Two-segment electric-field structure electrostatic spray system, array and using method

A technology of electrostatic spraying and electric field, applied in the direction of spraying device, non-gas spraying, etc., can solve the problems of limited control, difficulty in miniaturization of devices, difficulty in electrostatic shielding, etc., and achieve the effect of increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

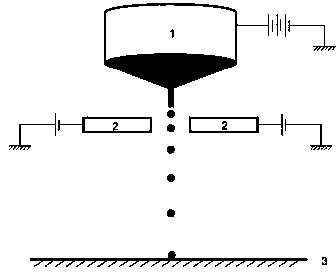

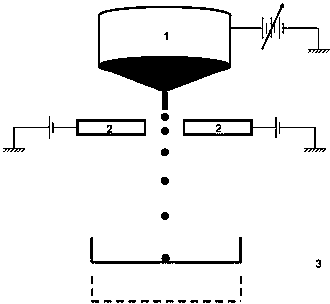

[0024] One unit static spray system schematic diagram; by adjusting the voltage of the sprinkler's voltage (the external voltage here is directly connected to the nozzle of the conductive, and it is applied to the spray liquid) to adjust the first electrical fieldAdjust the size and number of static spray droplets; the voltage and position of the control electrode remain unchanged; by adjusting the spray base (here to collect the electrostatic droplets with a grounded conductive cup)In the second section of the electric field, the spatial distribution and deposition rate of the liquid droplet that enters the second -stage electric field can be changed.

[0025] Example 2:

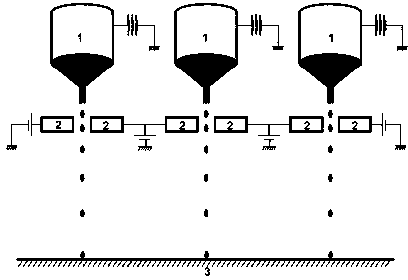

[0026] The three -stage and two -segment electrical field structure static spray system array array schematic diagram, three units are sprayed side by side, but different adjustment methods: the spray unit on the left by adjusting the voltage of the nozzle and the spray base (the grounding conductive cup) to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com