Electrostatic spraying device

An electrostatic spray and atomization device technology, applied in the direction of non-gas injection, can solve the problems of long electrostatic high-voltage transmission distance, high electrostatic cost, and long transmission distance, and achieve low high-voltage transmission loss, improved reliability, and reduced costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

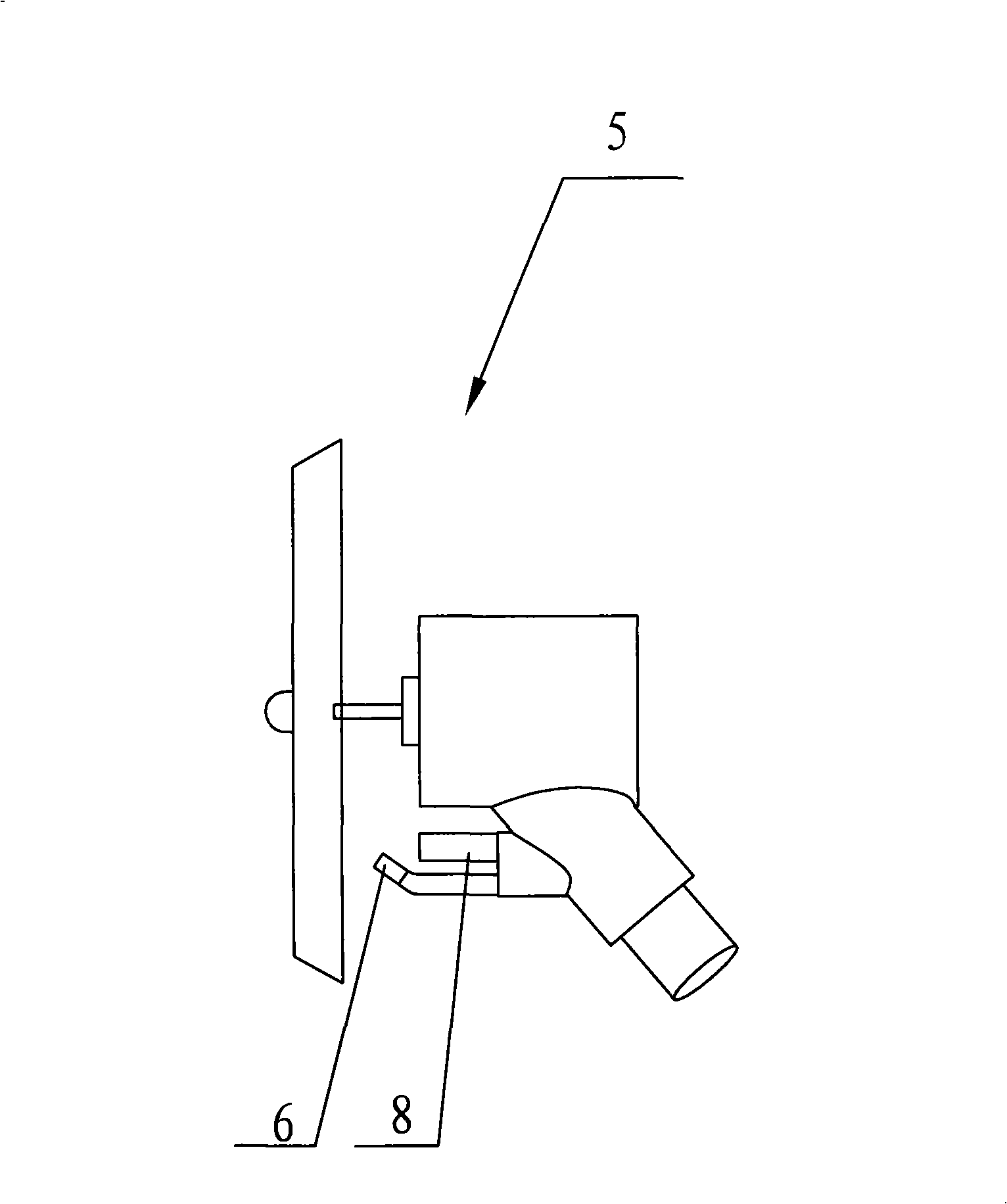

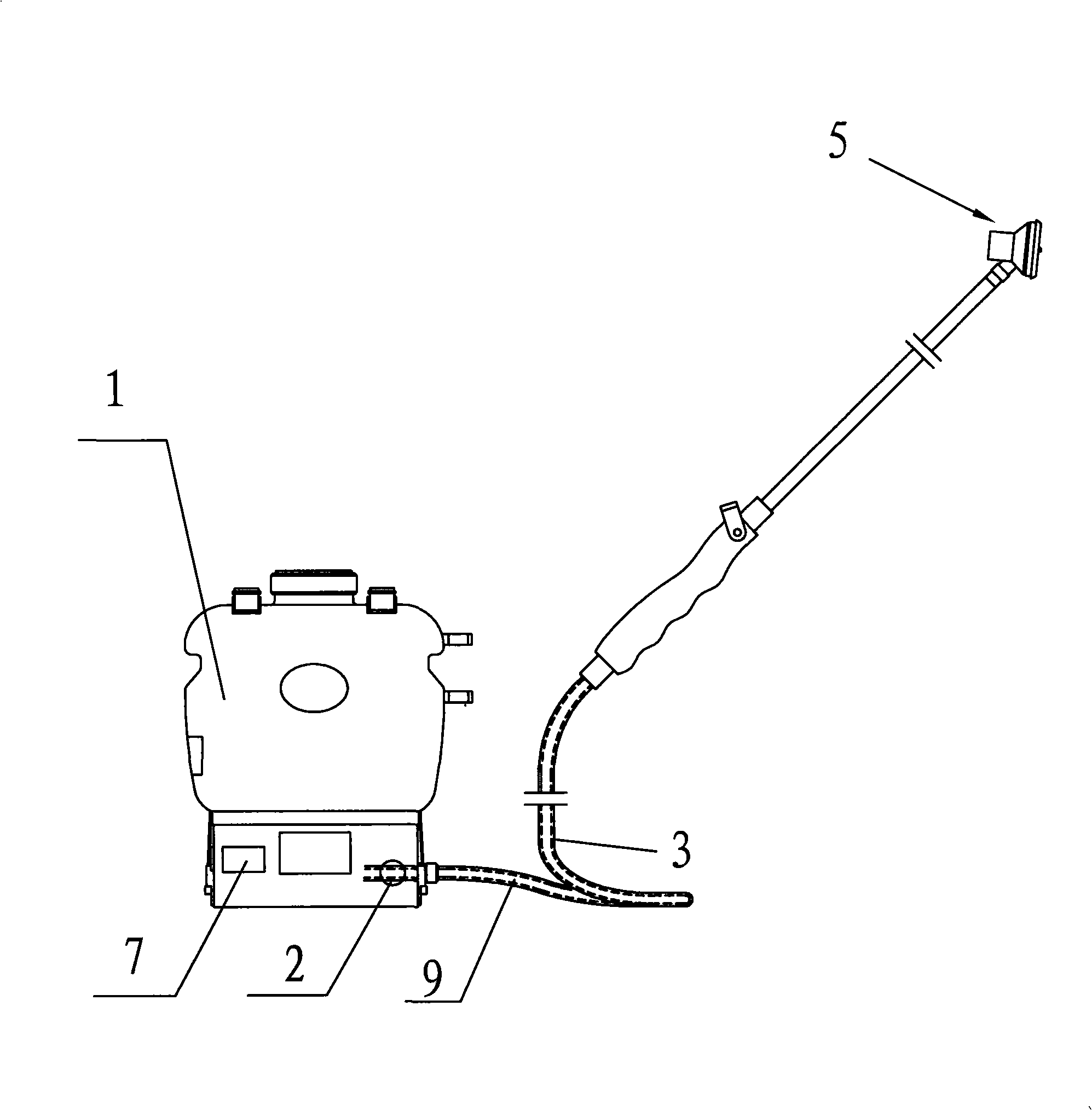

[0020] Embodiment one: as attached figure 2 An electrostatic spraying device shown includes a liquid storage container 1, a liquid pump 2, a high-voltage electrostatic generating device 7 with a high-voltage electrostatic electrode 6, a connecting hose 3, and an atomizing device 5. In the connecting hose 3, An infusion tube 9 is provided, one end of the infusion tube 9 communicates with the liquid storage container 1 and the other end is connected to the atomizing device 5 .

[0021] The infusion tube 9 is connected with a three-way connecting pipe 4, two ports of the three-way connecting pipe 4 communicate with the infusion tube 9, and the high-voltage electrostatic electrode 6 is located on the three-way connecting pipe 4. The other port and extend into the infusion tube 9.

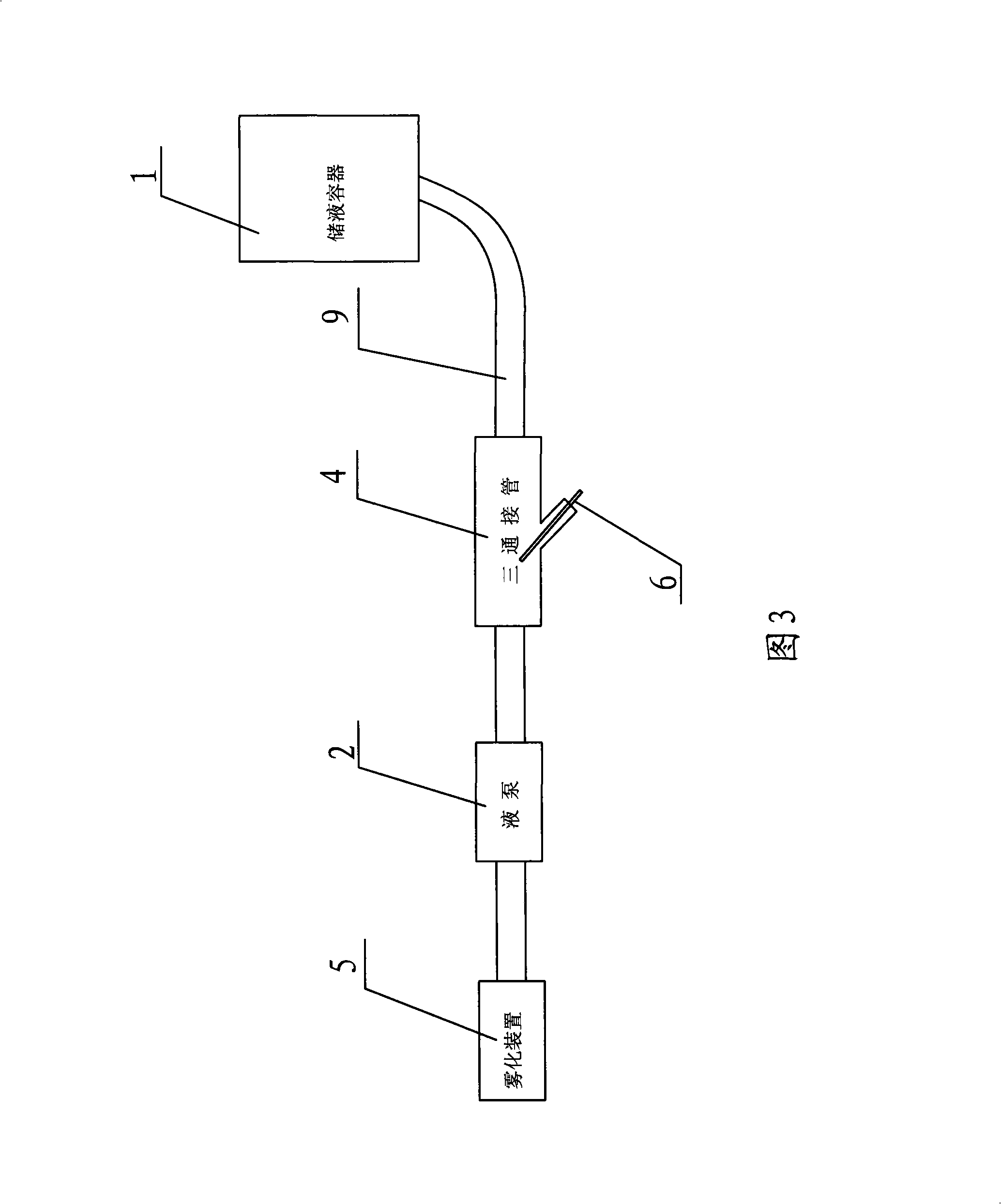

[0022] As shown in FIG. 3 , the liquid pump 2 is connected to the infusion tube 9 , and the three-way connection 4 is located between the liquid storage container 1 and the liquid pump 2 .

[0023] W...

Embodiment 2

[0027] as attached figure 2 An electrostatic spraying device shown includes a liquid storage container 1, a liquid pump 2, a high-voltage electrostatic generating device 7 with a high-voltage electrostatic electrode 6, a connecting hose 3, and an atomizing device 5. In the connecting hose 3, An infusion tube 9 is provided, one end of the infusion tube 9 communicates with the liquid storage container 1 and the other end is connected to the atomizing device 5 .

[0028] The infusion tube 9 is connected with a three-way connecting pipe 4, two ports of the three-way connecting pipe 4 communicate with the infusion tube 9, and the high-voltage electrostatic electrode 6 is located on the three-way connecting pipe 4. The other port and extend into the infusion tube 9.

[0029] As shown in Figure 4, the liquid pump 2 is connected to the infusion tube 9. The difference between this embodiment and the first embodiment is that the three-way connecting pipe 4 is located between the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com