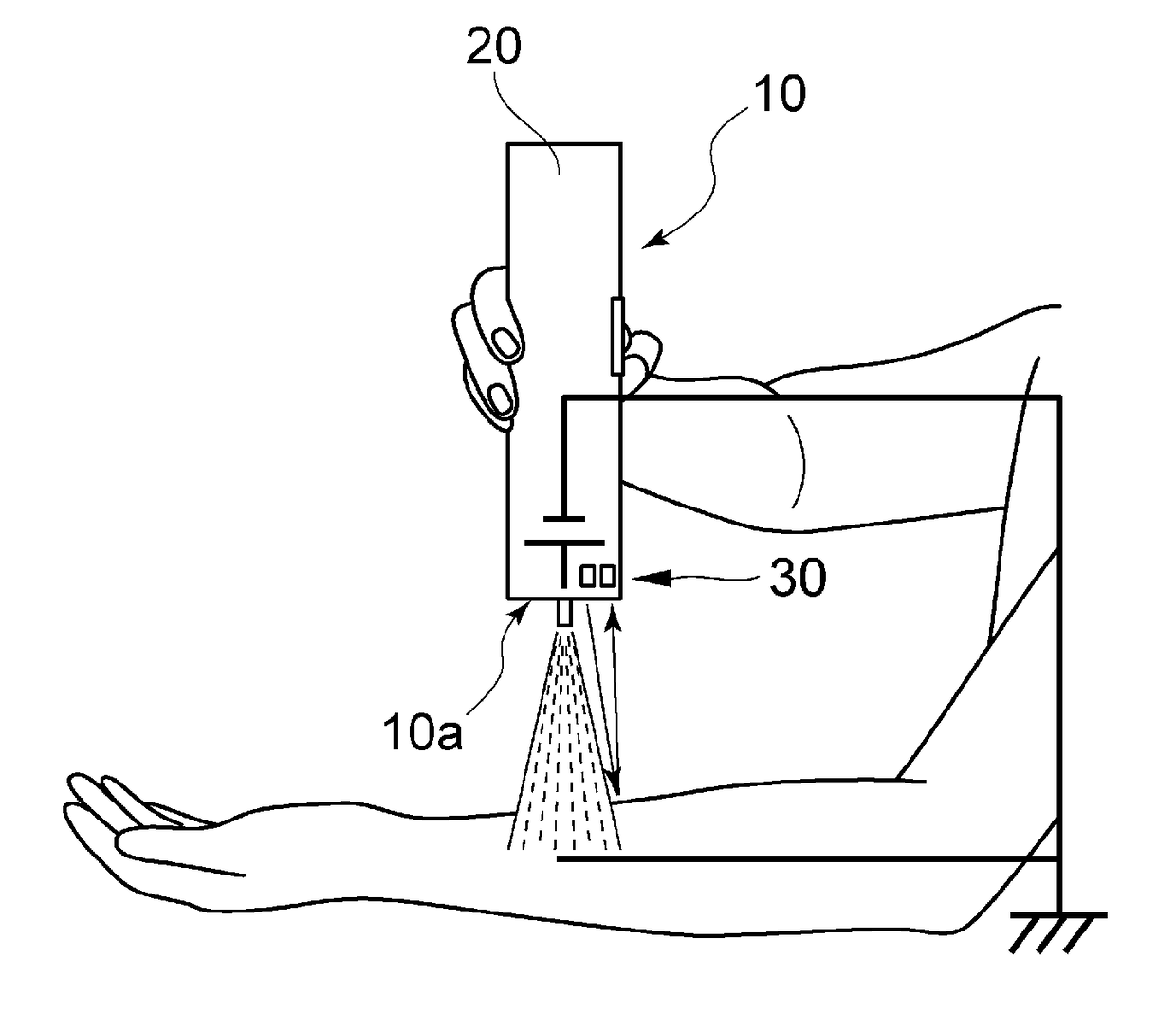

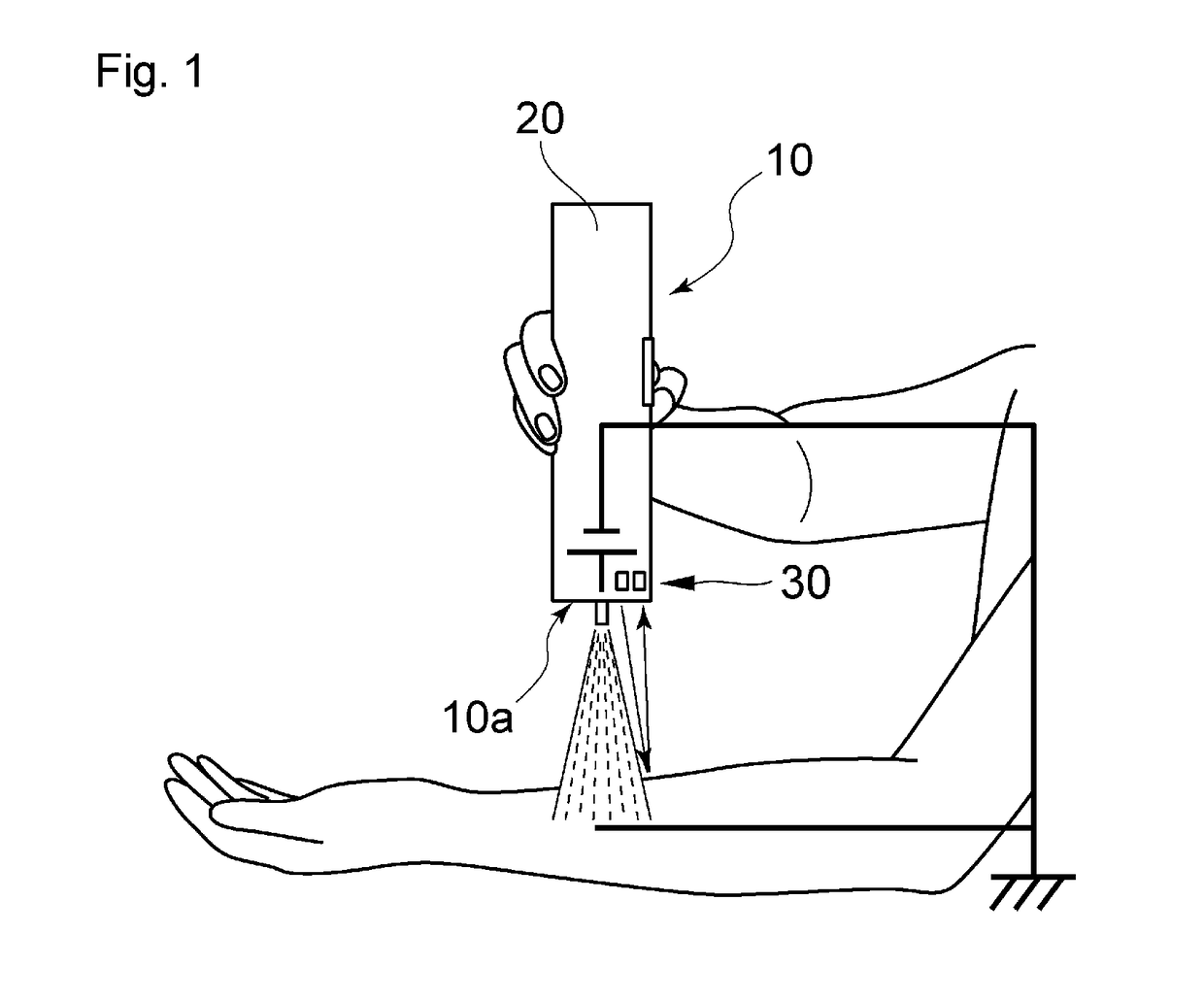

ActiveUS20180317627A1Easy to storeHigh speedCosmetic preparationsToilet preparationsHand heldDecision unit

A film forming device 10 including a distance measurement unit 30 for measuring the distance between the skin S and the device 10, a distance decision unit 31 for deciding whether the distance measured by the distance measurement unit 30 is proper for electrostatic spraying, and a distance notification unit 32 for notifying a user of the decision by the distance decision unit 31. The film forming device 10 is of hand-held type small enough and configured to be held by the user's hand. The device 10 preferably includes an angle measurement unit 42 for measuring the angle between the electrostatic spray direction and the skin S.

Owner:KAO CORP

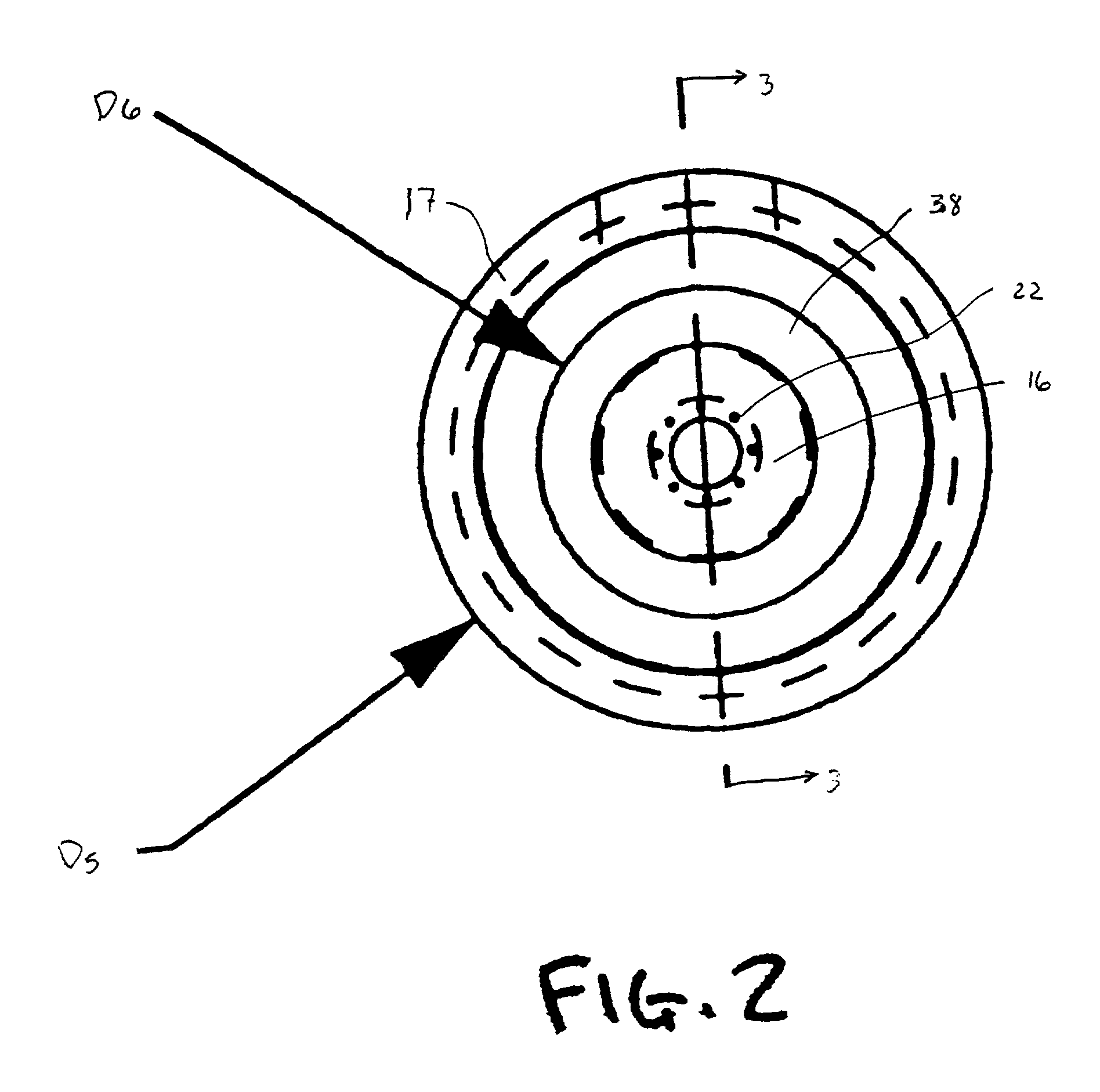

Method and apparatus for high throughput charge injection

InactiveUS6964385B2Improve operationGreat tendencySpraying power supplySpray nozzlesCharge injectionBiomedical engineering

An apparatus for dispersing fluent material comprises a body defining a plurality of orifices arranged around a central axis and a charge injection device arranged on the central axis.

Owner:CHARGED INJECTION TECH

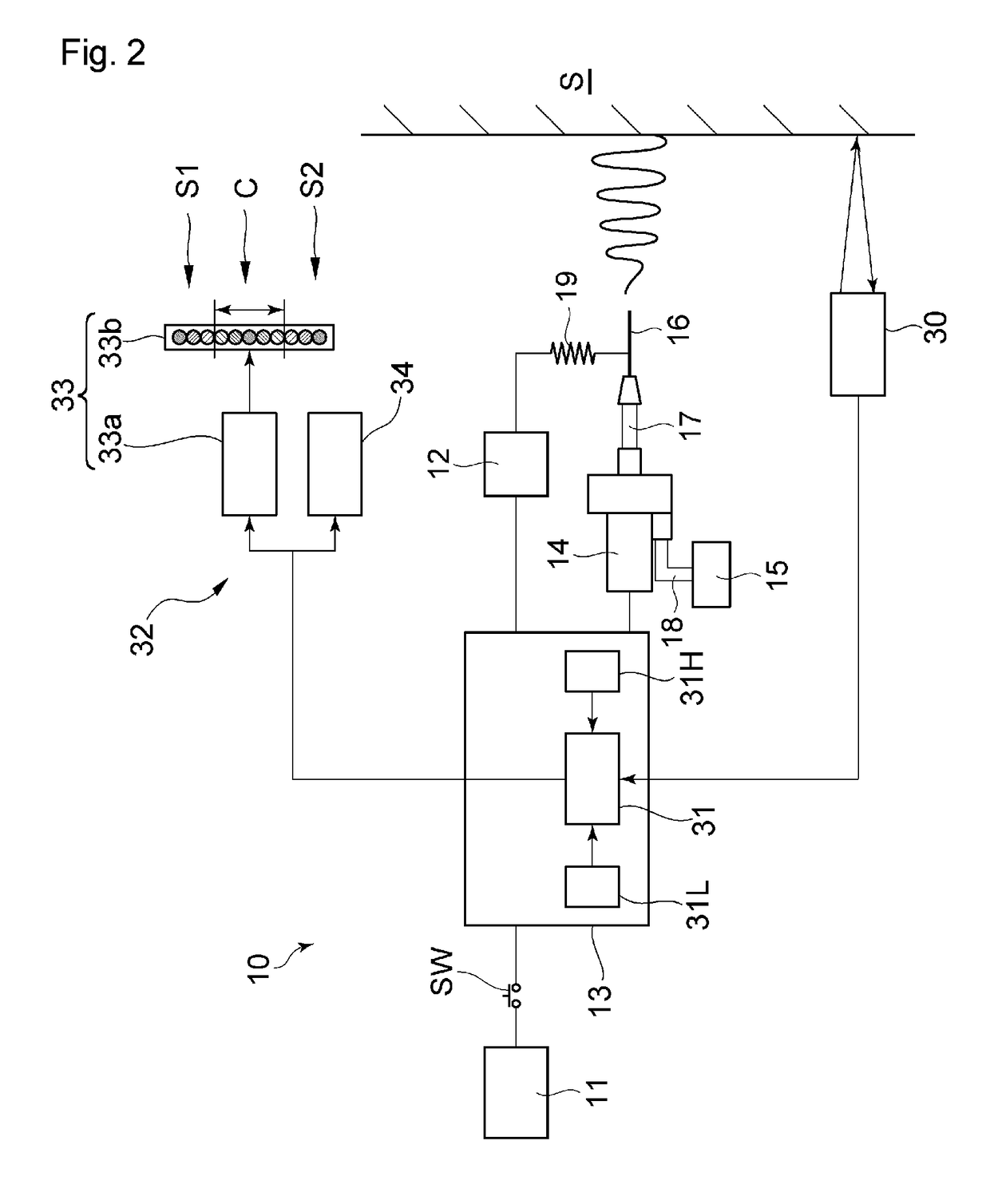

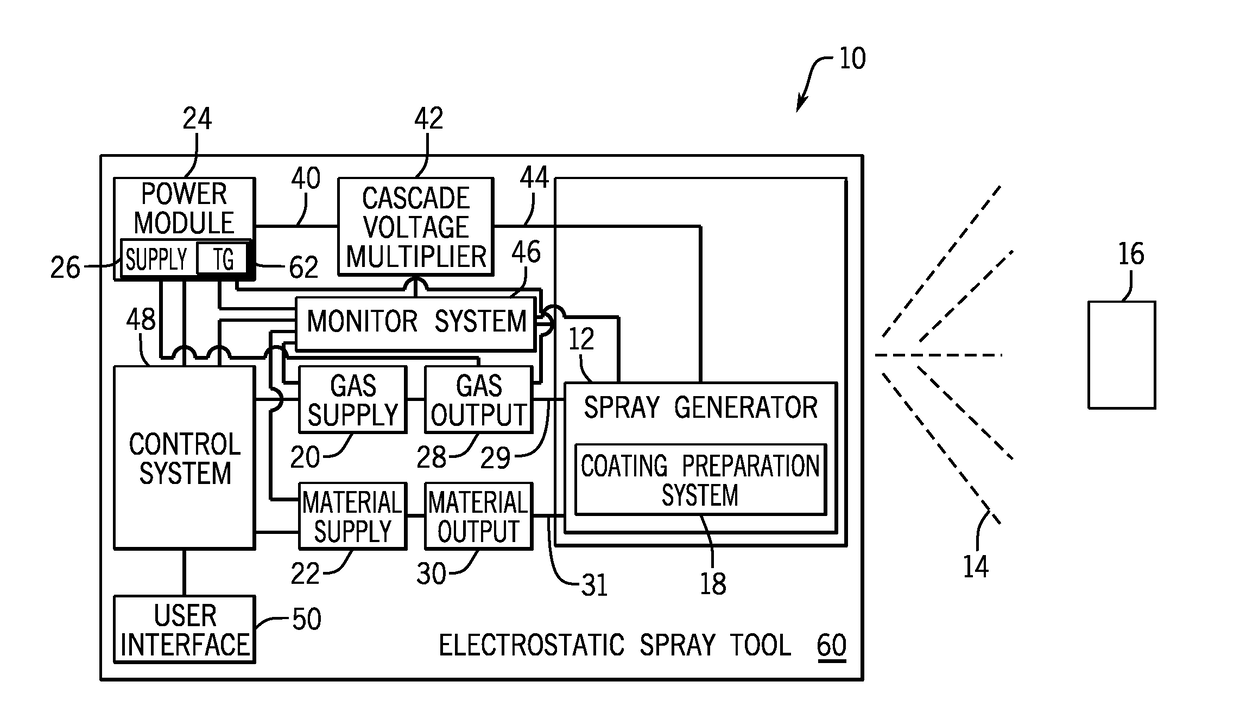

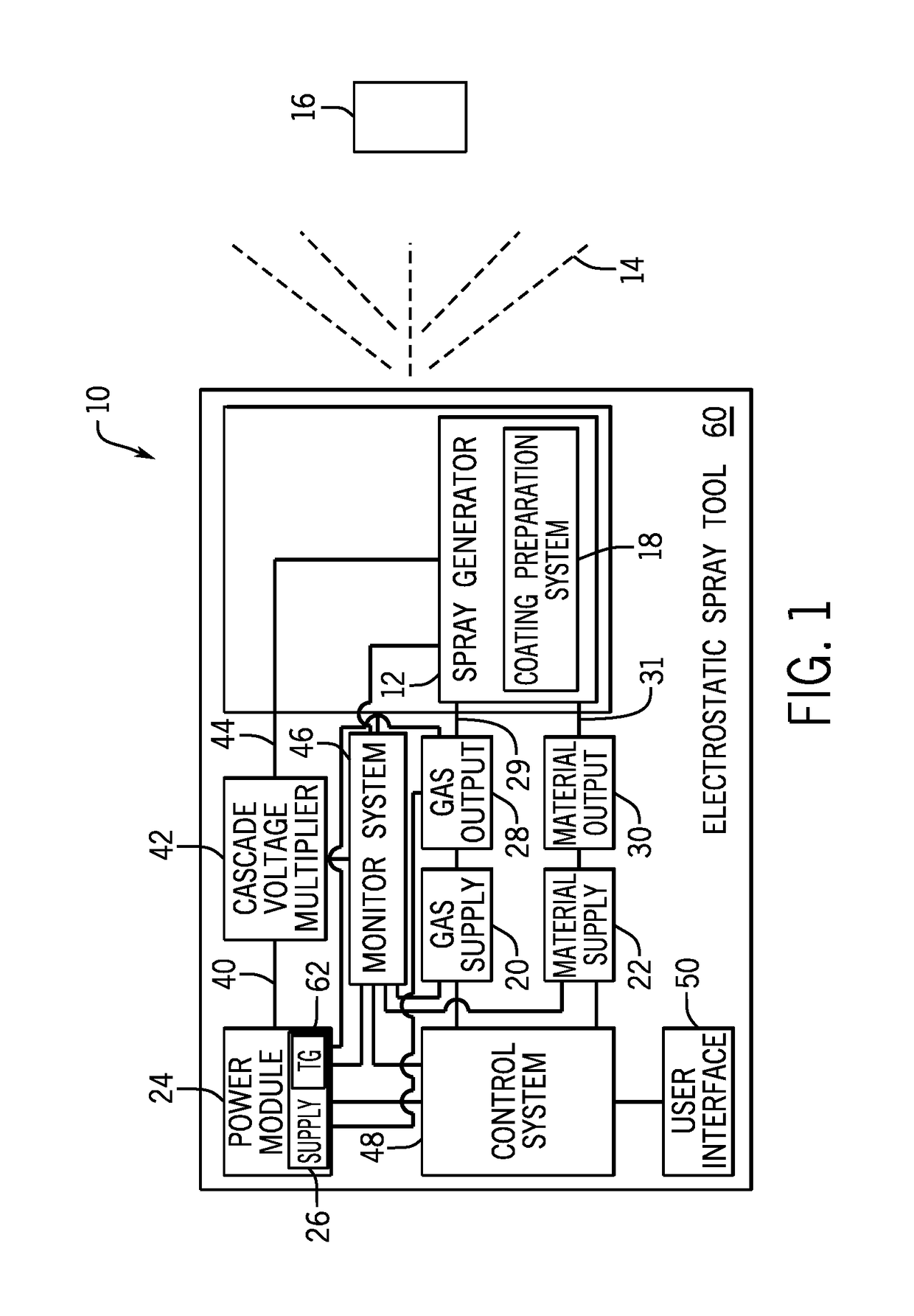

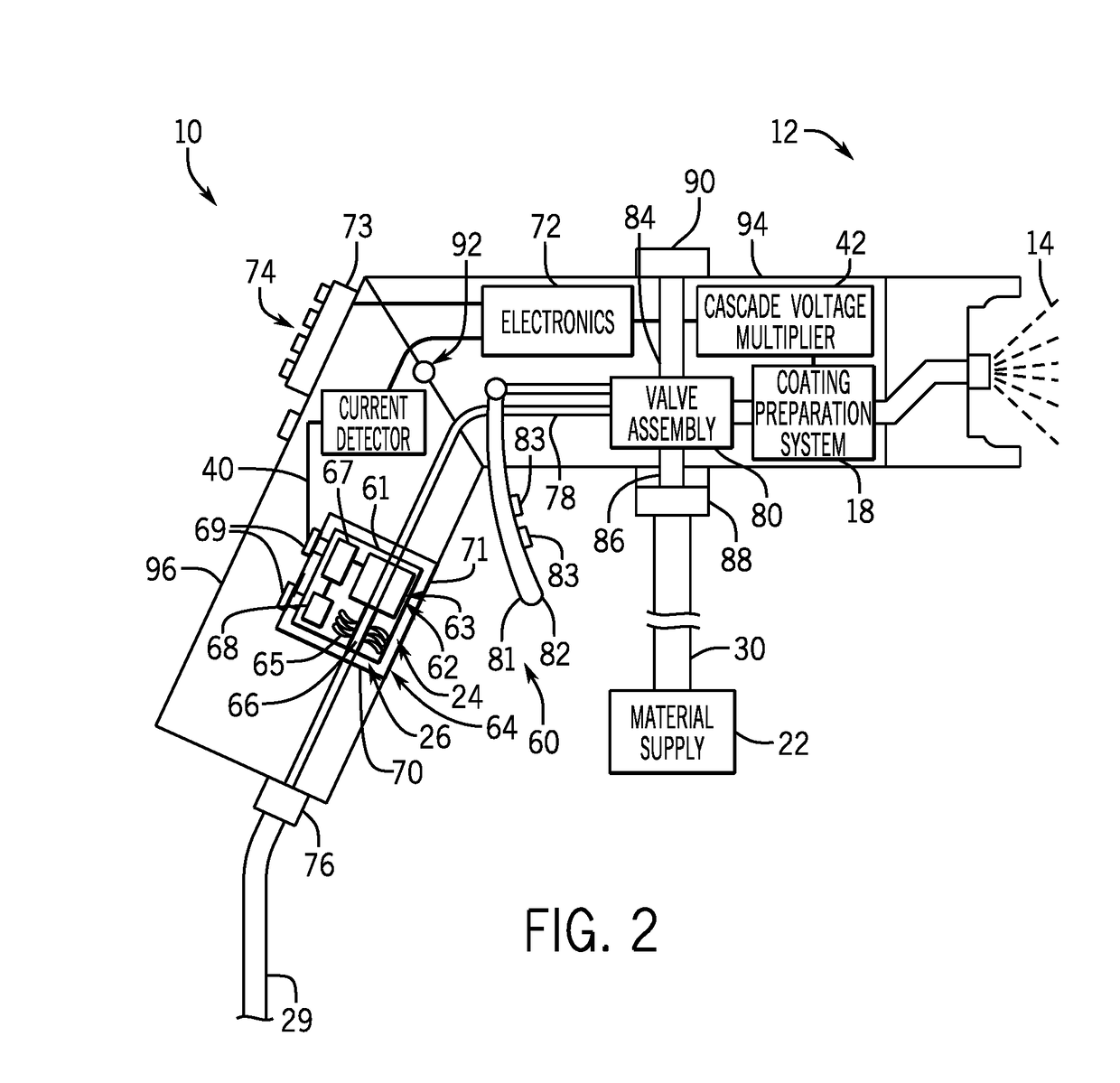

Spray tool power supply system and method

ActiveUS20170151577A1Selective operationLiquid supply arrangementsBatteries circuit arrangementsTurbineGas supply

A system may include an electrostatic spray tool having a turbine generator configured to generate electrical power to electrostatically charge a spray. The spray tool also may include a controller configured to monitor the electrical power from the turbine generator and to instruct a gas supply to vary a gas flow to the turbine generator based on feedback received from one or more sensors.

Owner:CARLISLE FLUID TECH INC

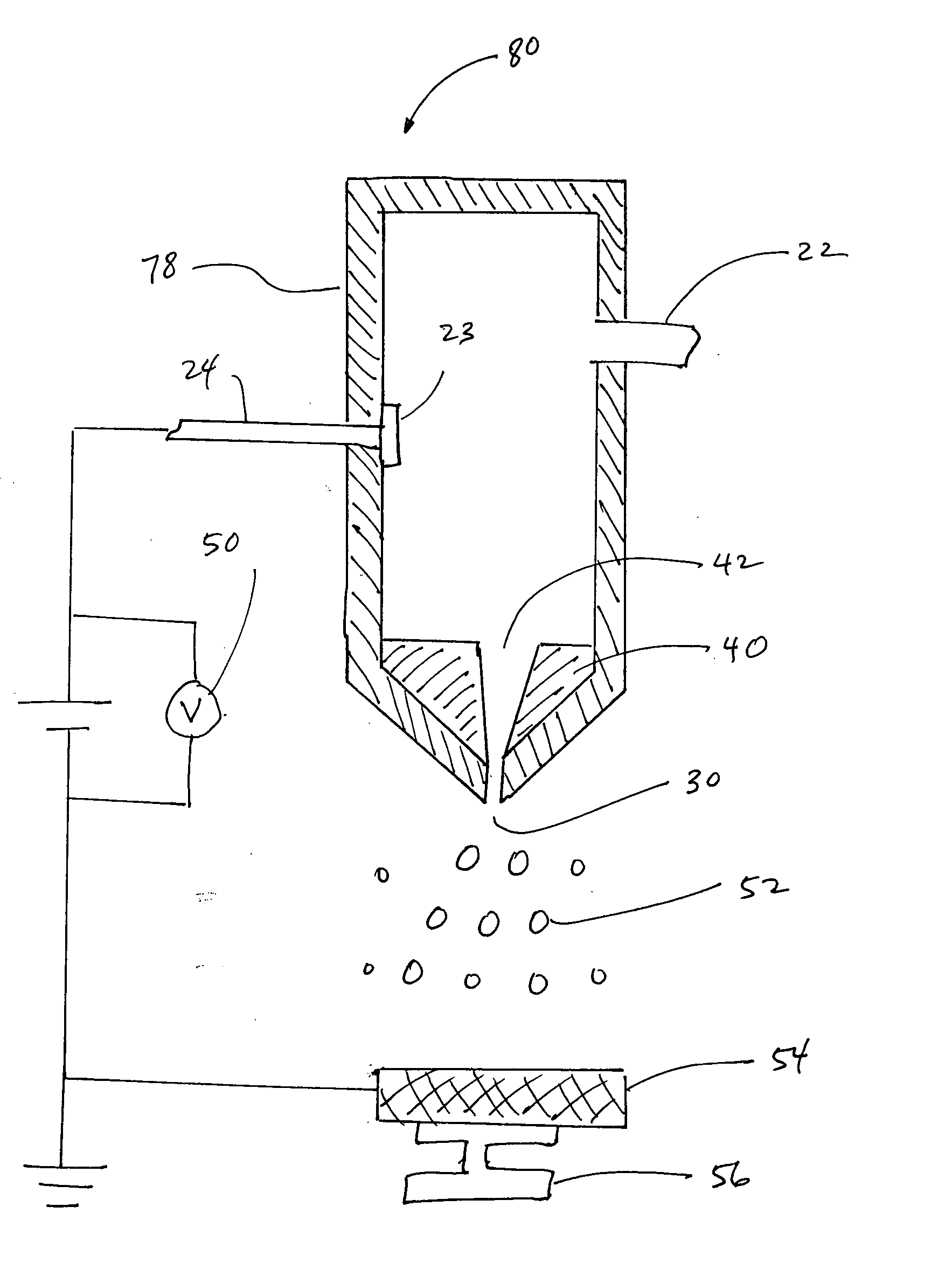

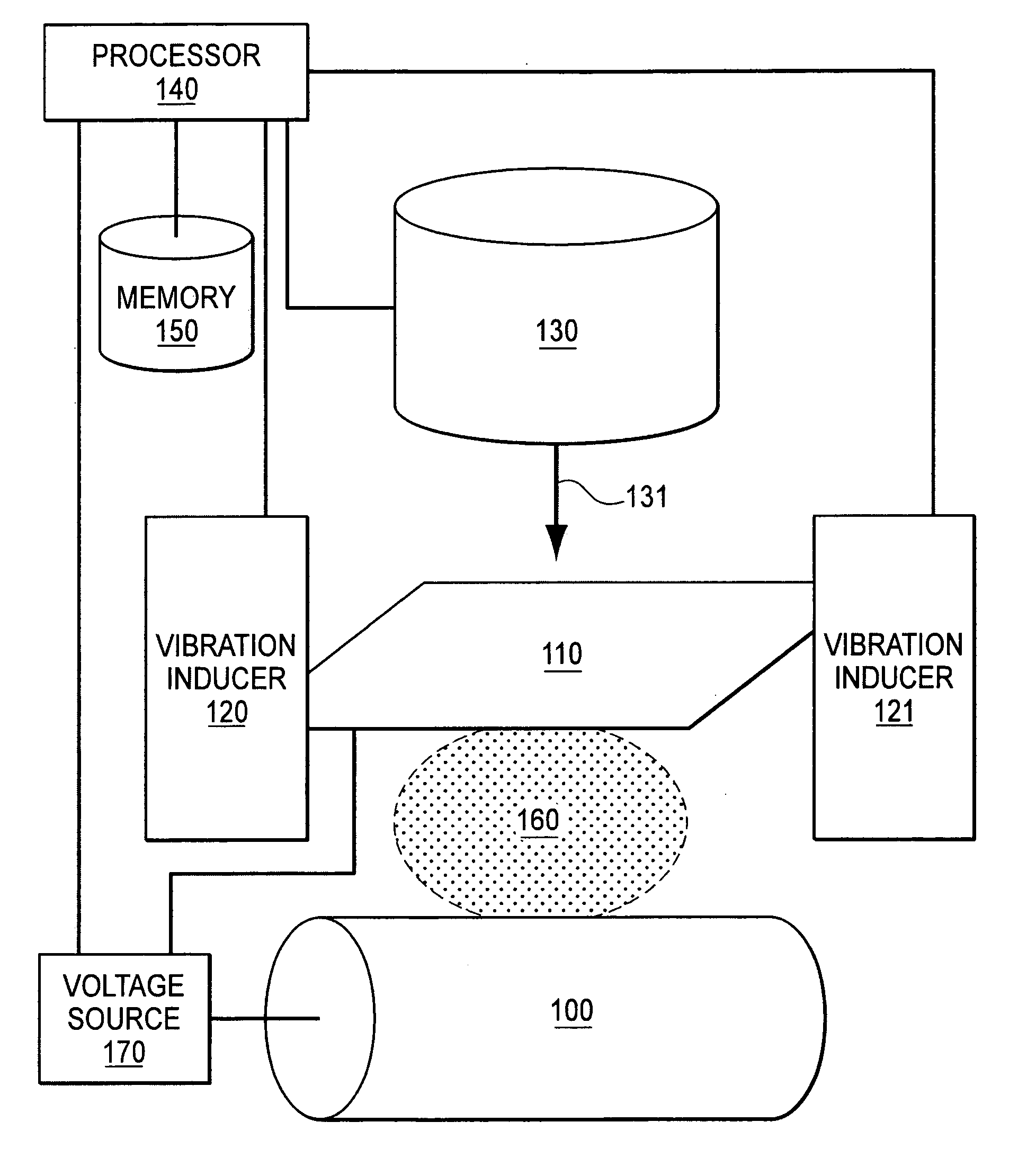

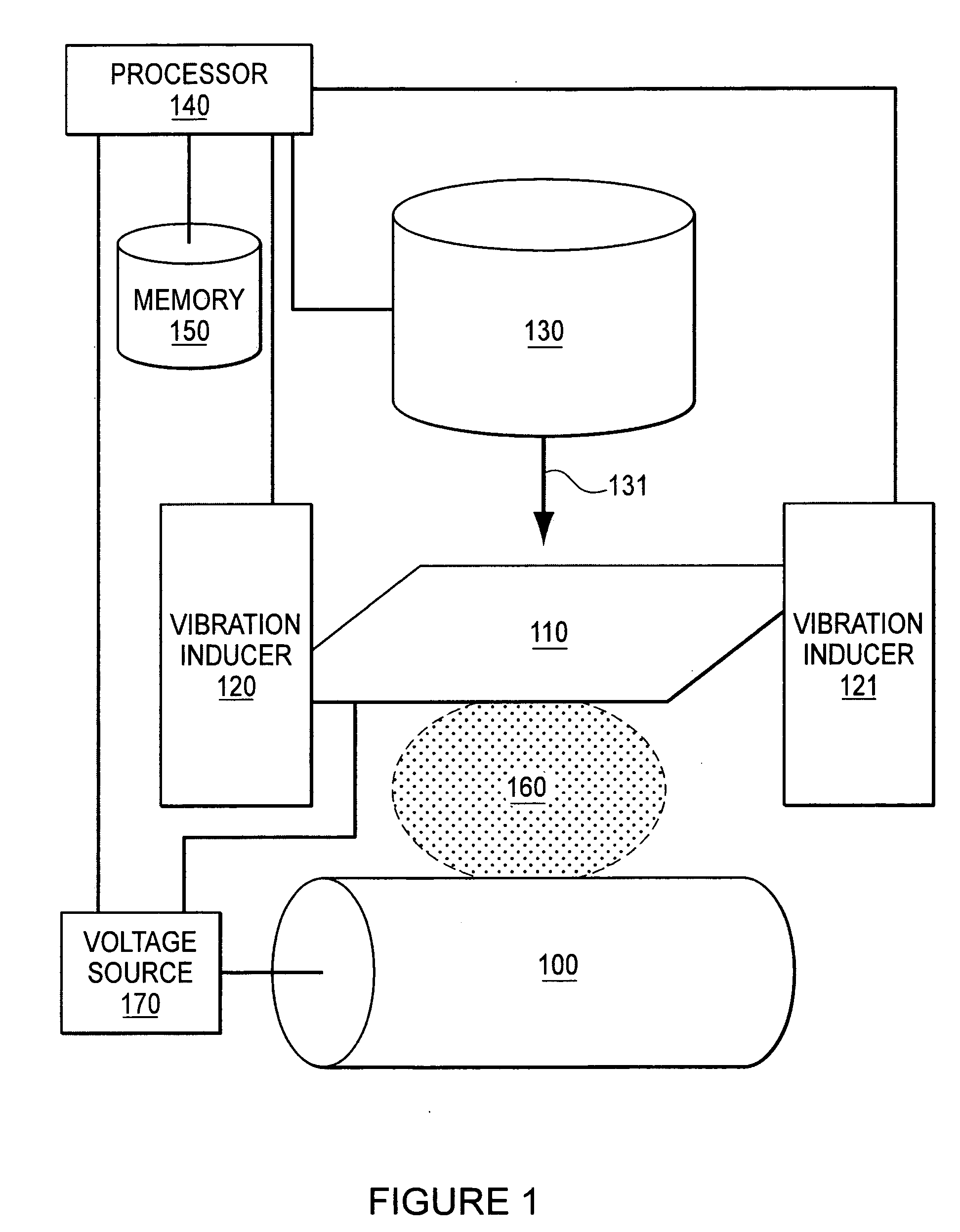

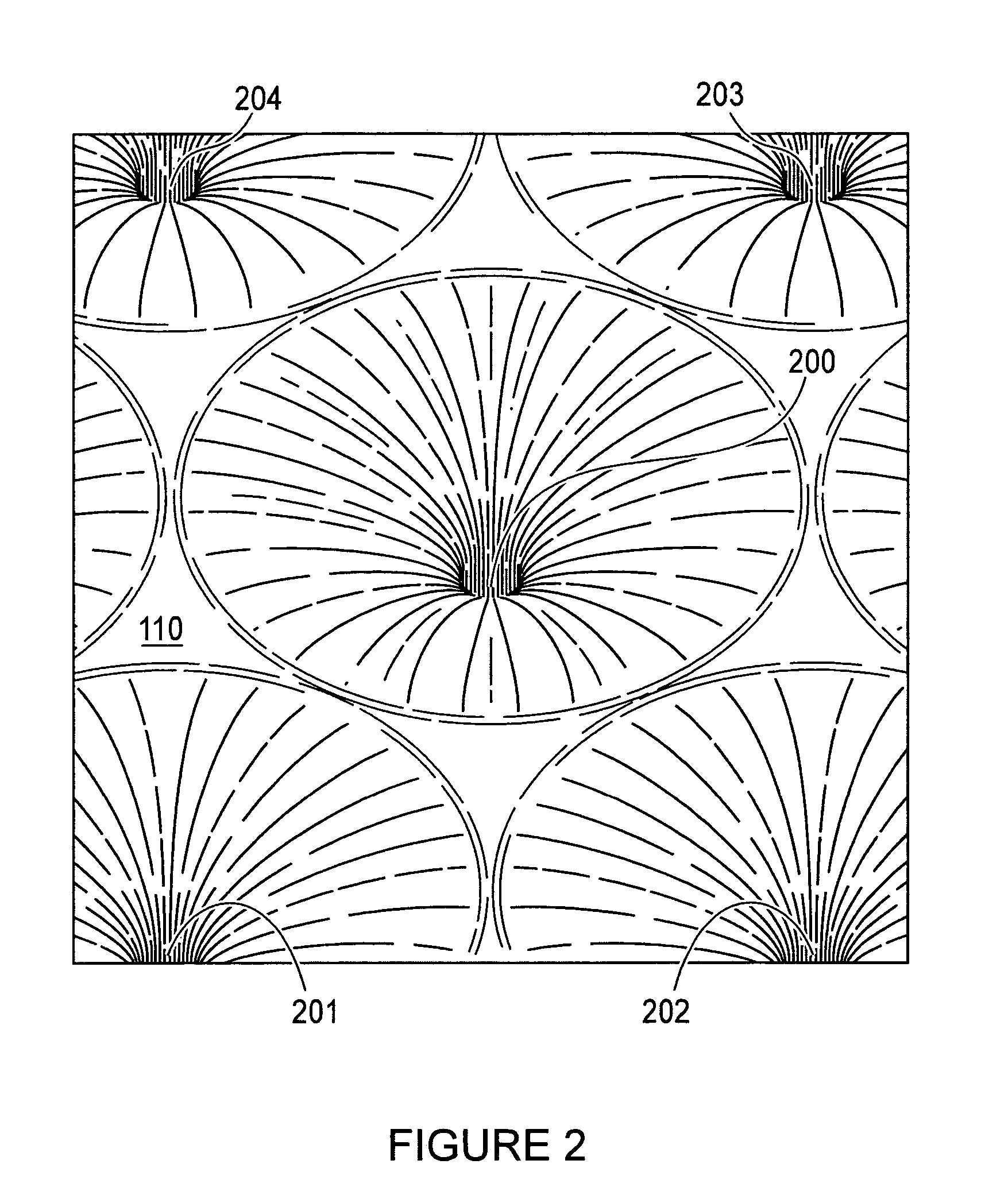

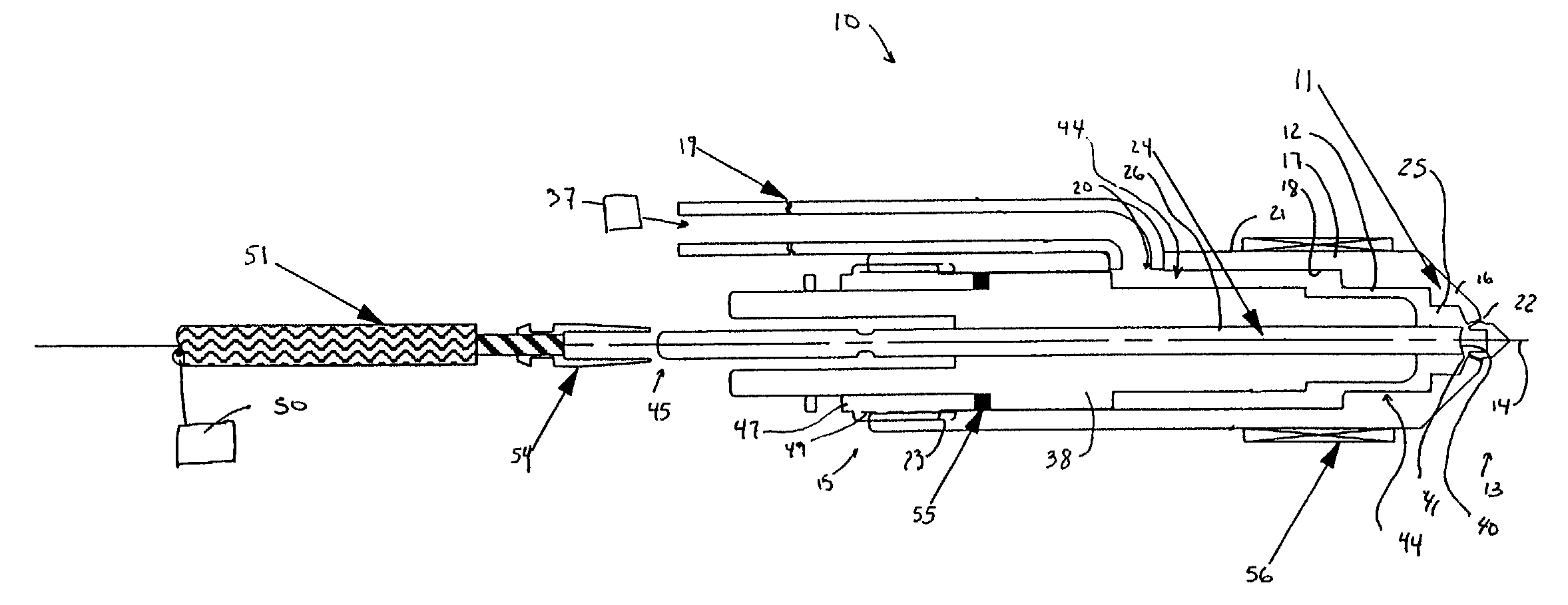

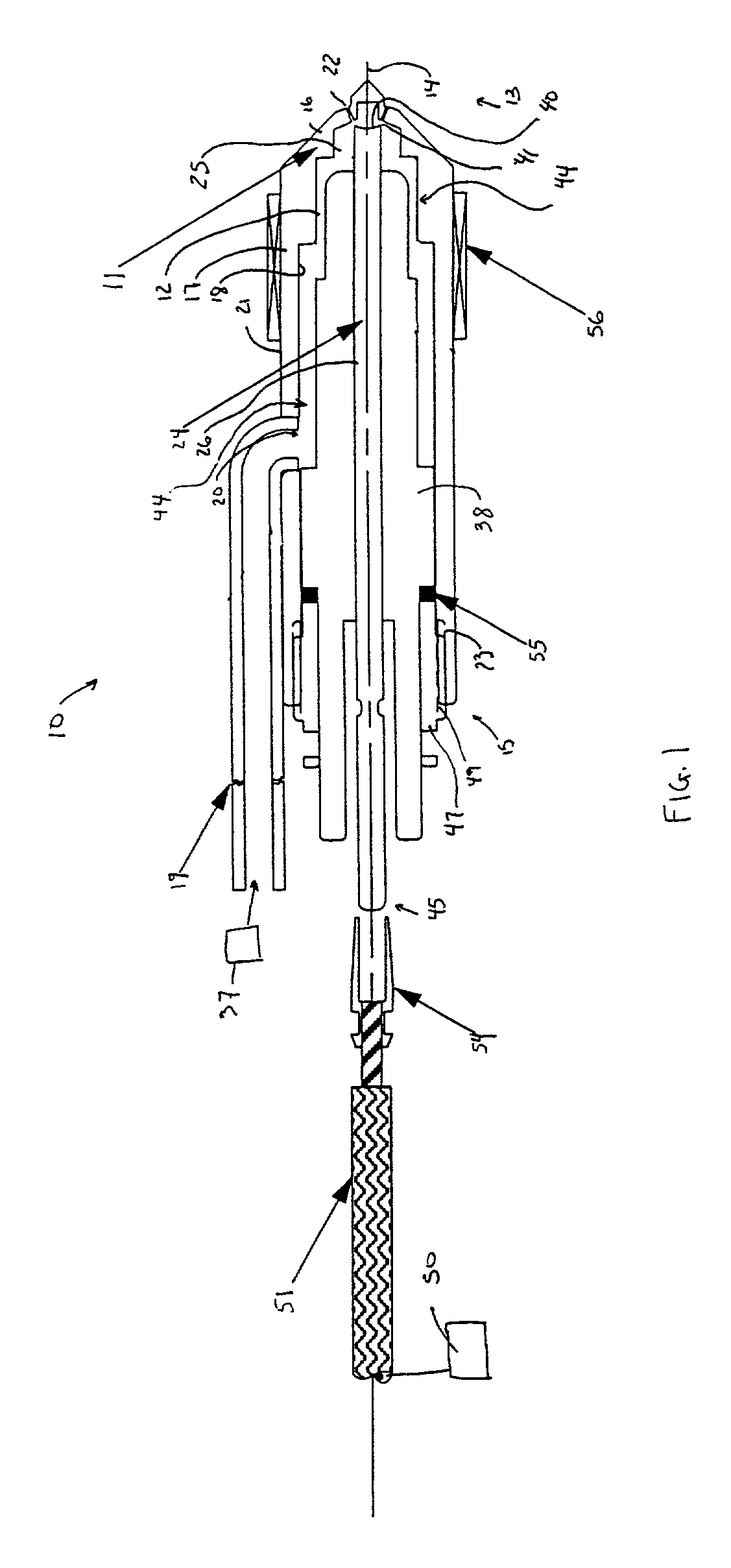

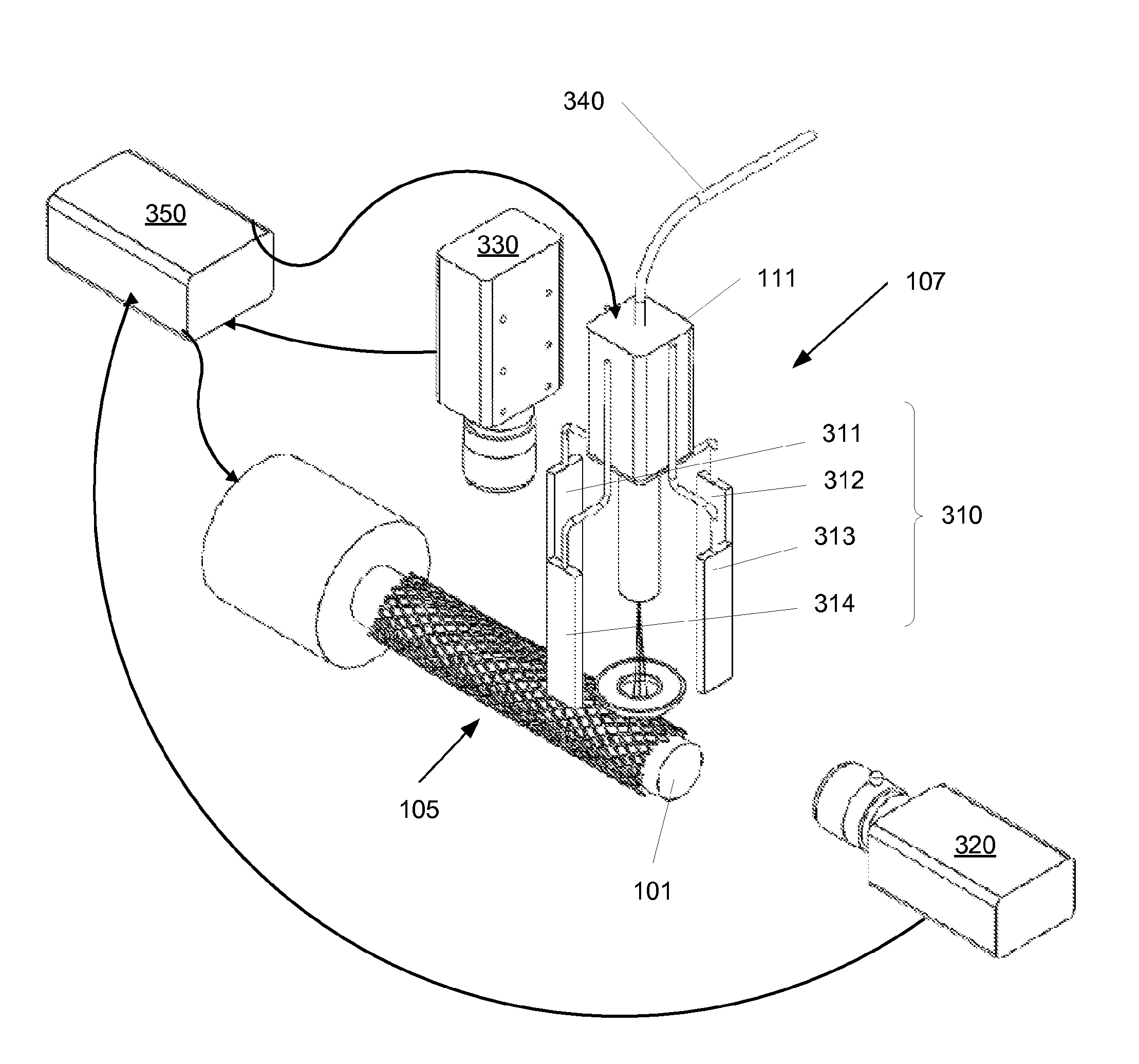

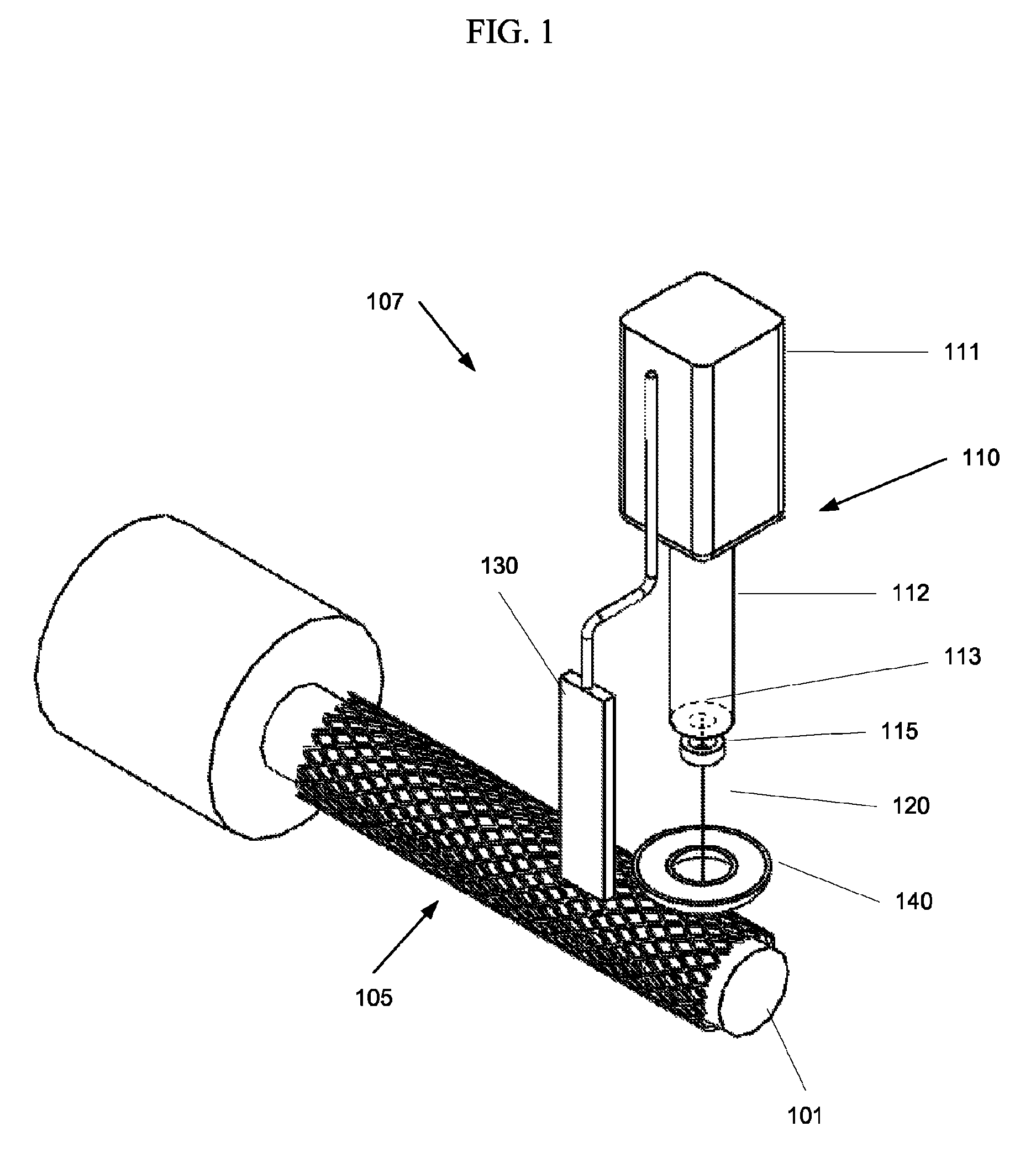

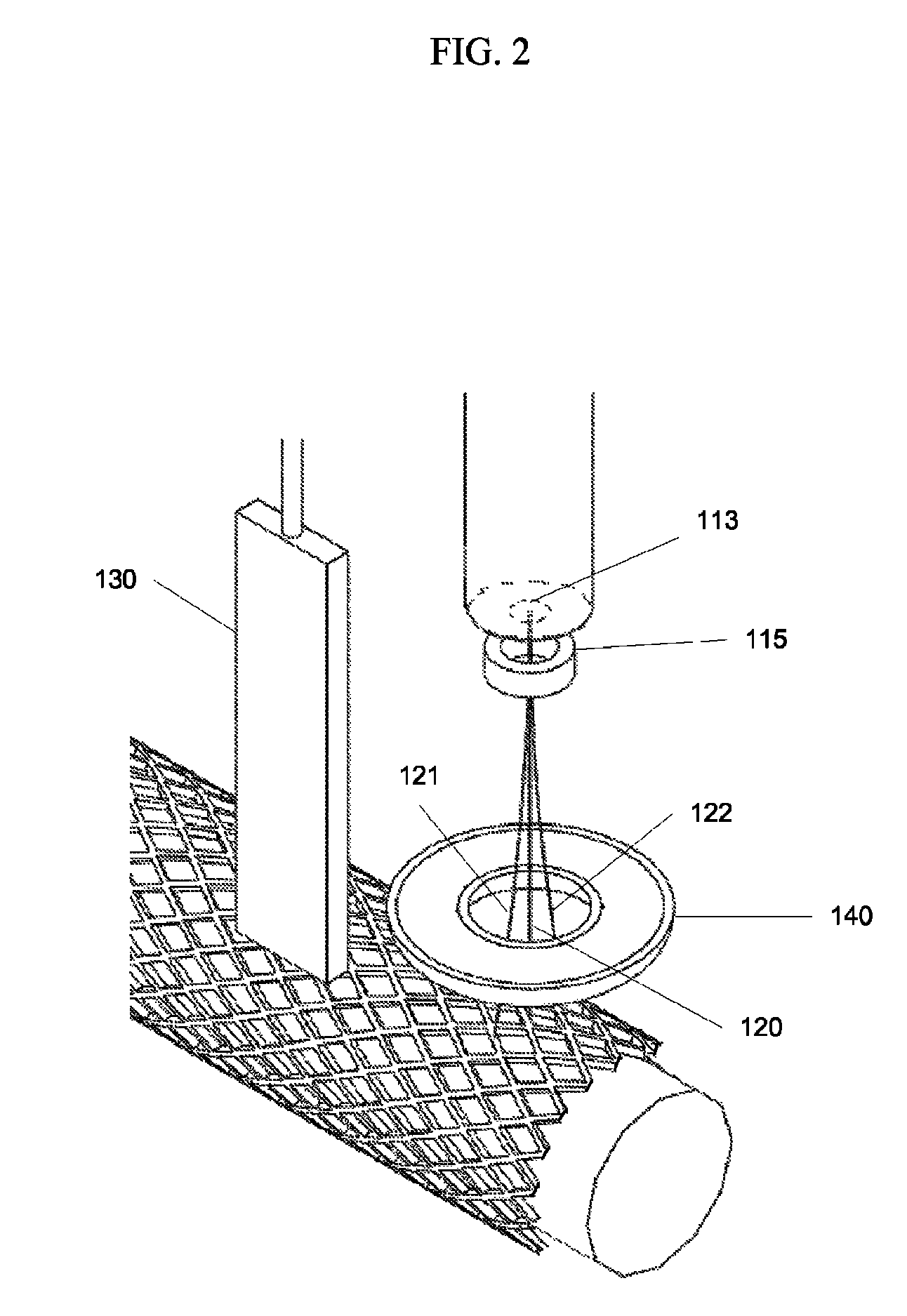

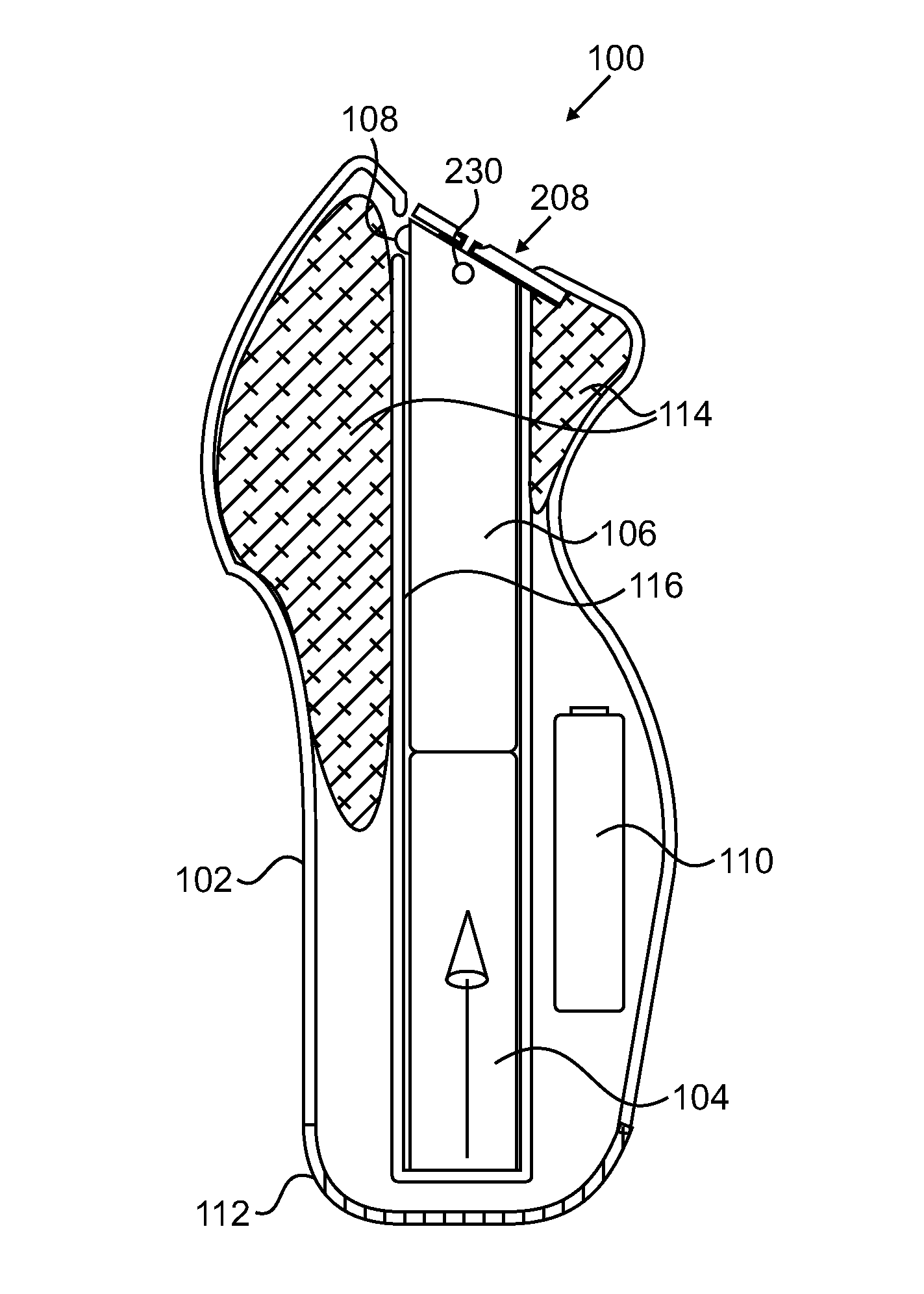

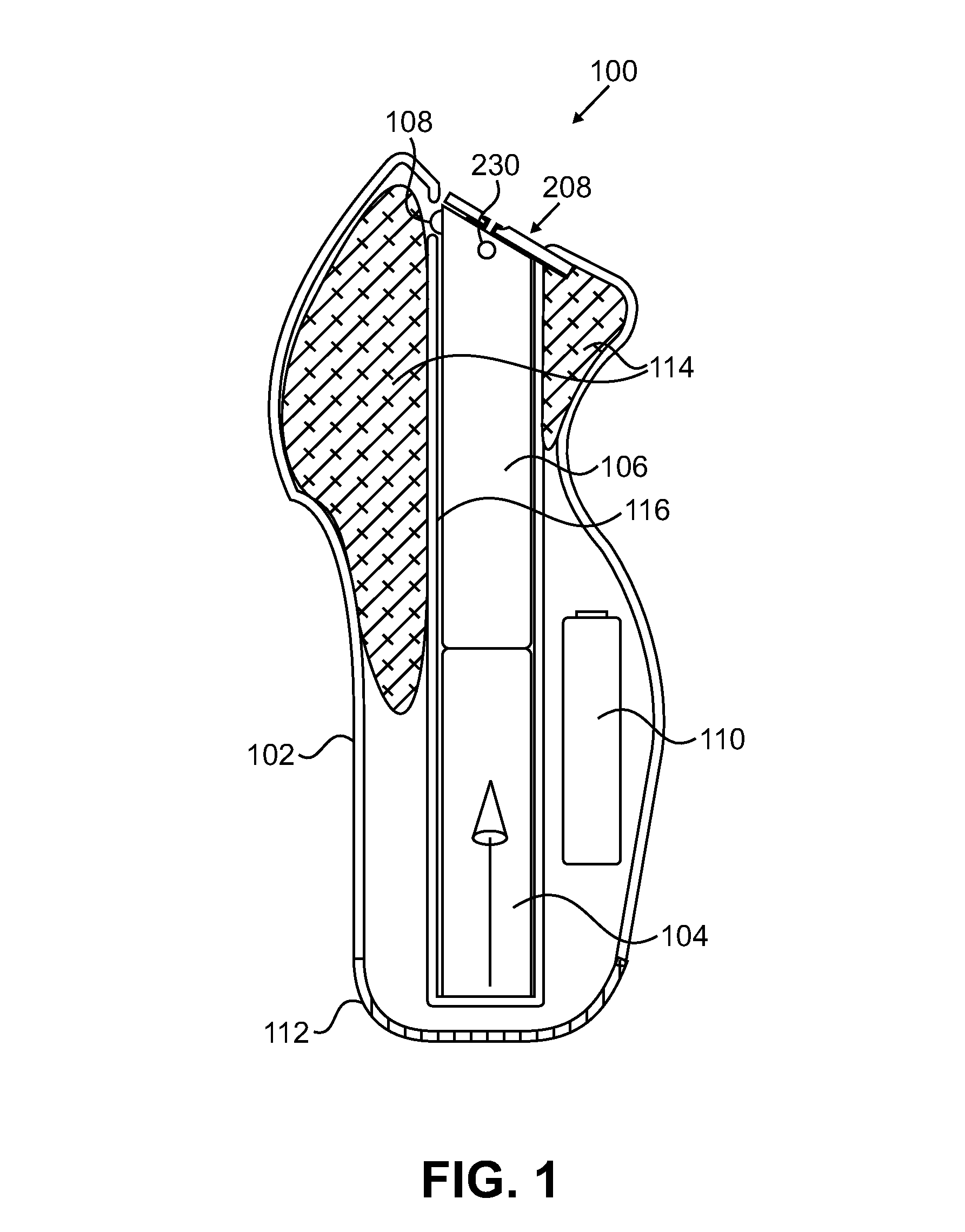

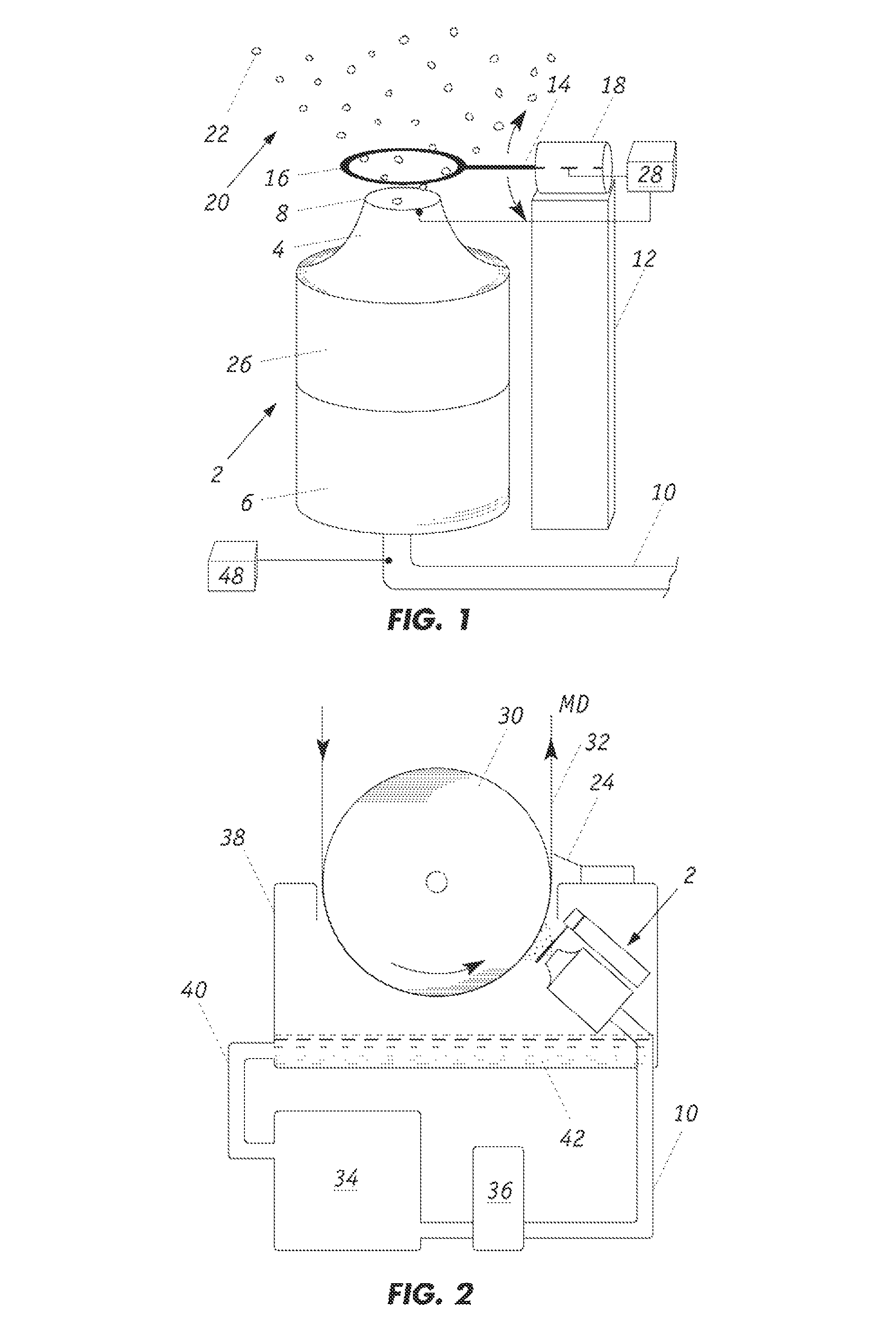

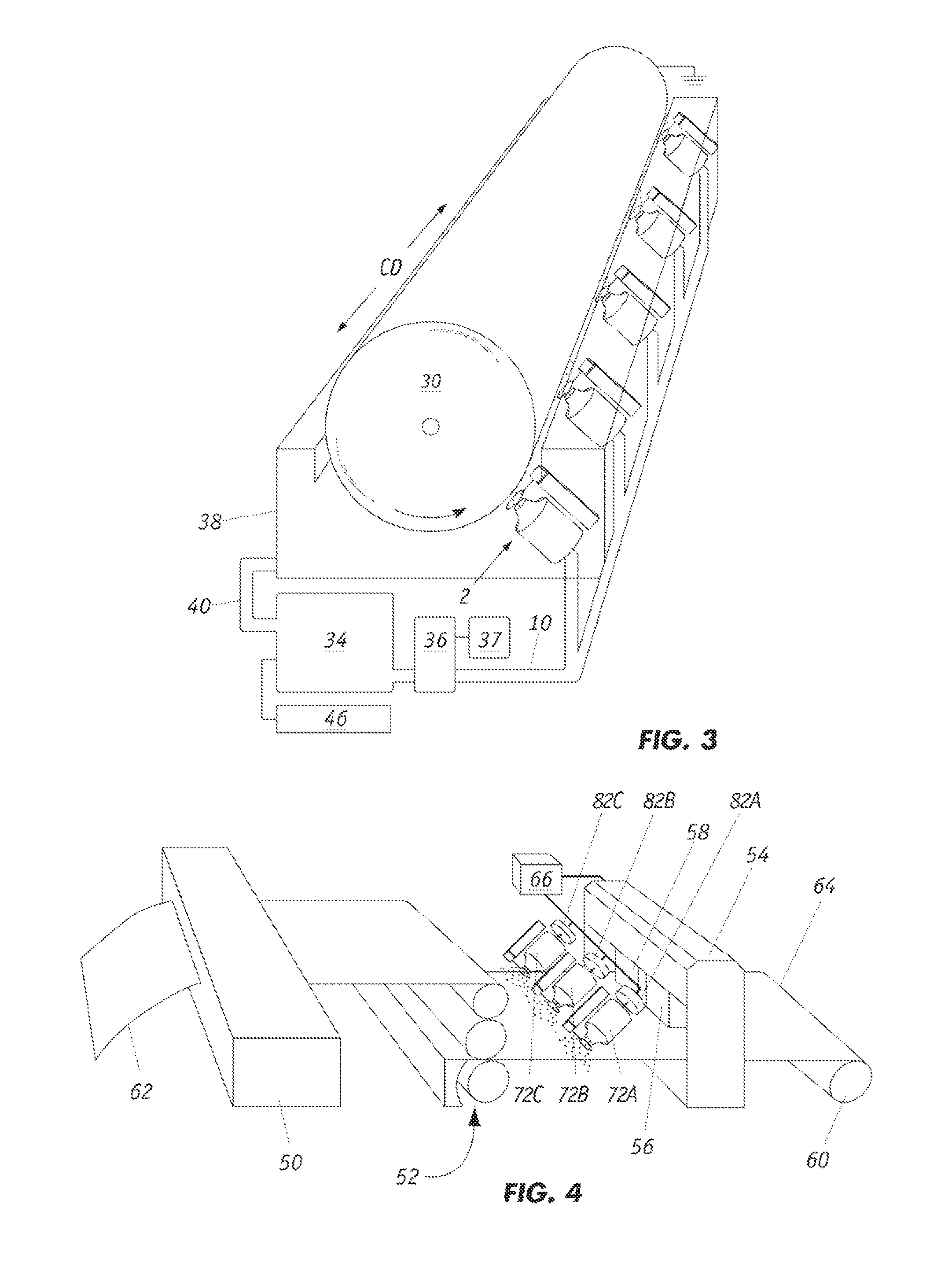

Microdrop ablumenal coating system and method

InactiveUS8277867B2Easy to controlAccurately and efficiently coatedStentsPharmaceutical containersControl systemCoating system

Systems and methods for coating medical devices are provided that allow for relatively precise control over the deposition area and coating uniformity with improved efficiency. A microdrop source is used to provide a flow of coating microdrops. A charging electrode disposed near the outlet of the coating source gives each microdrop an electrostatic charge. As the microdrop travels toward the medical device to be coated, a control electrode alters the trajectory of the microdrop. The invention can include a scanner to scan or image the medical device as the coating is applied and a control system to adjust parameters of the deposition process based on information provided by the scanner.

Owner:BOSTON SCI SCIMED INC

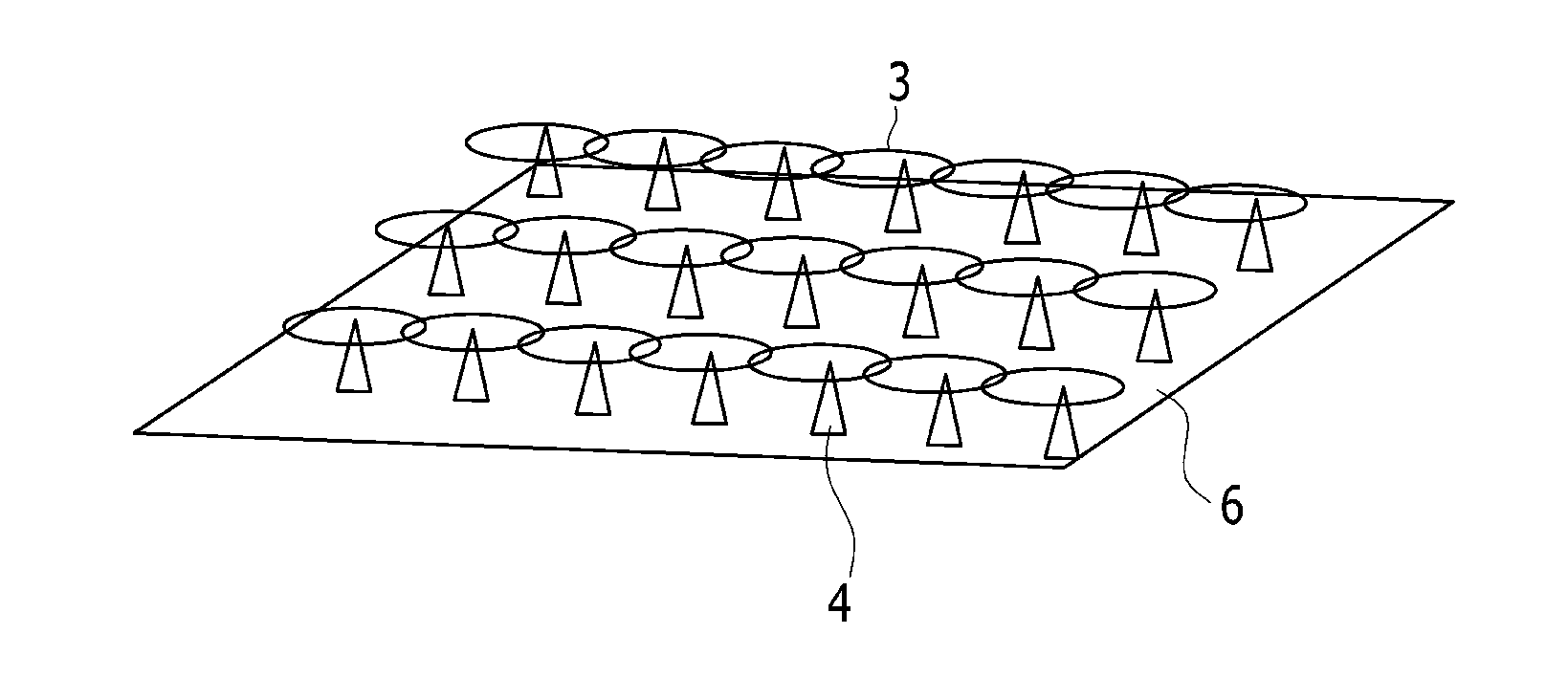

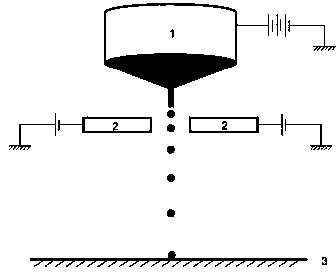

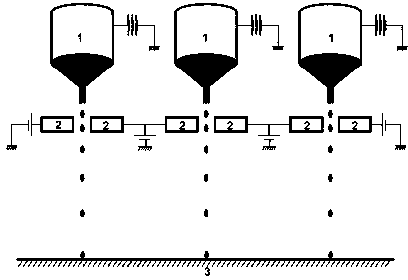

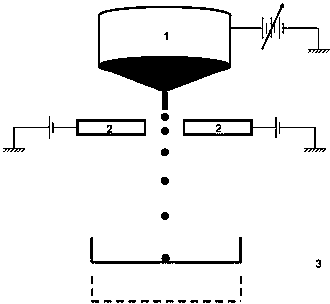

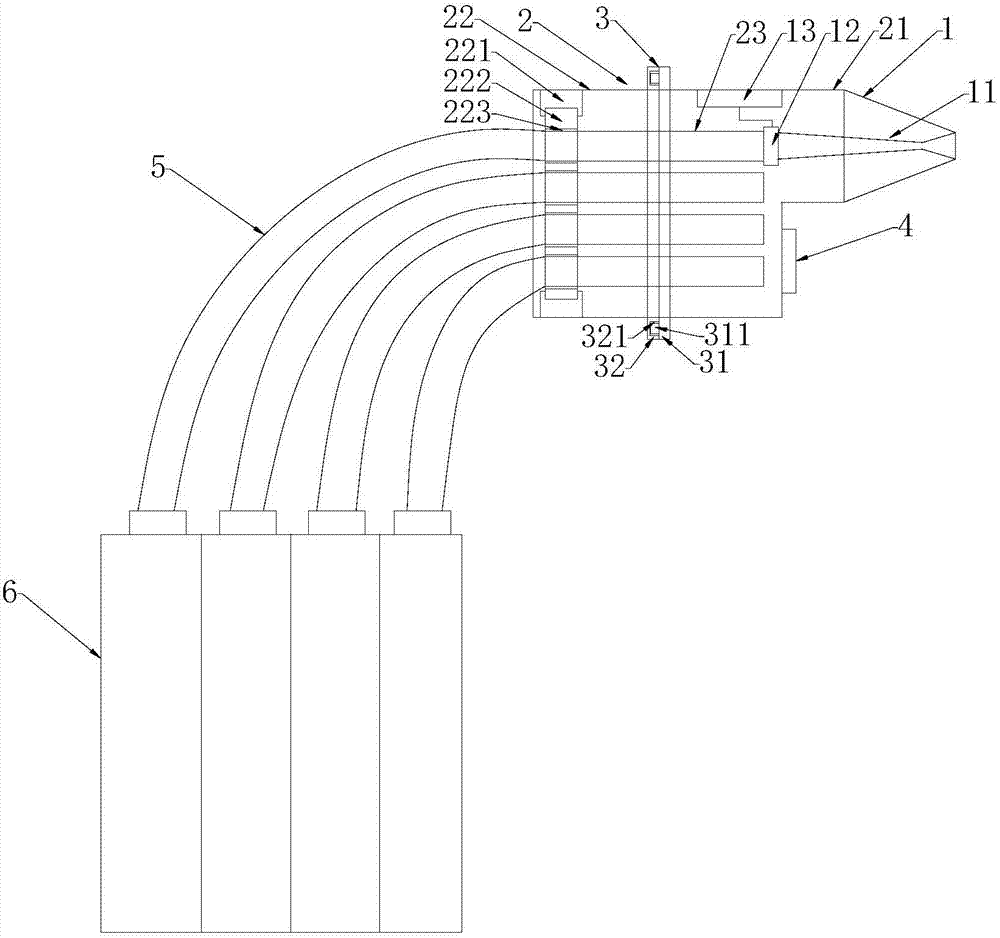

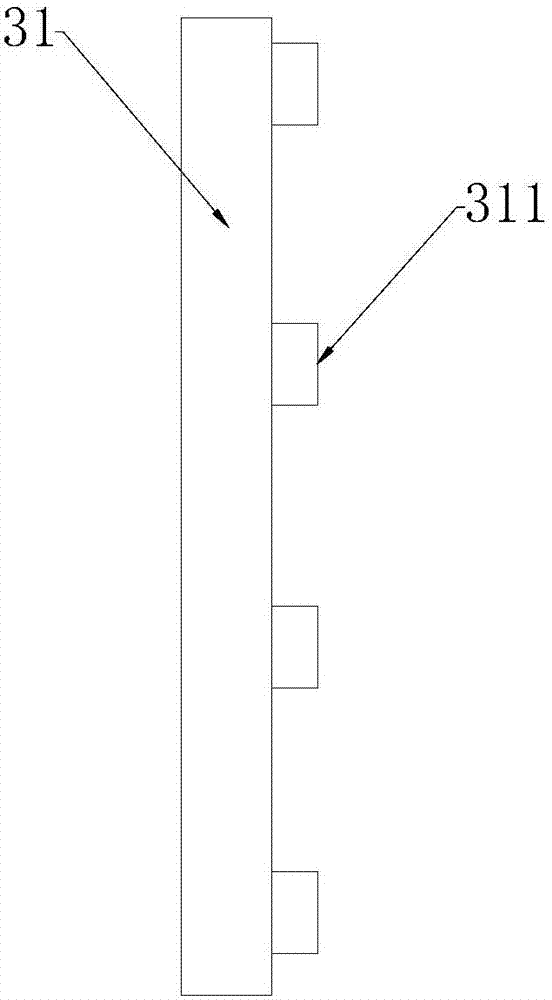

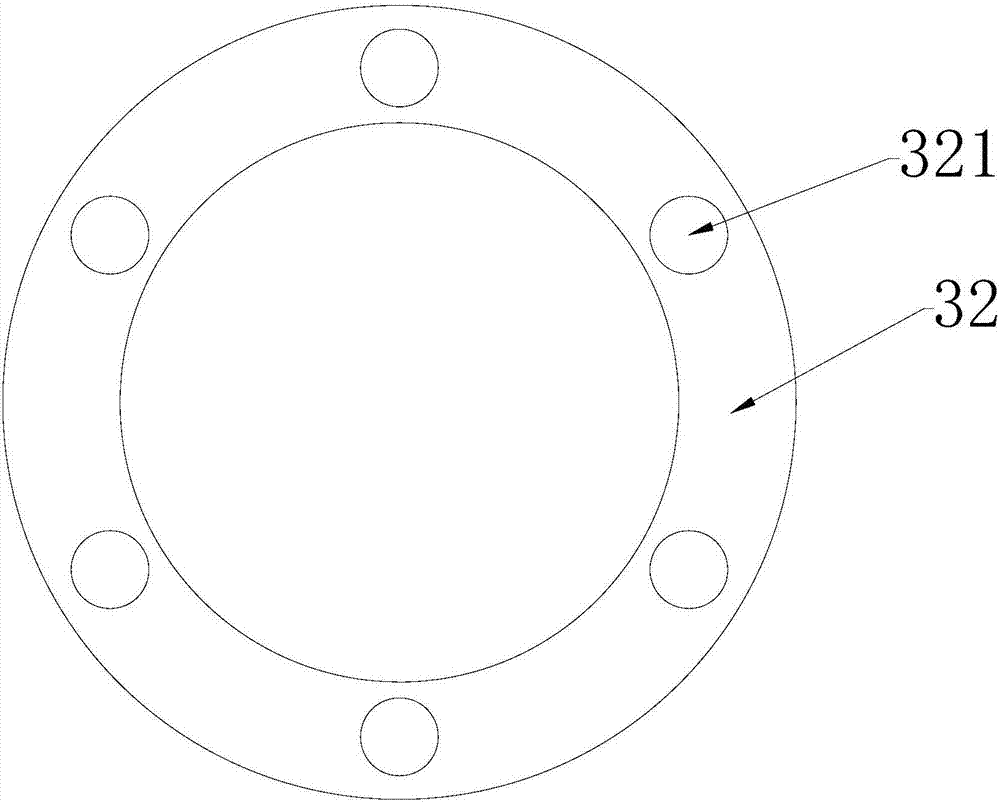

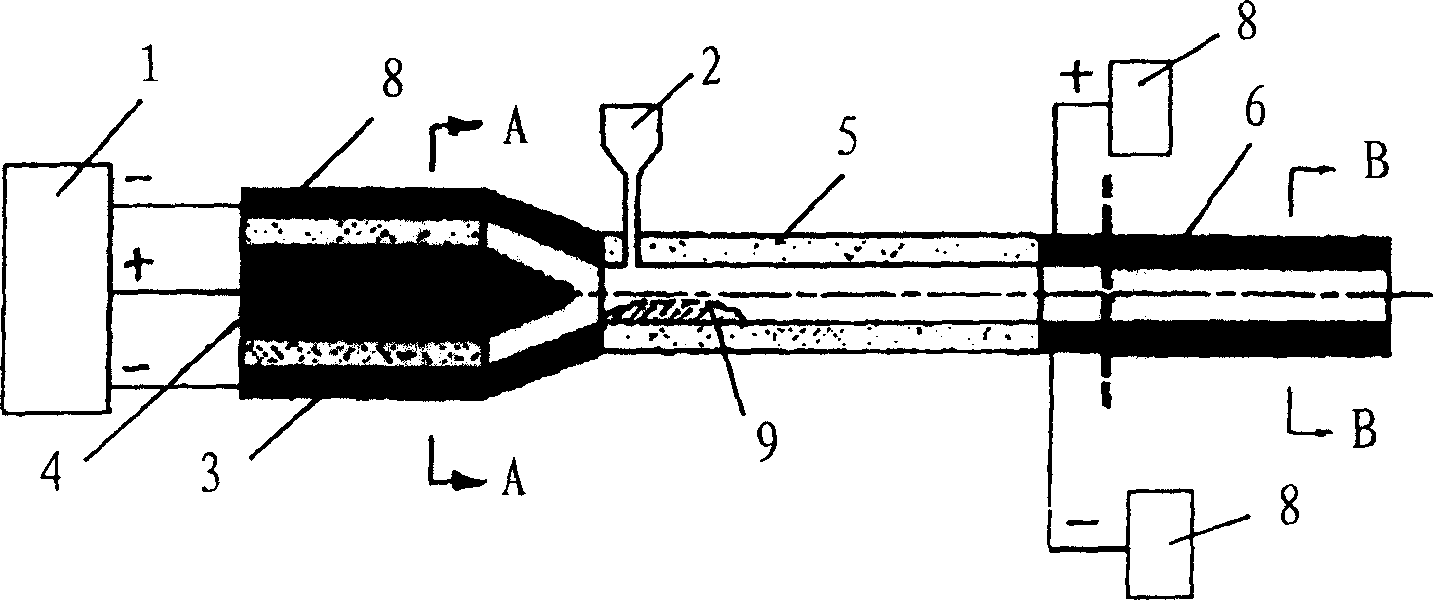

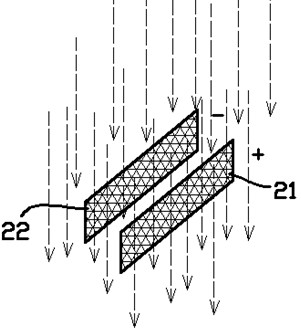

Two-segment electric-field structure electrostatic spray system, array and using method

The invention provides a two-segment electric-field structure electrostatic spray system, array and using method, and belongs to the technical field of electrostatic spraying. The system comprises a nozzle (1) accessed to a first potential, a control electrode (2) accessed to a first potential, and a spray base (3) grounded or accessed to a third potential; the control electrode (2) and the nozzle (1) form an electrostatic liquid drop producing device, and the control electrode (2) and the spray base (3) form an electrostatic liquid drop collecting device. According to the two-segment electric-field structure electrostatic spray system, the control electrode is adopted to separate the producing device and collecting device of electrostatic liquid drops, a traditional one-segment electric field is separated into a two-segment electric field, a first segment of the electric field is utilized to produce the electrostatic liquid drops, and a second segment of the electric field is utilized to control movement and space distribution of the electrostatic liquid drops, so that security and flexibility are improved, space is saved, efficiency is improved, and the system is particularly adaptable to using in arrayed and miniaturized systems.

Owner:JIANGSU JICUI DEPTH SENSING TECH RES INST CO LTD

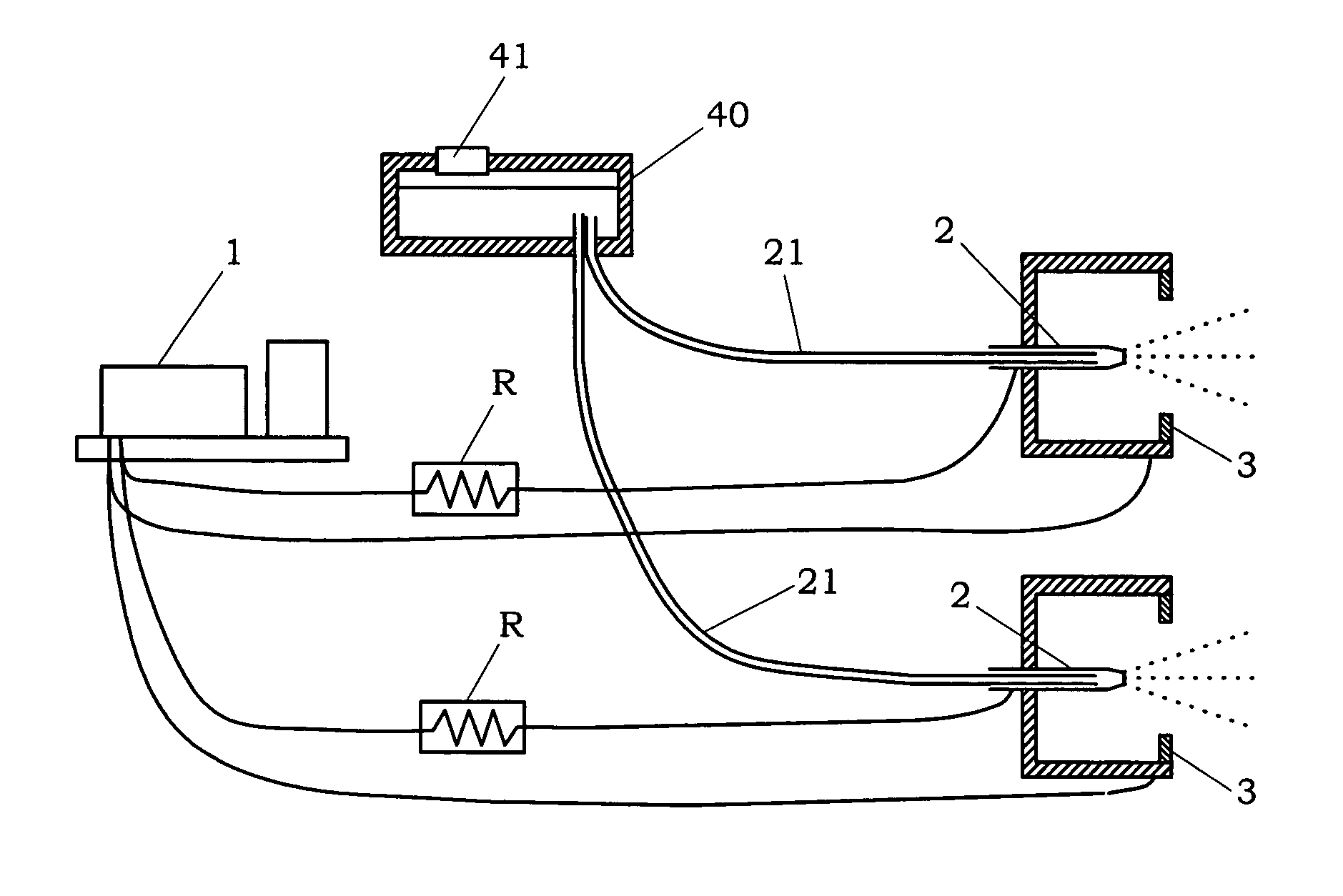

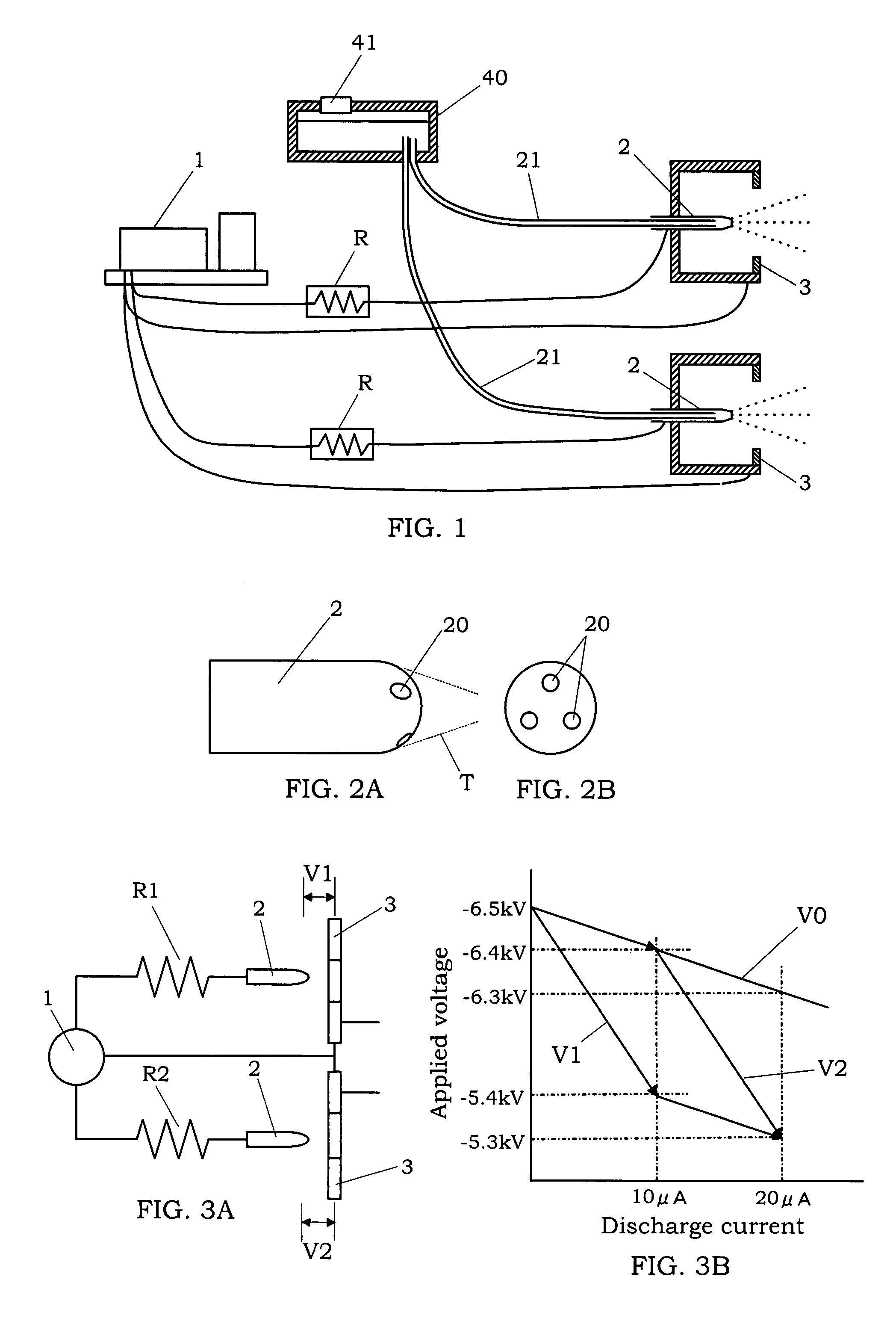

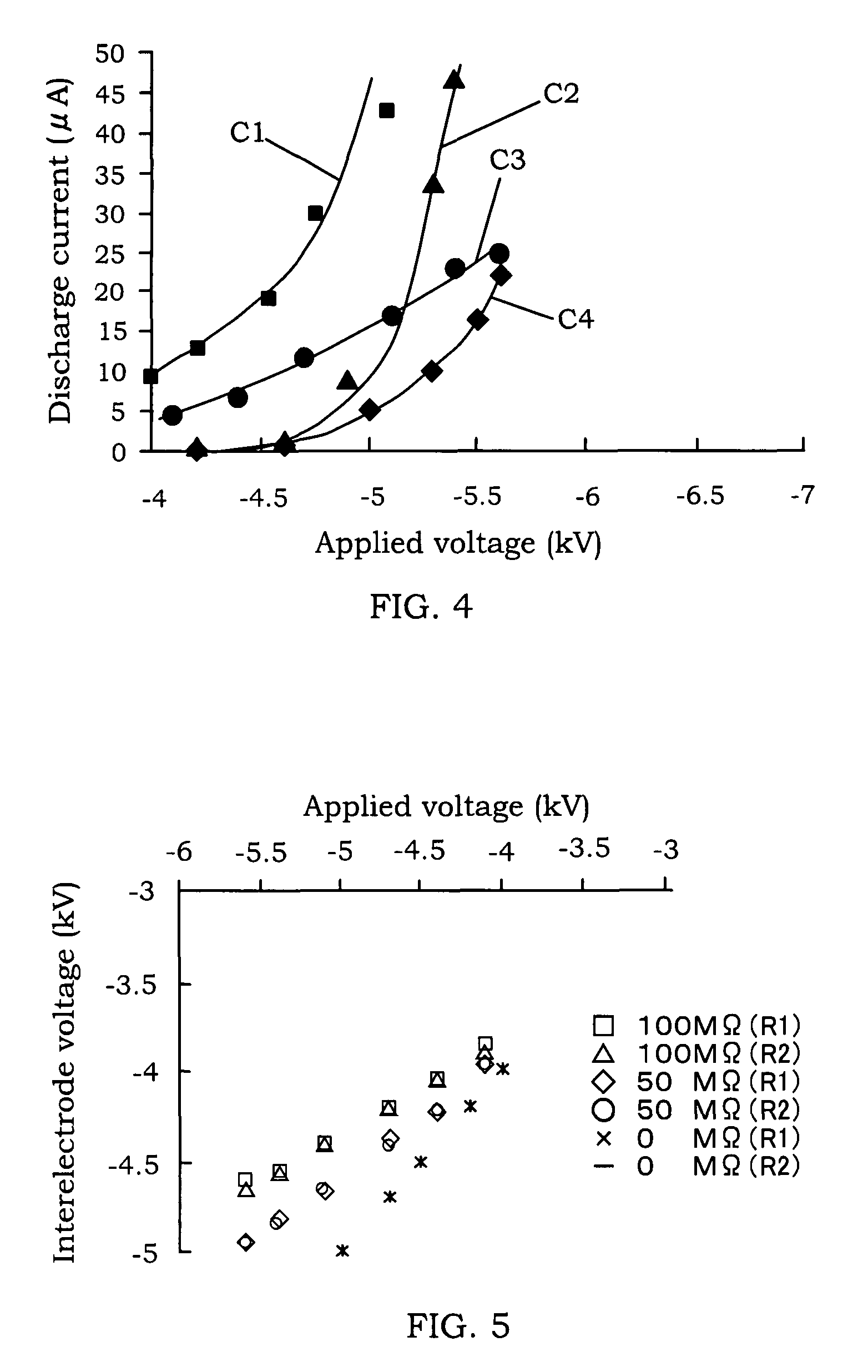

Electrostatic atomizing device and air blower using the same

InactiveUS7883034B2Increase generationBurnersLiquid spraying plantsElectrical resistance and conductancePower flow

An electrostatic atomizing device, which is capable of increasing the generation of a fine mist, while suppressing abnormal discharge and the generation of ozone. This electrostatic atomizing device is equipped with a plurality of atomizing electrodes, to which a high voltage is applied by a single high voltage generating circuit, counter electrodes disposed so as to face the atomizing electrodes; and a liquid transfer means for transferring a liquid (e.g., water) to each of the atomizing electrodes. The atomizing electrodes are connected in parallel to the high voltage generating circuit, and a resistive element for suppressing discharge current is inserted between the high voltage generating circuit and each of the atomizing electrodes.

Owner:MATSUSHITA ELECTRIC WORKS LTD

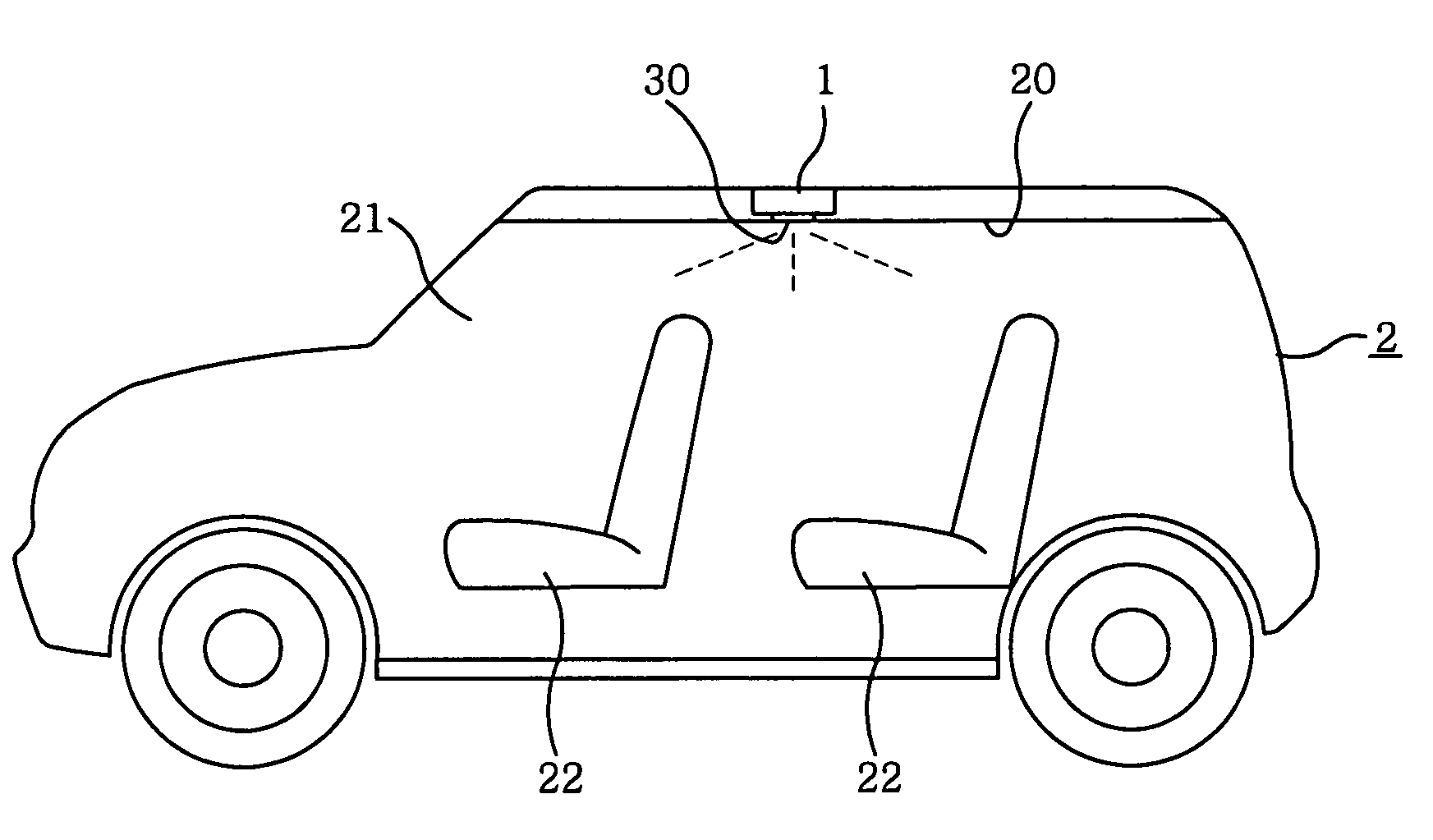

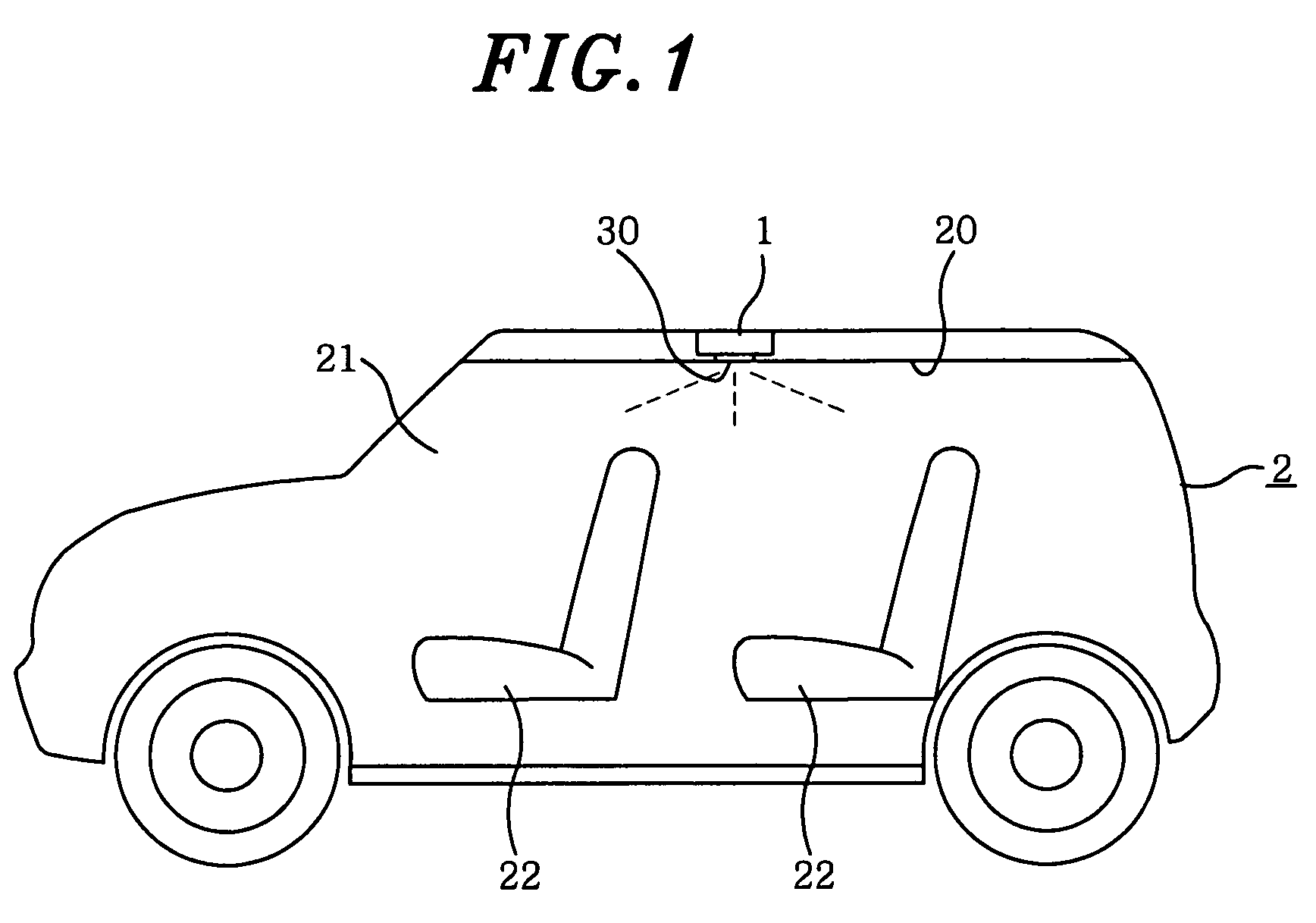

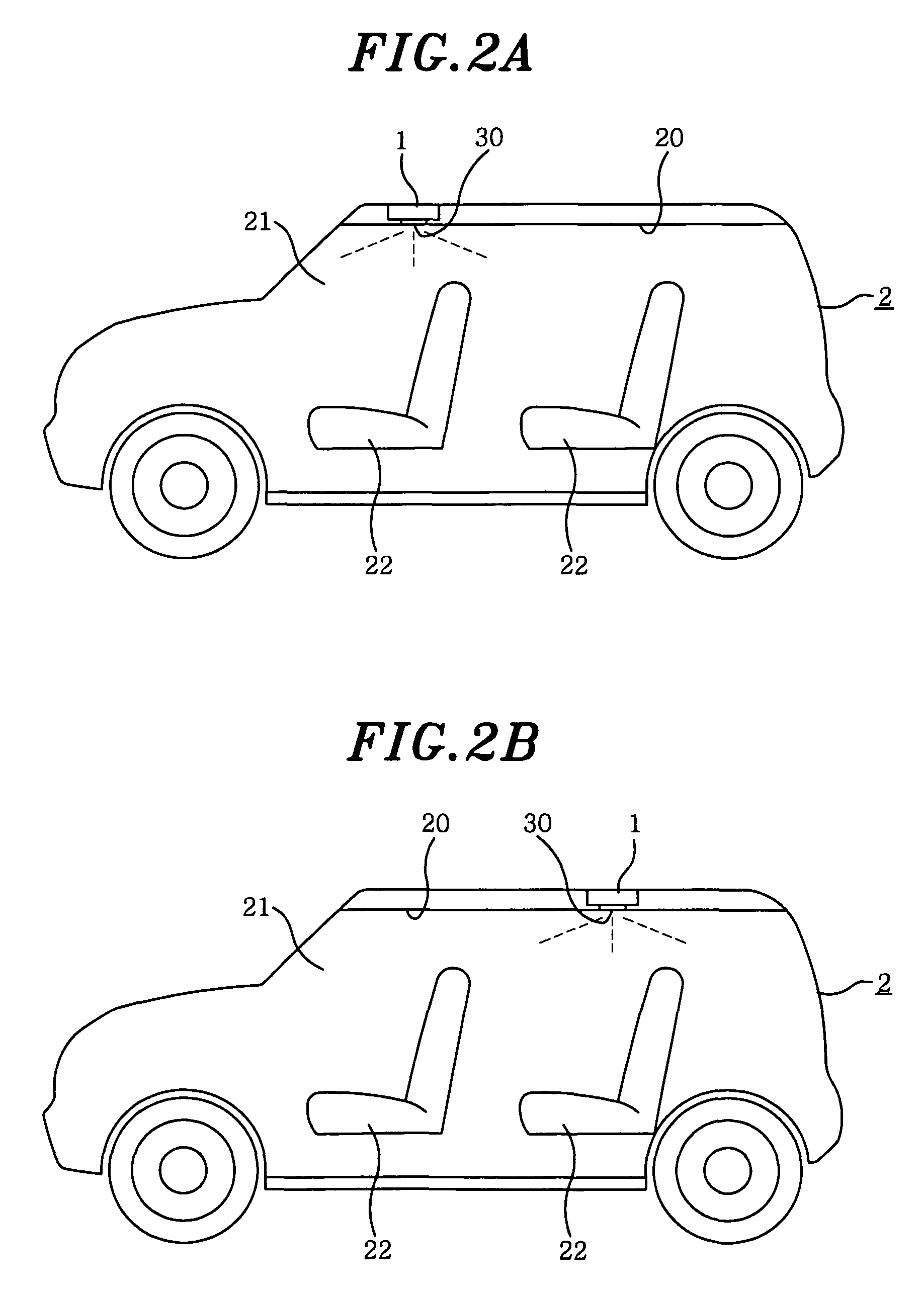

Electrostatic atomizer for use in a motor vehicle

InactiveUS8109452B2Efficient sprayingStable generationBurnersAir-treating devicesMobile vehicleEngineering

An electrostatic atomizer, for use in a motor vehicle, includes a discharge electrode, a water supply unit for cooling the discharge electrode to generate water condensed on the discharge electrode, and a high voltage applying unit for applying a high voltage to the water on the discharge electrode to electrostatically atomize the water. The electrostatic atomizer is arranged in a ceiling of the motor vehicle. The electrostatic atomizer further includes an ejection portion provided in the ceiling of the motor vehicle for ejecting electrically-charged water particles generated by electrostatic atomization and an ejection direction changing unit provided in the ejection portion for changing an ejection direction of the electrically-charged water particles.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Electric charge concentration type droplet dispensing device having nonconductive capillary nozzle

Provided is a droplet dispensing device having a nonconductive capillary nozzle. The droplet dispensing device comprises: a nonconductive capillary nozzle disposed in a downward position; a pump connected with the nonconductive capillary nozzle through a hermetically sealed fluid tube and generating a negative pressure to decrease the influence of gravity on a solution within the nonconductive capillary nozzle and the fluid tube; and an open circuit voltage supplier applying a voltage to the solution. The droplet dispensing device supplies the solution by capillary force to regularly maintain the shape of a droplet surface in the tip of the nonconductive capillary nozzle without using a separate driving device.

Owner:SAMSUNG ELECTRONICS CO LTD

Microdrop ablumenal coating system and method

InactiveUS20090074943A1Stable flowEasy to controlStentsPharmaceutical containersControl systemCoating system

Systems and methods for coating medical devices are provided that allow for relatively precise control over the deposition area and coating uniformity with improved efficiency. A microdrop source is used to provide a flow of coating microdrops. A charging electrode disposed near the outlet of the coating source gives each microdrop an electrostatic charge. As the microdrop travels toward the medical device to be coated, a control electrode alters the trajectory of the microdrop. The invention can include a scanner to scan or image the medical device as the coating is applied and a control system to adjust parameters of the deposition process based on information provided by the scanner.

Owner:BOSTON SCI SCIMED INC

Electrostatic spray gun for rapidly spraying multicolor paint

PendingCN107008583ARealize color changeGuaranteed fixed effectGasless sprayingEngineeringColor changes

The invention provides an electrostatic spray gun for rapidly spraying multicolor paint. One end of each of paint pipes is connected with a paint tank, and the other end of the corresponding paint pipe is connected with a gun body; the gun body is connected with a nozzle; a controller is connected with the nozzle through a circuit; a spraying channel and a paint sucking pump are arranged in the nozzle; a paint connector is arranged at the bottom of the spraying channel, and connected with the paint sucking pump through a pipeline; and the paint sucking pump is connected with the controller through a circuit. According to the electrostatic spray gun for rapidly spraying multicolor paint, which is provided by the invention, a color changing upper cover and a color changing lower cover are arranged, so that color change among multiple colors can be realized through the change of the relative position of the color changing upper cover and the color changing lower cover, and the fixed connection of the gun body is guaranteed.

Owner:科威嘉粉末涂料(天津)股份有限公司

VOC-less electrostatic fluid dispensing apparatus

Systems and methods for rapidly atomizing and dispensing electrostatically atomized insecticides and similar low electrical conductivity active materials without the use of VOCs. The active materials are dispensed via insertion of a disposable cartridge in a dispensing apparatus. The dispensing apparatus is hand actuated and the exhausted cartridge is minimized to the size of a wad of chewing gum and it is doubly sealed to prevent any residual active material from leaking into the environment. Spray flow and configuration may be user selectable.

Owner:FOURY LLC

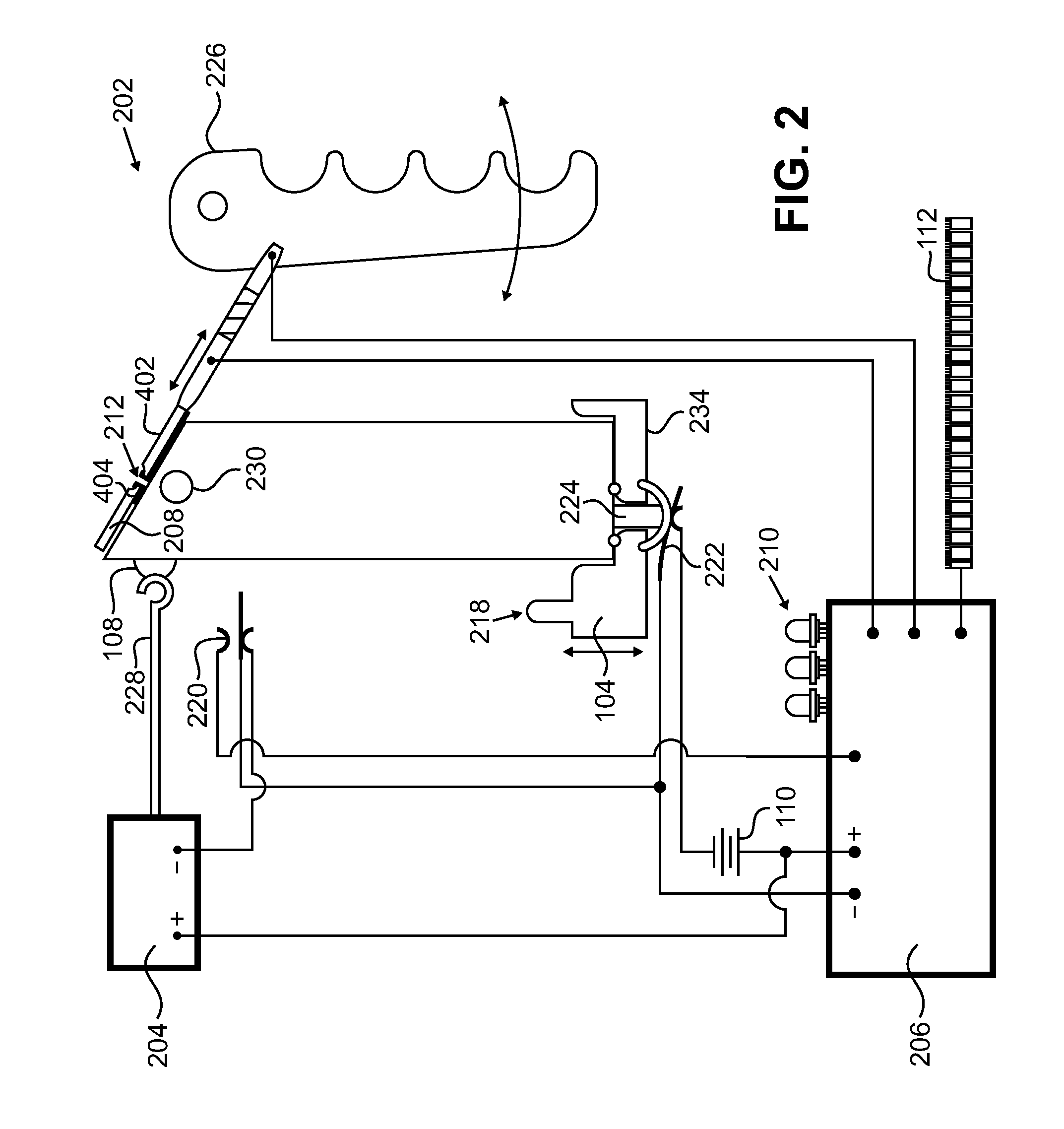

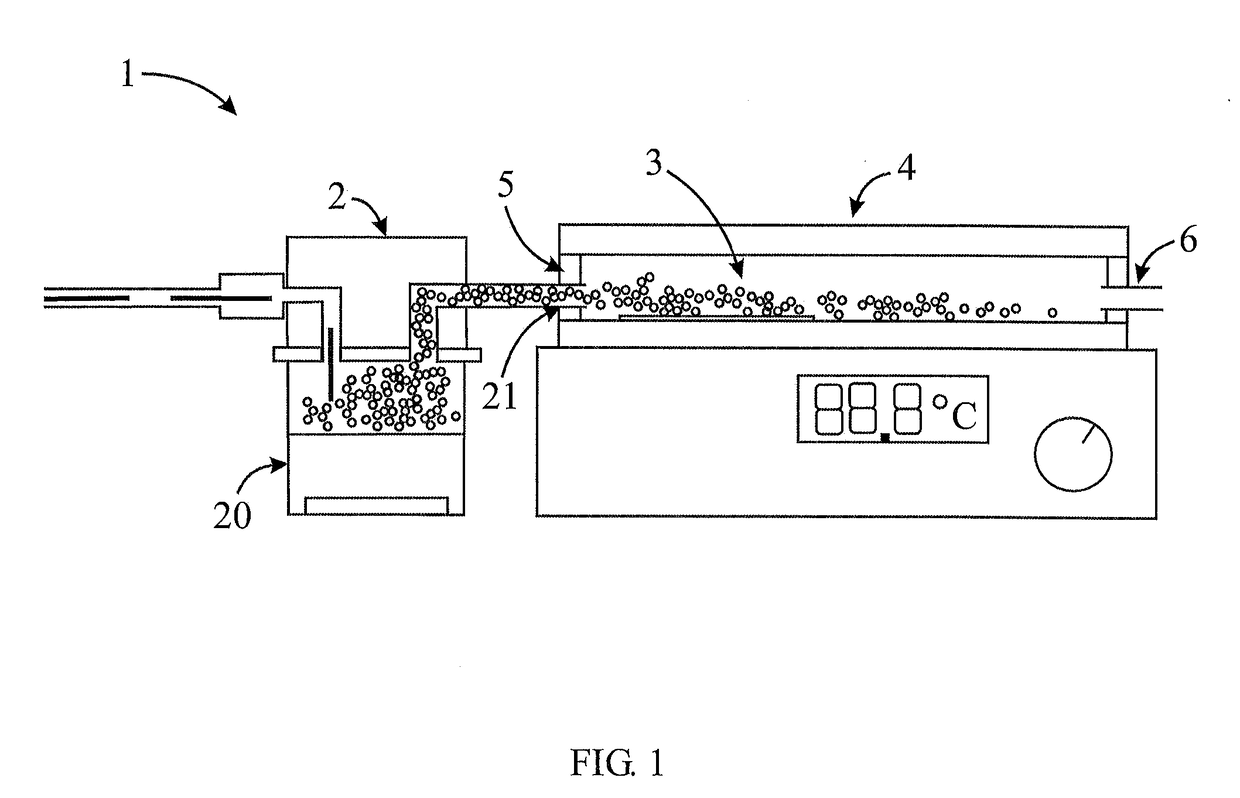

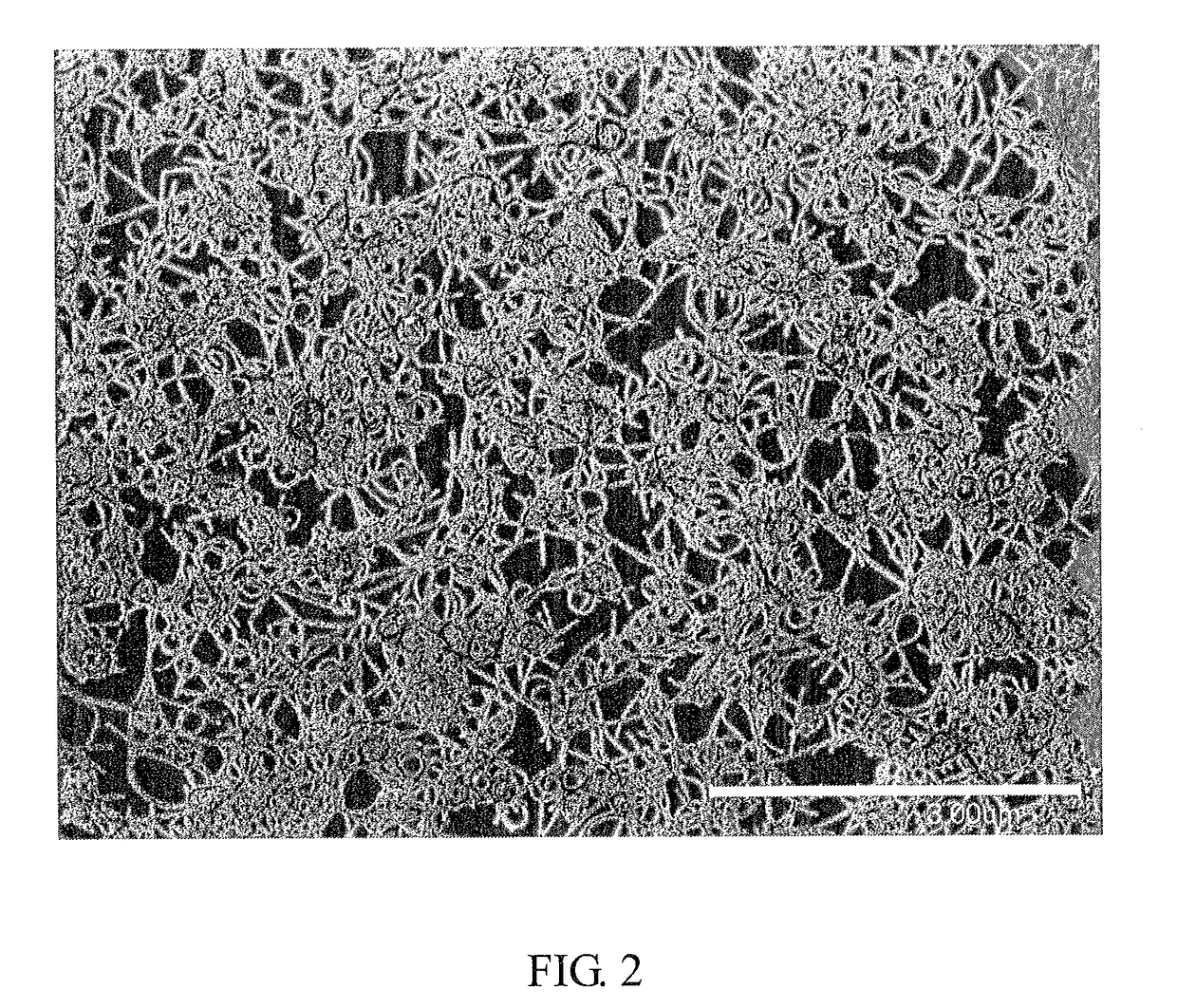

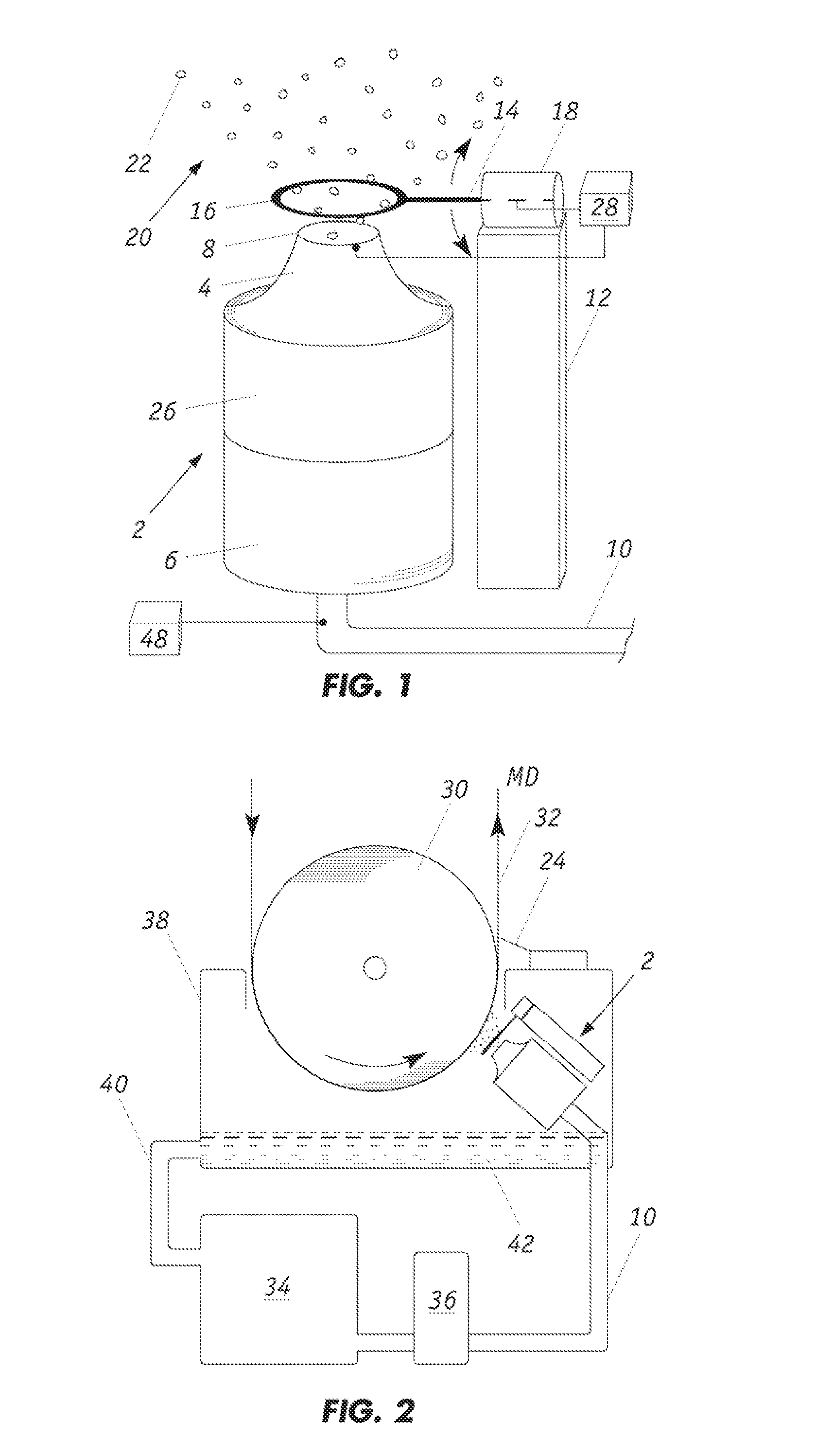

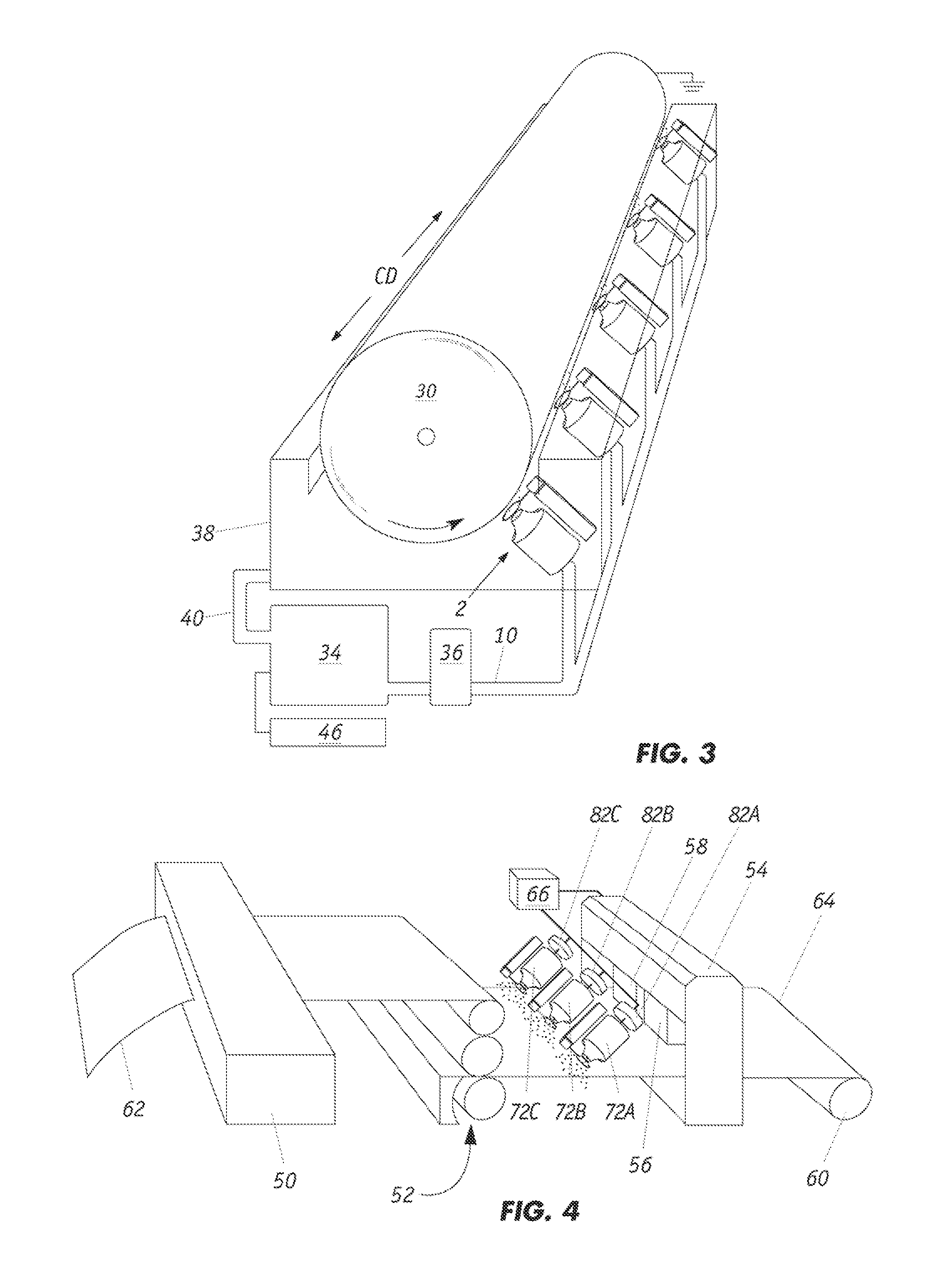

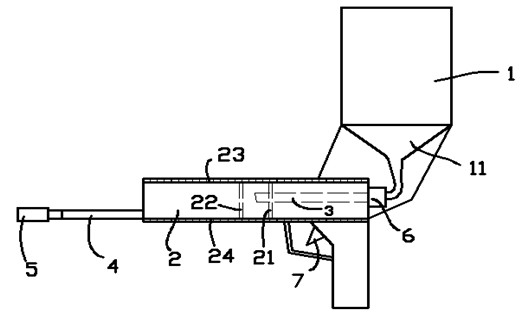

Apparatus and method for aerosol deposition of nanoparticles on a substrate

InactiveUS20190001360A1Minimal hysteresisMinimize impactMaterial nanotechnologyLiquid surface applicatorsNanoparticleAerosol deposition

Provided is an apparatus for aerosol deposition of nanoparticles on a substrate. The apparatus includes: an aerosol generator for generating an aerosol of micron-sized droplets, each droplet having a limited number of nanoparticles; and a deposition chamber for receiving the aerosol from the aerosol generator. The deposition chamber having an electrostatic field for attracting droplets in the aerosol to the substrate. The electrostatic field being substantially perpendicular to the substrate. The apparatus allows for films / networks of nanoparticles to be patterned on the substrate to sub-millimeter feature sizes, which allows the fabrication of transistor devices for printable electronics applications. Also provided are methods for depositing nanoparticles on a substrate and materials having networks of such nanoparticles.

Owner:NAT RES COUNCIL OF CANADA

Spray coating technology for preparing high melting point coramic coating layer

InactiveCN1757793AIncreasing the thicknessImprove wear resistanceVacuum evaporation coatingSputtering coatingPower flowSpray coating

A process for preparing the high-smelting-point ceramic layer or ceramic-metal layer on the surface of substrate includes such steps as conventional pre-treating on the surface of substrate, charging the powder material to be sprayed in the cavity of spray gun, applying a high shock current to electrodes, electric explosion for preheating and pushing said ceramic powder to the inlet of stage-2 spray gun, breaking through its electrode for generating high current and forming a plasma channel, heating and pushing the powder to move forward at high speed, and colliding with the surface of said substrate to form said ceramic layer.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

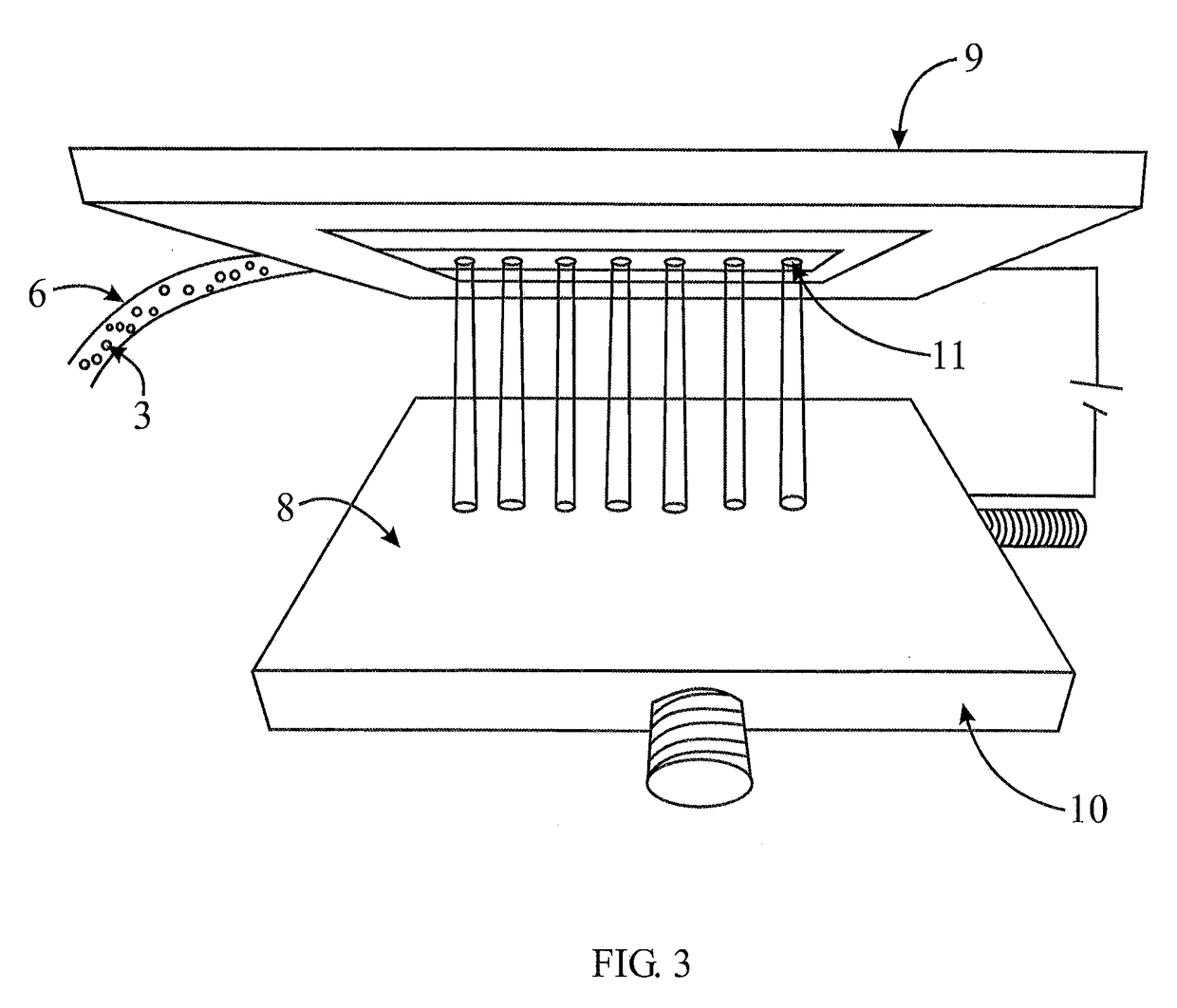

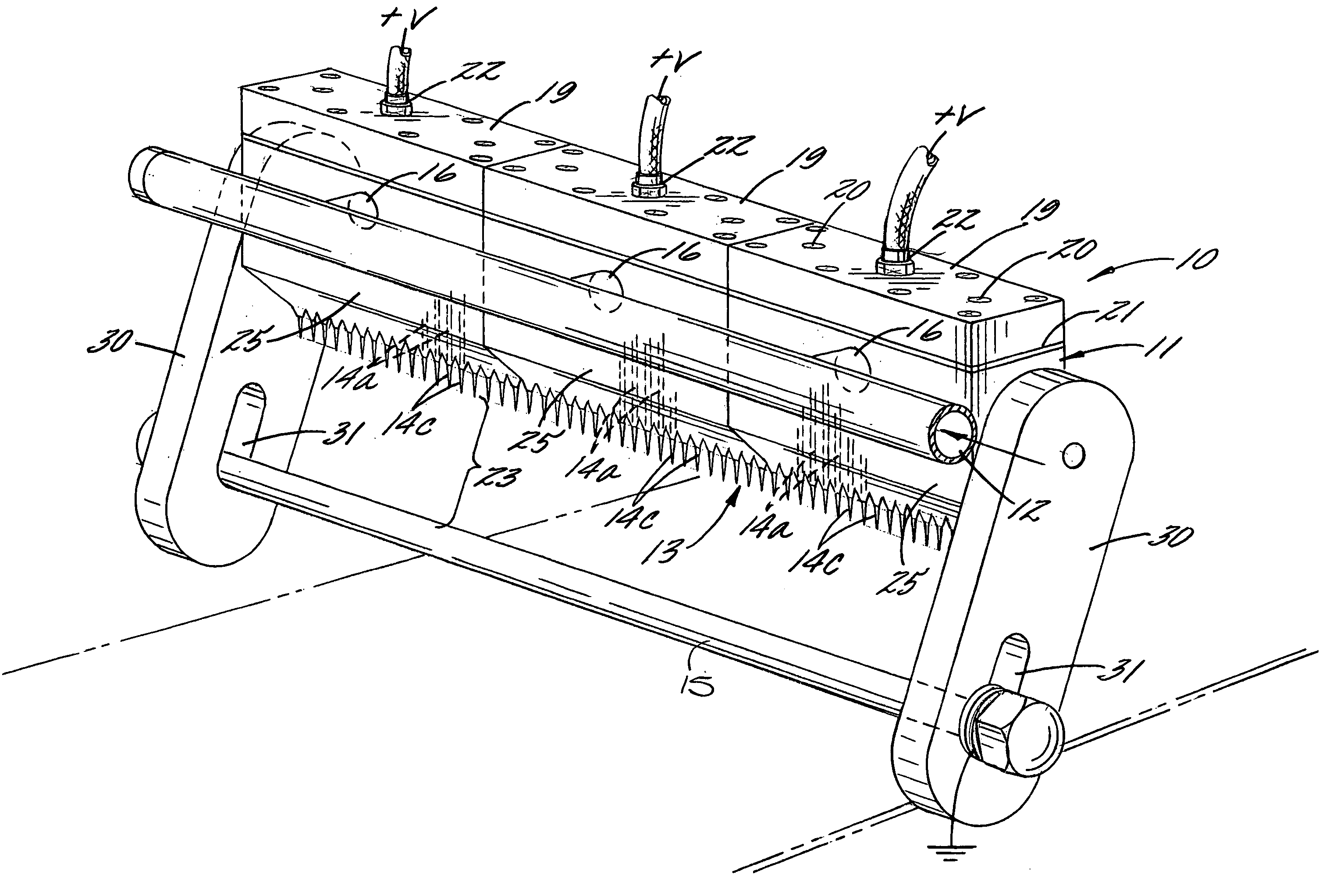

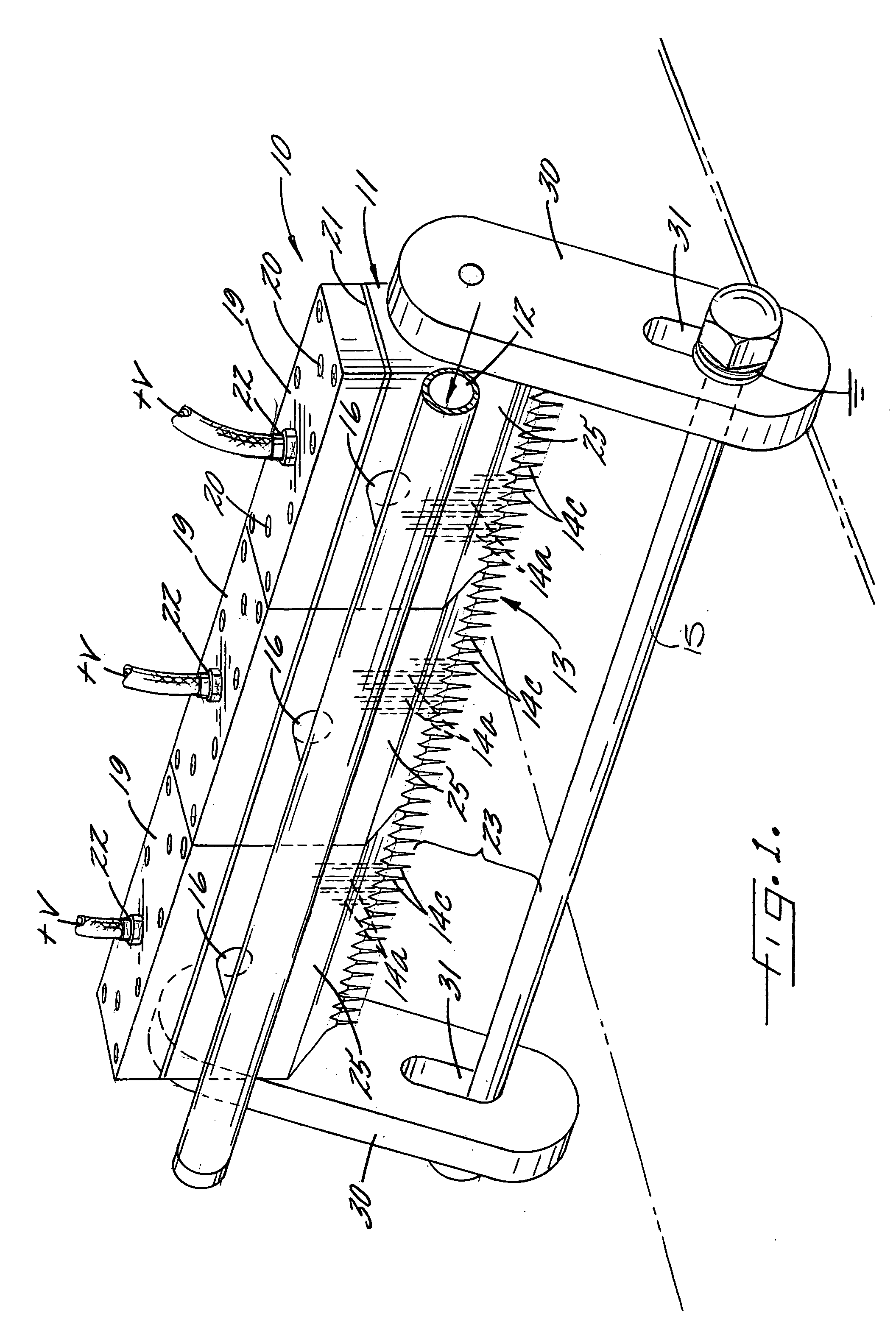

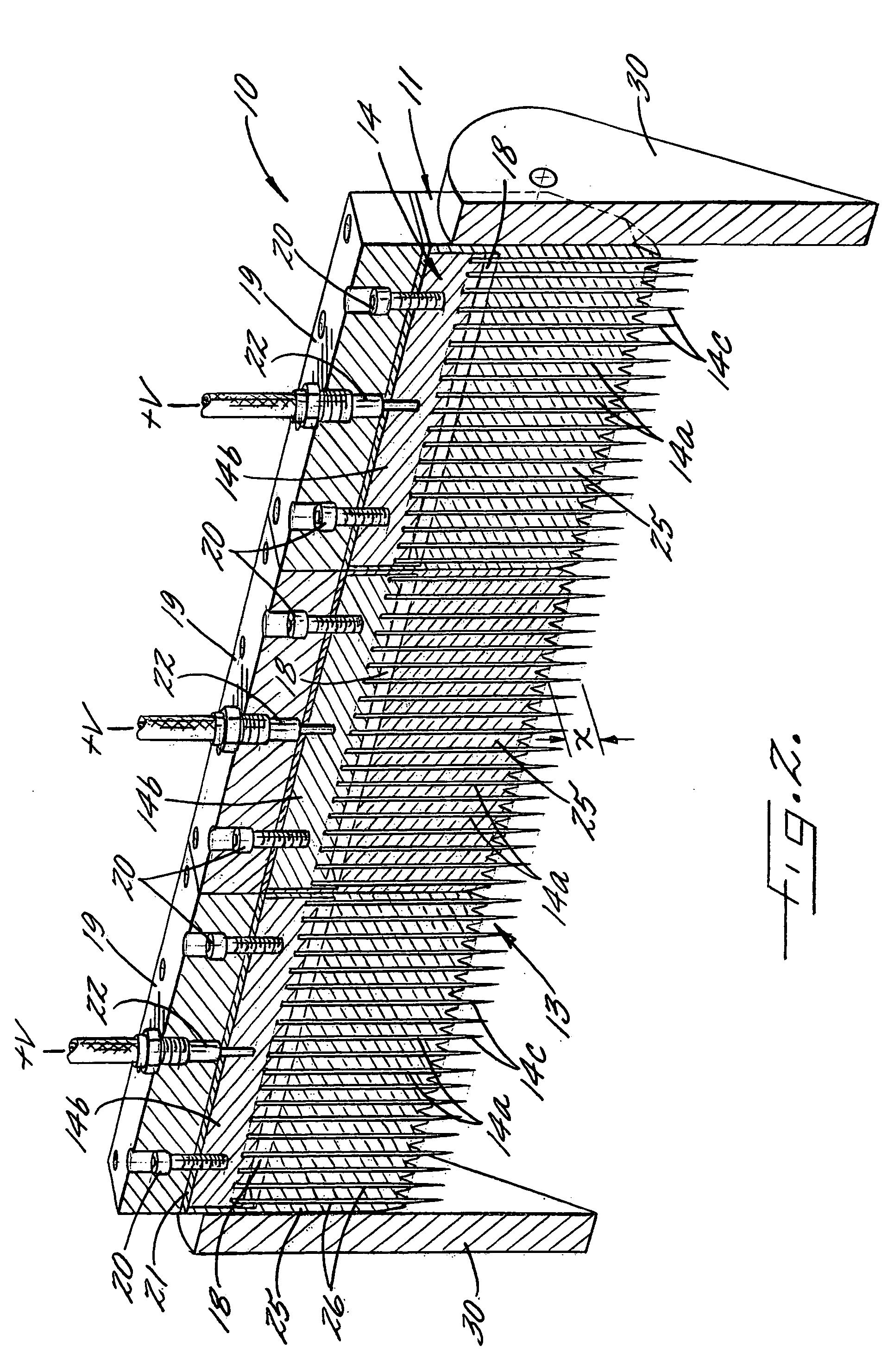

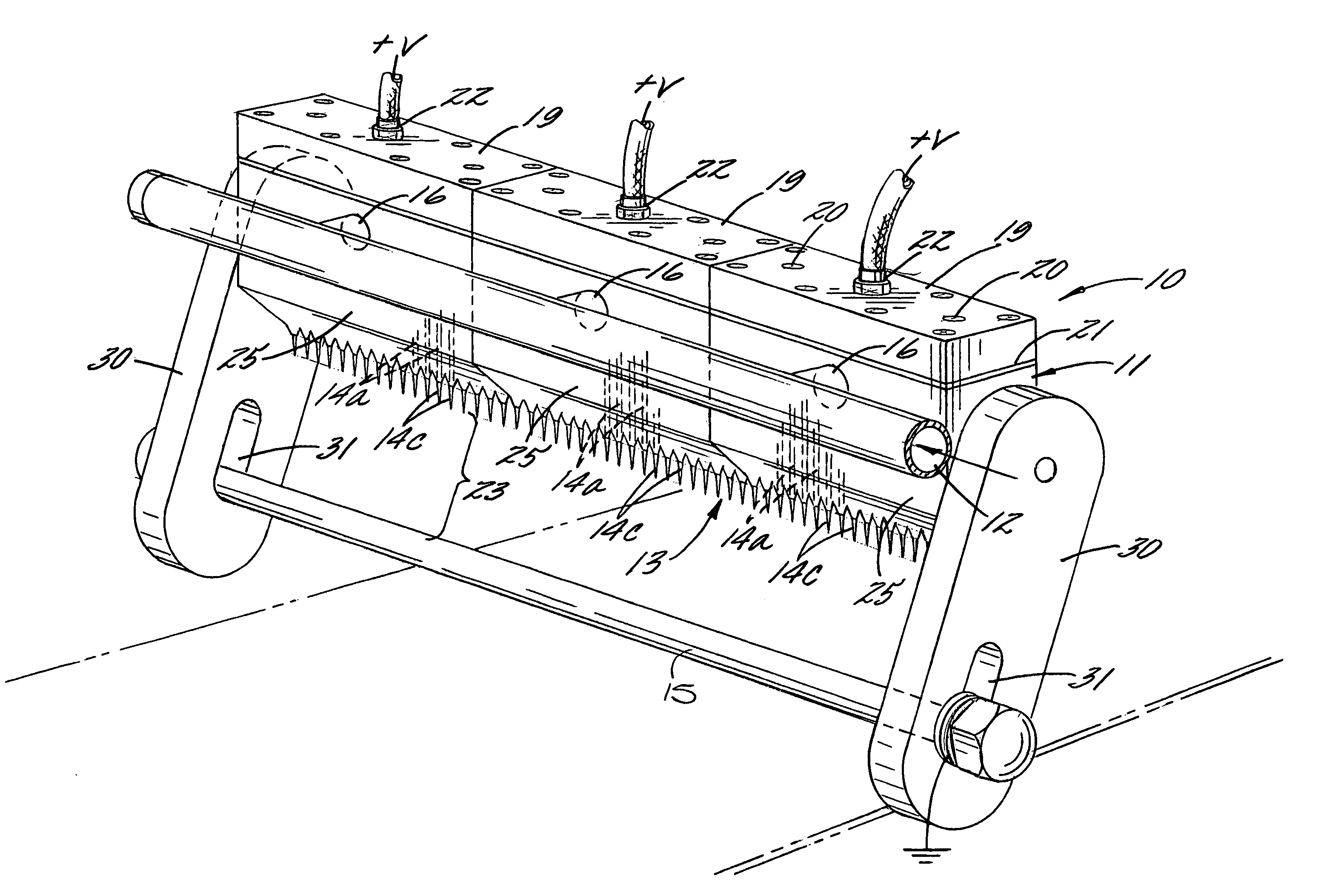

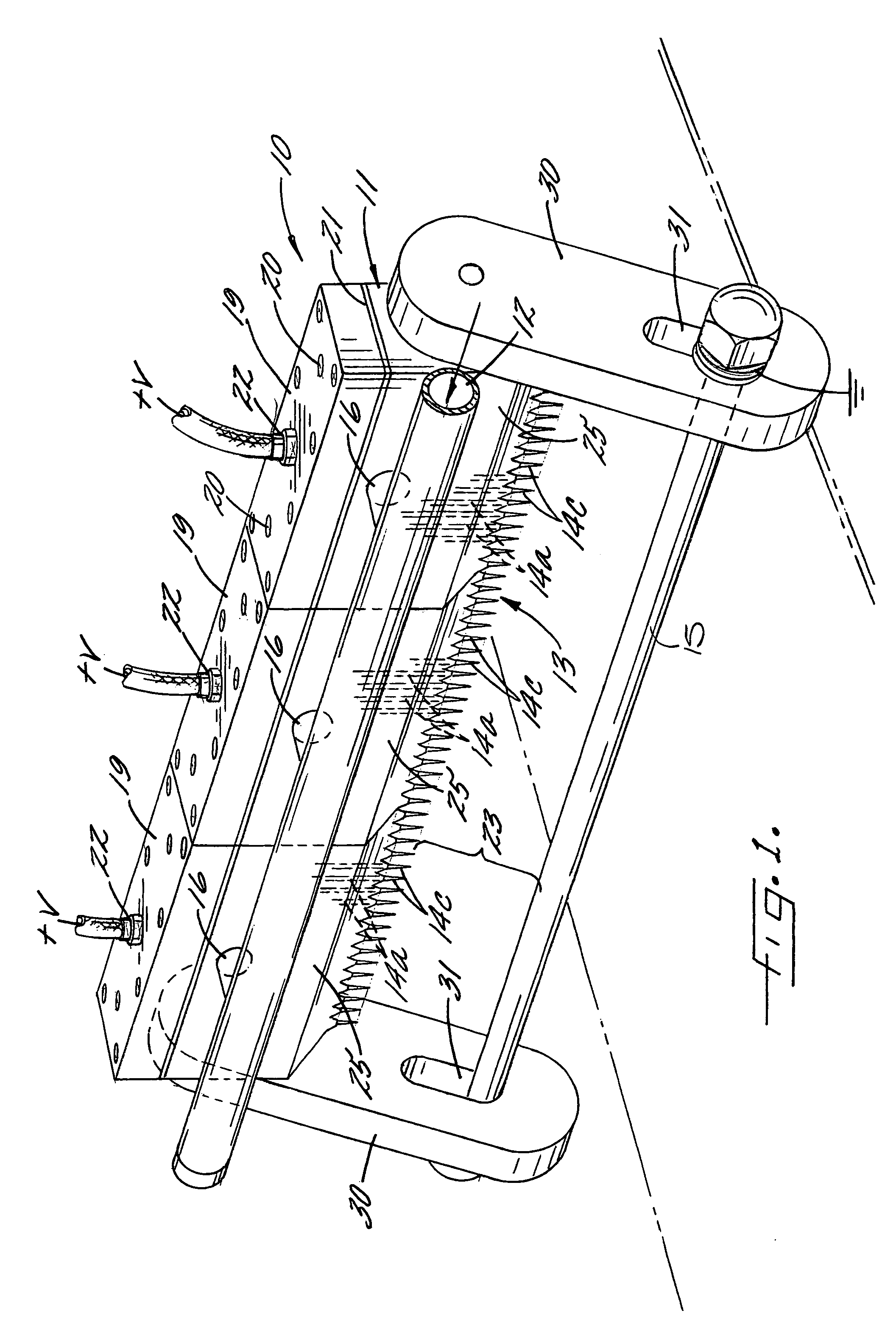

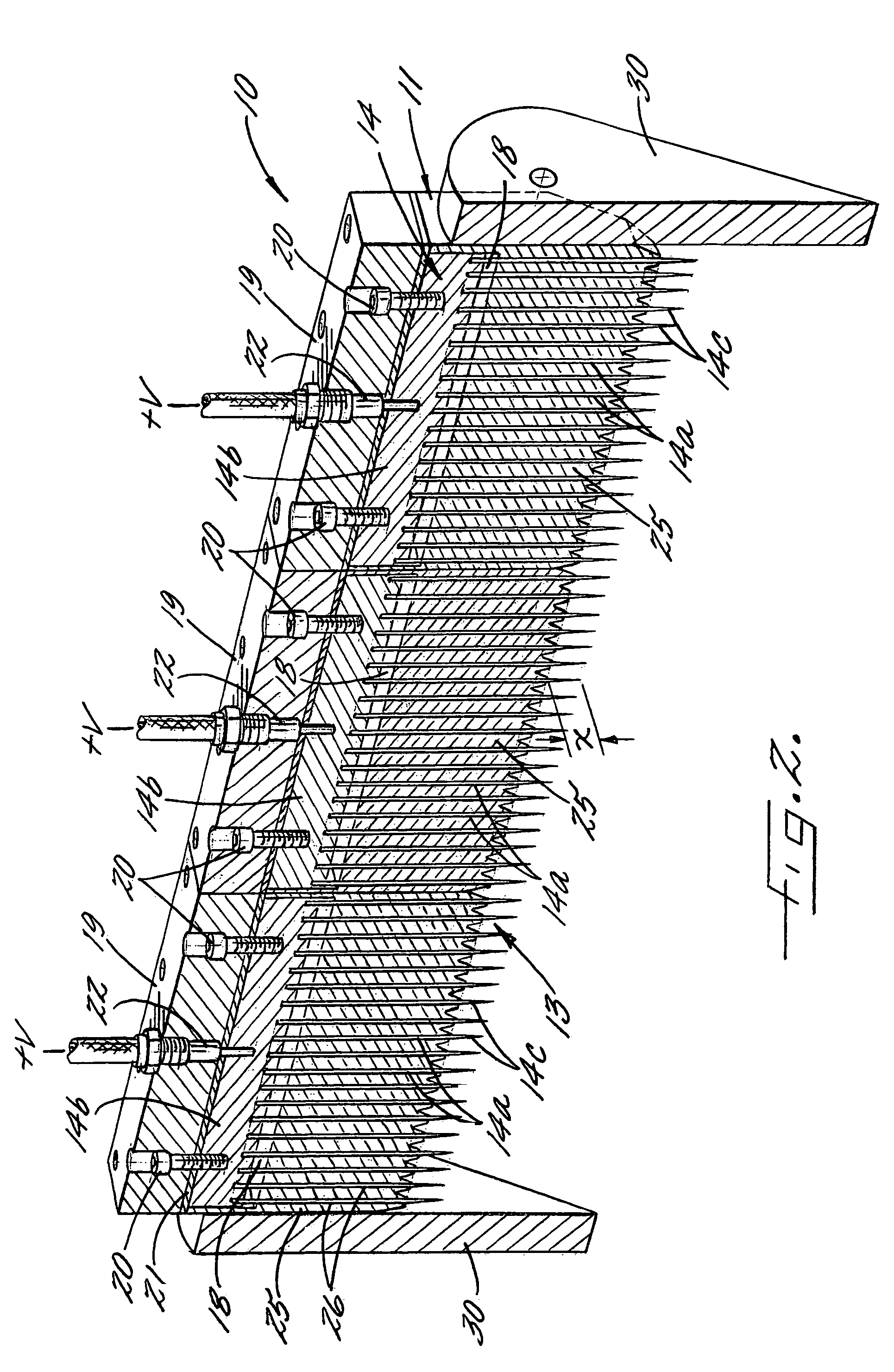

Electrostatic spray system

ActiveUS20050194476A1Efficient and reliable sprayingMade preciselyBurnersSpraying power supplyVoltage sourceElectrical and Electronics engineering

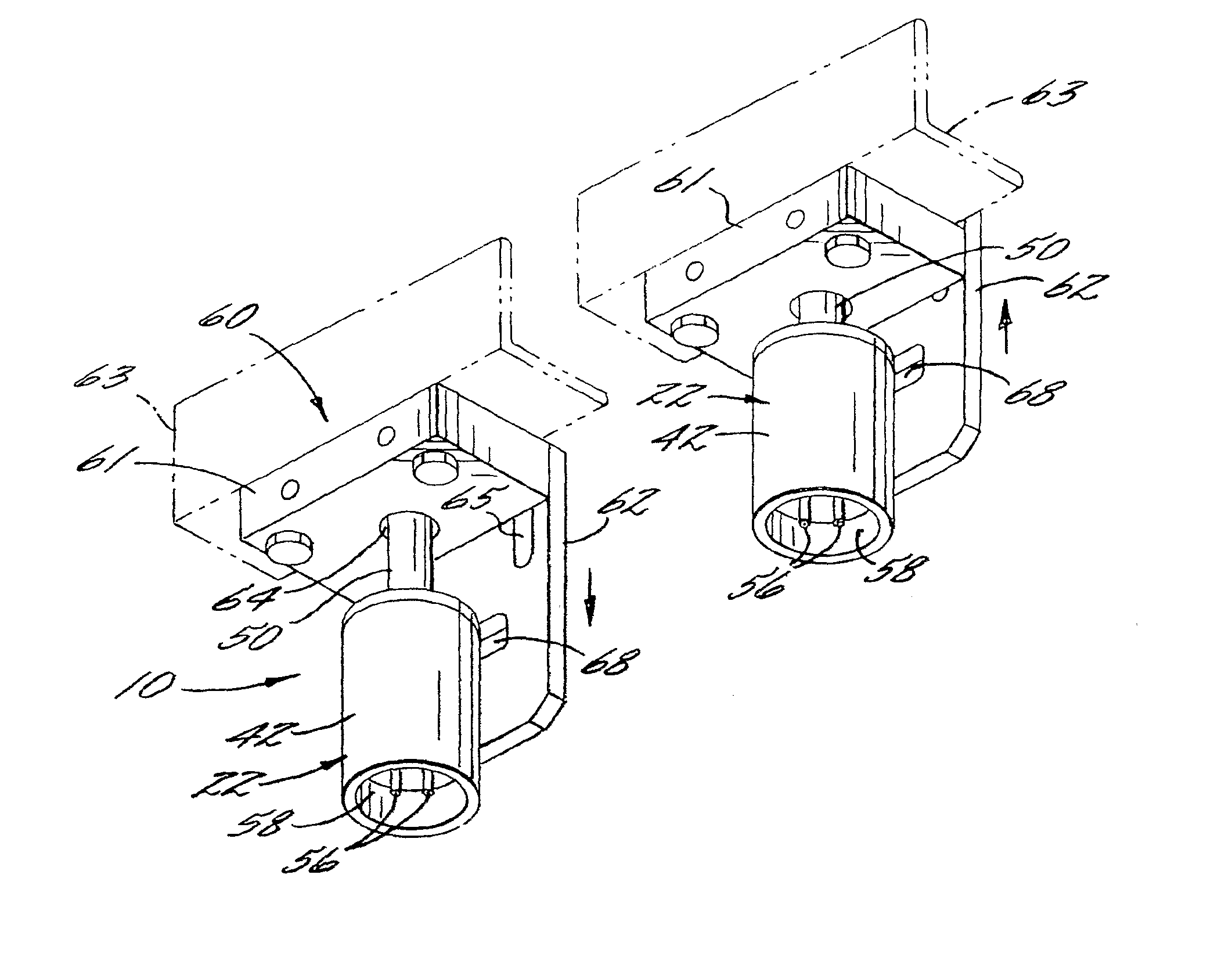

An electrostatic spraying assembly is provided. The spraying assembly includes a housing having a fluid inlet passage that is connectable to a fluid source and communicates with a plurality of discharge passageways each of which extends through the housing to a downstream end at a discharge end of the housing. The housing has a one piece construction and is made of an electrically insulative material. The spraying assembly also includes an electrode assembly. The electrode assembly includes a plurality of elongate electrode elements each of which is disposed in a respective one of the discharge passageways in the housing and an electrode header. The electrode header is electrically connectable to a voltage source and each of the electrode elements is electrically connectable to the electrode header.

Owner:SPRAYING SYST

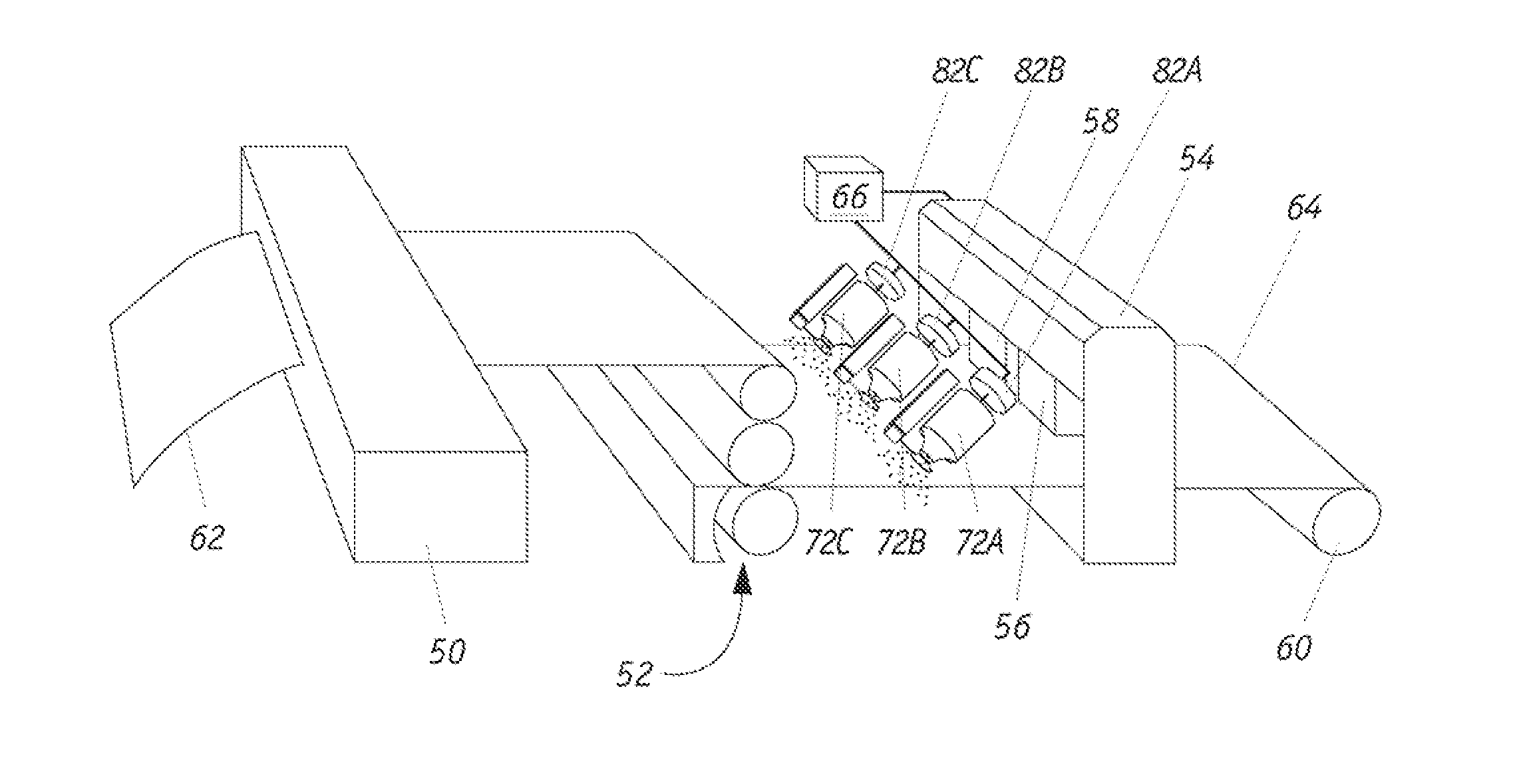

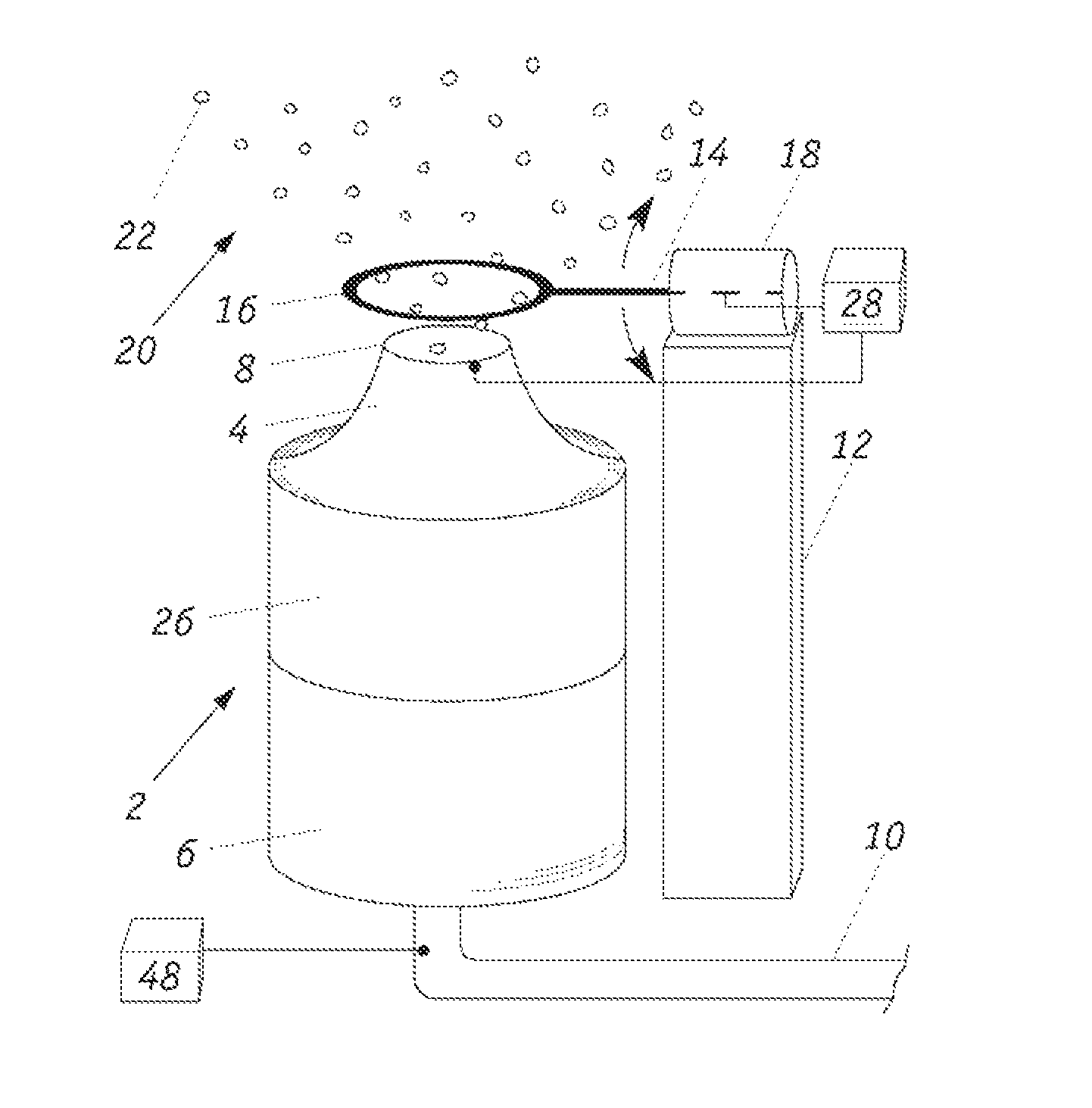

Method to Create Uniform Distribution, Minimize Applied Solution Volume and Control Droplet Size of Water and/or Coating Applications for Web Applications

ActiveUS20130156970A1Quantity minimizationPromotes even distributionBurnersLiquid spraying plantsWeb applicationSpray nozzle

A coating apparatus produces a spray of charged droplets and controls the spray angle of travel of the spray toward the object to be coated. Electrically charging droplets minimizes the amount of coating material required to uniformly coat a surface as compared to conventional web coating techniques such as blade coating. An inductive ring guides the spray charged droplets as they exit the nozzle of a spray device. The electrostatic repulsion between the charged droplets insures that a uniform coating of liquid formulation can be applied to a web surface.

Owner:HONEYWELL ASCA INC

Apparatus for producing a spray of changed droplets of aqueous liquid

ActiveUS8985051B2Quantity minimizationPromotes even distributionBurnersPaper coatingSpray nozzleEngineering

Owner:HONEYWELL ASCA INC

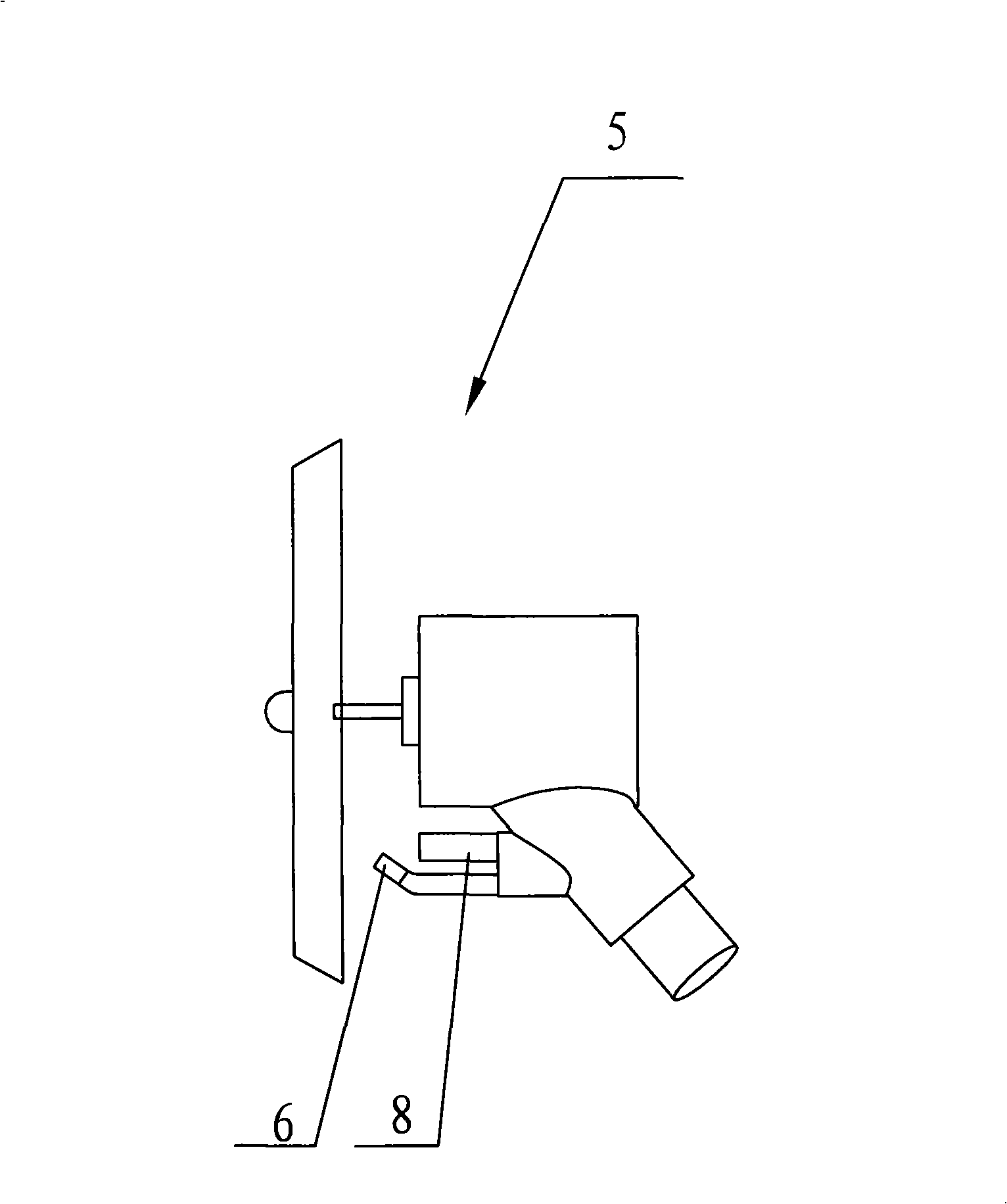

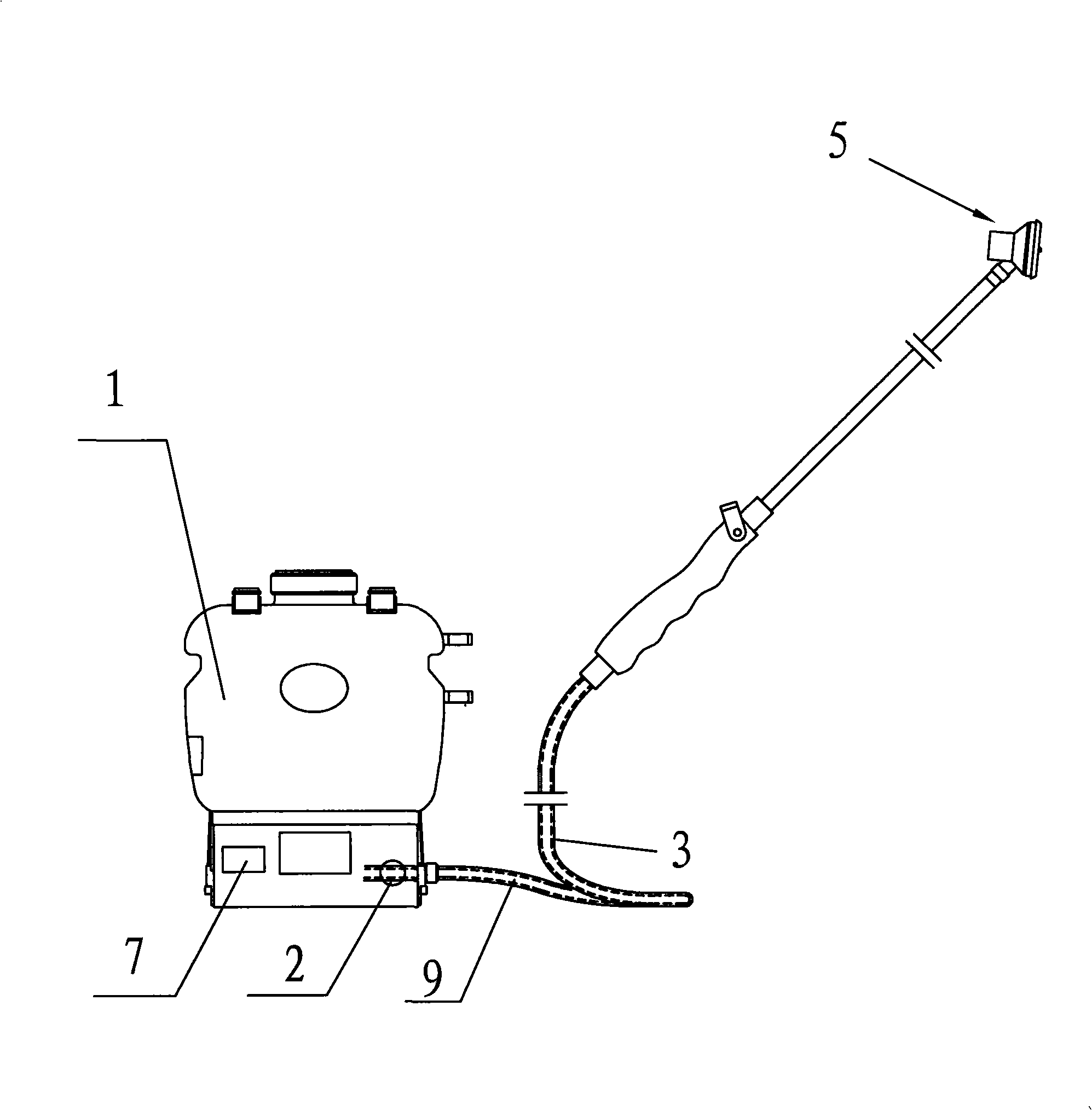

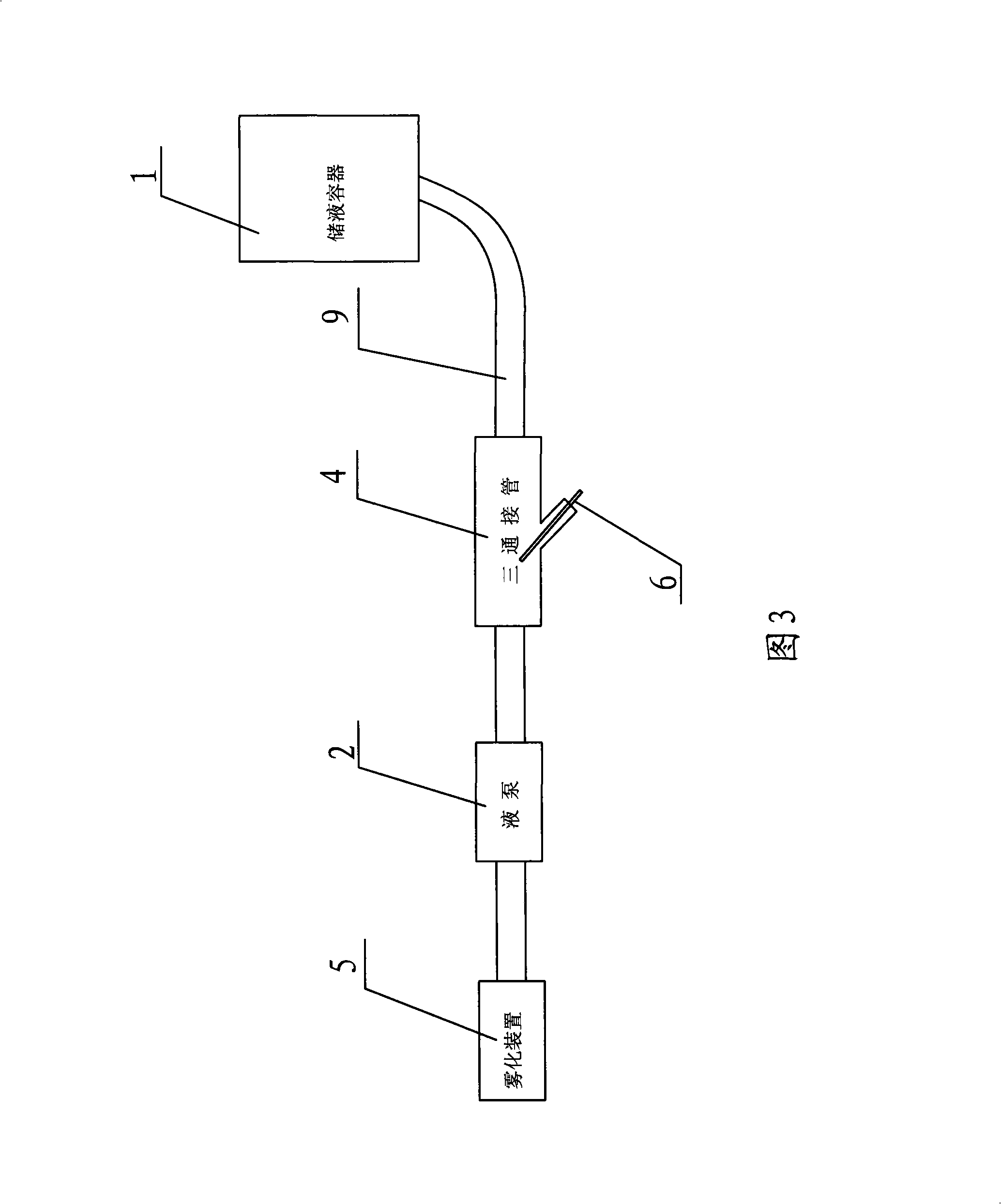

Electrostatic spraying device

An electrostatic spraying device comprises a liquid storage container, a liquid pump, a high-voltage electrostatic generating device provided with a high-voltage electrostatic electrode, a connection hose and an atomization device; an infusion tube is arranged in the connection hose; one end of the infusion tube communicates with the liquid storage container, and the other end thereof is connected with the atomization device; the high-voltage electrostatic electrode extends into the infusion tube. Compared with the method for enclosing the high-voltage electrostatic electrode in the position of the atomization device in the prior art, because the high-voltage electrostatic electrode exerts static electricity on liquid medicine output from the liquid storage container (or on liquid medicine output from liquid pump) through the infusion tube, infusion tube including electrostatic charge is delivered to the atomization device from the liquid storage container, and the distance between the high-voltage electrostatic generating device and the high-voltage electrostatic electrode is shortened; therefore, the high-voltage transmission loss is low, the insulation is easy to process, and the cost is greatly reduced; furthermore, the reliability of a high-voltage electrostatic system is greatly enhanced.

Owner:苏州稼乐植保机械科技有限公司

Electrostatic spray assembly

ActiveUS7455250B2Efficient and reliable sprayingMade preciselyBurnersSpraying power supplyVoltage sourceElectrical and Electronics engineering

An electrostatic spraying assembly is provided. The spraying assembly includes a housing having a fluid inlet passage that is connectable to a fluid source and communicates with a plurality of discharge passageways each of which extends through the housing to a downstream end at a discharge end of the housing. The housing has a one piece construction and is made of an electrically insulative material. The spraying assembly also includes an electrode assembly. The electrode assembly includes a plurality of elongate electrode elements each of which is disposed in a respective one of the discharge passageways in the housing and an electrode header. The electrode header is electrically connectable to a voltage source and each of the electrode elements is electrically connectable to the electrode header.

Owner:SPRAYING SYST

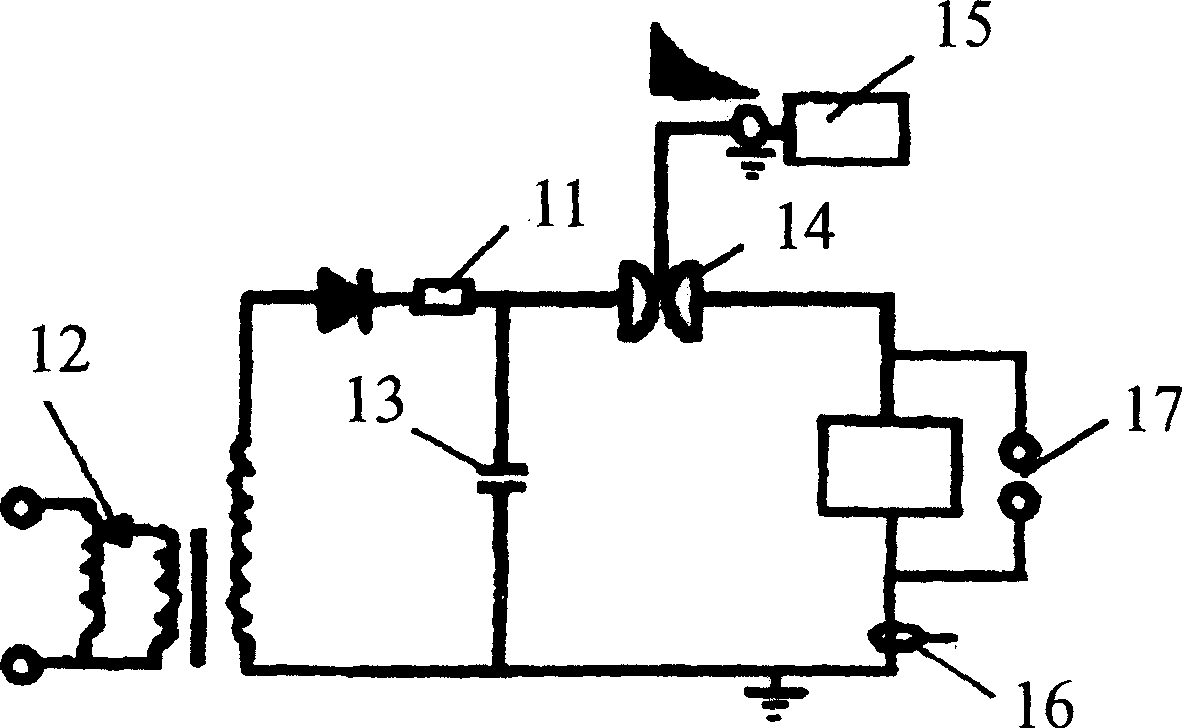

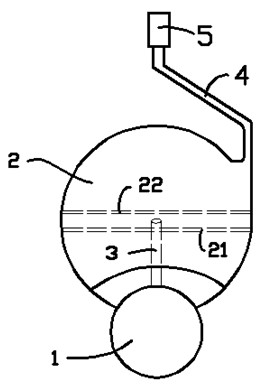

Lawrence electron accelerator type electrostatic spray gun

The invention discloses a Lawrence electron accelerator type electrostatic spray gun, which comprises a coating container, an electrostatic generator, a gun barrel and a switch, wherein a solenoid valve and the electrostatic generator are connected in series below the coating container by a feed pipe and are connected with an electron accelerator; the electron accelerator is in a horizontal circular box shape; upper and lower end faces of the electron accelerator comprise a pair of opposite magnetic poles which can form a uniform magnetic field inside the accelerator; the inside of the electron accelerator comprises two metal net plates which are parallel mutually and parallel to the uniform magnetic field; the two metal net plates are arranged on two sides of the diameter of the electron accelerator; the feed pipe extends between the two metal net plates from the outside of the electron accelerator; the metal net plates are connected with a high-voltage alternating power supply; an inlet of the gun barrel is communicated with the inner part of the electron accelerator from the periphery of the electron accelerator; and the switch controls the turning-on and turning-off of the alternating power supply and the solenoid valve. By the electrostatic spray gun, noise-free spraying can be realized, the divergence of coating granules is high, and the spraying uniformity also can be improved further.

Owner:吴江云峰金属购件涂装有限公司

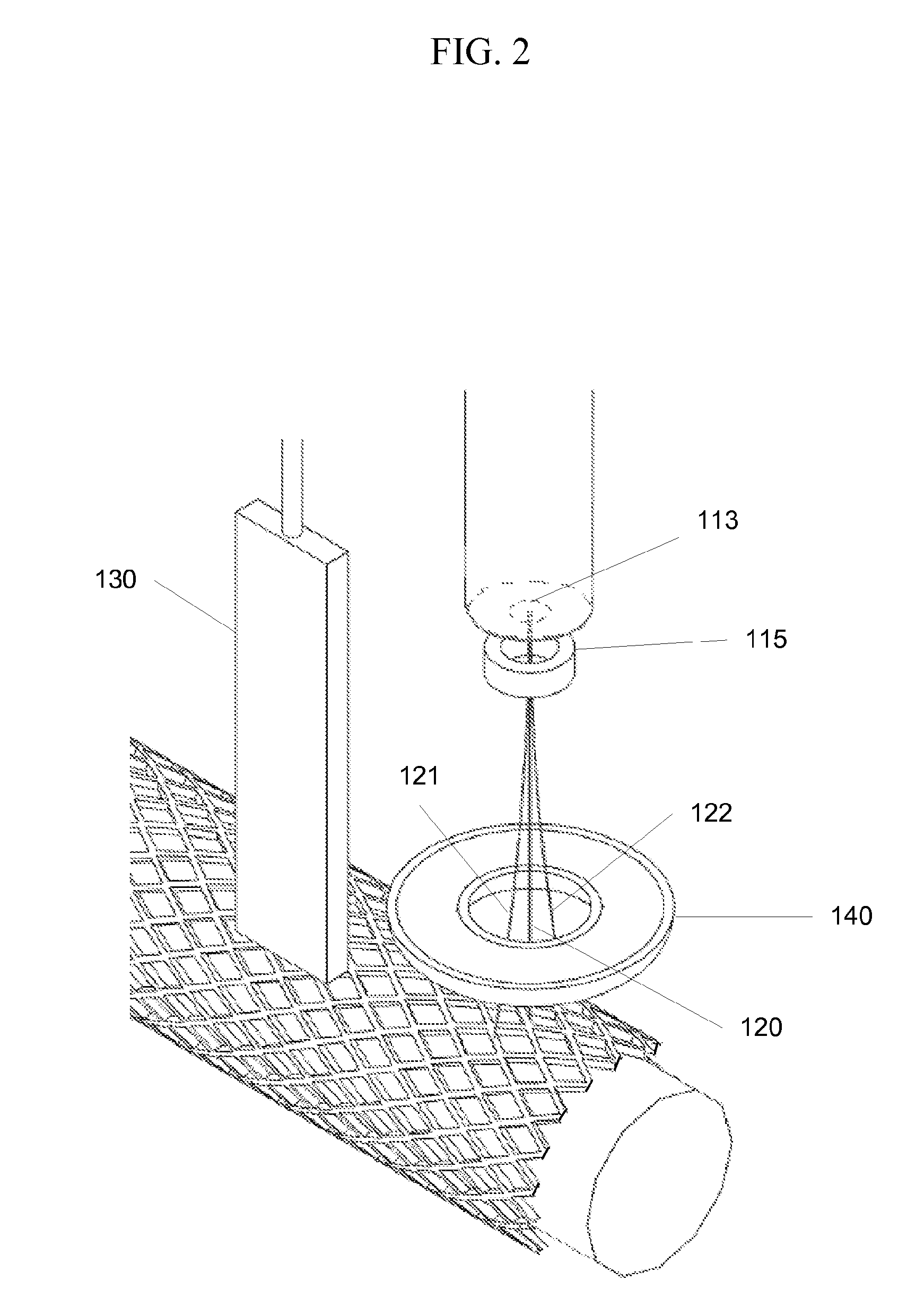

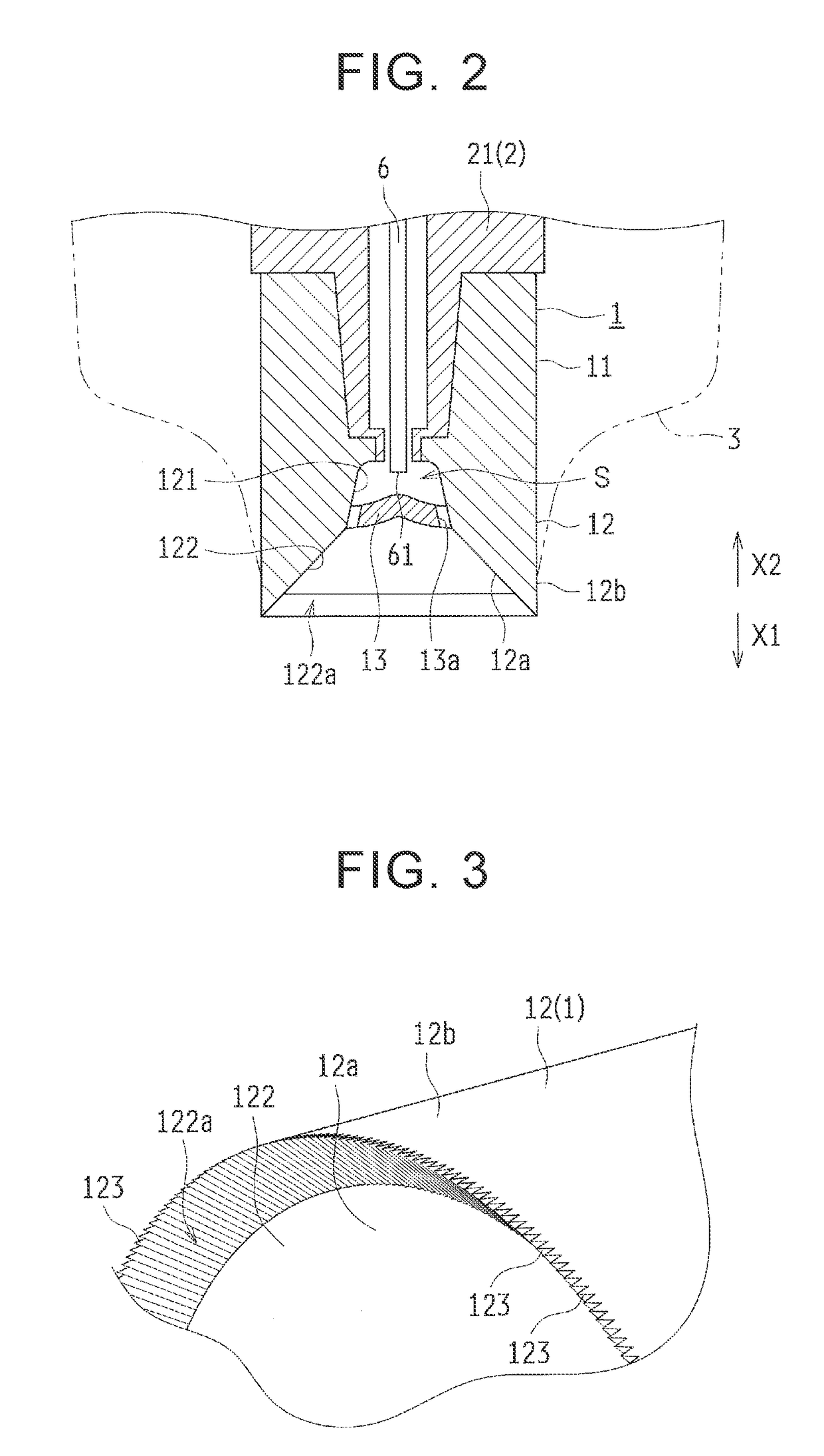

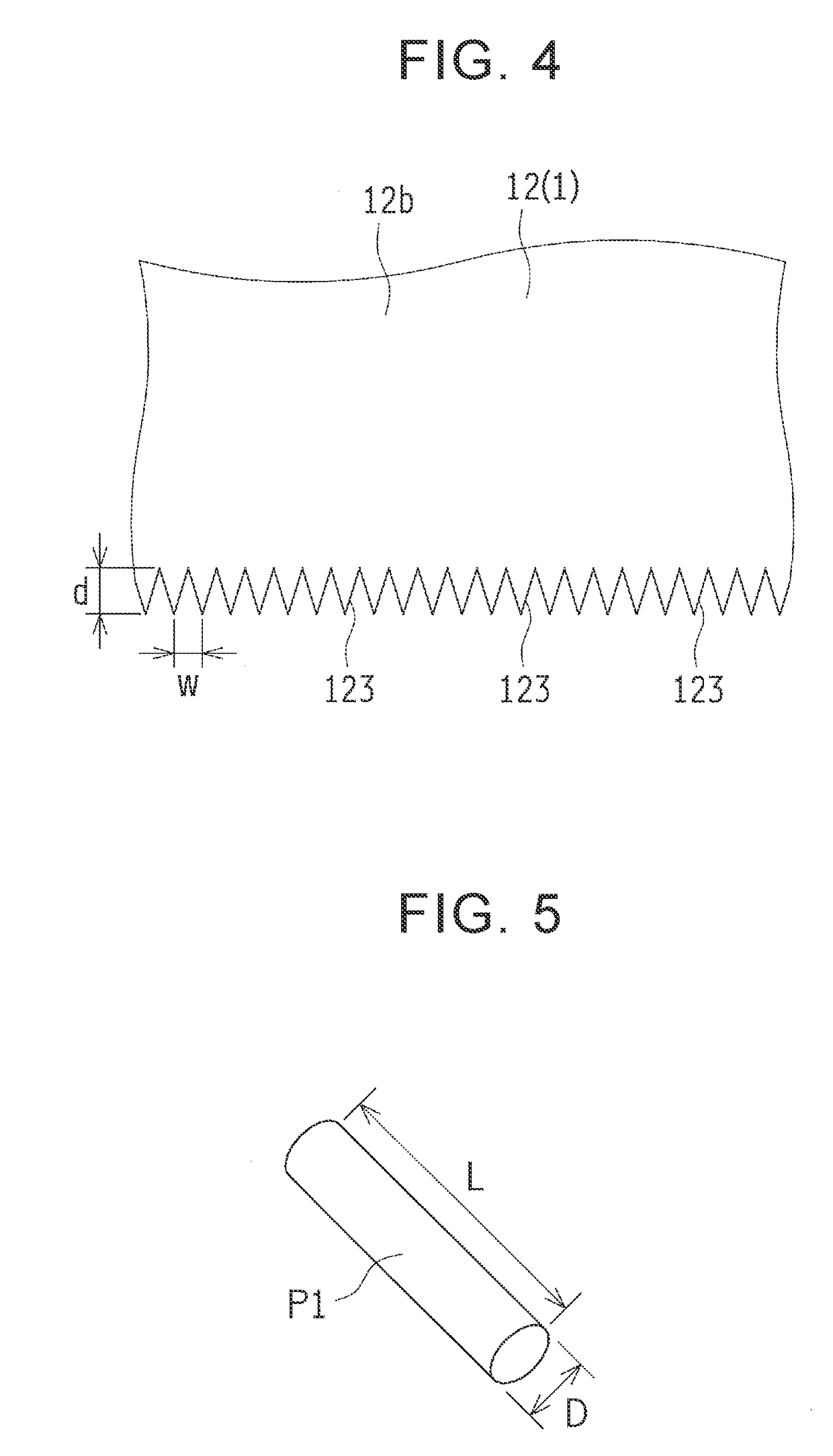

Coating device

ActiveUS20190083994A1Cross-sectional areaLiquid surface applicatorsSpraying power supplyEngineeringCentrifugal force

A coating device is equipped with a rotary head, a drive unit, and an electric power supply unit. The rotary head is configured to be supplied with a coating material. The rotary head includes a diffusion surface that is configured such that the coating material is diffused toward an outer edge portion of the diffusion surface by a centrifugal force, and a plurality of groove portions that are included in the outer edge portion. The rotary head is configured to discharge a threadlike coating material from the groove portions. Also, the coating device is configured such that a diameter of the threadlike coating material is set equal to or larger than 0.03 mm and equal to or smaller than 0.1 mm and that the threadlike coating material is electrostatically atomized.

Owner:TOYOTA JIDOSHA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com